Stucco for outdoor walls. The advantages of facing plaster. Silicate and silicone materials

The main purpose of the facade plaster is the finishing design of the walls of the building outside. This finish is available at a price, the coating is rather durable and has decorative properties. To sort out what plaster is better for the facade, consider it varieties and features.

There are 5 main types of this finishing material. All of them have their advantages and disadvantages, differ in the method of applying and specifications.

Features of facade plastecrockers

Plastering formulations for external work differ from coatings intended for operation indoors. They contain additional additives, increasing strength, frost resistance, water-repellent properties and plasticity of the coating.

The facade cement-based plaster is made with the addition of high-strength its brands (M400 and higher). The proportions of the main operating components are also distinguished. So when preparing a solution for external work, the percentage of cement and sand will be 1: 3, and not 1: 4, as in the case of a mixture for interior decoration.

Primary requirements

Compositions for external work must comply with a number of requirements. Facade plaster can be considered as only if it is:

- moisture-resistant;

- resistant to temperature drops;

- strong enough to protect the facade from mechanical damage;

- vapor permeable;

- provides heat and sound insulation;

- it has decorative properties.

If you live near industrial facilities, the selected facade coating must have resistance to harmful radiation. The abundance of modern finishing compounds allows you to find plaster corresponding to all listed items.

Heat insulation

The layer of any facade plaster contributes to the preservation of heat inside the building. But if the walls are thin and may not provide due insulation, for the external finish, a composition with a special filler is needed.

The so-called "warm" plaster additionally contains polystyrene foam, perlite, vermiculite, foam glass or sawdust. Their addition significantly increases the thermal insulation characteristics of the walls - the 3-centimer layer of such plaster replaces 15 cm brick masonry.

Soundproofing

Plastering can also serve as a sound insulation material. This property is useful for those who live near the motorway, construction or other objects producing objects.

But with noise insulation, not any plaster mixture will cope. It should be present cement with pumice or slag or pumice and magnesite. Porous inclusions muffle the sound, partially absorbing it.

Of course, it is not worth counting on only the plaster, it is effective as auxiliary. With a high noise level, it is necessary to use additional sound insulation materials - foam plates, mineral wool.

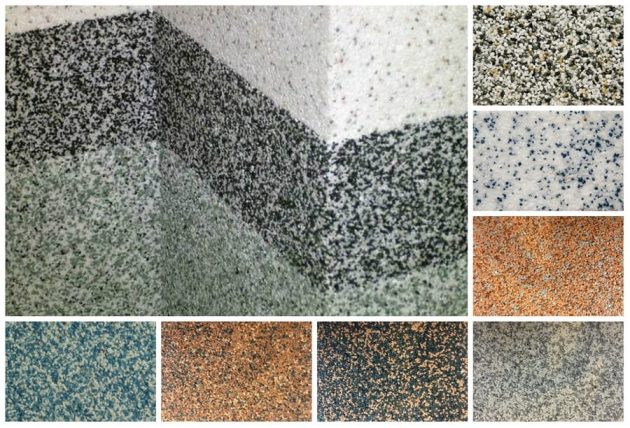

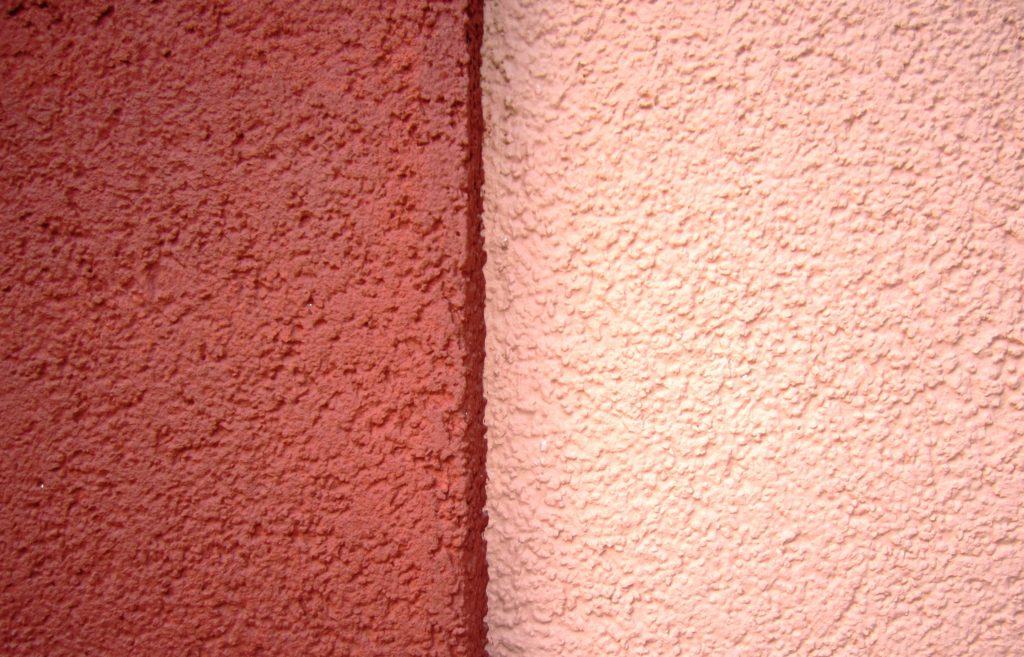

Color and texture

Facade plaster not only protects the walls of the house, but also decorates them. With the help of such a finish, you can achieve an optimal combination of the facade with other elements of the building, pick the desired color and texture.

Stucco for exterior walls is available in a wide color palette. If you need to create a pronounced texture, a mixture is used with the addition of stone crumbs or ceramic granules.

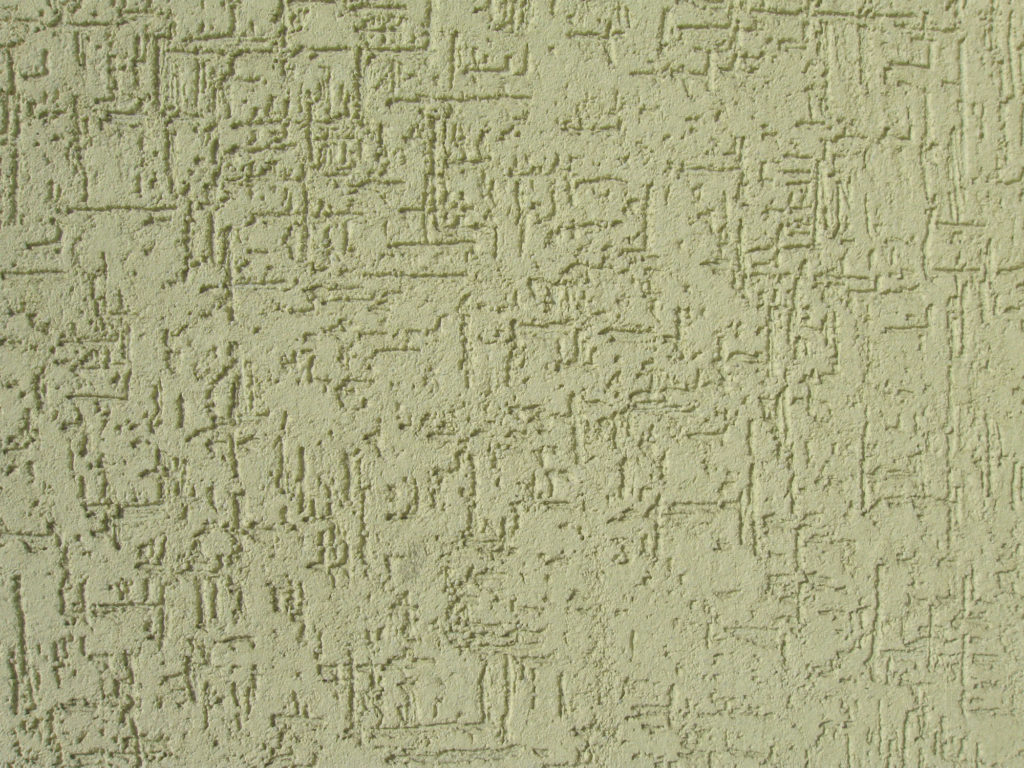

Also, the surface of the plastered layer is treated with special graters, changing the cover of the coating. This method creates popular patterns, such as "Coroed", "lakes", etc.

What a decorative plaster is better for the facade - in each case it is solved individually. With it, you can create any patterns, right up to the simulation of brickwork and natural materials (Woods, stone).

Varieties

There are 5 types of facade plaster. They differ in the composition, properties and technology of application.

Mineral Plaster

Mineral plaster consists of hazed lime, M500 grade cement, and above, stone crumb, color clay or other small fillers. Additional additives that increase the resistance to mold and fungus may be present. Plaster is implemented as a dry mixture in bags, it is required to dissolve it with water.

They are applied by spatulas by manually either by a mechanized way. The finished solution is suitable for work for about 60-90 minutes. After drying, the coating forms a durable non-combustible layer with heat and sound insulation properties. Granules and supplements provide decorative decoration.

Depending on the characteristics of a particular product, mineral plaster retains its properties at temperatures up to -25 or even -50 degrees. The service life of the finish is about 15 years.

But it must be borne in mind that this type of coating poorly tolerates vibration. The use of mineral facade plaster is not recommended near railways, as well as in zones with seismic activity.

Acrylic plaster

In the acrylic facade plaster, acrylic resins are used instead of cement. In addition to them, there are:

- modifiers that increase strength, plasticity and other specifications;

- dyes responsible for the color of the coating;

- filler (sand, granules, stone crumb), creating a surface structure.

Acrylic plaster is sold in the form of a finished solution suitable for applying. The service life of such a coating is about 15-25 years. The plaster with the addition of acrylic is resistant to temperature drops, but easily attracts dirt. However, it is easy to clean, watering with water from the hose.

Before applying an acrylic coating from the surface of the walls, dust and residues of the previous finish are necessarily removed. If there are places affected by fungus and mold, they are previously treated with a special antiseptic.

Acrylic plaster grasps in 20 minutes, but it takes up to 48 hours to complete drying. At this time, the coating must be protected from direct sunlight from entering to avoid cracking. Because of the rapid frost, noticeable joints of the layers are often formed, so professional needs should be performed.

Silicone

Silicone facade plaster contains silicone resins, filler, coloring pigments and additives that increase the durability of the material. It is produced in the form of a finished solution.

Among the advantages of silicone coating, elevated moisture resistance, elasticity, self-cleaning ability, simplicity of application. The service life of such plaster - 20-25 years. The only drawback is a high price.

The solution is well seized on any, pre-purified from dust and dirt, surfaces. The technology of applying and drying conditions of silicone plaster is similar to recommendations for acrylic mixtures.

Silicate

Another expensive, but high-quality material is silicate plaster. It contains the same substances as in mineral, but there is one additional component - liquid glass.

Silicate plaster is realized as a solution. Just like silicone mixtures, it has antistatic properties, that is, repels dust. The finished coating has increased abrasion resistance, waterproofing and elasticity. Service life - 25 years or more.

Of minuses silicate plaster It should be noted too fast frozen after applying. Because of this, only a professional who is able to perform work without errors from the first time can be engaged in plastering. In addition, silicate plaster requires the use of special primer.

Cement

Cement plaster - composition, tested by time. This inexpensive type of finishing material is used in Russia when lining inner and outer walls with decades. Its basis, as is clear from the name, - cement. It also includes lime or sand, there may be other additives that increase strength.

The mixture is sold in packaging in the form of a powder and divorced with water immediately before use. Cement plaster is different shades, but the color range is strongly limited. This problem can be solved by subsequent staining.

Explicit disadvantages of cement plaster are the need to prepare a solution and low decorative qualities. Given the coverage and service life, on average it is 10 years.

Technology wet plaster

Probably, many have heard the term "wet plaster". Under it implies plastering over the multilayer "cake" from the primer, insulation and the reinforcing grid. Such a finish of the facade makes a point of dew beyond the limits of the house, taking on condensate. As a result, housing is obtained dry and warm, the optimal microclimate is created.

The thickness of the layers and their sequence may be different, but more often the order is as follows:

- Base (wall).

- Fixing primer.

- Adhesive layer.

- Thermal insulation material fixed by dowels.

- Reinforcing layer.

- Primer to improve adhesion.

- Decorative plaster.

It is very important to choose the appropriate heat insulation material. What insulation is better for the facade under the stucco? A good option in this case - plates OSB., mineral wool or. They are moisture-resistant and reliably preserve heat.

Advantages and disadvantages of facade plaster

Facade plaster, like any method of finishing, has strengths and weaknesses. Various views differ significantly from each other, but you can still highlight the qualities common for this group of facing materials.

The advantages of plastering for external work include:

- fire resistance;

- thermal insulation properties;

- resistance to temperature differences;

- the ability to perform work without special equipment;

- small weight of the material;

- rapid production of decorative coating.

But there are disadvantages. Stickers stability to mechanical exposure lower than in ceramic panels, facing tiles and other similar materials.

If we are talking about decorative coverage, it will require professional skills. In addition, you can only perform work at temperatures above +5 degrees, and complete drying with a thick layer of plaster will take a lot of time.

How to choose?

The choice of facade plaster depends on the material of the walls of the task, the operating conditions of the coating and the requirements for it. Whether the composition with granules or with a smooth texture is a matter of taste. The same applies to color decoration.

If you think that the house requires additional warming, pay attention to the compositions containing perlite, vermiculite, foam glass, etc. Those who wish to repair the facade, suitable plaster with high strength - silicate or silicone.

Previous mix

In cases where it is necessary to perform work quickly, and the experience in this business is not enough, it is better to purchase ready-made compositions. With them, the risk of mistakes when mixing the solution is missing. There is a ready-made mixture and other advantages - convenient storage and transportation.

Selection of plaster for a specific surface

The answer to the question is what plaster will be better for the facade, directly depends on the material of the walls. Even high-quality plastering composition may not justify hopes when applied to an inappropriate basis.

Optimal combination of types of facade plaster and base material:

- Brick walls - cement or silicone mixture.

- Aerated concrete - silicate or silicone composition.

- Wooden walls - silicate plaster.

- The insulation plates - the composition based on acrylic, applied over the reinforcing mesh.

- Other options are a silicate mixture.

Facing with decorative plaster is a modern, inexpensive and reliable way to design the facade of the house. Subject to the application of applying and compliance with the material of the base composition of the mixture, you will definitely get durable and decorative coating. If you plan to create a complex pattern, but there are no necessary skills, it is worth contacting professional builders.

Useful video: How to choose decorative plaster?

The facade finish is a very important process that determines the appearance of the building and its environmental compliance. Several variants of facade plasters are isolated, which differ in composition, texture and type of binder. On the advantages, technology of application and the peculiarities of each of them will be talked further.

Benefits of facade plaster

Before moving to the advantages of the use of facade plaster, we will define the functional features of the facade finish:

- outdoor finish protects the building from negative atmospheric and mechanical impact;

- gives the building an attractive appearance and desired texture.

For tinting and adjusting the color of plaster, a dye is added to it. This finishing material is distinguished by a wide range of gamut.

Among the main advantages of the facade plaster, we note:

- High adhesion with base, elasticity and high-quality composition.

- The possibility of long-term storage, in non-divided form.

- Resistance to mechanical effects, moisture, temperature regimens, ultraviolet radiation.

- Environmental safety - material during operation does not emit toxic substances.

- It is characterized by minimal absorbability of dirt, it is easy to clean. Some plaster options are self-cleaning.

- Paropropusability - provides comfortable conditions for accommodation in the room. The coating passes air, creating natural ventilation.

- The ease of application and a variety of plastered options for texture, composition, color, method of applying.

In the ratio of the compositions of plasters, options are allocated:

- mineral;

- silicate;

- acrylic;

- silicone origin.

The first option consists of cement with the addition of polymer inclusions, which improve the adhesion and give the composition of greater elasticity. Silicate plaster mass contains fiberglass inclusions and plasticizers, has good performance characteristics.

Plaster by acrylic basis Contains an acrylic resin, and silicone - silicone. If the wall is made of natural materialThe plastering formulations of mineral, silicate or silicone origin are used for its finishes. These compositions have high vapor permeability, well interact with insulation in the form of mineral wool. For polystyrene insulation systems, options for plastering on an acrylic basis are suitable.

Outdoor plaster for the facade on an acrylic basis is characterized by good characteristics and the greatest service life. Mineral plaster is the cheapest, but also in operation - the least durable. The average resistance to the exposure to the external environment is distinguished by plaster with silicate and silicone composition.

The structure of plaster also determines the duration of its operation. The greater the surface differs, the faster it is covered by cracks. Therefore, we recommend to give preference to rough surfaces.

Stucco resistance Before burning is directly determined by the saturation of the tones. The lighter tone of plaster, the better it retains the color indicators.

Types of facade plaster and their characteristics

Read more with the main types of plaster for outdoor decoration Buildings. First of all, consider the main types of plasters in the ratio with the composition.

Stucco with acrylic binders - is distinguished by good parpropusk abilities. This composition, with a lack of moisture in the room, gives it, and with an excess - absorbs, thereby maintaining optimal microclumatic conditions. This is ensured by the presence of a resin dispersion on a synthetic basis. Among the additional advantages of this composition, we note: good resistance to temperature fluctuations, elasticity, resistance to microorganisms: fungus and mold.

Despite this, acrylic plaster has certain disadvantages, namely:

- it is easily contaminated, as it does not have electrostaticity;

- differs high cost.

The facade plaster of silicate origin also has high record permeability. This coating is distinguished by a wide range of applications, as it has neutral electric static. The main element of this plaster is a potassium-based liquid glass. The coating is not prone to pollution, it is well tolerated by moisture, fluctuations in temperature, ultraviolet radiation is not cracking.

Mineral plaster - one of the most popular finishing materials consists of cement with additional polymeric substances. The material is characterized by the highest strength characteristics available to the cost and wide range of use. In addition, we note the following advantages of mineral-based plaster:

- high level of vapor permeability - no condensate on the walls, adjust the microclumatic conditions indoors;

- high pH provides stucco resistance before the advent of fungus and mold;

- frost resistance, resistance to precipitation and ultraviolet radiation;

- fire safety - the material is not inclined to burning;

- environmental safety - in the composition of plaster does not have toxic substances, harmful to health;

- ease of washing - Conventional water or additional detergents are used to clean the walls;

- after drying, it is not amenable to shrinkage and does not crack, subject to the technology of applying plaster on the wall.

However, mineral plaster is characterized by a limited color scheme, although after drying, it is painted with facade paints in almost any color. The process of applying plaster requires compliance with strict technological standards and dosages, otherwise the coating will not have the necessary strength.

The duration of the coating operation is about ten years, the material is characterized by sensitivity to vibrations, under their influence cracks.

Silicone plaster is distinguished by maximum durability, good dirt-repellent abilities and resistance to atmospheric precipitation. The walls on which this finishing material is applied is not inclined to form mold or fungus. Silicone Plaster - Universal Composition, which combined all the advantages of plasters on mineral and acrylic basis:

- excellent moisture-repellent abilities;

- good vapor-permeable characteristics;

- resistance to fungus, mold and other microorganisms;

- increased level of resistance to temperature fluctuations;

- the absence of not only cracks, but also microcracks on the facade part of the building;

- high level of elasticity;

- high-strength adhesion with any of the coatings.

Several textural options for silicone plaster:

- coroede - is used to finish the facade, insulated by foam, additionally reinforced with a glasswork;

- lamb - different roughness;

- stone-type plaster - is distinguished by a smoother texture and a stone is added to it as a filler;

- plastering on a Venetian-based basis - contains a marble crumb, in appearance is similar to polished marble coating.

Mineral Type Facade Plaster Mounting Technology

Before the start of applying mineral plaster - align the base. If necessary, remove the old finish, get rid of cracks and other surface defects. Remove bold spots and rust. Next, the surface is covered with a primer on an acrylic basis, this composition has a powerful antiseptic effect and improves the clutch of the wall with further finishing material.

At the next stage, a plaster mortar is prepared. Preview the instructions in which the preparation recommendations are indicated. Two ways of applying plaster are distinguished:

- manual;

- mechanical.

The first implies the use of a metal spatula, and the second is based on the use of special pumping equipment. The optimal air temperature for this kind of work is from +12 to +24 degrees.

Mixed mixing equipment greatly simplifies the process of applying plaster, evenly distributing it on the surface. For use, follow the instructions below:

- Prepare a tool to work, take a gun in your hands and turn sideways to the wall.

- Install the pump into the container with the plastering solution. Open the valve, and wait for plaster on the wall.

- Apply the composition at first upwards, and then right left. First fill in small irregularities and depressions.

- Upon completion of work, close the valve, then using the rule to split the surface.

Manual application of plaster is a more complex process, since the solution is applied to the surface with a spatula. At the same time, it is important to choose the optimal thickness of the layer. After applying the solution, wait half an hour to grasp it. Next follows the process of manufacturing texture of plaster using a special grater.

Use decorative plaster from one manufacturer and preferably one batch. Perform work with the use of protective equipment in the form of gloves, safety glasses. After applying plaster, at least three days, protect it from excessive solar radiation, wind and moisture.

Application of facade silicone type plaster

At the initial stage of working with silicone facade plaster with their own hands, carefully prepare the surface. In the presence of seams between the masonry material, they are sewn to a minimum to one centimeter. To improve the clutch with the surface, the facade decreases the seams of a deformation character. Next, the surface is dustd and moistened.

At the next stage, a plaster mixture is prepared, the optimal time to use the plaster mortar is 1-2 hours. Next, the composition loses the strength characteristics.

Next follows the process of applying plaster spray. For these purposes, you will need to have a tool for installing facade plaster and certain skills to work with it. Throwing should be sharp and strong, so that the solution is good adhesive to the surface.

- it is forbidden to apply plaster on recently constructed walls, since when shrinking there is a risk of her cracking;

- the gypsum solution is not applied to the concrete base, since in the future such plaster will swell and fall off, first the wall is separated by plaster with the content of lime, and then with a plaster;

- stouting plaster is performed a few days after it is applied, the plaster becomes tough, but not completely captured;

- thickness of one layer plastering should not exceed two centimeters.

Use a special grater from a tree or aluminum to grout and aluminum, on top of which foam plastic is pasted. Circular movements pierce it to the surface, pushing it with a solution.

Features of the facade coating acrylic type

An ordinary spatula is used to apply on an acrylic basis. This plaster is characterized by the highest drying rate. Therefore, before applying the composition, it is recommended to align the surface as much as possible. The processing of the selected fragment is performed quickly and continuously. Otherwise, there is a chance of the appearance of joints, irregularities and differences in color.

Pre-divide the wall into several sections, to which the plastering solution is stucked. If necessary during the break, before applying plaster, moisten the boundaries of the previous section with water.

A variant of applying acrylic plaster using special equipment in the form of a spraying machine. Up to the complete drying of the composition, protect it from atmospheric precipitation.

Please note that the color of the dry acrylic plaster is always darker than liquid. Therefore, the facade with time after drying it darkens. For the maximum long period of operation of acrylic plaster, apply it to a pre-prepared surface.

Clean the facade from the old plaster or paint, get rid of fat or corrosion stains, drive the surface. The thickness of the applied layer should not exceed three millimeters. The time of setting the composition is 25 minutes, and complete drying from 10 hours. Special rollers use special rollers to impart the walls. For washing acrylic plaster enough use warm water with a sponge.

Facade plaster video

When a person passes by any structure, he first turns attention to the appearance, and more specifically, on its front part, which is called the facade. By how qualitatively, the decoration of the building is made, you can get a general idea of \u200b\u200bits owner, about its financial capabilities and even the character. This is perhaps one of the main reasons, because of which the facades are attached great importance. The modern and beautiful facade of the structure can be decorated with various methods, including marble tiles, and all sorts of lining panels such as siding or aluCobonda and even simple plaster or effect "fur coats" on the facade. But the most extravagant and exotic way for facing the facade is currently facade decorative plaster, whose features will be discussed later in this article.

Decorative facade plaster is not simply responsible for the beautiful appearance of the building, but also serves as an additional protection of the walls from various atmospheric manifestations, for example, from wind, water and ultraviolet radiation. Today, many options for mixtures for various surfaces and conditions of application are produced. Types of facade plaster differ from each other not only by their composition, but also characteristics and features of their use.

Properties of decorative facade plaster

The basis of the material function is that it forms an attractive design of the facade, and also protects against various external influences leading to destruction. These all requirements are achieved due to the fact that outdoor plaster There are the following properties:

- Waterproof, since the plaster under the action of moisture is not modified and is a kind of layer for protection, which prevents the effects of destruction from moisture.

- High resistance to climatic changes and temperature drops, which is especially valuable for regions with a significantly different seasonal difference in temperature. High-quality facade plaster has sufficient resistance to the effects of sunlight and precipitation, and some of its species also have to radiation compounds.

- High strength, and although the facade of the building is not so often subjected to mechanical loads, but even if such a place, the plaster will be able to withstand them.

- Parry permeability, that is, the ability of air flow or vapor outside, which makes it possible to maintain the primary structure of the structure of the structure.

- Enhancing sound insulation I. thermal insulation quality at home. Using facade plaster, you can save on heating, since this material increases the thermal insulation parameters of the house. In addition, due to such a finish, the level of noise coming from the street is reduced.

- The ability to create various textures and the presence of a wide selection of color shades. Thanks to the decorative facade plaster, you can realize almost any ideas of design. Coatings are a variety of colors that can be obtained by adding killers. You can also improvise with patterns and textures, while the main thing is to correctly apply the layer of plaster and use stencil if there is a need. For example, if the facade plaster of the type of "cored" is used, then the impression is visually created that the surface of the walls is made by insects. At the same time, this design of design attaches general image Construction originality. The choice of color solutions and ornaments depend only on the technology of coverage and fantasy customers.

- The comparative ease of application of the plaster mortar, as the plaster of the outer walls can be carried out even with their own hands, if there is a certain experience in construction business.

- Cost of material. When comparing the average price of other finishing materials, plastering will be quite profitable. At the same time, each variety of the mixture has its own price, depending on the final structure of the wall coating, which is available in the composition of ingredients and properties.

The listed qualities are characteristic of almost all types of facade plaster, but, one way or another, the degree of manifestation of certain basic properties may differ depending on the type of mixture used and its composition.

Varieties of facade ornamental plasters and recommendations for their choice

The facade plaster for external work may have various binders, however, the role of a filler will always perform fragmented stone with different fraction From large grains of 5 millimeters to small sand.

Cement plaster for finishing facade

Cement plaster is made on the basis of portland cement and fractional sand with water-retaining and other additives that improve their operational qualities. Also, decorative plaster for external work include elements that are responsible for the texture of the resulting surface. For example, the facade mixture of the type "cored" contains grains of crushed granite with a fraction of 0.5-3 millimeters.

Distinctive features of facade decorative plasters on cement based The following are:

- High degree of strength of the finished coating.

- Such plaster does not have wall permeability negative influenceSince such a coating is "breathable."

- The material is not smoldering and does not burn, does not release toxic gas when heated.

- It has an affordable cost relatively to the rest of the facade finishing materials for external work.

- Good and high qualityly paint with mineral paints.

- Qualitatively falls on most varieties of facade surfaces. To apply plaster on the insulation, the plaster grid is mounted in advance.

The lack of material is not too rich in the palette of colors for the outer finish, and if the existing range does not suit the Customer, it will have to be included in the budget also costs for the appropriate paint.

It should be paid to the fact that the degree of strength of the obtained outer coating depends directly from the exact compliance with the proportions of the ingredients. It is advisable to buy at once the finished front dry mixture, rather than make it with your own hands. Accidental attention is also required for the preparation process for use.

Silicate plaster for decorative facade cladding, as well as cement, is mineral. Here, potassium liquid glass is applied as a binder. The filling composition of approximately the same sand and / or stone crumb, water, mineral pigments and improving additives in small quantities.

Aesthetic and operational characteristics are specified by liquid glass:

- high exterior windproof and moisture resistance of the facade

- long service life and high decorative properties;

- good adhesiveness with concrete, lime-concrete and silicate exterior compositions;

- fireproof material quality;

- a fairly high degree of vapor permeability of the facade coating;

- the variety of color palette;

- the possibility of staining with silicate paints.

The lack of such decorative plaster based on liquid glass consists in high cost.

It should be noted that the facade decorative silicate-based plaster can be applied on all types of insulation and the outer draft finish. For example, such works are not acceptable polymer insulation and surfaces that are covered with varnish or oil paints. Gypsum and other external gypsum-containing bases are considered conditionally suitable and need a trial application.

The material base is a stone crumb, coloring pigment, sand and hydrophobic additives. Acrylic resins serve as a binder, and more specifically their water dispersion. They are produced in the form of decorative prepared mixtures for external work.

Decorative facade plaster on an acrylic basis for outdoor works are the following characteristics:

- Good wind protection and moisture resistance;

- High degree of elasticity of decorative finished facade coating. Due to this, the probability of cracking of the coating is practically eliminated.

- Resistance to abrasion and shocks.

- Wide color assortment.

- The ability to color the facade after cladding.

- Good prilence of material with many outer coatings.

The disadvantages of the outer composition on an acrylic basis consist in low stability of the pigment to ultraviolet radiation.

It should be known that acrylic outer coatings are not intended for work with them over the plates of mineral wool. Conditionally suitable can be called cellular concrete in this case.

Facade plaster for external work with facades produce from a combination of coloring pigments, mineral fillers and silicone resins. The material forms a thin layer of decorative coating. It is impossible to call such an outdoor plaster cheap, however, such a cost is justified by its aesthetic and operational qualities:

- The material is suitable for the behavior of the work in difficult weather conditions.

- Performs good defense From atmospheric impact, including moisture.

- Released more than 200 shades.

- Color decorative pigment has resistance to sunlight and, therefore, does not fade.

- The service life of the coating is more than 10 years.

Minus silicone facade plaster is that it cannot be applied to the outer insulation. The problem is solved by creating a basic layer under decorative on the reinforcing grid.

Another species should also be noted - decorative silicate-silicone outer plaster. The connected substance here serves composite from the dispersion of potassium silicates and silicone copolymers. Such a cladding for external work on the operational qualities is quite close to Silicon.

It should also be said about the varieties of external plaster textures. There are several types of textures:

- The effect of "cored", for which the working mass includes stone grains with a certain fraction. It depends on their size, how intense will be the relief on the surface of the walls. The textured surface is created precisely at the expense of these grains. The texture is obtained like a drawing on wood, trained by the beetle-tree.

- The effect of "lamb", where filler contains stone grains different sizes, making a decorative surface soft blades.

- The effect of "fur coat", in which the relief depends on the features of the filler directly in the working mass, and not from the application technology.

- Crupes or pebble plaster, which contains in its composition a lot of stone large grains of the same size. Such plaster gives a small-baked surface.

- Mosaic decorative plaster with decorative stone. Such a material, in contrast to the rest of the above, there is only in silicone and acrylic compositions. The binder is transparent, and the surface has the form of a tightly laid stone crumb.

- Color decorative plaster based on a solution of sand and limestone with the addition of coloring pigments. It is used to treat brick surfaces, as well as tuff, light concrete and porous blocks. Such a plaster is applied by creating combined or set textures. In a plastic or hardened form, it gives a specific form by applying special tools and shapes.

- Stone texture of decorative plaster - cement decorative plaster, which contains granules and grains of natural stone, which makes it possible to obtain a mosaic facade or imitation of granite, marble or limestone. It is used to finish brick and concrete surfaces. According to the technology of applying facade plaster, it is additionally treated with mechanical pathways or etching hydrochloric acidand then washed with water. As a result, the cement layer is destroyed, leaving a relief surface with a stone crumb. This method is considered one of the most complex options For finishing the facade of the building.

- Terrazite decorative plaster, which is obtained from terrazite mixtures, which includes lime, cement, mica, stone crumbling and quartz sand. It can be used for any part of the building. Such plaster in the almost hardened state is treated with a nail brush or sandblasting machine. The resulting surface appearance is similar to sandstone or tuff.

- Fewer graphite, allowing to create unusual embossed images and a colorful surface. It is made, combining several colored solutions. This plaster is used to decorate the design and restoration of buildings. First of all, the preparatory layer is applied, and after 2-3 additional layers. After six o'clock on the top, a cut off has not yet solidized layer, allowing you to expose the bottom layer. The result is an unusual embossed pattern.

Choosing a suitable mixture of facade decorative plaster for outdoor work

There are numerous features of the facade plaster for external work. To select the most optimal of them, taking into account the parameters of resistance to aggressive external factors, the compatibility of any type of facade plaster with the surface is to be applied. It is from these parameters that the exterior decoration will be. For example, cement formulations are good at the walls of any quality, while the only condition is that if the works are on top of the insulation, it is required to pre-mount the plaster grid.

Stability depends on various factors. Each decorative mixture is good, but something loses the rest of the species. For example, acrylic plaster is able to withstand a mechanical impact, and the service life reaches 15-25 years, but it has a tendency to burn out the color. But if you plan to paint the facade for a couple of years, then such a moment will be insignificant. Thus, it is necessary not only to compare the facade plasters, but also evaluating its priority for itself. The least durable of all is considered cement plaster With a service life of 10 years before the next cosmetic repair. The greatest resistance to atmospheric precipitates is observed in external facing materials on acrylic and silicone basis, and the smallest - in silicate and minerals.

To prevent the formation of mold and fungus into silicate and mineral mixtures, antifungal and antiseptic reagents are added, and the types of outdoor decoration with greater water resistance do not need it.

Direct influence on the durability of decorative outdoor facing It has the texture of plaster for the facade. Internal stresses are worse than the smooth surfaces that are easy to crack. Coatings with roughness and more persistent and can also mask cracks due to relief on the outer surface.

The durability of color coating depends on several conditions. First, whether painting the outer surface was made with paint and varnishes or pigment was evenly distributed in the total mass. Secondly, the antistatic quality of the material, which prevent the deposition of dust to the surface. Third, the factor of the resistance of the pigment to fading, that is, resistance to ultraviolet rays. In all parameters, silicone plaster for external work has the highest performance.

Choosing the material, it is also necessary to take into account the coverage of the working mass. In the work, plastering mixes are divided into thin layer and thick layers. Tolsti-layer include silicate and cement decorative compounds, and to thin-layer - silicone and acrylic. The thin layer type of plaster is more demanding a reason for which it is applied.

Among the popular manufacturers can be allocated as follows:

- Knauf (Knauf), Ceresit (Ceresit), Caparol (Kaparol) - the most famous and at the same time worthy trading companies that are founded in Germany. Their products are distinguished by high quality and the same high cost. This brand is produced in many countries of the CIS countries and Eastern Europe, but this does not reduce product quality.

- POLIMIN (Ukraine), Baumit (Austria), Kreisel (Germany), Atlas (Poland) are located on the next step in popularity. Produce reliable and high-quality finished and dry construction mixes For external I. internal work.

- Synerges (Kazakhstan), items (Russia), Bolaris, VOLMA - Dry plaster for external work with sufficiently mediocre performance. Their advantage of their advantage is in the low cost of products relatively with branded expensive brands.

Preparation of the necessary tools

What to produce plastering No specialized tools need, and everything you need can be found at any economic store:

- spatula - It is advisable to use several options;

- capacity for the manufacture of the solution;

- roller and brush, and if there is an opportunity, you can use a sprayer, which will make the procedure for applying plastering the plaster even faster;

- sandpaper.

To ensure your own safety, work is better to take the mask and gloves with glasses, since there were cases when the solution got into the eyes or irritated when the skin came into contact. You must also try to wash the instrument after each working stage so that dried plaster does not damage the next time the surface.

Technique of applying decorative facade plaster for outdoor work on various surfaces

Flow consumption

Foreign decoration In most cases, they are equally applied to the walls equally, with the exception of the so-called "complex" surfaces, for example, insulated with foam surfaces, bruschers, chipboard and OSB.

Facade finishing from aerated concrete and surface with a layer of reinforced leveling coating

The easiest way to apply a plaster mixture on bricks and on aerated concrete blocks. In addition to standard actions for leveling and applying adhesive soil, there are no preparation of walls. Additional work will be necessary when using thin layer material. In this case, it is necessary to treat the walls with a roller with a staining color of the future facade plaster.

Step-by-step process manual application It is as follows:

- Dry stucco for outdoor work is diluted with water in required proportions And as it should be stirred. The mixture is completely ready 10-15 minutes after stagnation.

- If necessary, the prepared amount is applied.

- The spatula is buried by mass and laid out on the lower edge of a wide cell.

- Kelma with a solution is applied to the wall almost perpendicularly, during the movement, reducing the angle to the tool almost to the parallel position.

- Kelma is almost without pressure on the wall, stretching the plaster mixture until the layer of the desired thickness is obtained.

- After performing a plot of approximately 1.5 square meters, a plastic grater is taken and the surface is maintained until the desired texture is obtained.

The actions of paragraphs 3.4, 5 and 6 are repeated until the building facade complete finishes. At the same time, it is better to work at once with squares, and not square meters. Thus, the coating will have a homogeneous texture. If it is not possible to separate the planned areas, the connecting seams need to be issued using painting tape.

Outdoor activation technique for mineral wool, polystyrene foam or penplex

These two material have a surface, difficult to finish, so in this case it is necessary to perform the preliminary installation of the facade mesh under the plaster. An error that is usually allowed during the reinforcement of insulation is to apply adhesive composition only on the membrane. The special composition of the glue with an area of \u200b\u200b1.5-2 square meters is correctly applied to the surface. The grid segment is taken into the hands and fixes in the corners with small thin sticks.

The process of plastering of outdoor frame walls on wood - OSB, chipboard and bruus, implies two types of work:

- The technology is identical to the above for finishing wall foam.

- The outer surface of the facades is closed with construction paper, reinforcing the protection of the base from various atmospheric manifestations. Such paper can be attached using a construction stapler.

It is important to consider that the woods are very hygroscopic, and the facade can "lead" from moisture, which is contained in the working mass. In order to avoid such consequences, it is necessary to apply a special hydrophobic soil and the impregnation of a tree to perform external work.

On top of the construction paper, a metal largest facade mesh for plastering is mounted. The grid can be fixed with the same stapler. The degree of adjustment of the web and its slope in relation to the outside of the facade depends on its evenness. In this case, the plaster layer is made quite thick, so the profile limiter from aluminum is fastened to the lower edge of the grid. The first layer of the outer reinforcing grid should almost hide the grid under his way. After drying, the second leveling layer is applied to the facade. Works for finishing finishes are performed according to the method described for gas-silicate concrete.

Calculation of the flow rate of the mixture for decorative plastering of facades

External plaster consumption for one square meter Calculated with several factors: the fatality and type of base, the nature of the binder and the filler. On the packaging of working materials, the indicators are provided with the above parameters. On average, the figures of the material look like this:

- mineral plaster - 2.5-4 kilograms per square meter;

- silicone plaster - 2.53.9 kilograms per square meter;

- acrylic plaster - 1.5-3 kilograms per square meter.

It should be noted that to calculate the necessary working material it is required to add 5 percent of the result obtained on working loss. Thus, it does not have to reach the plaster mix, delaying the work, and the parties of the material will not differ in color.

A wide cell is taken in the hands of 30 centimeters long and it is carried out on the grid with a small pressure in different directions. In this case, the adhesive composition appears outside, practically hiding the reinforcing membrane under him. The edges of the plaster mesh of the facade hanging down on the basement is flexing down and is lined with the same composition. To handle the bend, it is better to apply a spatula, which has a surface complex in a triangle. Thus pass on all the walls of the building. When the glue dries, it is applied again, but on top of the grid.

In addition to the above-described method, for calculating the volume of consumable material, you can find a lot of special calculators on the Internet, allowing more accurate calculation of the amount of bag for any type of decorative facade plaster.

Various technologies for applying facade decorative plaster

Textual varieties for the external use of decorative plaster are quite limited, which is associated with the peculiarities of their operation, namely the exposure to the aggressive effects of the environment. One way or another, by combining various textures and colors, you can find out which texture will be most common with the common style of the house.

To fulfill work, medium and large spatulas will be required, as well as the average and large celma. Works are performed in the following sequence:

- Small spattela material impose on a large and applied to the wall. Movements are made from bottom to top from the angle.

- The mixture after applying is smoothed.

- When it grab, namely, 5-10 minutes later, depending on the humidity and temperature, the formation of the image with plastic cells is performed. The drawing can have vertical and horizontal lines or at an angle in the form of "rain".

- After 40-50 minutes, when the processed area is completely dry, it is possible to walk along the outer layer of a shallow grater or a pure plastic cell.

Plaster with the effect of "fur coat" is the most technological type of facade plaster. There are several methods for mechanized applying a facing mixture. On a pre-prepared surface of the walls, a mixture can be applied using a special mechanical device "Charmanka" or a pneumochloric device. The easiest way to apply "fur coats" is the use of already ready-made outer mixtures, which are designed to apply a roller. One of the varieties of "fur coats" is the texture of "lamb", which refers to the outer peasor facade plaster. It characterizes a more rounded surface relief. It is also released in the ready-to-work mixtures and apply a spatula. Another embodiment is the "crocodile" or "rubbing fur coat", which is a conventional mixture of "fur coats" with the presence of fine-forming quartz sand up to 1 millimeter, which is peers outdoor surface.

Mosaic facade plaster is an acrylic knitting and multicolored marble crumb with a shallow fraction to 1 millimeter. Such an outdoor decorative plaster for the facades is applied to the surface prepared in advance with a bellma or a wide spatula from the bottom up. The advantage of such a finish is that it does not require subsequent processing. High resistance to humidity and mechanical damage make it ideal in order to cover the grounds for the facades.

Conclusion

After the surface of the surface is ready, it is desirable to stock up with a small number of plaster for the future on the event that it is necessary to cut the sections on which defects from physical contact with any objects will appear. Caring for the facade of the house, finished decorative plaster, simple, you just need to periodically wipe it with a dry cloth from dirt and dust. You can also use compressed air and blew the surface. This cleaning will be much more efficient. This is probably all that is worth considering during the operation of decorative facade plaster.

Decorative plaster for facing the facade will give the possibility of the transformation of the appearance of the building. This coating does not have drawbacks as in the coatings of a putty, as it is moisture-resistant, durable and durable finishing material. It is possible to qualitatively to apply facade plaster with their own hands, without even having a lot of facing work. At the same time, the main thing is to clearly observe the order of the process and the technology of forming a decorative plastering layer.

The modern market offers a rather diverse selection of materials for outdoor work. One of the oldest and proven finishes is plaster.

Usually this building mixture consists of a binder component and any filler (gypsum, cement, sand or lime). Depending on the composition allocate different types Facade plasters.

All of them can be used for the finishing coverage of the outdoor walls of the building. For the application of facade plaster requires pre-processing of the facade of the primer, grout and putty.

Benefits of facing plaster

- Watching does not miss steam and moisture, protecting the facade of water. Walls "Breathe", as in hinged facades, due to the conservation of the main principle - increase the moisture permeability of the material from interior Wall To the outer.

- With the help of facade finishing materials, it is not only a smooth, but also embossed facing. A wide range of textures allows you to implement original design ideas.

- It is possible to apply mixtures for external work not only on brick or stone walls, but also on the insulated foam or mineral wool facade.

- Facade plaster allows you to change the color of the house with minimal cost time, forces and financial resources. For comparison: To change the color of the house, lined with siding, you will have to dismantle siding and install a new one.

Types of plastecocks

Manufacturers building materials Offer four types of finishing mixes for the facade:

- mineral;

- acrylic;

- silicate;

- silicone.

These plaster mixes differ not only by the components and properties, but also the features of application.

Mineral Plaster

The basis of this category of the facade mixture is ordinary portland cement, due to which it is the most durable type of coating.

The basis of this category of the facade mixture is ordinary portland cement, due to which it is the most durable type of coating.

It is sold in bags and today is the cheapest. Its importantly, its dignity is the infertility of the appearance of fungi and mold, which is explained by the properties of components included in its composition.

The disadvantage is the small color scheme. But this can be corrected due to silicate paint, which is applied on top of this type of plaster. Silicate paint can be any shade, it deeply penetrates the mineral mixture, strengthening it, reduces moisture permeability.

Facade plaster based on minerals is the simplest in applying.

If after docking there are distinctions, they are easy to paint, and then they are practically invisible. That is why mineral mixtures "Cameshkovaya" and "Coroed" are most popular for finishing facades.

Acrylic plaster

The properties of this finishing material directly depend on the composition of the mixture itself, which is water solution Acrylic, which radically distinguishes it from other types of plaster.

It is quite plastic and resistant to the temperature differences material for outdoor work. The only drawback of acrylic plaster is neutral electrostaticity: the material attracts dirt and dust.

However, due to the low absorption acrylic, the dirt is not absorbed and is easily washed off with water. The best way to care for such a coating is rain or water jet.

Another difficulty associated with the acrylic-based finish is the order of its application. The fact is that Acrylic dries quickly, and if you dreamed halfway, and return to work in time, then a noticeable difference in the joint will be found in the joint zone.

Therefore, apply acrylic mixtures preferably planes and take a break, only when moving to another wall of the facade. With the help of various kernels you can give any color.

Do it better with the help of computer equipment, because with manual staining in different buckets It may turn out a different shade. A acrylic mixture is sold in ready-to-applying form.

As positive moments You can allocate:

- high steaming ability due to which the walls covered with acrylic give excess moisture, and interior not moisturized at the expense of the steam accumulating in them;

- elasticity and resistance to temperature differences;

- low absorption - the accumulated dirt and dust is easily removed by water;

- protected from microorganisms due to biocidal supplements;

- the solution is produced ready for use and already contains all the necessary additives;

- a wide range of decorative options: "Lames", "Coroed" and so on.

Silicate plaster

This type of plaster includes mineral components. The difference lies in the binder element, which is liquid potassium glass.

It is the composition that the high moisturefrost ability and low elasticity is explained, due to which this type of facing coating can be used on difficult surfaces, like a cellular concrete.

The essential plus of silicate plaster for external work is that it does not attract dirt or dust to itself.

So the issue of care for it is removed automatically during operation. Like acrylic, it is produced in the finished use of the form and has an innumerable amount of various shades.

As a minus, the appearance of microcracks on the plastered surface can be called, so the facade plaster based on liquid glass is most suitable for facing the facades from the shell. Often the same composition covers walls from aerated concrete and foam concrete. The reason for choosing consists in high vapor permeability of this material.

Silicone plaster

This is the most expensive kind of facade coating of decorative plasters for outdoor work. After all, due to the silicone basis, the smallest particles of the filler can be added to it.

For example, with the help of quartz sand added to the silicone plaster on the outer walls, you can create a natural stone effect.

As the main advantages of silicone plaster allocate:

- a wide range of color palette (white silicone plaster is easily kernel with painting pigments);

- self-cleaning (silicone compounds are easily cleaned from dust with rain and wind, so the facade will not have to be washed during operation);

- elasticity (silicone plasticity exceeds even acrylic mixtures);

- parry permeability (as a result of this quality, the plastered walls "breathe").

Manufacturers

Selecting decorative plaster, it is necessary to pay attention not only to the properties, composition and view of the mixture itself, but also on the manufacturer's company.

Since the quality and product range often depends on the attitude towards it producers. Since the decorative coating is usually expensive, it is better to give preference to proven trademarks.

Among the manufacturers whose products are distinguished by high quality and invariably enjoy the respect of professionals, such companies can be distinguished as "Knauf", "Bolls", "Ceresit", "Chrysel".

It is these companies that produce universal products whose quality can be fully trusted.

Products of Bolls

The facade plaster "Bolls" is part of the extensive range of the Russian company producing building mixtures. Finishing materials "Bolls" on cement and plaster basis are used for exterior and internal works.

They are perfectly applied to concrete, brick and stone walls. The composition of some "Bolls" plaster is introduced sand for amplification plastic properties Or crumb from marble to strengthen the structure. Decorative mixtures "Bolls" are used to create original patterns on the outer walls. Depending on the composition, they are divided into plaster and cement.

Decorative plaster "Bolls" imitate marble or stone coating, create a radiance effect or wet silk - All this makes it possible to create original facing of any level of complexity.

For external works, the Bollox plaster is made from a mixture of sand, cement and polymer additives. Due to the composition, it hits well with the walls, does not crack from the drops of moisture and temperatures.

Bolls manufactures options for manual or machine application. Also there are frost-resistant varieties of plasters, suitable for applying under conditions of low temperatures.

Products of Knauf

Construction I. decoration Materials "Knauf" has been known to consumers and specialists for a long time. To date, little construction object costs without dry mixtures "Knauf". Initially, this company was known thanks to his gypsum MaterialsAnd today it also produces plaster mixes on a cement basis.

Construction I. decoration Materials "Knauf" has been known to consumers and specialists for a long time. To date, little construction object costs without dry mixtures "Knauf". Initially, this company was known thanks to his gypsum MaterialsAnd today it also produces plaster mixes on a cement basis.

The range of cement compositions "KNAUF" is rather diverse. Thus, the rather popular "Knauf-Unterputz" plaster is used to finish the facades and internal works. A mixture of "KNAUF-ZOKELPUTTS" has increased strength, it is able to withstand high humidity.

The decorative plaster "Knauf-diamond" on a lime-cement basis is suitable for internal and external work. After applying and structuring, it can be painted.

Also, it is also impossible not to mention the plaster with polystyrene granules called "Knauf Grunband". The foam reduces the density of plaster compared to other mixtures and makes it a truly water repellent. It does not give a shrinkage, increases the thermal insulation of the wall and goes well on any surface.

The exterior decoration of buildings should be durable, moisture-resistant. After all, the term of its durability directly depends on the impact of weather conditions. Facade plaster not only beauty should give the outside of the house, but the most important thing is to protect against rains and winds. We offer to discuss the correctness of the choice of plaster for facade works.

Rental of the autotower allows you to perform various facade and installation work. Contact avtovishki.ru.

What should be the facade plaster for outdoor work

Which plaster compositions only do not exist! By the way, when choosing this material it is important to take into account the region and its climatic features.

And so, standing before choosing a material, it is important to take into account the characteristics of the facade plaster:

- It should be moisture-resistant. And this is first.

- Fireproof, i.e. And not flammable.

- Resistant to mechanical effects.

- Sustainable frost.

- Responsible to repairs and recovery.

- Aesthetic.

In our selection of photos of facade plaster, see how different types of material look like.

Types of facade plaster

Thanks to the richest assortment of this product, everyone may choose exactly what he needs. Class material in various ways.

![]()

Depending on the structure

This means that it will be as a result of a ready layer of plaster. He can be:

- Smooth. The surface is smooth or matte, color, the layer is fine enough.

- Special. Creable to perform certain tasks, for example, heat and waterproofing, etc.

- Textured. The structure of such a material is rather pronounced. For example, it can be a croroede. And there are such materials that form a relief surface and simulate it.

- Stone type of plaster, characterized by external species After it was processed using a special tool.

Depending on the type of binder

Any solution consists of binding, special additives and fillers. It is from the binder a lot depends, which affects the properties of the facade plaster, which happens:

- Mineral, based on a mixture of cement or lime with cement. They have excellent properties, they are durable and moisture resistant, vapor permeable, and "work" with a variety of materials. They have an affordable price range, as well as the widest gamma of colors.

- Silicate, in which sodium or potassium glass is used astringent. Here are the most ordinary fillers. And the material itself can be stacked on any surface of their stone or brick. This is a fairly moisture-resistant and vapor-permeable material. But if you have a foam or aerated concrete structure, silicate facade decorative plaster - exactly what you need!

- Acrylic, which are incredibly easily applied and are offered in a wide variety of colors. They are elastic and plastic, and therefore do not crack over time. But they have a significant minus in the fact that they are unstable to UV rays and high temperatures.

- Silicon, which includes all positive qualities of mineral and acrylic type. They are super-resistant to damage to mechanical exposure and will last for a long time.

Depending on the destination

Of course, the stucco must have excellent aesthetic qualities. But in general, it happens:

- Aligning, which is indispensable when there are cracks and rusts, drops in height and other flaws. Such materials are used as a base before applying other finishes.

- Decorative, ensuring the aesthetics of the upper layer.

How is the plaster mix?

If you compare costs, then you need to take into account the purpose of the materials. That is, if we talk about leveling and decorative plaster, for the first consumption, much more always. To them, as a rule, refers cement mix, and a single square meter consumption will be 12-19 kg. But this is provided that with a thickness of 1 cm.

But as for plaster for aesthetic, that is, the textured, it is placed in such a layer, as well as the diameter of the grain. And in this case it will be appropriate to say what expense to form a layer. And from here we obtain that if a layer is 0.8 mm in thickness, it is necessary to 1.5 kg of material with a fine texture for each square meter. Well, if the layer should be a two-million meter, then the average-power plaster is taken, and at least two and a half kilo.

If the material is large-faced, and there is also a stone in it, it is consumed much faster. And so that one square meter is covered with this type of material, you need to take four to five kilograms.

If the material is thin-layer and smooth, then depending on the resulting thickness of 1-3 mm, the flow will be required from 1.2 to 3 kg per square meter.

In general, both materials that are sufficiently resistant to high humidity, frost and UV can be facade plaster. Also, when choosing it is necessary to take into account the price of the material and how much it corresponds to the materials of the surfaces of the buildings.

Winter gardens are glad with aesthetic and functional purpose. That is, that they were beautiful, and also that it was warm enough and light to ...

Modern kitchens, whose photos can be seen on the Internet - today the most functional premises in the house. An important task is to correctly arrange it ...

It is impossible to imagine the office, a room for storing collections, a library or a place of negotiations without a written table and its unchanged companion ...

Beautiful and reliable fence from the source is necessary on any plot. He does not just protect the territory, but also creates a feeling of psychological comfort ...

Modern owners of private houses and household plots see their legitimate possessions not just as a territory for the work of righteous landing and Sat ...

Gabions - Wicker wire containers, which are filled with coarse-grained stone. In fact, these elements do not represent these elements without filler ...

Nowadays, the garden car is a subject of considerable - convenient in use, for a long time serves and stands relatively inexpensively. If you wish, you can make your own ...