How to properly detect knives on a planer machine. Installation and setting of the knife of the Fuganka. Algorithm for replacing knives on electrolake

The first task that stands in front of the master if he wants to qualitatively perform work - this is the creation of a smooth square blank. This article will consider such nuances as the installation of the knives of the Fugan, their setup, the principles of the instrument. In order to form your overall picture, you need to consider techniques that allow you to keep the fugalok in working condition, after which it will be possible to learn some features that should be considered when working. Many novice experts experience difficulties with knife tuning, first of all, this article is created for them.

Work on the removal or installation of knives largely depends on the mounting mechanism and can be varied. In most cases, even a newcomer will not be difficult to remove the knife of the Fugank and put it back.

Not much important is not to install knives, but adjusting the knives of the Fugank, setting the tables.

It often happens that the workpieces are irregularities, for example, bulges or concavity. Before rushing to configure knives, you need to make sure that the problem is not related to the table. This is alarmed, primarily concreteness. This means some of the parts of the tables are tilted below the desired height. To determine the unevenness of the table, use a flat line. The convex edges sign that the internal parts of the tables are overly inclined to the cutting head.

How to determine the correct installation of knives

Proper knife installation - the key to successful work Machine. Experts argue that the height of the blades should be about the same as you are the height of the desktop. In order to determine whether the machine is set correctly, you need to try to handle the workpiece. If, after work on its surface there will be irregularities or noticeable chips, then, most likely, knives are incorrectly adjusted. Professionals are used to determine the accuracy of the machine setting a ruler or a very smooth wooden bar.

Knife adjustment work

In order to extract knives or consolidate them, you will need a wrench. In the first case, you just need to unscrew the nuts and extract the tool, in the second case, the same work is performed in the reverse order.

Removed and necessarily require cleaning from contamination with the help of organic solvents, you can also wipe the blades with engine oil. This procedure is carried out so that they remain more sharp and have not been corrosion. For better work, you will definitely need a perfectly smooth board, which will be used to adjust the mounting knives.

Setting the knives of the Fuganka is possible, only if they are easy to fasten, this is done so that you do not have difficulties during configuration.

To simplify the work, use a wrench that will be attenuated by the pressure, the knitting bracket nuts is not necessary to delay.

Adjustment is carried out by moving the blade down or up. Pay attention to the tree with knives, it will need to turn over, and move the knife to the blade up. Then you need to put a pre-prepared board on the machine, which in length should be slightly more than the back area of \u200b\u200bthe machine.

Put the board so that its edge is just above the blade of the knife, and gradually twist the shaft in different directions, thereby adjusting the height of the knife. Gradually, the blade will be strengthened into the board, at this moment you must fully consolidate it. After that, you need to proceed to adjust the second knife, or the rest if there are several in the machine. When the work is done - rotate the cutting head, all blades should only slightly touch the line or bar. After you have done this work at least several times, the question of how to install knives on Fuganke is unlikely to worry you in the future.

Electrical placard is a convenient and efficient tool for wood processing. Its use will significantly speed up the work of work compared to the manual instrument. Naturally, the efficiency of the electrolabank depends on the quality of the knives installed and their status.

The replacement of the knives of the electrolabank is made due to their wear or shift type of work.

Types of knife

Before you understand how to install knives on electruruck, it is necessary to choose the right one.

For various tasks, knives with certain specifics can be used:

- Straight - used to overse and sampling wood;

- Wave-like - are used for artistic processing, in particular to impart the surface of the aging effect;

- Rounded - allow you to do smooth transitions between planing lines, and are used when working on a wide surface.

In addition, knives may have different sizes. Installation of knives on electrurubank implies that you found out which knives are used in your instrument. Some manufacturers design tools in such a way that only the knives of certain sizes come to it (as a rule, differ from the most common options).

Replacing knife

Consider how to install knives on electruruckics:

- Turn off the power tool.

- Remove the steering wheel accumulated on the work surface with a rolling mocking in a solvent.

- Included with the tool must be the key with which it is necessary to weaken the bar, presses the knives in the drum. You can use the usual wrench if it is suitable, or pliers, if there are no suitable keys.

- After that, remove the bar with the drum knife.

- The knife on the bar is usually attached to a conventional bolted joint, and is easily removed.

- After removing the old knife, a new one is fastened on the bar.

- The bar is inserted into the drum and fixed slightly.

- After adjusting the position of the knife, finally fix the bar. The adjustment of the knives of the electrolabank is the most difficult part of the procedure (and most important).

Adjustment

Now consider in more detail how to adjust the knives on the electrolakeanka:

- After fixing the knife on the bar and installation of the plank in the drum, make sure that the knife does not hurt the part of the plane.

- The position of the knives is adjustable using special eccentrics, which rotate with a flat screwdriver.

- Install the plane metal line on the rear sole (edge). The knife must be installed in such a way that the blade concerns the line.

- Alternately apply a ruler on the left and right side. The blades should be uniform. If there is a breakdown, the eccentric from the desired side should be adjusted.

- After completing the work, fix the plate with the knife by screwing the appropriate nut.

Having understood how to put knives on the electrolake, keep in mind that this procedure is quite long and requiring accuracy. It is not worth a hurry here, since the efficiency of your work will depend on the quality of the installation of the knife.

In the hands of a professional knife can become an accurate tool or weapon. A variety of tool features amazes - from sharpening pencils to combat use.

In this case, the effectiveness will increase repeatedly if the right knife sharpening angle is provided. The centuries-old use formed on only a variety of traditions, but also a scientific approach to the shape of the blade.

If you acquire a high-quality knife, it has an optimal angle of the faces formed by the manufacturer or master. During use (if you bought a tool for collective storage), the cutting edge is inevitably dulled.

You can give the blade into sharpening professionals, but the real owner performs this work independently. In the presence of skills and special devices, the quality of the island is not worse than in the factory conditions.

The presence of expensive equipment in itself does not guarantee the correct processing of the cutting edge. It is necessary to withstand the correct angles of sharpening depending on the type of work performed.

IMPORTANT! Any knife has several planes, each of them has its own degree deviations in relation to the plane.

To understand the process, consider the device hunting knife

Immediately make a reservation that such a blade requires permission to wear because it is a cold weapon. Regardless, you apply it for its intended purpose, or it hangs on the carpet as an interior decoration.

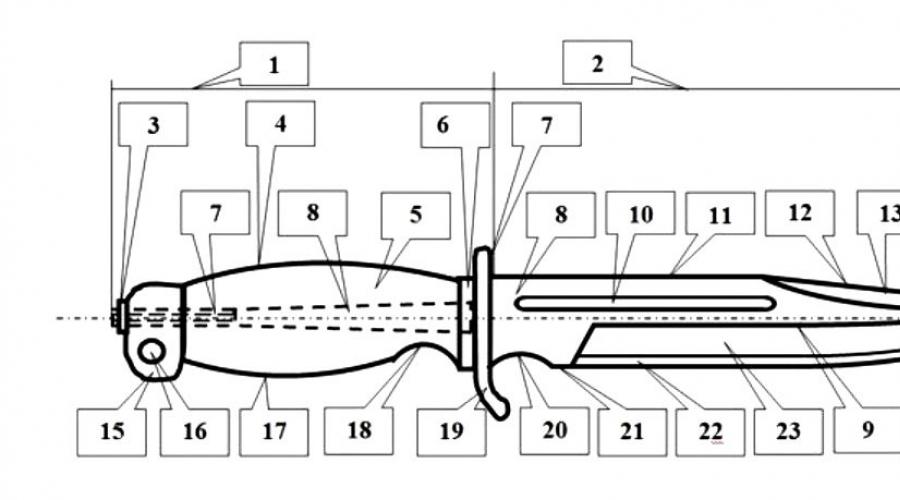

The main parts of the knife are the handle (1) and the blade itself, or the blade (2). The correct blade corresponds to the length of the entire tool, that is, its plane (8) extends along the axis (14) from the nose (25) to the nut (3), the locking cutter (5).

At the back of the plane, the sleeve (7) is made or welded, which, with the help of a tip (15), fixes the handle. The hunting knives in the head can be a hole (16) for a leather belt.

The handle is separated from the blade with the window (6). This is not just a handle, it has a rather complicated design. The back (4) and the abdomen (17) are comfortably lying in the hand. For fixation, the subfold removal (18) and cutout (20) can be provided. So that the hand does not jump at the direct strike - the limiter is set, or the canine (19).

In the age of modernization, the market is rich in various construction tools that simplify and accelerating the work process. Also, no repair or construction is also without an electrician. Each tool has additional components elements, but the Planer has these additional elements are knives, with which the tree is processed. Such knives are bilateral and go to the configuration of two pieces. If the cutting elements have become bad to remove the chips, then they came into a non-working condition, and they must be sharpened.

But before you begin to disassemble the tool, you need to know how to put knives on the electrolakeanka. In this regard, it is important to examine the principles of the ruining of the Rank.

The cutting elements are installed on the Rubanka Drum, which rotates. The purpose of knives is the planing of the upper layers of wood in the processing process. This design is equipped with one or two cutting elements. Knives, standing by the latter, are swivels, if necessary, their position is easy to change, if one side stuck. Knives for electrourub are made of tungsten carbide or from instrumental steel. Products made of steel can be repeated.

Blades have a different configuration and divided into form:

- Direct - they are installed when sampling quarters and when processing small parts.

- Rounded - are used when planing wide parts of parts, as the transitions between the planed lines are made smoothly.

- Wave-like - similar knives are used when performing antiquity imitation on wood.

Share Sharpening Options Knife Rubanka: A - On the donkey, b - on a grinding stone, in - the position of the chamfer of the blade of the cutter when sharpening on the donkey, r - sharpening on the disk of the grinding stone using a stubborn device.

Before starting work, the electrolabank must be verified in the correctness of the installation of the knives. If some errors were discovered, then you need to properly put knives on the electruruck. The cutting part of the element must be located in parallel sole of the plane and perform a little up. To determine the correctness of the knife adjustment, it is enough to turn it upside down and raise the planer at the eye level.

Usually the cutting part of the knife protrudes on 0.5 mm above the level of the sole. But Shirbel, which serves for the first draft planing, its cutting edge is produced at least 1 mm. You can adjust the adjustment without problems. At the same time, it is important to turn the right to the right and a small and large adjusting screw to the right and left until the cutting part in place. These screws are located at the back of the platform intended for the electrolabank knife.

After all manipulations, the knife is installed in the tool itself and is fixed by centering fasteners on the top plate. If the electrolake is new, then, as a rule, it has knives adjusted, but when using the setup tool is knocked down. In this regard, if the Rubank did not work for a long time, it is recommended to be pre-adjusted. It is also important to remember that immediately after setting it is not recommended to work immediately on the details, without having tried the tool on an unnecessary board.

Back to the category

Classification of modern knife

Cutting elements for electruruckics are classified in size.

The planer of imported production, such as SKIL, is equipped with standard 82 mm knives, the common name of their "record". If you choose inexpensive and at the same time durable options, the masters advise the knives "bison", which are made of carbon steel. Such products are universal, as they are suitable for most plants of various foreign manufacturers. They are used even in well-known tools like Bosh and Makita.

The exact dimensions of standard knives are available: with a length of 82 mm, with a width of 5.5 mm and with a thickness of 1.2 mm. Today, on the shelves of specialized shops and markets, you can find knives of different manufacturers, and their price will fluctuate depending on the company producing this product. For example, BOSH knives have a cost of two times more, in comparison with simple "bison", "Styer", etc. But, of course, the quality of the product will noticeably vary.

There are knives made specifically for individual models of Rubankov. Pretty popular electrolake "Interskol" and "Baikal" have individual knives, whose width and thickness are greater than that of ordinary plates. Thanks to its parameters, they have higher qualities and are strong, which means that if suddenly, when working with an electric ruble, a nail or a knuckle will fall, the knife will not break, and the jar is easily removed on it.

Such knives usually have a width of about 1 cm, and they visually differ from their fellow. The length of such knives is 82 and 102 mm, and it corresponds to the Rank model. If they fumbled, they can be applied without any problems independently.

There is also another kind of knives for electrical Rubankov. They are made wide and thick and equipped with holes for fastening. Such a model of knives is exceptionally specific, as it is suitable only for certain models. Such models refer to the Rubir company, they possess a capacity of 2000 watts. A distinctive feature of these knives is a large thickness and power, and its width can reach 110 mm.

Back to the category

How to replace Knives Electrolabank?

Electrolack knives require a special approach to themselves, and very high demands impose. When knives are stupid, it can be determined by the naked eye. For this, just the chamfer is examined in the light. It must be considered by turning around the cutting edge. If at the end of the chamfer was formed a polished strip thick with a thread, then the cutting part fastened. The knife is sharpened at an angle of 30 degrees.

Modern manufacturers began to produce knives with swivel blades. It is convenient: when one of the blades fits, it is simply turned over.

In the electrolake, the cutter is installed in a special erector. It is located in a conical sinus and clamping with three nuts. The height of the protrusion can be adjusted by the screws that are located from the edges. When removing the nut element weakened, the screws are twisted, which allows you to push the holder from the groove.

Next, it is selected for the product size under the size and it is knocked out of the groove. The next action will be replaced or turning the element, which gently rushes into the previous place. When installing the cutting product, it is important to ensure that it is in parallel to the holder.

By replacing, it is necessary to put knives on the electrolabank, adjusting them in height, after which they are clamped with nuts. It is important to take into account the same gap when installing both items. It is necessary to avoid the unbalance of the shaft.

After sharpening the cutting edges, it is important to raise the blade immediately, by removing several chips. This is important, since the blade of the tool, which immediately began to use after sharpening, is very smaller. To avoid frequent sharpening on the sharpe, it is necessary to monitor the status of the cutter, and when the initial signs are initial, it is better to immediately rule the blade.