Glue for laying ceramic tiles. Choose tile glue. Arguments: What glue is better for floor tiles.

Facing the walls and floor with a ceramic, clinker, tiled or ceramic tiles is one of the most complex finishing processes. Tile installation requires an artist not only accuracy and professionalism, but also the knowledge of the features of the use of different building materialsFirst of all - tiled glue.

Basic tile glue requirements

The familiar concrete sand mixture for tile laying was almost completely replaced by special adhesive compositions. This is due to the undeniable advantages of glue for ceramic tile:

- The concrete sand mix is \u200b\u200bnot able to ensure the durability and reliability of masonry.

- When performing large-scale construction, the necessary proportions of the preparation of the working solution are not always observed.

- Working with tiled glue is easier than with a concrete sandy mixture.

- The adhesive consumption is less, since even a small layer provide a sufficient coupling of materials.

- A large range of glue allows you to choose the optimal composition based on the type of tile, base and operating conditions of the finish.

Before deciding which glue for tile to choose, you need to know the basic requirements put forward in front of high-quality adhesive composition:

- High adhesive properties. The glue must securely hold the plates different by weight. It is desirable that the composition quickly grasped and sticking to the surfaces.

- The plasticity of glue is responsible for ensuring that the composition does not grow on the tile and the base.

- When choosing glue for outdoor tile It is necessary to pay attention to the compositions with elevated spreadability. It is necessary so that the mixture filled all existing emptiness.

- The rate of water recoil is frozen the solution. It is important that the glue is not too quickly frozen, and it was possible to adjust the location of the plates.

Classification of tiled adhesives in composition

Depending on the type of component components, tile glue is made to divide into such groups:

- adhesions cement based;

- epoxy adhesives;

- dispersion formulations;

- polyurethane adhesives.

"Cement" Adhesives have an affordable cost, so enjoy popular among consumers. The glue includes cement, sand and polymer additives. All listed ingredients give the adhesive composition of the necessary qualities: water resistance, plasticity, adhesion plates with the base of the cladding and the presence of a deformation range. Before use, the solution must be dissolved with water. The glue has a short period of setting, so it is necessary to work with it fast enough. Elastic characteristics of the composition depend on the type and number of polymer additives.

Epoxy adhesiverecommended for use for working with facing materials having a smooth base. This is a multicomponent composition - a set includes epoxy resin in a liquid form and a catalyst. Before use, you need to mix both elements by following the instructions on the package. Epoxy glue has the following advantages:

- provides a reliable "coupling" of materials;

- waterproof - glue is suitable for use in wet rooms;

- frost resistance;

- the epoxy mixture does not shrink;

- the glue turns into a monolithic polymer and cracks are not formed on its surface;

- porous materials when gluing are not stained.

To the number of flaws of glue can be attributed:

- higher cost compared to the "cement" composition;

- when working it is important to strictly observe the proportions for mixing the adhesive components;

- in the cold, the components of glue can crystallize.

Dispersion glue Does not contain solvents, the type of composition is pasty. Dispersion glue for tiles - reinforced, as it has elevated hitch properties. This quality allows you to use the composition for processing non-standard materials: sheets of plasterboard, plastic, wooden and metal surfaces, slippery walls. The purchased glue is ready for use and does not need additional preparation.

The dispersion composition is the optimal glue for the outer tile, which can withstand the severity of the volumetric elements. Minus such adhesion is a high cost. However, its consumption is almost two times less than other adhesive blends.

Polyurethane glue For tiles may be single or two-component. The composition has such characteristics:

- resistance to chemical compounds;

- lack of moisture absorption;

- withstands temperature fluctuations in the range from -55 ° C to + 125 ° C;

- provides additional insulation of the base;

- lack of specific smell;

- reliable tile hitch with base surface.

Polyurethane compositions are classified according to the method of application. Some formulations are better suitable for the arrangement of "warm" floors, while others - for the processing of bases exposed to periodic deformation / vibration.

Varieties of adhesive mixtures by method of use

According to the international classification, the glue for laying tiles is divided into 5 main categories:

In addition to the listed adhesives, there are specialized formulations: heat-resistant for facing of furnaces and fireplaces, frost-resistant for external work in harsh climatic conditions

Dry and ready-made mixes: advantages and disadvantages

To buy glue for the tile can be in the finished form (in buckets) or in the form of a dry composition (in bags) for cooking. What is their difference and what mixture to choose?

At the heart of dry mixtures lies cement. The main advantage of such adhesive is that it can be laid on non-aligned walls having various crumism differences. Glue, besides the main purpose, performs the role of the leveling layer.

The essential plus of dry glue is an affordable cost. With the same quantity of the cooked mixture and bought glue, the price of the first option will be an order of magnitude lower.

For finished mixtures (on a polyurethane basis) a smooth base is required. However, such a composition is more durable and reliable than cement-based glue.

Tiled glue selection criteria

In order to not be mistaken with the choice of glue, it is necessary to compare the characteristics of the adhesive composition, the type of facing surface and the conditions of operation of the finish. We present the main selection criteria for tiled glue:

Overview of tile glue manufacturers: characteristics and prices

The same types of glue from different manufacturers may differ in composition. Buying tile glue, it is desirable to choose products of popular, proven companies. The following mixtures of tile laying have proven in the construction market.

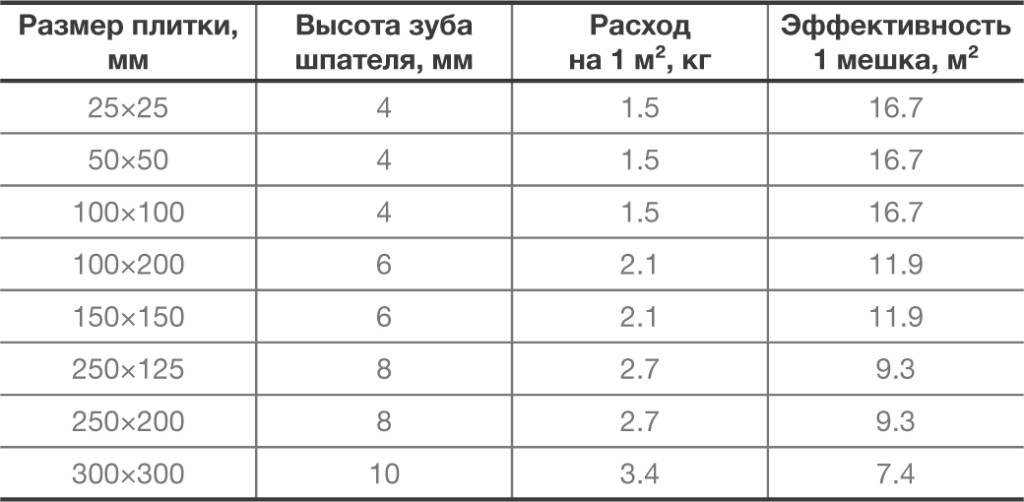

Ceresit CM-11 - dry cement mixture with additives of polymers and mineral fillers that increase adhesion. The main purpose is the installation of a faience facing and ceramic tiles with dimensions from 50x50 mm to 400x400 mm on non-deformed bases. The cost of one bag (25 kg) is about 200 rubles. Specifications:

- glue consumption - 2-7 kg / m2;

- the base temperature is not less than + 5 ° C;

- drying time - 1 day;

- the shelf life of the prepared mixture is 60 minutes.

Ceresit CM-17 - Elastic tiled glue used for cladding different species surfaces outside and inside buildings. Application area:

- facing tanks and pools;

- decoration of furnaces and fireplaces, provided that their surface is not heated above 80 ° C;

- cladding of glazed surfaces, including without removal of old coating;

- laying tiles on the terrace, balcony, operated roof, base, etc.;

- arrangement of heated floors.

Ceresit CM-17 is no cheap glue for tile (price for 25 kg - about 800 rubles).

Moment - Budget option for laying ceramic tiles. It is designed for cladding with tiles with dimensions of no more than 30x30 mm and water absorption above 3%. Suitable for cement-lime, concrete, brick and cement-sand bases.

Important! If the glue is used for facade finish, then it is necessary to add a special emulsion

Characteristics of glue moment:

- the base temperature is from + 5 ° C to + 30 ° C;

- the temperature in the room during work is about 20 ° C, humidity - no more than 60%;

- adjustment time - 10 minutes;

- the cost of glue - 125 rubles / 25 kg.

Litokol Litoflex K80 - Elastic high-adhesive glue with an increased period of the open layer for fixing porcelain stoneware. The base is dry adhesive mix - Portland cement, inert fillers and organic additives. This is a universal glue, designed for outer / inner, wall-mounted / floor facing. Suitable for fixing porcelain stoneware, ceramic tiles, natural stone and clinker for stable and prone deformations / vibrations of the base.

The tile glue consumption depends on the state of the surface and is 2.5-5 kg \u200b\u200b/ m2, the cost of the dry mixture (25 kg) is 1700 rubles.

Keralastic (Italy) - two-component polyurethane glue for styling stone and ceramic tiles. The composition has a sliding resistance and has a wide scope of application:

- installation of ceramic tiles, mosaic and stone plates over plastecrops, screeds, metal, PVC, wood, reinforced polyester, higgoton, etc.; Works are carried out both outside and indoors;

- laying plates on balconies, terraces, open flat roofs;

- fixation of roofing marble, slate and composite materials subject to swelling under the influence of moisture, shifts, deformations and vibrations.

Keralastic is great for facing vertical surfaces and is able to hold a large slab. The cost of glue is 2800-3000 rubles / 5kg.

Lux Plus. - Dry glue composition of increased strength. The glue is used in the execution of finishing works inside and outside the floor facing, walls different materials: artificial / natural stone, mosaic, marble, transparent or thin tiles. The main purpose is laying the tiles in the bathroom, saunas, baths and pools. The composition is recommended for use in places with high loads on the separation. The price of glue (25 kg) is about 260-300 rubles.

Tire Adhesion Tips: Video

How to apply glue for tile in the bathroom, what to choose - this should be known in advance, better before performing work. Purchase of an unknown brand of glue can lead to unsuccessful laying of facing material. You can not apply a certain adhesive composition on the surface, if it is not suitable for processing them. By the way, water is used to remove fresh product residues, and for dried together with tiles - chisel and hammer, that is, a mechanical method.

What is this article

Tying glue types

There is a normal, reinforced and heat-resistant version of the adhesive composition for porcelain stoneware (tile). A certain kind of product is selected depending on the surface planned to be covered with tiles.

When buying glue for ceramic tile, it is necessary to get acquainted with the instructions for its use, since this product is suitable in specific application conditions. The adhesive agent made of cement is the most budget version of the glue for laying tiles in the bathroom.

The dry product consists of sand and cement, it adds a certain amount of polymer additives that give the mixture additional elasticity and improving adhesive qualities. Cools for tiles in the bathroom are sold in bags of 25 kg. The cost of one package is 250-300 rubles. Such price is medium, but there are options and cheaper, and more expensive.

To glue a tile in the bathroom, it is recommended to choose the adhesive composition of the following marks: Knauf, Ceresit and Unis. These types of materials can be bought at an affordable price, and the quality of the product itself will be appropriate. In most cases, the universal adhesive composition of Ceresit CM 11, which is very popular with professional tiles.

There are 3 types of compositions that allow you to lay a tile in the bathroom:

- One-component.

- Two-component.

- Cement.

One-component (dispersion) glue is a material that is ready for use. It is sold in plastic buckets. This allows you to save time for its breeding. The composition has high adhesive properties, allowing to glue the tile on the vertical surfaces. Works are carried out without pre-training Basis.

The best embodiment of the dispersion material is the facing of the surface of the surfaces of the GLC, plastic, wood, or metal. One-component adhesive composition is better not to use when cladding the tile base from concrete. The material has a high cost, but it is compensated by the economical expenditure of glue.

Two-component (epoxy or polyurethane) glue is a product that includes a hardener and an activator. The finished adhesive composition can be obtained by mixing these components to the occurrence of a chemical reaction, as a result of which the mixture turns into glue. It should be used until it dries. Full culmination of glue occurs after 20 minutes.

Characteristics of the species of tiled glue

Different types of adhesives for laying tiles in the bathroom differ in their properties. To choose the best of them, you need to know the basic properties of the tiled glue, which are provided by GOST:

- The density denoting the weight of the mixture is measured in g / m².

- Plasticity providing high-quality application.

- Adhesion showing the quality of the adhesive hitch with different surfaces.

- Viscosity indicating the number of gluing components.

- Water resistance determining the degree of resistance of the composition to moisture.

- Shrinkage, detecting the degree of surface deformation under the influence of various factors.

- Strength characterizing the level of maximum load perceived by the surface.

- Drying speed indicating the shelf life of the mixture.

- Consumption depending on the level of density.

To determine the last indicator of the list given, it is necessary to divide the weight of the adhesive mixture to 1 m² of the area of \u200b\u200bthe bathroom. To glue outdoor tiles in the bathroom, on average, it is from an 8 kg of a mixture to 1 m² of room area.

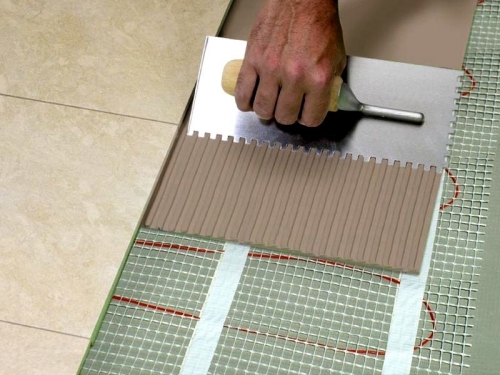

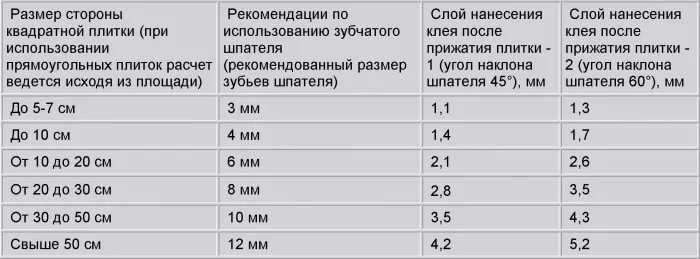

Determine the adhesive consumption of the adhesive mixture depending on the size of the tile will allow the table. All data in it are compatible with ideal conditions under which the floor in the bathroom room is thoroughly aligned. To ensure such a consumption of glue, requires professional experience. Beginners' glue consumption often increases by 50%.

Considering, before choosing glue for tile in the bathroom, it is relatively small cost, you can purchase a certain amount of packages with a margin. It can be 15-20% of the greatest consumption.

Dry mix of Ceresit CM 11 and 17

Choosing, what makeup it is better to glue a tile in the bathroom, you should pay attention to the product from the manufacturer Cerezit. The brand of this composition on which people pay attention most often is cm 11. This universal mixture used in order to facing the house inside and outside, which is ideal for laying a porcelain stoneware and ceramic tiles in the bathroom. Product moisture and frostable.

For the maximum possible coupling, the ceramic tile should have an indicator of water absorption more than 3%. The corresponding size of this material is usually 40x40 cm. The composition is suitable for laying the tiles in low-load rooms on the base. Before masonry with the help of this adhesive composition, it is not recommended to soak tiles.

When choosing glue to laying tiles in the bathroom, you should familiarize yourself in advance with the installation instructions for the coating of porcelain book or tile. The tile is placed on the adhesive composition and pressed no later than 25 minutes after it is applied. During this time interval, the position of the tile will succumb to the adjustment, and the glue should be pulled to the hands. The adhesion contact of the adhesive composition should have an area that makes up at least 65% on the walls and no more than 80% on the floor surface.

Ceresit CM 17 is a dry mixture with elasticity and adhesion. This allows it to be used not only in the process of mounting the tile coating in the bathroom, but also to lay a deforming base. Production of a dry mixture CM 17 is carried out in normal form and with low dust formation. Product supply is carried out using special packaging. These are multi-layered paper bags of 5 and 25 kg. The average price for them is 560 rubles.

The stacked porcelain sticks should not be glued. The width of the seams can be set depending on the size of the tile material and the conditions for its use. When filling out the seams of cladding, you can use the Ceresit Ceres of the CE group not earlier than 24 hours after laying the tile. The air temperature and base should be + 5-30 ° C. Relative air humidity may be no more than 80%. The dry mixture of Cerezite can be stored in the package without any damage not more than 12 months from the date of creation in a dry room.

Adhesive tiled EG 2000 and 3000

Thinking over what glue for tile is better in the bathroom to use, you can choose the product of the EC 3000 or EC 2000. After complete drying, this glue acquires strength and can no longer be shrinking. The dry mixture of EC 3000 is produced with a cement content, fractional sand, modifying additives and special fillers. This set of the main components in the adhesive composition ensures excellent performance.

According to the instructions on the use of tiled adhesive of EC 3000, the ceramic tile must have an average or small size. The composition has a level of water absorption not more than 1%. It can be applied to concrete, brick, aerated concrete or plaster. Its price is 230 rubles.

EF 2000 glue is often used when creating outdoor coatings From porcelain stoneware. With this product, it is possible to finish a warm floor, the lining of the walls inside the house and outside. The material is a composition of widespread use, they can align the surface. The applied layer must have a thickness not exceeding 5 mm. The cost of the product is 205 rubles. for packaging.

Composition of Knauf Flisen

The strength indicators of the adhesive composition are high enough. The main advantage of glue for laying tiles in the bathroom consists in its economy. It is capable of keeping the tile, does not slip, so laying the tiles in the bathroom can be carried out from top to bottom.

During the production of the product, a dry powder has a cement, special polymer additives and filler. The material stacked by a thin layer is consumed in an amount of 2.4-2.9 kg per 1 m² of surface area.

Knauf Flisen has the following advantages:

- resistant to temperature regime drops;

- the ability to resist the effects of moisture.

The material allows finishing inside and outside the house. The composition can be applied immediately to the surface having a large area. With it, it is possible to glue a tile in the bathroom to the floor and on the walls. Buy Clay Knauf Flisen can be 276 rubles.

Tile adhesive fastener

By making a decision on what glue to strengthen the porcelain books, you can choose the glue faste, the cost of which is 280 rubles. Solving is glue for laying tiles in the bathroom, designed for external or interior decoration. It has excellent adhesion with a surface made of concrete, cement, drywall and gypsum. The composition with the content of an accelerator of hardening to a substantial extent reduces the deadlines for the commissioning of construction objects.

The main advantages of adhesive composition include:

- plastic;

- water resistance;

- frost resistance;

- high chain (0.7 MPa);

- the possibility of applying when arranged the "Warm floor" system.

After diluting the mixture with water, an elastic mass is formed, which is able to maintain its qualities even in conditions of severe frosts. The product includes fractional sand and cement.

The tile adhesive composition is a good binding material that can be involved when laying a 400x400 mm tile. The thickness of the tile can be 8 mm, and the height is 1 m.

The use of this composition is allowed for laying tiles to a surface with a high level of heat transfer, for example, a fireplace finish. If you choose a faste, having antifreeze in its composition, then you can lay the tile at temperatures up to -10 °.

How to choose glue for floor tiles, because the facing of the tile is used by many - this is a practical coating that is easily removed and serves a long time. Work on laying Many people prefer to perform independently due to the essential reduction of the finished flooring.

The diversity of the intake glue

Self-laying implies thoroughly choose glue for sexy tiles. From what glue will be selected, the quality of gender depends. Special attention must be paid to how much the tile glue dries. Drying time is important, since the long-haired compositions will significantly slow work.

The main criterion for choosing glue is its appearance and composition. Types of glue are characterized by liquid and dry. The use of dry or liquid glue is determined by each master individually. For large areas, a dry look is used because it is more economical for the price.

Dry type tile glue happens:

- Dry type of cement mixture, produced using various additives that improve the properties of the composition. This glue for floor PVC can be used everywhere, including in sanitary facilities.

- Sometimes portland cement acts as a substitute for cement. The difference is that Portland cement contains more silicate additives. But its use is absolutely the same as in cement glue.

Cement glue

The glue on a synthetic basis is supplied in a liquid form. The composition may contain different synthetic materials, but most often in liquid form apply such types of adhesives:

- Epoxy composition is characterized by the presence of epoxy resin in the mixture. This tile adhesive is often used for outdoor work, since it is capable of working well in street conditions.

- Glue for outdoor dispersion type tiles is characterized by the fact that they have increased quality on adhesion.

- Putting the tile using liquid nails. This composition is characterized by the presence of rubber and polymer additives. Use tile glue is preferably in general-purpose rooms and be sure to indoors. This glue composition is absolutely not able to withstand moisture.

Choosing glue for floor tiles, you need to pay attention to the base, rough floors. For a screed or plastered bases, it is recommended to glue a tile on cement types of glue. Plasterboard, wooden or plywood floors are suitable for synthetic species.

Floor glue

Using glue for floor tiles, everyone is interested in its consumption. The parameter for many indicators is determined. An exemplary adhesive consumption can be treated according to the flow tables, as well as focusing on the manufacturer data that is specified on the packaging with the composition.

Tile glue

Choosing a tile glue for the floor it is important to take into account that the liquid composition is more applied in small areas. If there is a sticker of PVC tile on the floor in large rooms, then a dry composition is used.

The final difference digit will depend on such factors as:

- Liplinking of rough floors. All irregularities on a bad base will be filled with glue when the tile laying on the floor will occur.

- If the tile glue is thick, then the flow will also be higher. Too liquid glue will be spread over the entire surface, which will lead to an increase in flow.

- The work of the master should also be taken into account. From his handling of tools, the consumption of glue can both increase and decrease.

- The type of floor ceramic tile may vary, the porous structure will absorb more adhesive composition. Consumption to increase significantly.

The approximate scheme for calculating glue to one room is very simple. For its application you need to know the size of the room and the manufacturer's recommendations. Alternating these indicators receive approximate consumption. Such a calculation scheme does not take into account the above factors, to hope for it very rashly. Better, applying this scheme to add another 10-20% of the figures received. This action learns valid flow.

Preparatory work

Using glue for floor tiles, you need to be able to work with it. Thanks to the skillful work sticker pVC tiles On the floor will not create difficulties.

To start the work, it is necessary to prepare the basis, divide glue with water, determine the place of the starting point:

- The preparation of the draft floor is to correct it, if there are irregularities and cleansing from garbage or dust. Concrete floors are easy to fix from irregularities by applying plaster or concrete solution. The wooden floor will have to allocate or lay the base of plywood or drywall.

- The final stage of the preparation of the floor is the use of a vacuum cleaner. It is necessary for cleaning the surface from dirt and dust.

- After performing these work, it is necessary to progress the base, better by 2 times. The primer dries quickly and after the second layer of drying can be seized to laying the material. For a larger clutch, the surface can be a bit of sand.

- Dry glue, before putting the tile, you need to dissolve with water, in the proportions indicated on the package with the mixture. Most often water is required from 200 to 250 mm. Water should be cold and clean.

- The liquid composition does not need preparations.

- Determination of the work site is very important because appearance Important. Tile lay out so that the floor pattern is not broken. Single material is started to lay out so that the supposed trimming leaves to the opposite entry wall.

Selection of tools

An important point will be the choice of the right tool. The correctly selected tool will provide a certain ease of masonry and the optimal consumption of glue. In addition to the buckets, a drill with a nozzle "Mixer", to knead the composition, the spatulas will be required.

They need 2 types: smooth and with a toothed edge.

The smooth spatula is used to patch the beehive mixture on the tool tool.

To the toothed spatuer presented the requirements for the size of the tile:

- If the tile used has a size 30 to 30, a spatula with teeth is 8 mm.

- Tile 15 by 15 cm. Requires the use of a spatula with a cloth 6 mm.

Little tile size requires smaller spatula. Thus, the optimal layer of glue is adjusted. If we put a tile different sizeThe use of different spatulas is preferably.

How to apply glue to lay tile

Working with glue is to apply the composition on the tile or floor. Most often, the composition is applied to the tile, roll up and pressed to the base. Pressing you need to produce nonsense. The layer thickness is regulated by a toothed spatula. If the wizard put the tile for the first time, then make the right thickness will not be easy.

Tile glue

Application on the floor involves the imposition of tiles within 10 minutes. Tile must be glued as correctly as possible, be sure to observe the horizontal level. On the sides, plastic cross crosses are rushed into the composition to create the optimal seam. Application of grouts should occur after the achievement of optimal drying.

Styling tiles with glue on the floor

Tiled Glue Drying Stages

After completing the work, many are interested in how much tile glue. This information is very important because the use of sex should occur after complete drying.

Select 3 types of drying time:

- Primary - when the composition is so much so that the tile does not move.

- Secondary drying is characterized by the fact that it is possible to use a rapid composition.

- Full drying involves the use of the surface completely. That is, on the coating you can walk and put furniture.

Primary gas drying step.

The primary drying occurs in the first hours after dilution of the adhesive composition. During this period, the composition freezes so much that the position of the tile cannot be adjusted. If the composition is in the container, it can save plasticity, but if the tile is already laid, then the moisture is given quite quickly. In the period from laying to the impossibility of adjustment takes place not more than 12 hours.

Secondary stage

Secondary drying occurs in the first 48 hours after the primary one. During this period, the glue gives moisture and grasps very well. After this time, the rapid composition can be applied. Adhesive mass will well perceive the grout and not to select moisture. If the composition is to select moisture, then the grout will fall into the seam, crack. It will be necessary to impose several layers of grouts, which involves an increase in time and consumption of a cloud composition.

Third stage (complete drying)

Full drying occurs approximately 2 weeks after laying. During this time, the glue completely freezes, gives moisture. The return of moisture is characterized by some shrinkage. It is unlikely to notice it, but it should happen. After that, on the floor, you can walk, arrange furniture, turn on the warm floors, if this system has been mounted.

Quick-drying composition

If a quick-drying composition is used, then how much the tile glue dries will be especially interesting. Drying time of this species is reduced by half. Full load can be given in 10 days. The use of such a type of composition makes sense in time limited on time. Most often, such formulations consist of fully synthetic substances. For the floor used at home it is better to choose a more natural, cement composition.

The use of glue requires considerable attention both in the selection and in operation. It is important to consider in what conditions the composition will be used. The work associated with laying tile should not occur in a hurry, it is necessary to highlight sufficient time for drying and shrinkage. If you observe all the requirements, then as a result, it turns out a reliable and beautiful floor that is easy to clean.

If you bought the most supermodic tile for the bathroom or bath, without a high-quality adhesive composition, the end result may disappear. In modern outlets, it is proposed in abundance of the adhesives of domestic production, as well as imported. However, it is not very easy to navigate. Let's find out what glue glue ceramic tiles.

Properties of adhesive composition

When choosing a composition for decorative tiles, it should be known useful characteristics. If the composition does not answer the requirements listed, it is not worth buying it in any case. After all, in this time, no one gives warranty that the tile will stick and quickly fall off. So, pay attention to:

- Plastic. This indicator must be moderate. If the composition spreads excessively, then you will not be able to make a suitable layer. The plasticity of glue should not change, regardless of whether you made it thick or rare.

- Elevated spreadability. When choosing glue for floor ceramic tiles, remember that it must have the ability to fill all emptiness when applied. Otherwise, the tile will simply disappear or breaks if some thing falls on it with a lot of weight.

- High adhesive characteristics. Simply put - glue must hold the material of any weight. Well, if this property is complemented by the speed of adhesion to the surfaces. When laying a porcelain stoneware with large sizes will also be relevant.

- Lack of rapid water return. You should always be able to adjust the tile that was incorrectly attached while working. It should be considered that glue should dry slowly. So it will get higher strength.

Composition of glue for laying tiles

Considering the composition, the types of glue for ceramic tiles are as follows:

- Glues made on cement basis. Thanks to a balanced price, glue is very popular, which includes cement and sand. In addition, in a small amount it contains polymer additives. It is they who increase the characteristics of the adhesive - its plasticity, water resistance, a deformation range and tile adhesion with a facing surface. All hypoallergenic components. Glue is for sale in a dry consistency, which during work is diluted with water to a viscous substance.

- Dispersion adhesives. This composition is characterized by a higher price, but its flow is less than two times. It is inherent in the increased properties of the clutch with the surface, so the composition is used when fastening the tile on non-standard material: wood, plastic, metal surface, plasterboard sheets, prone to bending and vertical surfaces and even slippery wall. At the same time there is no need to primer or grind the base. Dispersion adhesives for ceramic tiles are sold ready for further use.

- Epoxy adhesives. This substance is multicomponent, in front of the process, the tile stickers are injected with a catalyst, which is packaged in separate containers. However, before using the substance, remember that it does not forgive missions and needs skill and scrupulsiness. If, for example, the glue fell on finishing materialHe stands to immediately remove it, because he will freeze, turning into a very strong substance. And it is almost impossible to eliminate it. Epoxy glue is characterized by excellent quality for open-air use, indoors with high humidity. It does not react to the impact of alkalis and solvents.

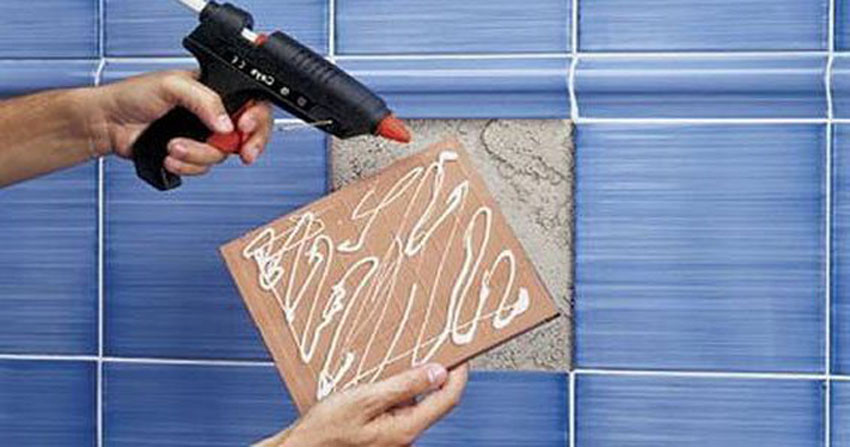

- Liquid Nails. This adhesive composition is relatively new. As a rule, it contains polymers with a synthetic rubber. Liquid nails on an neoplative basis are distinguished by increased strength, they are toxic, in addition, they are inherent in the opposite smell. And harmless water-based glue is not suitable for operation in the bathroom or bath. After all, it does not have moisture resistance. Thus, ceramic tiles are advisable to fix on liquid nails only during restoration repair, or if several mosaic fragments or small tiles dropped.

Varieties of glue for ceramic tiles

According to international classifications, adhesive for ceramic tiles is divided into the following groups:

- Glue for internal work. This composition is the cheapest and intended for fastening the tile on the walls of household premises. In such a substance, there are few all kinds of additives that are responsible for improving it. functional properties. However, the adhesive for ceramic tiles quite well glues a standard tile to concrete and a brick base. The main thing is that there are no temperature differences, as well as high humidity.

- Adhesive adhesive adhesive. Such a composition is characterized by a high level of clutch and strength. Since it can withstand substantial stretching loads, it can be used with significant dynamic impacts, high temperatures, To attach the material to the old surface, for example, painted, or other cladding (provided that it lasts firmly). Great when using stone and large-format tiles.

- Universal glue. The composition of the standard carries such a name, as it uses almost all the tiles, when fastening the tile outside the house and inside. However, this substance is designed for standard conditions. Operation where there is temperature fluctuations, large humidity or elevated loads are not appropriate. In addition, it is not necessary to glue a tile with dimensions more than 30x30cm.

- Glue for floor tiles. It differs from the other large percentage of the present plasticizer. Therefore, when laying tiles on the floor, the solution is able to fill all emptiness. But for the walls it does not fit, otherwise the tile will float. According to other glue parameters comparable with standard.

- Water-repellent glue. This composition is indispensable for use in the bathroom, bath, with a facing of a porch, fountain, pool. This adhesive adhesive adhesive with the addition of a modifier that is responsible for hydrophobic properties. It is not cheap, therefore, as an option when laying a tile, you can use the composition of increased fixation, and then rub the seams with a water-repellent mixture.

- Specialized formulations. For example, here also include heat-resistant glue for ceramic tiles - for facing furnaces and fireplaces. White compositions are recommended to be used when there is a translucent tile laying, as well as marble and mosaic. In addition, there are frost-resistant adhesives For an open balcony.

Criteria for selection of glue for tile

When choosing an adhesive composition for lining with decorative tiles, it is recommended to take into account some criteria. Global nuances exist three. Let's look at them in more detail:

- Terms of Use. Take into account exactly where the tile is to be laid. When carrying out work in the kitchen, buy glue, which is designed for the work indoors, the universal version is also suitable, including for the floor facing. For the bathroom it is worth picking up a more serious substance - with water-repellent properties. However, you can always use a universal composition with a special grout for seams. For the pool, you need a water-repellent, for the porch - frost-resistant glue for ceramic tiles.

- Foundation characteristics. When choosing a decorative tile glue, consider the properties of the composition to the adhesion with a certain material. Say, dry cement mixes It is not advisable to apply for floor cladding from OSB. Simple foundations are all solid, which are not amenable to deformities. These include brick, concrete, screeds with sand and cement, cellular concrete. Complex - plastic, glass, metal and drywall, already lined with tiles of the surface, the base, which is easily deformed and exposed to vibrations. When lining a small tile of simple bases in a dry room is worth buying glue, the adhesion coefficient of which is ~ 0.2-0.5 MPa. The facing of complex surfaces requires adhesion in 1 MPa and more.

- The dimensions of the facing tiles. Remember: manufacturers claim that the larger the sizes have tiles, it is worth choosing a stronger adhesive composition. First of all, this rule concerns the wall cladding procedure, although usually do not use a large tile in this case. But when attaching outdoor tiles, you can buy a universal composition, because the material will keep well and on it.

Ready and dry mixes

When choosing glue for facing tiles, it is worth knowing that the compositions are made in a dry form (sold in bags) and ready (in buckets). What such substances differ among themselves? All dry mixes have a cement base, ready - polyurethane. This difference affects the final value of the product - the composition on a polyurethane based will be more expensive to you.

In this case, dry mixtures have significant advantages over ready:

- The dry makeup allows you to mount the tile on the walls of any curvature. It can be used to align the walls, without making additionally the plaster surface. But polyurethane adhesive for ceramic tiles requires perfectly smooth walls or floor, but great for facing the mosaic.

- The price of the adhesive substance is lower. The difference is tangible when buying the same volume of one and the other mixture.

- When analyzing the qualities of both formulations, it can be argued that both perfectly cope with their task. Polyurethane glue will be kept almost forever, dry - no more than 50 years. But if you get tired of the tile, laid on a cement-based glue, it will be possible to remove it faster, because the dry composition is easier to dismantle (for example, with a perforator). But the polyurethane can only be removed along with the base.

Decorative tile manufacturers

The demand for dry glue for tiles is significant, therefore many companies that are engaged in the production of such compositions. Consider the most famous:

- Adhesive composition is the usual, reinforced, as well as accelerated fixation. The most popular brands: POLIMIN P-9, P-12, P-14, P-16, P-22; SILTEK T-80, T-81, moment; Glue for ceramic tile Ceresit CM 11, CM 12, CM 17; Master Standard and Normal.

- Thermocles, which is intended for furnaces and fireplaces (-300- + 1600 degrees): Master Flex, Polimin P-11, Siltek T-84.

- Glue for open balconies and terraces, pools, fountains, porch, water heating floors and for fastening indoors with humidity: POLIMIN P-24, P-25; Ceresit CM 17, SILTEK T-84.

- Adhesive Express, which serves to quickly fix: POLIMIN P-16, CERESIT CM 14.

- Glue for gluing mosaics, tiles of light color and made of marble: Master Crystal, Ceresit CM 115, SILTEK T-82, POLIMIN P-23.

- Glue for stone, whether it is artificial or natural material: The moment is elastic; Master Stonefix; Ceresit CM 117; POLIMIN P-14, P-22; SILTEK T-81.

Whatever happens, and you are simply obliged to choose the best glue for ceramic tiles, because the quality of the adhesive tile is depends on this, the durability of the operation of the finish. If you are planning to work with the help of universal glue, then do not rush, and think over more than more detailed, since it has the limit of the opportunity. Especially - in which room the work is coming, what is the characteristics of the foundation.

If you decide to use the tile when repairing, it is important to determine which tiled glue is better. The building materials market presents a huge variety of these compositions, among which the budget and expensive options can be distinguished. The consumer, visiting the store, is lost in the assortment. That is why you need to consider all the features of existing adhesive compositions before purchasing.

Features of the selection of tiled glue

Each private wizard should be aware of the key parameters that should be guided when choosing a suitable adhesive composition for laying tiles. The cost at the same time plays a key role, since expensive mixtures are used in exceptional cases. Its dimensions, conditions of operation, the type of roughing base, to which the decorative material will be labeled are affected.

Dimensions and type of tiles

If you think about the question of which tiled glue is better, it is originally necessary to pay attention to the material and dimensions of the tile. Experts argue that for more severe material it is necessary to select a glue composition, which has impressive strength characteristics. The mixture should be well gripped with a rough base. Manufacturers This characteristic of the mixture is called adhesion. The quantitative value of this magnitude can be found on the package. The more this indicator, the higher the value of the adhesive composition will be. Thinking over the question of what tiled glue is better, the consumer should pay attention also to the level of water absorption tile, this affects the porosity of the material, this indicator is measured as a percentage, the number of which can also be found on the packaging of decorative finishing material.

If you think about the question of which tiled glue is better, it is originally necessary to pay attention to the material and dimensions of the tile. Experts argue that for more severe material it is necessary to select a glue composition, which has impressive strength characteristics. The mixture should be well gripped with a rough base. Manufacturers This characteristic of the mixture is called adhesion. The quantitative value of this magnitude can be found on the package. The more this indicator, the higher the value of the adhesive composition will be. Thinking over the question of what tiled glue is better, the consumer should pay attention also to the level of water absorption tile, this affects the porosity of the material, this indicator is measured as a percentage, the number of which can also be found on the packaging of decorative finishing material.

Selection of adhesive composition under the operating conditions

If you faced the question of which tiled glue is better, then you need to pay attention to the alleged operating conditions. This is one of the main determining factors for choosing adhesive composition. It is important to determine the temperature range, air humidity level, alleged load on the tile. Thus, if the implementation of floor cladding is made on an open loggia, it will have to use frost and moisture-resistant glue composition.

If you faced the question of which tiled glue is better, then you need to pay attention to the alleged operating conditions. This is one of the main determining factors for choosing adhesive composition. It is important to determine the temperature range, air humidity level, alleged load on the tile. Thus, if the implementation of floor cladding is made on an open loggia, it will have to use frost and moisture-resistant glue composition.

All adhesives are divided into three subgroups. The first includes the usual compositions that are manufactured on the basis of cement. Similar mixtures belong to C1 class. Such compositions are intended for external work. The basic type of glue has adhesion to the base, which is 0.5 MPa. Such formulations are used both in dry and in humid premises.

The second group can include improved cement-based mixtures, which have additional characteristics. Such formulations are used to carry out internal work. Mixtures of this species have adhesion, which is 1 MPa, such products are distinguished by increased elasticity.

If you decide to purchase glue tile, the characteristics of the composition must certainly explore in advance. The above product perfectly manifests itself when laying tiles in rooms, the conditions of which are characterized by significant temperature differences and high humidity. The glue will be able to undergo significant dynamic and static resistance.

The third group includes adhesive compositions special purposewhich possess specific characteristics. This includes modifications of heat-resistant composition, which is used for facing furnaces and fireplaces.

Consumers who choose adhesive tile, the characteristics of the composition must certainly consider. Quite often, buyers decide to use a translucent mosaic or marble tile when finishing. This will be indispensable white glue mixture.

Selection of adhesive composition by variety and base characteristics

If you need glue tiled, consumer reviews will allow you to decide on the choice. It is important before the acquisition of the composition to draw attention to the species of the foundation, which can be complex and simple. A simple surfaces can be attributed to durable, non-changing linear dimensions, solid bases by type of those that are made of concrete, cellular materials, bricks, or based on cement-sand tie.

If you need glue tiled, consumer reviews will allow you to decide on the choice. It is important before the acquisition of the composition to draw attention to the species of the foundation, which can be complex and simple. A simple surfaces can be attributed to durable, non-changing linear dimensions, solid bases by type of those that are made of concrete, cellular materials, bricks, or based on cement-sand tie.

It is often necessary to work with complex bases, for example, with glass, metal, wooden or plastic. If there is a need to linger the dry room with tiles, then the base glue composition should be chosen, the adhesion coefficient to the base of which is equal to 0.2-0.3 MPa.

If you choose the adhesive tile, feedback about it should be interested. For example, consumers claim that when laying ceramics, they use the most simple mixeswho have proven themselves well. As an exception, there are cases when there is a need to lunch flexible surfaces. Among these, it is possible to highlight Phaneur or plasterboard.

If you choose the adhesive tile, feedback about it should be interested. For example, consumers claim that when laying ceramics, they use the most simple mixeswho have proven themselves well. As an exception, there are cases when there is a need to lunch flexible surfaces. Among these, it is possible to highlight Phaneur or plasterboard.

Varieties of adhesive compositions for tile

Adhesive Tile "Standard" is used as a universal means, but sometimes there is a need to apply mixtures with special characteristics. The most common compositions made on the basis of cement are the most common. They are realized in the form of a dry mixture, which contains modified components to ensure the desired degree of adhesion and plasticity. If you cannot decide which composition to purchase, pasty or dry, then it is worth considering that one-component pasty mixes in quality are somewhat worse compared to dry. However, they won in price. These include polyurethane and allow them to be applied solely when conducting interior decoration.

Adhesive Tile "Standard" is used as a universal means, but sometimes there is a need to apply mixtures with special characteristics. The most common compositions made on the basis of cement are the most common. They are realized in the form of a dry mixture, which contains modified components to ensure the desired degree of adhesion and plasticity. If you cannot decide which composition to purchase, pasty or dry, then it is worth considering that one-component pasty mixes in quality are somewhat worse compared to dry. However, they won in price. These include polyurethane and allow them to be applied solely when conducting interior decoration.

If you decide to buy tiled glue "Knauf", then you should pay attention to two-component mixtures. Compositions that contain polyurethane and epoxy additives increase the adhesion, and also have more impressive qualities of plasticity. Among other things, thermo- and moisture resistance, durability and durability are ensured.

Properties of tiled glue

Tile glue "Knauf" today is quite common in the market of relevant goods. However, choosing it or the composition of any other brand, it is necessary to pay attention to the basic properties that high-quality glue should have. The mixture must first of all be resistant to sliding. It is important to pay attention to the expiration date, this indicates a period of time, during which the mixture will not lose its characteristics and can be used when conducting facing works. Tile glue frost-resistant, as a rule, for three hours after kneading can be used.

Tile glue "Knauf" today is quite common in the market of relevant goods. However, choosing it or the composition of any other brand, it is necessary to pay attention to the basic properties that high-quality glue should have. The mixture must first of all be resistant to sliding. It is important to pay attention to the expiration date, this indicates a period of time, during which the mixture will not lose its characteristics and can be used when conducting facing works. Tile glue frost-resistant, as a rule, for three hours after kneading can be used.

Consumers pay attention to the open time of work, involving the interval, during which the already applied mixture can maintain its characteristics. This indicates that during a certain time you can lay the tile. If we talk about ordinary adhesive compositionsThe open time is about 20 minutes. Available in the form of a quick-conacious composition, which gains strength of everything for 10 minutes. During this time, you can have time to adjust the position of the tile.

Conclusion

Whatever composition is chosen - the junction tile adhesive or a mixture of any other manufacturer, you should pay attention to the value of the product expiration date, since the mixture that was produced for a long time ago, and was also kept incorrectly, could lose its operational characteristics.