Rotband Plaster Description. Instructions for using the mixture for plastering. Technical characteristics of a plaster mix of Rotband Knauf.

An integral part of the repair is plastering. They are performed by various plaster mixtures, which includes a binder and filler. Rotband plaster manufactures Knauf, known for high quality and variety of products. The binders in the plaster is the gypsum, which has proven itself as an excellent material for internal works.

Builders know that using gypsum solutions, you can get a smooth surface. But their minus is the speed of grasp. Therefore, the time for plastering is limited. With this you can fight in two ways:

- breed a small amount of mixture, but it increases the duration of work;

- qualitatively to apply plaster from the first time, but it is available only to professionals.

As a result, some masters refuse to work with plaster mixtures, despite the high quality of the finished surface. In the Plaster Rotband, the manufacturer managed to eliminate the main disadvantages. By introducing various additives, it turned out a little slowing down. The presence of adhesive components has improved the adhesion of the solution to the base. This universal mixture is convenient in operation, after drying it does not crack.

Advantages and disadvantages

- Ecology. Gypsum is obtained by processing natural stone. The decoration of it positively affects the microclimate indoors. Due to the porous structure of the gypsum absorbs moisture from the air when it is excess and gives back in shortness. The gypsum mixture does not secrete harmful substances, does not smell.

- The speed of drying. Already after 3-4 days in fresh plaster can be carried out further work. And after a week there is a complete setting.

- Fire safety. The composition is not lit, increases the level of safety of the room.

- Plastic. She simplifies the work of the plaster, significantly increases productivity.

- It can be combined with insulating materials. Due to this, the sound and thermal insulation of the room is improved, which is especially relevant for panel houses.

The finished coating is distinguished by durability. It does not appear, it does not crack, steadfastly tolerates mechanical impact. In addition, Knauff has been developed by the series building materialswhich are perfectly combined with each other, complement each other. Their sharing allows you to save and even improve the characteristics of individual materials.

The disadvantages of mixtures with plaster are shrinkage that they give in the drying process. This is especially manifested with a large layer thickness. For example, when removing deep cracks or holes, the installation of beacons. Prevent the appearance of this lack allows accurate observance of application technology.

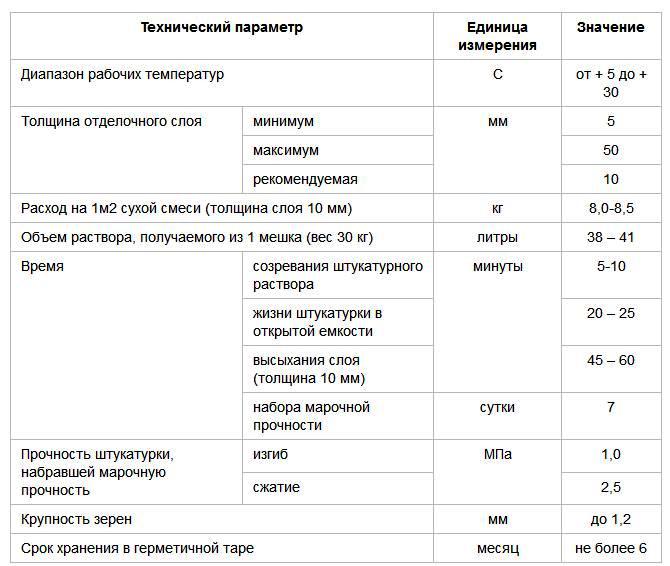

The main characteristics of the mixture

Fans and professional builders are noticed that it is convenient to work with the Rotband plaster, and the result is always distinguished by high quality. Despite the fact that you can find cheaper mixtures from other manufacturers, the popularity of this brand does not fall. There is only a problem with fakes. Therefore, when buying needs to pay attention, whether the holographic sticker is on the package. It will not be superfluous to check the integrity of the bags, the shelf life.

The main indicators characterizing the quality of the plastering mixture include the size of the grain of the filler, the thickness of the layer, the speed of the durability. For Rotband, they make up:

- the maximum grain size is 1.2 mm;

- the layer thickness is minimal - 5 mm, maximum - 50 mm, optimal - 10 mm;

- for a set of regulatory strength, a week is required;

- for the "ripening" of the solution will be needed 10 minutes;

- time to apply a solution to the surface - up to 25 minutes;

- the average drying rate of the layer is 40-60 minutes.

A small explanation: the drying of the mixture depends on the surrounding conditions. The temperature is most affected (the optimal range of 5-25 degrees) and humidity. Drafts, the thickness of the layer, the thickness of the solution - also have their own action.

Features of use

This plaster is suitable for processing any surfaces: from reinforced concrete, gas-concrete, brick, polystyrene foam. The cost of Rotband plaster is higher than similar blends from other manufacturers. It is due to its high quality that guarantees the smoothness of the finished surface. At large drops in the plane of the walls, it is recommended to perform the main part of the work. cement-sandy mixtureAnd Rotband use as a peculiar finish coating, which can then be painted.

Sometimes the use of such a mixture is substantiated on partitions from plasterboard or gypsum fibrous sheets. If the sheets are laid with large drops, irregularities at the junctions, then the putty cannot be eliminated. Plaster from Knauf in this case will be the perfect solution.

Most importantly: Rotband is designed to work in the premises. It does not use it on the outer walls.

Calculation of the number of material

Each owner is interested in economical material expenditure. It is relevant and when performing plastering. Usually it is not about one or two kilograms, but about several bags. Given the fairly high cost of any materials, the purchase of two or three unnecessary bags may not significantly, but still affect the final cost of repair.

Determine the number of plaster is easy. It depends on the thickness of the plaster layer. It does not differ in homogeneity, because the main task of plaster is just the leveling of the surface. It is not necessary to calculate it with 100% accuracy. First, the characteristic points are determined, that is, those in which the deviations from the vertical are most significant. For example, it was determined that at three points of deviations were 1, 4 and 6 cm. These values \u200b\u200bare folded and divided by their number: (1 + 4 + 6) / 3 \u003d 3.6 cm. The resulting number will show the average layer thickness. It should be borne in mind that there is a concept of minimum thickness. It must be more lighthouse thickness (0.6 mm). Therefore, if the deviation is less than one of the indicators, it is increased to the minimum.

Now you need to look at the packaging, what consumption is provided by the manufacturer per unit area. For Rotband, this value is 8.5 kg. The next calculation step: you need to multiply the area of \u200b\u200bthe wall, which is subject to plastering, on the average layer thickness and normative consumption. Consider on the example. If you need to fly the wall with an area of \u200b\u200b22 m 2, then we calculate: 22 * \u200b\u200b3.6 * 8.5 \u003d 673.2 kg.

Complete the calculation by determining the number of bags. Knowing that the weight of one bag is 30 kg, we get 673.2 / 30 \u003d 20.44 pcs. The result is rounded to the whole. Total on plastering 22 m 2 will need 21 bag. It should be noted that the bags are different weighing - 5, 10 and 25 kg. Therefore, the calculation must be adjusted with the container. In addition, experienced masters recommend to take a material with a margin. For this increase the result by 10-15%.

How and how much can the mixture be stored?

Rotband plaster plaster comes in dense paper bags. The mixture consists of small particles like dust. The color of the material is gray, pink, white. It is determined by impurities present in natural gypsum. It is not necessary to worry about color - this does not affect the properties.

Packaging with plaster stored in a dry room. It is best to install bags on wooden pallets, not print. In this form, it can stand up to six months. If the bag is open or accidentally violated the integrity of the packaging, then the mixture is properly pecking into a hermetically closing container. It needs to be used faster.

Application procedure

Before use, the mixture must be dissolved with water, the amount of which is indicated on the package. 30 kg take 18 liters of cold water. If you need to dissolve less than the mixture, the volume of water is recalculated. There should be a homogeneous pasty substance.

The surface for plastering is purified from the residues of the old coating, fat, dust, cleaned irregularities. The wall is necessarily covered with a primer, give it to dry. Install working beacons from galvanized steel. They are not corrosion, so they can not be pulled out and leave in plaster.

The mixture is applied by a spatula, moving upwards. Movements should be applied. Then the solution is smoothed by the H-shaped rule. Somewhere in 20 minutes, when the seizure starts, the trapezoidal rules will be aligned. They are cut off surplus, filled out the excavations.

After a small excerpt (about 15 minutes), a richly moistened surface is watched by a spongy grad, moving circular movements. When small mattness appeared, it is embarrassed by a smooth iron or a wide spatula. The finished coating is suitable for wake-up.

You can get an even smoother surface. To do this, it will be necessary during the day the wall is abundantly moistened, to lure a metal grater. Such processing allows you to do without shtpocking, the wall is prepared for high-quality staining.

Literally, a plaster mixture based on cement was used to create a smooth surface on the ceiling and walls. To date, a variety of gypsum mixtures are used in good demand. One of them became plaster called Rotband.

This product is a universal mixture based on plaster, which includes polymer additives. Application is made indoors with a normal level of humidity for surface finishing on the walls and ceilings.

It is well combined with concrete and brick structures, with bases from cement-chipboard or polystyrene foam. The optimal air temperature during operations should be from + 5 to +25 ºС. Rotband plaster is very economical. It is added two times less than a conventional mixture of sand and cement. The minimum layer is only 5 mm. When contacting with moisture, additional treatment with waterproofing solution is necessary. Keep the Rotband in a dry form by 6 months.

Pros:

- Creation of flatness and smoothness of the surface without subsequent shpalian

- Not subjected to cracking, does not rescue and does not sit down

- Environmental properties

- Low price

- Good combination with porous surfaces

- A small mass that allows you to use the Rotband when plastering ceilings

- Wonderful heat and sound insulation

- The ability to regulate moisture mode indoors by absorption and moisture

Preparatory stage

Before starting work, it is necessary to clean the surface from contamination and the old coating layer. The discovering parts of the metal structures (self-tapping screw, fittings, etc.) should also be cleared and additionally primed, otherwise the rust fits on the plastered surface and spoil it appearance. Concrete walls or ceilings must be processed by primer, which is based on quartz sand. For a porous base, a primer mixture of deep penetration is used.

Then you need to determine the horizontal ceiling. When the heights drop over 3 cm. The ceiling plaster does not make sense. The next step is to carry out the ceiling tooling and reveal the lowest point, transferring it to the level on the walls and angles of the room. The points obtained are marked with a dowel, which clings to the thread from durable material And stretches parallel to the walls and diagonals of the ceiling. This should avoid its sagging. Then there is a placeac. The markup is made in the intervals of 30-40 cm, depending on the size of the rule. Lighthouses are mounted with an indent from the wall by 20-30 cm. When marking and installing beacons, patience should be revealed and responsible. It is better to spend more time and achieve the desired result than then redo. After performing these procedures, you can start kneading the solution.

Preparation of plaster mortar

The instruction says that in finished video The mixture is frozen for 20-30 minutes, and then loses its properties, respectively, becomes unsuitable when working. Therefore, it is better not to prepare a large amount of solution at once. In the instructions for the product you can also find detailed description How to breed Rotband. To do this, you will need a clean capacity of plastic, in which you can easily stir the mixture, giving it a homogeneous thick look. The plastering solution is made in proportion 2: 3 (on 2 parts of the water there should be 3 parts of the mixture). First, the container is filled with water, and only then in a small amount, the mixture is falling asleep. The main thing is not to hurry so as not to "overdo it", but gradually add the required amount of powder as it is stirred.

Important!!!

Use only H-shaped rule !!!

To achieve the desired consistency, it is better to use an electric door with a special nozzle, or a building mixer when stirring. It should not be installed too much, otherwise the solution can occur. To achieve the required degree of readiness of plaster, you need about 10 minutes. Then re-stirring is performed. Whether the plaster reached the condition, you can check in this way: to apply the mixture on the trowel or the spatula, and then turn over. If the solution remains on the instrument, you can start working. According to the instructions, additionally add liquid, any amount of dry powder, or other components is prohibited.

After stirring, the tool should be immediately washed. This is due to the fact that the plaster dries quickly and it will be problematicly removed after a long time.

Using a plastering mixture for finishing the ceiling

When using Rotband, you need to use the spatula. The plaster is applied in small portions, then aligned with the rule of movement to itself and from side to side. The mixture is better used with excess.

After the process is completed, the beacons must be removed. After them, stripes remain, which are placed using the remaining solution. It is better to make several thin layers than one big thickness. Each next layer should be applied only when the previous will dry completely. If this condition is ignored, then the plaster layer will soon be peeling and turning.

When the ceiling is driving, it is necessary to inspect it. If there are skipping or irregularities, it is better to mark them with a pencil for better visibility, and then additionally walked.

At the final stage, the ceiling surface is polished until perfect evenness is achieved. This may require several approaches.

Work with gypsum plaster "Rotband".

The opinion of the builders

(Magazine "Construction Technologies" №1 / 12 - 2001)

Gypsum plaster is an economically advantageous alternative to traditional leveling compositions on cement based In plasterers indoors. Such conclusion came construction workers Svetlana Andreeva and Sergey Koloskov. In this article, they share their experience in the use of the Rotband plaster mix, give recommendations on the technologies of its application.

For the alignment of walls and ceilings indoors, cement and cement-lime plastering formulations are also used and applied. These materials have a number of shortcomings, which include a tendency to cracking, insufficient plasticity, relatively high density and low manufacturability. Plastering mixtures on a plaster basis, which not so long ago appeared on russian market Building materials have not yet been widespread that, as it seems, is explained by their higher cost. Based on the own practical experience of the application of a plaster mixture "Rotband", which manufactures Knauf, we, as the employees of the team of special coatings (BSP) of the construction company "Center Ard", we want to disprove the view of the high cost of materials of this type. The universal dry plaster mixture based on the gypsum with a slight aggregate "Rotband" (white-oscilla packaging) is designed for manual shockting of walls and ceilings indoors, including kitchens and bathrooms. As practice shows, "Rotband" has excellent adhesion to brick, concrete and ceramzite-concrete surfaces, does not shrink, and does not form cracks. For four years of work with this composition, we have never encountered such problems. The material is much more plastic, convenient and easy to work than plastering compounds on a cement basis.

Packaging "Rotband" (30 kg), which currently costs about 180 rubles, allows you to shock at least 3 m2 of the surface with a layer thickness of 10 mm. A bag of plastering mixture on a cement basis (50 kg), which costs about 90 rubles, with the same thickness of the layer, allows you to plaster slightly more than 1.5 m2. This implies that by its effectiveness, the use of the "Rotband" plaster is not more expensive than cement compositions. It should be taken into account that the surface plastered by the composition on a cement basis requires, as a rule, the subsequent application of three - four layers of putty (approximately 300 rubles per 25 kg), while for the "Rotband" is quite enough. In addition, plaster on a plaster basis is easier, as it has reduced density. This makes it possible to reduce the load on overlapping and reduce transportation costs, which is essential for large amounts of work. "Rotband" dries faster cement mixtures (approximately one and a half times), shortening, thus, the duration of work. The use of gypsum plaster makes it possible to significantly increase productivity. With the average thickness of the layer to 20 mm, one worker per shift is able to shock at least 15-20 m2 of the straight vertical surface (including the preparation of the solution). And with certain skills, and more. In case of use plastering On a cement basis, even an experienced plaster for a similar time is difficult to perform work on an area of \u200b\u200bmore than 10 m2.

Sequence of work.

The technology that our brigade applies when aligning walls and ceilings, we use for several years. So far, no complaints of the quality of customers have been received. This is exactly what allows you to recommend working in the specified sequence and other.

Preparation of the foundation.

This stage of work is extremely important, since any deviations from the technology or the unscrupulousness of the performers can lead to the smallest consequences, up to peeling the leveling layer from the surface of the base.

Works should be carried out under normal conditions (18-23 s, the humidity is about 60%), and the basis for which the leveling layer is applied should be clean, dry and not promoted. On the smooth concrete surface it is advisable to make shallow notches. First of all, this refers to horizontal surfaces (ceilings). The base must be carefully cleansed from dirt, dust, paint residues or lime blots. and primed deep penetrating primer. We use the "Cerezit St-17" primer for this purpose (Henkel). After drying, the primer can be started to install the guides.

Installation of beacon profiles serving guides for the rule and defining the thickness of the leveling layer is a very responsible operation from which the final result largely depends. There are light air profiles from galvanized steel with building height (Rib thickness) 6 and 10 mm. The latter have greater rigidity, and therefore they are easier to mount them. But the consumption of the leveling mixture increases by approximately 1.5 times. By purchasing profiles, you need to ensure that they are smooth (not bent). It should be transported very carefully, not allowing strain.

The installation of lighthouse profiles is the work of the painstaking, requiring much attention, and not tolerant fuss (photo 1). Even the experienced worker mounts for a shift of only 25-30 pillis profile. On the walls, the main task is to set profiles strictly vertically, so the use of the construction level should be considered mandatory. The best result is achieved when using a long level, if possible, is not shorter than the length of the beacons. The installation of each segment of the beacon guide must be completed before setting the "Rotband" solution, therefore it is impractical to impose a large amount of solution.

On the opposite side of the profile, pre-cropped at the height of the room, applied to the "Rotband" solution, the profile leans to the wall and, as it were, "carries out" to the base of the reflective movement of the level (with continuous control of the verticality) on the working curor of the profile (photo 2). Level must be pressed over the entire length of the profile. Local clearances between the beacon guide and the level are eliminated by the removal of the plastic solution "Rotband" to the interval between  profile and wall. In extreme cases, you can apply wooden clins that are necessarily removed after the solution hardens. It is more difficult to eliminate the local bulge of the deformed profile, but after some training it is possible. The use of hammer when performing this operation is completely unacceptable. If the surface of the wall is very uneven, the application of the "Rotband" solution only on the beacon profile may not be enough. In this case, the solution is applied (in the form of a vertical strip of 30-40 mm wide) also on the base. The required thickness of the leveling layer for this surface is determined after the plane of the plane using a stretched cord.

profile and wall. In extreme cases, you can apply wooden clins that are necessarily removed after the solution hardens. It is more difficult to eliminate the local bulge of the deformed profile, but after some training it is possible. The use of hammer when performing this operation is completely unacceptable. If the surface of the wall is very uneven, the application of the "Rotband" solution only on the beacon profile may not be enough. In this case, the solution is applied (in the form of a vertical strip of 30-40 mm wide) also on the base. The required thickness of the leveling layer for this surface is determined after the plane of the plane using a stretched cord.

The distance between the beacon guides depends on the length of the rule that will be used to pull the solution. If the width of the leveling surface allows, we recommend using a rule with a length of 2.0 m (a rule of 3.0 m long has insufficient rigidity). In this case, the guides are exhibited at a distance of 1.7-1.8 m from each other. With a width of a wall to 4.0 m, there are enough two guides installed symmetrically relative to the middle of the wall. First, the space between the guides, and, then, after setting the solution, the side sections of the wall. At the same time, the solidification of the "Rotband" surface is used for the rule between the beacons. The described technology allows you to set beacon guides from the size of the gap between the level and the working surface of the profile not exceeding 0.5 mm, which fully meets the requirements of standards.

For the preparation of the Rotband solution, we use a plastic container (bucket) of 15 liters (if one person works). It does not make sense to notice, since the solution is relatively rapidly collapsing and is suitable for operation only for 20-30 minutes. In turn, the use of less capacity contains dramatically reduces  labor productivity.

labor productivity.

Capacity for about one third is filled with clean, cold water (Warm water accelerates the collapse time), after which the dry mixture of "Rotband" is added to it and is thoroughly mixed to produce a homogeneous lump-free mass, close by consistency to very thick sour cream. For stirring, an electrode is used with a power of at least 800 W with a stirring with a diameter of at least 100 mm (photo 3). The solution is exposed for 5-8 minutes to increase elasticity and is re-stirred.

The solution is applied to the leveling surface (pre-primed) removal of a wide spatula in the bottom direction (photo 4). It is also possible to damage the embroider method (if there are appropriate skills). In one method, the solution is applied to a portion from the guide to the guide and 70-100 cm, after which it is embarrassed. To perform this operation, it is recommended to use an aluminum rule with a bevelled edge, the use of which provides  excellent results. The rule is tightly pressed to the beading guides and move downward, removing the excess leveling solution (photo 4). These excess are removed from the surface of the ruler with a spatula and return to the container with a solution for reuse. Usually,

excellent results. The rule is tightly pressed to the beading guides and move downward, removing the excess leveling solution (photo 4). These excess are removed from the surface of the ruler with a spatula and return to the container with a solution for reuse. Usually,  in one pass, a satisfactory result cannot be obtained. Surface defects (sinks, warehouses IT.) are filled with a solution using a spatula (with some excess) (photo 5), and the stretch operation is repeated (photo 6). After that, the solution is applied to the next section (photo 7) and processed by the rule, as described above. It should be borne in mind that the plastic solution "Rotband" slightly floats under its own weight, therefore, aligning the plot behind the site, it is necessary

in one pass, a satisfactory result cannot be obtained. Surface defects (sinks, warehouses IT.) are filled with a solution using a spatula (with some excess) (photo 5), and the stretch operation is repeated (photo 6). After that, the solution is applied to the next section (photo 7) and processed by the rule, as described above. It should be borne in mind that the plastic solution "Rotband" slightly floats under its own weight, therefore, aligning the plot behind the site, it is necessary  periodically stretch the finished surface from the nose itself, removing the resulting excess material. If, for some reasons, it is required to plastering the inwards of the layer, the recommendations shown on the "Rotband" package should be followed. We did not come across such a necessity, since a layer of up to 70 mm (verified) can be applied in one pass.

periodically stretch the finished surface from the nose itself, removing the resulting excess material. If, for some reasons, it is required to plastering the inwards of the layer, the recommendations shown on the "Rotband" package should be followed. We did not come across such a necessity, since a layer of up to 70 mm (verified) can be applied in one pass.

If the base is designed for cladding ceramic tiles, no additional operations (Apart from the priming of dried plaster) is not required. Surfaces under the pasting wallpaper or color must be burned.

The burning of the plaster layer can be started after 40-50 minutes after the completion of the pulling process. From the point of view of technology, the discharge does not differ from the shovels. A small amount of the "Rotband" mixture is divorced to the consistency of the liquid sour cream, it is applied to the not yet dried plaster and "is presented" with a rectangular ironing stainless steel (photo 8). If necessary, the operation can be repeated multiple times (after setting each newly applied layer). Score  allows you to completely eliminate the shells, jackets and other defects, inevitably arising when stretching plaster. As a result of this simple operation, the surface is somewhat hardening, becomes smooth and glossy.

allows you to completely eliminate the shells, jackets and other defects, inevitably arising when stretching plaster. As a result of this simple operation, the surface is somewhat hardening, becomes smooth and glossy.

Drying time (not to be confused with the time of setting!) Rotband plastering plaster depends on the temperature and humidity indoors. Under normal conditions and the thickness of the plastering layer to 20 mm it is about 7 days. The process is accompanied by a change in the color of the surface (from the dark-gray to light gray), which, unfortunately, is not an indicator of complete drying. Experience shows that in warm, but rainy weather, plaster can dry 2-3 weeks. In rooms with insufficient ventilation (pantry, bathrooms, etc.) the process lasts longer than in rooms with normal air exchange.

Additional operations.

A carefully stressed surface after drying is quite suitable for watering dark tones. The light wallpaper (especially thin) is undesirable to stick directly on the "Rotband", since the base can be shifted through the wallpaper. In this case, it is recommended to apply two layers of the putty "Vetonit KR" or "Vetonit LR" (Optiroc). To protect external corners from damage, inevitably arising during the operation of the room, we strongly recommend the use of a special corner profile from galvanized tin. We do not use an aluminum alloy profile because, as practice shows, it has obviously insufficient rigidity. The corner is also fastened with the help of the "Rod Band" solution. In the process of installation, the profile verticality is controlled (in two, mutually perpendicular, planes) long (at least 2.5 m) level. The corner profile is mounted before the start of the shtlock process. Preparation of the surface under the color or finishing materials of the type of Venetian plaster requires, in our opinion, the mandatory pasteing fiberglass plaster grid. No matter how high-quality plaster material, it is impossible to completely eliminate the likelihood of cracks during the operation of the building. First of all, this belongs to the ceilings, since overlaps often have insufficient rigidity. Even minor (hair) cracks very spoil the kind of painted surfaces, and in severe cases, cracks can even break the wallpaper. The plaster grid protects (within reasonable limits) from cracking outwards. For this reason, we strongly recommend using it and on surfaces intended for pasting. In our practice there were several cases when the customer at the last moment decided to replace wallpaper on another type of finish. If the surface is prepared according to the "full program", such changes are painlessly both for the customer and performers.

Fiberglass plaster mesh with a cell 2x2 mm, for example, the production of TPO "Artel", passes on the basis by putting "Vetonit KR" or "Vetonit LR", which is applied to the surface with a conventional spatula. The grid is superimposed on a layer of putty and thoroughly grips stainless steel spatula to completely remove bubbles, folds and irregularities. In this case, the excess putty is squeezed through the grid cells and are removed by the same spatula. The grid panels are glued with an adhesive of 70-100 mm. The grid necessarily starts on the shelf of an outer corner profile approximately 15 mm, because, otherwise, the likelihood of the formation of a vertical crack along the mesh and profile boundary is great. Recently, we practice sticking the mesh on PVA glue, diluted with water for approximately one quarter, which is applied to the surface with a latch with a long pile. The grid is carved by a spatula, excess glue are removed, and the surface is rolled by a semi-dry roller again. The use of PVA makes it possible to significantly increase labor productivity and reduce costs for consumables. At the time of writing the article, there was no case of peeling of the grid on the base, which allows us to talk about a sufficiently high reliability of this technology for fastening the plaster grid. After drying, the grid is sweeping with two layers of "Vetonit KR" or "Vetonit LR", slightly processed over the entire surface of the fine-grained abrasive material ("skin") and, after removal of dust, is ground. As a primer under the color, Venetian plaster and other materials, we have already mentioned the composition of Cerezit St-17. Under the pasting, wallpaper is quite enough to treat a sliced \u200b\u200bwall with a solution of the wallpaper glue. The surface prepared in this way is completely suitable for finishing finishing by any decorative coatings.

Rotband plaster plaster

[Click on the photo

for increase ]

The dry plastering gypsum mixture of the Rotband is made on the basis of high-quality gypsum with polymer additives that improve the adhesion of surfaces to the base.

Rotband plaster plaster It has a fine-grained homogeneous structure and supplied different shades: from gray to pink, which does not affect the properties of the mixture. It is used to work with any surfaces: concrete, cement, brick, polystyrene foam, chipboard, CSP. Stunned smooth ceiling and wall surfaces in rooms with normal humidity, in kitchens, bathrooms.

The uniqueness of the Rotband plaster plaster lies in the fact that high-quality gypsum in its composition has low sound and thermal conductivity, and also has the ability to absorb moisture, and with high humidity to give it, creating comfort in the room.

READ ALSO: VOLMA - Gypsum plaster: smooth and environmentally friendly + video The volat is dry plaster based on high-quality gypsum with the addition of polymer and mineral components, which provide high adhesion and excellent moisture absorption.

Technology application

First, work is carried out on the preparation of the base, which is purified from dust, dirt, oil, layers of old plaster and is treated with a deep-rotating primer. Then a 30-kilogram bag of plaster poured into a pelvis with 18 liters warm water and mixed with a plaster mixer. If work is conducted by one person, then it is necessary to proportionally reduce the volume of the mixture and water, since the solution is quite quickly seized. The solution is applied to the prepared surface with a wide spatula from the bottom up. After applying about 1 sq. M surfaces, the mixture is pulled out with a spatula. The mixed mixture is used to float down, so it is necessary to periodically stretch it from below. After 15-20 minutes after applying the surface, the grater is loaded. During the day, the surface can be mixed again and ride. To do this, you need to make a mixture to the consistency of sour cream and ironing the smooth. The burning eliminates the sinks, jackets, drips and defects that occur during floating. As a result, it turns out an absolutely smooth and smooth surface. If the surface is prepared by tiles, then the re-burning is not required.

Drying time depends on the humidity of the room. Stucco can dry at a layer of 20 mm from 7 days to three weeks. When dried, it changes the color to light gray. But still light wallpaper on the Rotband glue is not recommended, because they can shine.

Advantages of rotband plaster plaster

Rotband Plaster Plaster provides perfectly even and main surface. Due to elasticity, it does not crack. Consumption is 2 times less cement-sand mixtures, easier application on the surface. Plaster universal - spit, plaster, used for repair, restoration works. Well keeps moisture, regulates the hygrorement indoors. Environmentally friendly building material. The rotband plaster mixture is made on the basis of high-quality plaster with polymer additives that improve the adhesion of surfaces to the base.

The basic requirements for building mixtures for leveling ceilings and walls are plasticity, no cracks during shrinkage and high drying speed. There are currently many such mixtures, but the Rotband plastering plaster was specially popular - the technical characteristics of this material comply with the highest requirements.

The main production of Rotband plaster is located in Germany, but the subsidiaries are also in our country. They produce this and many others construction mixes Under the brand Knauff for more than 20 years.

Compared to other similar materials of domestic production, it is somewhat more expensive: the price per bag weighing 30 kg is about 400 rubles. But additional spending are fully justified, as the Rotband is recognized as one of the most durable, high-quality and convenient plasters suitable for alignment of walls and ceilings.

Specifications

Before buying and using any material, it is necessary to obtain complete information about its properties and characteristics. This will help not make a mistake with the choice, decide on necessary quantity, calculate the time that will be needed to perform work with your own hands.

| Specifications | Units. change | Value |

| Minimum layer thickness | mM. | 5 |

| Recommended layer thickness | mM. | 10 |

| Maximum layer thickness | mM. | 50 |

| Temperature at which application can be performed | 0 S. | +5+30 |

| The volume of the solution obtained from the stucco bag Knauf Rotband 30 kg | l. | 40 |

| Dry mixture consumption with recommended layer thickness | kg / m 2 | 8,5 |

| Ripening time solution | min. | 10 |

| The time of the viability of the solution in the open container | min. | 20-30 |

| Drying time layer 10 mm | min. | 45-60 |

| The time required for a complete durability | day | 7 |

| Density of dry mixes | kg / m 3 | 730 |

| Density of finished dry plaster | kg / m 3 | 950 |

| Grain | mM. | less than 1.2. |

| Dry mixture storage | mes | Until 6 |

| Color | whiterozySurian | |

| The strength of the finished coating for compression | MPa | more than 2.5 |

| The strength of the finished coating for bending | MPa | more than 1.0 |

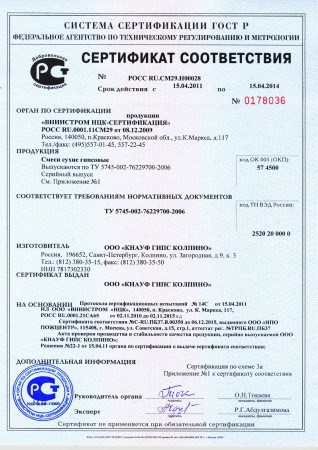

Council. Be sure to require the seller a certificate for the Rotband plaster. Only if available, you can count on the compliance of the material to the stated characteristics.

Benefits

A person injecting technical characteristics will not say almost nothing. He needs a detailed description of the material with all the advantages and disadvantages, as well as instructions for use.

So let's see what I like so much in this plaster and finishing specialists, and customers:

- The ability to align the drops of a depth of up to 5 cm in one pass;

- Even such a thick layer during drying does not give shrinking cracks;

- The surface is obtained sufficiently smooth that does not need. It can be glued to it;

- Uniform drying without harsh moisture loss even high temperatures and on porous bases;

- Increased compared to other gypsum mixtures time of grasp of the working solution;

- Excellent adhesion to any reasons due to the introduction into a mixture of polymer additives, which allows the use of the composition to level the ceilings;

- Small Rotband consumption - cement or cement-sand plaster spent twice as less economical;

- Parry permeability - plaster mixed walls can be "breathing", maintaining a comfortable microclimate in the room;

- Environmentally friendly - The composition of the Rotband plaster does not include substances harmful to human health.

Let's summarize. The material described is great for leveling surfaces indoors. Compared to cement plasters, it has less weight, therefore it has a smaller load on the walls and ceilings, it requires less transportation costs.

For alignment, it is often enough to apply only one layer. The solution is stacked and distributed easily, creating a smooth surface that does not require shtcloth. Special attention deserves the economy of plaster: one 30-kilogram bag is enough for finishing 3.5 sq.m. Surface layer 10 mm.

It is possible to apply a thicker layer without the risk of cracking after drying the solution, which makes it possible to eliminate serious defects and deviations from the level. If they are greater than the maximum allowable layer thickness, then the alignment is performed in several layers.

For reference. Due to the high plasticity and elasticity of the mixture, it is easy to operate with it. For one working shift, one person can fly to 20 sq.m. Taking into account the time spent on preparatory work.

Terms of application

It is unlikely that it is once again in detail to describe all the plastering technology, you can explore it by reading other materials of the site. But on some points it is worth focusing.

Preparation for work

In addition to such standard measures, as cleaning the surface from crumbling sites, dirt, dust and fatty spots, it is recommended to be primed up before using the rothband, using the soil of the same brand.

So:

- The bases with high absorbent ability are processed by primer Knauf Stuc Primer (see);

- Dense, smooth and low-purifying bases (for example, concrete), covered with the primer Knauf Betokontakt with the addition of crushed quartz sand, which gives surface roughness.

It is important! In no case cannot be neglected by this stage in the plaster of the ceilings, if you want the coating to hold on them reliably.

If the base is near Rotband - cement plasterthen it should be dry: you can start alignment not earlier than four weeks after it is applied. The fact is that the cement during drying decreases in the amount is much stronger than the gypsum, and if not allowed to grasp it, then cracks will appear on plaster coverage.

The main work is projected only after drying the primer.

Kneading solution

Since the viability of the finished solution is no more than half an hour, they prepare it in such quantities that will be spent completely during this time. Consider your productivity and number of employees.

If you are plastering alone, knead no more than 10 kg of the mixture. That is, if you have the plaster Knauf Rotband 30kg, then it will be a third bag. The proportions of water and powder are shown on the package.

Council. Use only cold water. What she is warmer, the faster it will harden the mixture.

To knead, you will need a drill with a special mixing nozzle. After the first mixing, the solution is allowed to stand a couple of minutes, after which they are stirred once again and immediately begin to apply.

Application

Rotband plaster is performed in the usual way. The solution is thrown onto the wall and spacked with a wide spatula. Either, if the plaster on beacons, long rule.

First of all, they are protected by external angles, establishing special perforated galvanized iron profiles on them. They are attached to the same solution that walls will be placed. The vertical position of profiles in the installation process is constantly monitored by a long construction level.

The thickness of the layer of plaster is limited to 40-50 mm. If a thicker layer is needed, the solution is applied in two or three receptions, without waiting for the complete drying of the previous layer.

- If you want to get a textured surface under painting, you have such an opportunity. Rotband is performed on a fresh layer, the texture is attached to the help of stamps, rigid brushes, decorative rollers and other devices.

Note. In this case, in the manufacture of a solution, it is necessary to add 100 g of PVA glue to each liter of water. The glue is introduced into a single mixture once before re-mixing.

- If a smooth surface is needed under the wallpaper, the surface after drying is first corrected with a spatula, which cut the tubercles and drips, then polished with a grater.

- Under the subsequent painting, the attached base is necessarily covered with finishing putty.

- Under or an artificial stone, the surface does not need to be grinding or put off.

It is possible to start with the putty, wallpaper sticker, staining and other types of finish finish only after the plaster dries. Depending on the thickness of the layer, it may die from 3 to 15 days.

Conclusion

Very often, the desire to save leads to even more expenses, when poor-quality coverage begins to flap from the walls along with decorative coating. With Rotband, this will not happen if all technological requirements will be observed in the process of working with it.

Check out the video in this article and see for yourself how easy it is to work with this material and what kind of quality it turns out the result.