Calculation of timber for deflection. A two-way wooden beam for overlapping and making two-ways with their own hands. Production of beams at home

For the arrangement of overlaps during the construction of the house, beams will be required. In private construction, wooden options are most often used. To select specific sizes, it is required to calculate wooden beams of overlapping.

Overlapping by wooden beams. Photo

What length do you need beams?

The required length of wooden beam overlap is determined by several points. Beams must block the span and have some reserve so that you can close them in the walls. If the walls are made of brick or concrete blocks, then the deepening of the beams is performed by 10 - 15 cm. The lower border for boards, top for a bar. In the walls of the tree, the deepening is made by seven centimeters.

Step 4: Installation and Installation of Wooden Outdoor Supports

The sizes of the beams are performed according to their loads and their support. Beams should be recommended by a professional, because it is necessary that the assembly corresponds to the current standards in the size of the floor. Distance in the center you want. Make sure the beam support is achievable. If not, specify the main reference frame. Determine the thickness of the plates and beams to better assess the level of landing of metal boots.

Step 5: Installation of beams and creation of a bunker: Wooden frame

Example: The thickness of the panel with a thickness of 22 mm is 222 mm below the level of the finished floor. As soon as the installation is completed, attach the beam to its support using the peaks of the corresponding length. Update the operation as much as you want until you get a fully supportive level. ATTENTION: In the case of the manufacture of the bunker, it is necessary to ensure its amplification by implementing a wooden trimmer. Hopper allows you to install a hatch, a staircase or a staircase.

In some options, beams are attached to corners, clamps and other devices. In this case, the length of wooden beams of overlapping is equal to the distance from one wall to another. Sometimes beams output 30-50 cm and they are involved in creating a roof skate.

Optimal beams made of wood for overlapping distances from two and a half meters to four. The maximum length that such an element can be covered with 6 m. Further, the strength is insufficient. For longer spans use options from glued timber or put additional supports, such as columns.

Step 6: Install wooden tiles

Be careful not to trim the beams for installing secondary beams. Also provided additional shutters for supporting beams on the main rays. Floor plates are specifically designed to connect on all four sides. Feel free to overlapping them to avoid weak points.

Step 7: Soundproofing and wood insulation of wooden floor

Floor tiles can be different wood species.

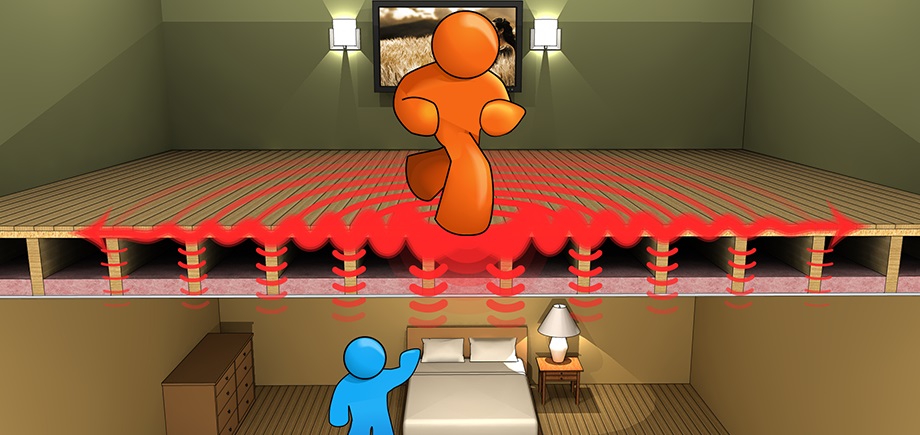

Soundproofing case

To provide sound insulation from the effects of shock influences on the floor, you can add isolation of wood fiber with a thickness of 10 mm to the beams before laying overlapping tiles. This will prevent the transfer of noise and vibration to the entire floor. How to determine the load?

On wooden ceiling beams, the load is constantly acting from several components. The first term is its own weight of all parts that make up the overlap. The second term is the operational load. It is temporary or constant. The exact calculation is quite complex, but it is quite possible to apply a simplified version of the formula.

If the load is calculated to overlap the attic, in which they will not store anything, then the constant load is accepted for 50 kg / m2.

Operational load in this variant will be: 70 * 1,3 \u003d 90 kg / m2. 70 - Regulatory value for this attic, 1.3 - stock coefficient.

The total estimated load is the sum of the two named, i.e. 50 + 90 \u003d 130 kg / m2. Round and get 150 kg / m2.

These calculations suggest that light insulation will be used. If materials with a lot of weight or the attic will be used to be actively used for different purposes, the regulatory load acting on the overlap rises to 150 kg / m2. In this case, 150 * 1,3 + 50 \u003d 245 kg / m2. This value can be rounded up to 250 kg / m2.

When creating attic, the weight is taken into account outdoor coating and the basis of sex, furniture, people. As a result, the load is obtained from 350 to 400 kg / m2.

Overlapping beams: section and step

When the length of the beam length is known and the total load calculations are carried out, you can define the desired section of this part and the installation step that should be used.

When calculating wooden beams, the overlap is taken into account that the optimal variant of the section is rectangular. Height and width must have a ratio of 1.4: 1.

The width of the beams varies from 4 cm to 20, and the height from 10 cm to 30. The height is trying to choose such so that it is convenient to lay the insulation.

On the section of the wooden floor beams affects such an indicator as the step with which they fit. Usually, the wooden overlap beam step is in the range from 60 cm to 1m. But it may vary at a smaller side of up to 30 cm and in a large up to 1.2 m. Sometimes the step is selected by the width of the plate heat insulating material. In frame buildings, it is tied to the step of frame racks to ensure maximum stiffness.

Online calculators that are widely represented on the Internet are suitable for verification and calculations.

![]()

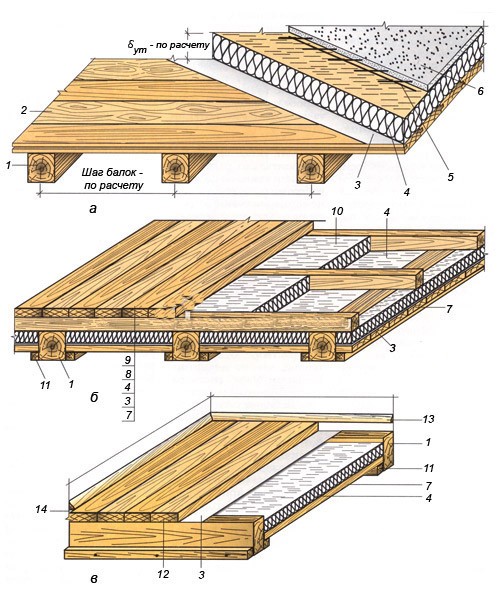

Economical overlap version

Economical is called overlap consisting of wooden shields. These parts are with a trim from one or both sides. They are connected by S. karcasthat helps them well withstand all vertical loads. Shields are carriers only when they are securely connected to frameworks. The boards are turned edges to shields and are connected to these surfaces. As the ribs from the boards and the casing are firmly connected into a single design, they have a carrying capacity of no less than the wooden beams of overlapping.

Excellent material for trim are construction plywood and slabs Chipboard. Applied and ordinary boardsBut they do not create overlap with high supporting characteristics. When they are used, there is a significant number of seams that have one direction.

There can be no additional carrier elements and drywall plates, as well as carpentry and cement-friendly stoves. The rationality of their use is small and because they cost more than chipboard and plywood.

Soundproofing overlaps

It is usually insulation of overlaps on wooden beams, but inter-storey overlaps do not require high heat insulation. Level soundproofing It is a more important indicator in this case. High strength of overlaps is not always combined with the necessary indicators of noise protection. Often the beam overlap in a wooden house has an additional isolateTo get rid of penetrating sounds. It is especially difficult to designers of prefabricated houses. They need to combine two directions. It is necessary to create a design that will differ high strength and withstand significant loads. In this case, it should be "soft" elements that absorb sound waves. They create the best sound insulation.

The beams filled with slag or clamzite do not correspond to modern standards. They are not suitable in the level of waterproofing, nor according to the technological features of the creation.

Modern norms Contain requirements for reducing the number of drum noise that can be skipped. At the same time, noise radiation should be increased even to the damage of the carrying capacity of the structure. As a result, new options uniting the indicators were created.

Began to be used spring brackets. They disconnect the lower trim and beams, thanks to which the shock noises are transferred less and faster.

Improve sound insulation help and special utyales inside the design. For this purpose, sand and other materials that reduce sound expire are used.

Insofar as sand The material is bulk, then its main drawback is connected with this. With a free sinking into the space of the overlap, it can wake down through the slots between the plates. To avoid this, the space is covered with a film or use special mats consisting of two layers of film and sand between them.

Instead of sand, plates can be used on cement based . Their main drawback is high weight. As a result, it is necessary to increase the strength of the beams, which makes the design less economical.

It is impossible to ensure high sound insulation for open overlap open. If the beams are not cut from below, but insulating materials are not laid inside, the noise penetration level will be high enough.

Protection of beams from moisture and other external influences

Special protection against moisture and climatic influences overlap beams in a wooden house is not required. All structures of attic, attic overlap of wooden beams, wooden elements outdoor Wall Securely protected if the roof is performed correctly and does not proceed.

Protect the wood of overlaps with special means is required only if the overlap is located above wet zone. It can be a bathroom, sauna, laundry and any other room with high humidity. Ventilation for overlaps is not required.

To protect any structures of fairly standard processing. Open beams or other types of non-ventilated overlaps can be treated with paint and varnish materials. Special chemicals for processing are not needed.

Protection of wooden floors from fire

Building materials must meet the standards fire protection. All materials are divided into two groups: combustible and non-combustible. The designs are half boss and fire-resistant. The first only delay the spread of fire, reduce the rate of ignition. The second is not lit, so they do not give fire to spread.

In residential construction, these rules must be respected as fully as possible. To ensuremaximum security. In particular, the overlaps, which are located in seven meters above the Earth must confront the fire at least than half an hour.

Since wood is often used for overlaps, it is recommended to usewhole wood. If others apply wood materials, then they must have a certain level of density. Often, the tree is treated with special substances that give fire resistance to fuel material.

When design is designed with open beamsThe effect of fire from several sides should be taken into account.

To identify the stability of the design to fire, special values \u200b\u200bare used. For example, for coniferous wood, the speed of burnout is received 0.8 mm per second.

Holding out the designs with open beams, take into account the required level of fire resistance. When the height is set in the parameters of the insulation, increase the width of the beams to increase the delay time of the fire.

Questions K. fire safety, just like to noise, still exist. They will continue to solve all interested parties in the near future.

Beam beams: Ways to enhance

To increase the carrier beam characteristics, several methods are used. First, attach pads from the boardIncreasing section.

Secondly, you can fix on the beam P-shaped profile Metal. It also increases its rigidity and strength.

Thirdly, reduced Step Between beams, i.e. They fit much more often than required. This gives a certain margin of strength and gives freedom of action without concern about the reliability of the design.

Periodically, the state of overlaps must be checked. Damaged beams are replaced or repaired using linings. Destroy their pests. Moisture together with rotting.

Looping beams overlap

Modern food beams Wooden floors are made of several materials. For their production, the timber is used, plates OSB. and coniferous wood. These beams have many positive characteristics. They are environmentally friendly, since it is made exclusively from materials that do not distinguish harmful substances. Serve foreign beams for a long time, and thanks to a special form and reliably. They are distinguished by a unique combination of low weight and high strength. These beams do not change their geometric parameters and are not deformed. They are easy to apply, since all surfaces are carefully verified, and all elements have the same parameters.

Food beams Wooden overlap. Photo

Prices for foreign beams depend largely from two characteristics. First -cross-sectional areaSpecifically, the height of the beam. Second -materialsfrom which the shelves are made.

Today, more and more often, when the houses are erected, the frame type of construction began to use. He implies an assembly of already ready-made design details, the production of which is carried out at the factory. But today it is possible to produce such products even at home. Their installation is very simple and does not take much time, but the resulting base for the floor is solid and aesthetic.

For a foreign beam, the presence of two elements, which are located in the form of two diametrically opposite letters T. If you decide to make such a design at home, it is necessary to use glued timber for these purposes.

On the video - the calculation of wooden floating beams of overlapping:

How to use dry oak edged board For the purposes of beams, you can from this

Now you can proceed to the calculations of the load on the overlap. The presented structure affects the load of its own mass, the operational load, which is included in the mass of furniture, gender, help elements.

Consider settlement activities on this example: an attic room insulated light material, there is a lightweight entry, can withstand the load of one's own mass of 50 kg / m2. To determine the operational load, you must use regulatory documents. If the attic overlap is made of wooden main materials and a lightweight heat insulator, then the load according to SNIP2.01.07-85 will correspond to: 70 * 1,3 \u003d 90 kg / m². 70 kg / m². As a result, it was possible to get a load taking into account standards. The formula has a reserve coefficient equal to 1.3.

To calculate the total load, such numbers must be folded: 50 + 90 \u003d 140 kg / m². To be sure of the reliability of the obtained value it is worth rounding to the biggest side. In this case, the overall load will be 150 kg / m2.

How much is the cutting board of the 50x150x6000 for use in the form of beams, you can learn from this

In the event that the room will be used intensively, it is necessary to increase the regulatory value of the load. For these purposes, the calculation is as follows: 50 + 150 * 1,3 \u003d 245 kg / m². After rounding takes 250 kg / m2. If heavier materials were used in the manufacture of beams, then it should also be considered when calculating.

When an attic arrangement will occur in the attic, then consider the weight of the floor and furniture. In this case, the overall load can reach 400 kg / m2.

How to use the cutting board size 40x150x6000 and what is its price can be found

Prices

You can purchase such a product in any construction store. Its price is not so high, it will be 200 -250 rubles per unit.