Quick-Mix TFP color grout for natural stone - a solution for filling the seams of polygonal plates. Grout for stone

Registration of tracks, facades or foundation with natural stones, it is not only to give fashion, but also practical and reliable, because the stone will serve for many years without deformation and visible changes. But over time, even durable masonry can be collapsed from winds and bad weather, although there is nothing to happen to the stone, but he will leave his place, instead there will be a hole for it, if after it laying does not use modern thicker materials for outdoor work.

The stone will decorate a house, a walkway or foundation on the street, with a large temperature drop in the winter and summer, suffer from bad weather - rain or snow. Of course, whether it is an artificial or natural stone, it is actually a durable material, but that he remains firmly in his place, has not changed his position for many years, you need a all-season putting, it can be:

- Made based on Portland cement;

- From sandy cement mixtures and portland cement.

The first version of the races are applied from the last century, the inventor is considered to be Joseph aspidine, who lived on the island of the same name, from where it has spread around the world.

On the photo clip for the stone for outdoor work

The structure of the patch of the first type includes only mixtures of cement, in which different smallest fillers have been added for viscosity or frost resistance. All of them are very crazy, well fill all interfacing spaces and reliably cement it in a permanent place. In addition, the grasp of them is excellent.

Preparation is very simple - a certain amount of the mixture is stirred by water or a special adhesive composition of their liquid latex.

The finished composition rubs the stone gaps of about 5 mm wide, but it is possible to learn more about the use methodology from the accompanying documentation.

On video grout for a stone for outdoor work:

Another kind - Sandy, it resembles the usual pulmonary of the mass into inter-spot space and water watering for sealing. This grout usually handle tracks to home or other buildings from natural or artificial stone. The reliability of the grout is minimal, over time, from the water and winds of the seams are taken off, and it is necessary to carry out work again. But the cost is incomparably lower than the previous version.

You can meet a colored sandy grout, usually it is sold complete with dry polymer compositions, and if you use sand in combination with polymers, the reliability of the protection of seams on the street is rising, and the tracks or foundation look the most decorative and unusual.

But! Draw your attention to! It is possible to use polymer additives to sandy grouts for street work, houses from heat and moisture they can evaporate substances harmful to health. Pay attention to the composition of the mixtures, and do not buy with an artificial composition.

Where can I use and how to do it correctly, it is described in this article.

What is the flow rate for the seams of the tile and how to install required amount, you can learn from this

What is the price of grouting ceresit se 40 and where it can be used, describes in detail in this

For internal work

Home Fireplace It is always comfort and comfort in the head of the country house, and if he is laid in a natural stone, then when cooled, warm air will still twist around the house, not stinging residential premises.

And some of the owners of country houses acquire an artificial special stone for the walls, and the original wall of stone, for example, in the dining area can not hit one guest.

For premises it is advisable to use grouts based on cement mixtures or silicone sealants.

The first option is suitable for filling the large sized seams natural stoneIts sizes can be non-standard - one more, and the other is much smaller. But you can add an additive that imitating natural color so that you can make invisible transitions to different stones in size. But over time, the cement base can be collapsed, it has the properties of home dust, and its particles will fall into lungs, as you understand, this is not always a reasonable grout for a residential building.

But if you need to equip the surface of the indoor pool, or tracks located on the inner space, or sides, then the best option Rubbing based on epoxy resins. It reliably protect the space from moisture ingress, which may be the cause of mold and fungus. But at home for processing, for example, a fireplace, it is better not to use it.

On the video clip for stone for internal works:

What suitable

Qualified specialists argue that if the stone seams need to be sweep in residential premises, and it does not matter whether it will be natural or artificial samples, then it is better for them than fastening on the basis of silicone sealant not to find, the more the range of the commodity group is very large. You can choose heat-resistant, with color splashes, and even absolutely colorless, it all depends on your taste.

Save on the grout - do the composition yourself

Be that as it may, it will always be better, and even significantly saving it. Moreover, the composition you can make it solely for your needs.

So, to make a durable and durable composition for internal works, you can take a simple bag of cement, add sealant to it, and a bit of sandy mass, stir up to the formation of a homogeneous composition, and neatly rubber spatula process all the seams.

Surplus remove, make it all high quality and smoothly, and then for a long time you do not have to re-work.

But what is the flow rate of the Cepese SE 33 and where it is worth using such construction materialwill help to understand this

What is and where you can use e, you can learn from this article.

But what a grout for tiles in the bathroom is best suited for use, it is very detailed in this

What moisture-resistant grout for seams tiles in the bathroom is the best. will help to deal this

Manufacturers and prices

When choosing a material, pay attention to the composition so that you will not suffer from headaches and other diseases.

Facades lined with artificial or natural stone, tiled or porcelain stoneware have a solid and prestigious look. Due to the set of variants of combinations of decorative plates and a solution, facing facial brick And the stone will always be relevant.

An important role in the aesthetic perception of the decoration plays the correct grout of the seams. This process is simple, but it is necessary to know all its subtleties. It is important not only to choose the incremental composition correctly, but also be able to work with it.

Types of stones for stone

Quickly and correctly fill the stamps of stone and ceramic coatings It is possible only with the help of high-quality elastic composition. The modern finishing materials market offers a wide range of rates. Compositions for working with stone and tiles are so many that can be confused. Therefore, you need to know what the criteria for choosing a quality product.

If the tiles of the stone were attached to the facade with the help of glue, in most cases it is also used for grouting seams. Similarly come with cement-sandy solution. But there is a line of products designed specifically to fill the seams between the elements of the finish. These are grout. When developing their composition, all nuances of operation of facing materials and all factors affecting them are taken into account. Therefore, experts recommend using glue by direct purpose, and filling the seams - the material that is intended for this purpose.

![]()

Composition for stone

- on the cement based;

- using epoxy resins;

- with the addition of latex plasticizers;

- with the addition of silicone;

- with the addition of rubber.

Any of these rates can be used for facade work. There are mixtures dry and wet. For facade works, taking into account their large volume, use dry. These mixtures are prepared in the amount that is required for processing the area of \u200b\u200ba certain area. As a rule, it is necessary to work out the composition for 30-40 minutes.

If you use wet mixtures, during breaks in work, they can lose their basic property: elasticity. This is another reason for choosing for facade works dry rates.

All manufacturers are included in their products supplements that provide frost resistance and moisture resistance. There are pigmented grouts of a variety of colors. There are mixtures in which you can independently make the coloring substance and achieve the desired shade. But despite a wide selection of rates, the technology of their application is the same for all types of compositions.

How to use grout for stone

In order for the work to go fast and smoothly, you need to properly prepare the rapid composition. On the package of each product there is an instruction manual, in which it is indicated, as in which proportions to dilute it with water. But in any case, for the manufacture of a wet mixture will be needed:

The seams are filled with three ways:

The first method is convenient because it allows you to reduce the time for cleaning the facing and is suitable for treating coatings with any surface. When using a gun, a thorough cleansing of the tile is not required, since a properly cooked solution is rarely falling on it.

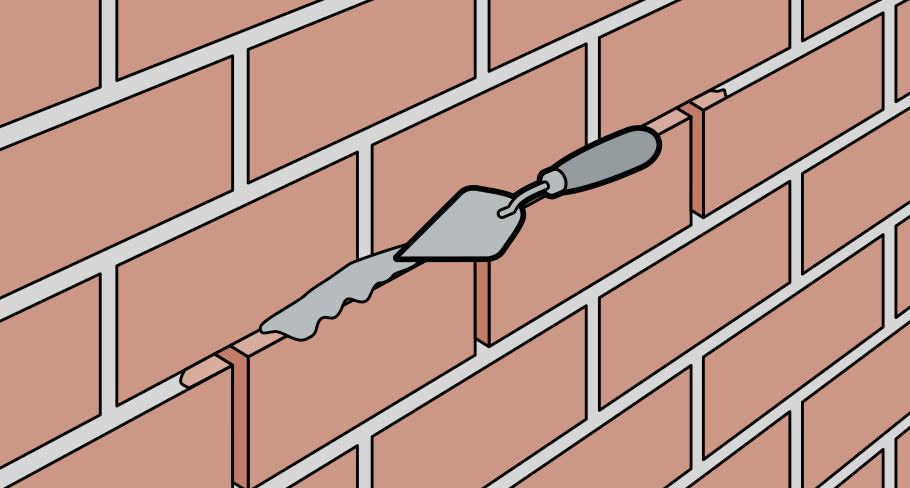

Shutter filling techniques with a syringe pistol

Step 1. Clean the gaps between tiles using a brush with rigid bristles.

Step 2. Moisturize the seams using water and sprayer.

Step 3. Prepare a solution according to the instructions.

Step 4. Fill with a solution with a syringe gun.

Step 5. Pressing on the piston of the pistol, fill the intercutric seams with a solution.

Step 6. At the beginning of the process of solidification, the solution is proceeded to the seams.

For this purpose, use a special tool: extection. It is carried out with uniform pressure along the seams, removing the excess solution. The latch is kept almost parallel to the wall, but with a slight bias from it. Such a position of the tool ensures the removal of the layer of the same thickness, which is important for external view Facing.

Schedule filling technique by sludge

The sludge method is suitable only for smooth and smooth tiles, as it provides for the applying of a cloud composition over the entire surface of the finishing material. This approach requires a large amount of mixture. But this method of grout has its advantages:

- with sludge adhesion of the solution to the side walls of the tile is significantly higher;

- seams are tight, smooth and smooth;

- the seam structure is homogeneous, so cracks rarely appear on them;

- no joints and splitting of seams is required;

- the time is reduced.

For sludge will be required:

- gloves;

- a grater with a metal or plastic sole (can be used to cell);

- putty knife;

- sponge for surface cleaning;

- brush with rigid bristles.

Stages of work

Step 1. Clean the seams.

Step 2.. Moisturize the surface of the wall with the help of water and sprayer.

Step 3. A small amount of grout is gaining on the grater.

Step 4. Distribute grip over the wall surface so that all recesses are fully filled. Continue until a certain section of the surface is processed.

Step 5.. Repeatedly apply a layer of solution to the sections where it is not enough.

Step 6. Carefully brack the seam location.

Step 7. Wash the sponge to clean the tiles with water and wipe the wall surface diagonally to the seams. They act in this way until all the extra solution is removed.

Step 8. If necessary, wipe the wall with dry rag.

Shutter filling technique with spatula

Popular and traditional method of filling seams with a spatula. Unlike the sludge, the mixture is applied only in the seams area, trying to fill them on the entire depth.

Grouting with a spatula provides for a thorough cleaning of the facing upon completion of the work. To perform this task, not only sponge, but also a wet rag. It is important not to miss the time and wipe the solution until it is set. Therefore, after processing each site, it is possible to clean it.

This requirement is especially important for cladding with a relief surface. If you don't remove the solution on time, it will freeze, and unsightly spots will remain in the recesses. They will significantly spoil the appearance of the facing.

Stages of work

Step 1. Prepare a grout mixture with a drill and mixer.

Step 2. Clean the seams between the tiles with a brush with a rigid bristle.

Step 3. Moisturize the seams.

Step 4. A small amount of solution is typed or spatula.

Step 5. Rub the solution in the seams between the tiles. This process in the language of specialists has its name: "Caption". The solution is applied in two layers using the Fresh Fresh Technique.

Step 6.. Enlarge the seams.

Step 7.. Clean the surface of the wall.

Let's smash the surplus brush

An important stage of work is the batch of seams. It is started at the moment when the grout dries to the state of wet sand. Surplus the solution is cut using the "Mason Box" tool. Instead, you can use any subject suitable for this purpose.

During the seam, a beautiful relief and a smooth surface come. During the period of solidification of the solution, it is periodically moistened with a sprayer. Freshled grout is necessary for 2 days to protect against atmospheric precipitation and direct sunlight. The easiest way is to cover the wall with a polyethylene film, while ensuring sufficient ventilation.

Survey for stone

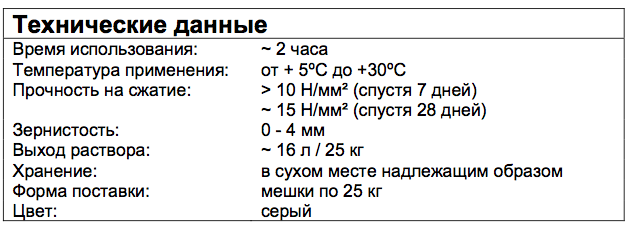

Grouting RSS

A high-quality RSS grout mixture is designed for sealing seams between any facade facing materials. The composition is made on mineral base, includes additives to ensure moisture resistance and frost resistance.

The mixture is sold in bags of 25 kg. To prepare a solution, the contents of the bag are mixed with 3-4.5 liters of water and thoroughly mix the drill with a mixer. RSS grout is convenient to use: does not flow, evenly fills the seams, has a good crack resistance. The mixture can be used for exterior and internal works.

Ceresit Super

Ceresit Super Roll Line allows you to choose exactly the composition that is needed for the finishing finish of a particular material.

| Product name | Purpose | Characteristics and conditions of application |

|---|---|---|

| For sealing seams width not more than 10 mm. For grouting seams of glass, ceramics, stone, porcelain stoneware, clinker. | It has waterproof properties and increased resistance to pollution. Finished seams have a premium surface "velvet". The total hydrophobicity of the composition occurs in 5 days after the grout. |

| For seams of seams width up to 5 mm | Moisture-resistant, frost-resistant, color palette includes more than 50 colors. Works with the use of this composition are performed at a temperature not lower than + 5 ° C. |

| For wide seams (up to 2 cm) | Moisture-resistant, frost-resistant, high-strength. It has a disinfecting effect, stable for deformations. |

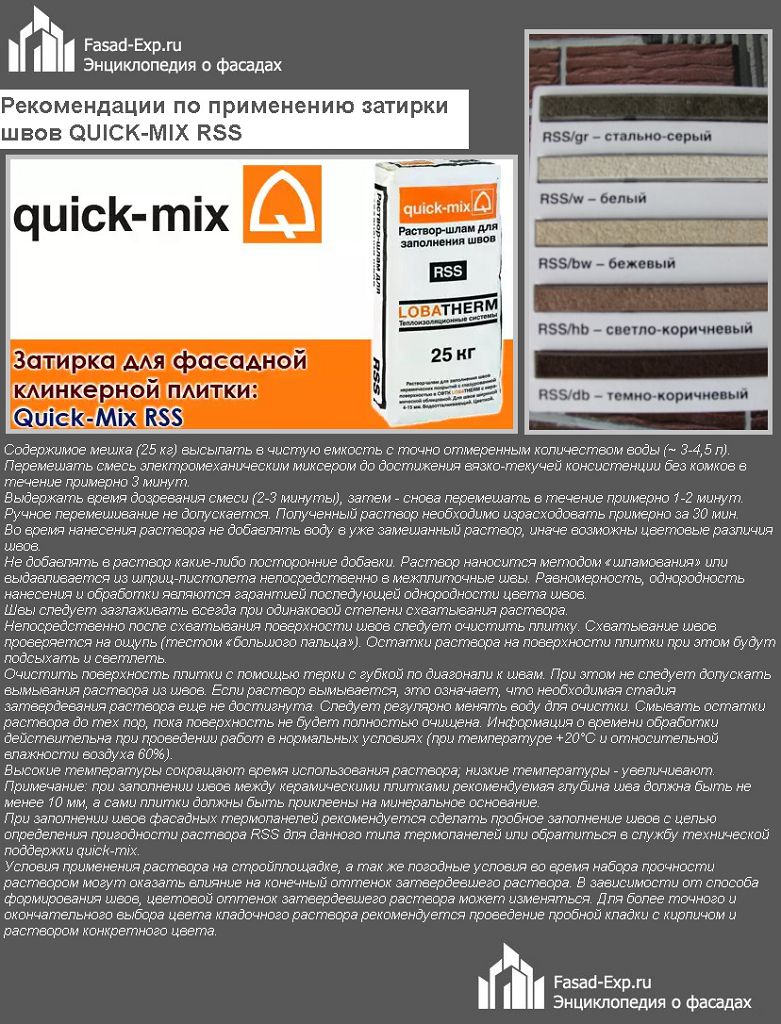

Kiilto Saumalaasti.

Kiilto Saumalaasti grout is designed for work inside and outside the premises. Made on the basis of cement with the addition of lime and polymers. Elastic, easily applied and washed off. It has moisture resistance, heat resistance and frost resistance. Used to fill seams with a width of 2-6 mm.

In front of facade works, it can be applied to concrete and a brick with humidity up to 90%. A solution ready for use is applied with a rubber spatula, drying time does not exceed 15 minutes. When preparing a mixture, it is important to keep water dosage. When the magazine is exceeded, it can be washed over the first 5 days after applying.

Freshly prepared composition has an alkaline property, so it is necessary to prevent its eye contact and on the skin. When mixing the mixture, it is recommended to use the respirator.

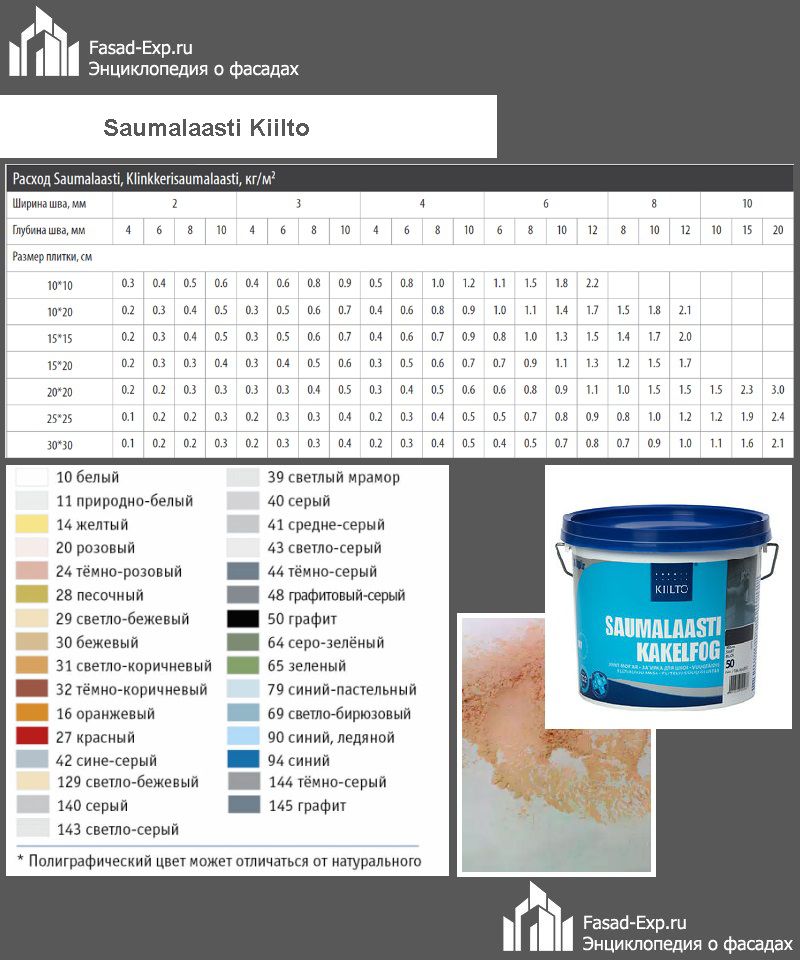

Perel

Perel Perel Line represents a wide selection of compounds, including mixtures for winter work with a high degree of moisture resistance and crack resistance.

Perel RL 5410 is one of the most commonly used mixtures for facade works. The demand of the product is due to its high quality and convenience of application. This mixture refers to the category of decorative used to obtain premium surfaces of intercutric seams. Used for finishing works with any finishing material. Suitable for filling the seams using a syringe gun.

Preparation of composition:

- in the deep container poured clean water at the rate of 4.5-5 liters per 25 kg of dry mixture;

- add the required amount of the mixture;

- for 2-3 minutes, the composition is stirred until a homogeneous mass is obtained using a drill and a mixer;

- leave a solution for 2-3 minutes;

- re-stirred for 1 min.

The prepared portion of the solution must be developed within 3 hours. At the first signs of the frozen mixture, it is re-stirred, without adding water and any other components.

Grout FM Quick Mix has its own features of cooking: 25 kg dry is required only 3 liters of water. The composition is stirred to obtain a homogeneous mass and achieving the consistency of a wet earth without lumps. Thanks to the optimal combination of aggregates, grout is easy and easy to use.

FM Quick Mix grout is available in 16 color shades. The product belongs to the category of professional and has all the necessary properties for facade works: moisture buildings, frosty, is durable. The mixture is made on a cement basis, environmentally safe.

Video - grout of seams of the front tile, putting the seams on the thermopanels

("Config" :( "IDPartner": 29 "," SiteID ": 163))

An example of using a solution to fill the TFP seams on the facility in the KP Marengino-3, 2013.:

Prices for stone grinding (for packing 25 kg):

| 56242 | 25 | 534.0 |

| 72476 | 25 | 567.0 |

| 72477 | 25 | 617.0 |

| 72478 | 25 | 568.0 |

| 72479 | 25 | 571.0 |

| 72640 | 25 | 595.0 |

This product is included in the warehouse program. "Monovay"

Characteristics:

Waterproof,

Elastic,

Simple and easy to use,

Prevents the appearance of lime spots and fading stone,

High adhesion to the side walls of the plates,

Improved formula due to polymer additives,

Prevents shrinking cracks.

Application:

For neat filling of seams between the plates natural stone, as well as concrete slabs of factory manufacture,

For surfaces intended for pedestrian, and light transport load,

Requirements for the foundation:

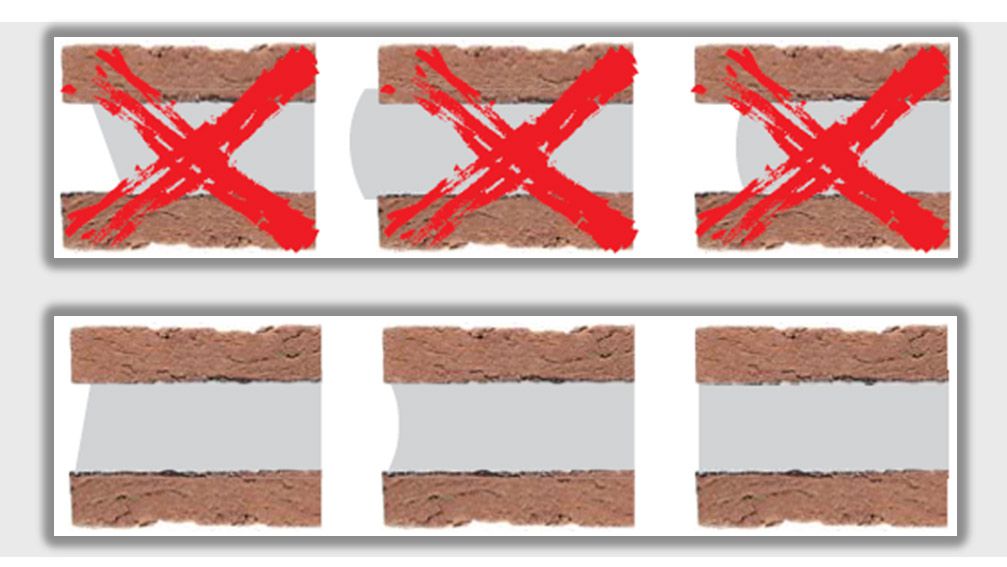

Before filling in seams, the plate from the natural stone must be securely recorded adhesive composition, such as. There should be cleaned from dust and residual solutions to the entire depth of stone. Before applying the suture solution, it is necessary to moisten, but there should be no water in the seams.

Technology manufacturing work:

The contents of the bag (25 kg) pour into pure container with 4 liters of water. Mix the electromechanical mixer until the low visual consistency is reached about 3 minutes. To withstand the time to ripen the mixture of 2-3 minutes and re-move within 1-2 minutes. The seams between the non-absorbent plates from the natural stone closed (granite, porphyr) should be filled with a rubber spatula under low pressure, providing a solid and complete fit. Do not allow the formation of emptiness in the seams, tfp molds should lay on the entire depth of the stone. Do not allow a long contact of the solution with the facial surfaces of the plates, otherwise, their cleaning will be difficult.

The seams between the absorbent plates from the natural stone with open pores (sandstone, limestone, etc.) should be filled with a syringe or a bunch, providing solid and deep filling. Depending on the type of plates used immediately after drying the surface of the seams (it is checked by the "thumb" test "after 1-2 hours), it is necessary to thoroughly clean the surface of the plates with a clean, wet sponge.

With dry weather, the filled seams may be subjected to a pedestrian load 24 hours after filling. It should be considered to slow down the drying of the seams at temperatures below + 15c. High pressure water jet cleaning of high pressure water is allowed not earlier than 3-4 weeks after filling the seams with TFP solution.

Termination examples TFP stamp:

Recommendations for the use of grouts for the Natural Stone TFP

What stone to use the tfp grout?

The tfp Quick Mix stone is used when working with polygonal plates of natural stone, a paving any type (sandstone, lemzit, granite, serisite, limestone, slate), sawn and calibrated plates from natural stone, including non-flowered, also allowed to use this Grouts with artificial stone.

The composition of the TFP solution includes the Rhine TRASS. Thanks to the unique properties of this component, the change sensitive to the shade of a plate of natural stone will not lose their color.

Can I use TFP grout on vertical seams?

According to technical characteristicsThe manufacturer recommends using this product on vertical and horizontal seams.

What is the suture size between stones?

from 1 to 5 cm

Why can not rub the seams with tiled glue?

The adhesive composition is not intended to compensate for the internal voltage, as a result of which cracks are formed.

What is the flow rate for TFP stone?

Consumption depends on the width and depth of the seam. The practice of using this product shows average flow 5 kg per m2.

How to apply grout for stone?

The finished solution should be applied with a spatula or from a package, providing full and solid occurrence.

TFP Solution Technical Map:

An example of using a solution to fill the seams of the TFP natural stone at the facility in the Kirzhach district of the Vladimir region KP "Pavoriki" 2013)

Waterproof tFP stone grout applied on the Russian market since 2011. Professionals highly appreciated the simplicity and universal properties of this product. TFP grout guarantees reliable stonework protection with vertical and horizontal installation. Color gamma meets the requirements of the Russian market and is selected specifically for the most common types of stones in the Russian Federation. Yellow color - perfectly combined with Rostov sandbags, brown with leverage, also present traditional colors white, black, gray. Also launched into the production of a colored solution for laying and simultaneously designing seams.

How to choose scatching color for stone?

Beautifully and gently lay out the stone, providing protection against fading and destruction - it is still half. It is very important to pick up the right grout color. After all, all aesthetics depends on it. Whatever original, dear, beautiful is a stone, if the grout is inappropriate, it will not look for such a laying. Specialists of the company "Kvik-Mix" developed colors perfectly combined with Russian natural stone:

Brown - for the Ural Natural Stone Lemezit and the burned Rostov gerbal. This color is suitable not only for "wild" or "torn" natural stone, but also derived from it various verming tiles and paving stones.

Yellow color - combined with the Rostov gerbal and tiger stone.

White and black - for connoisseurs of contrast solution.

Gray - Universal Classic.

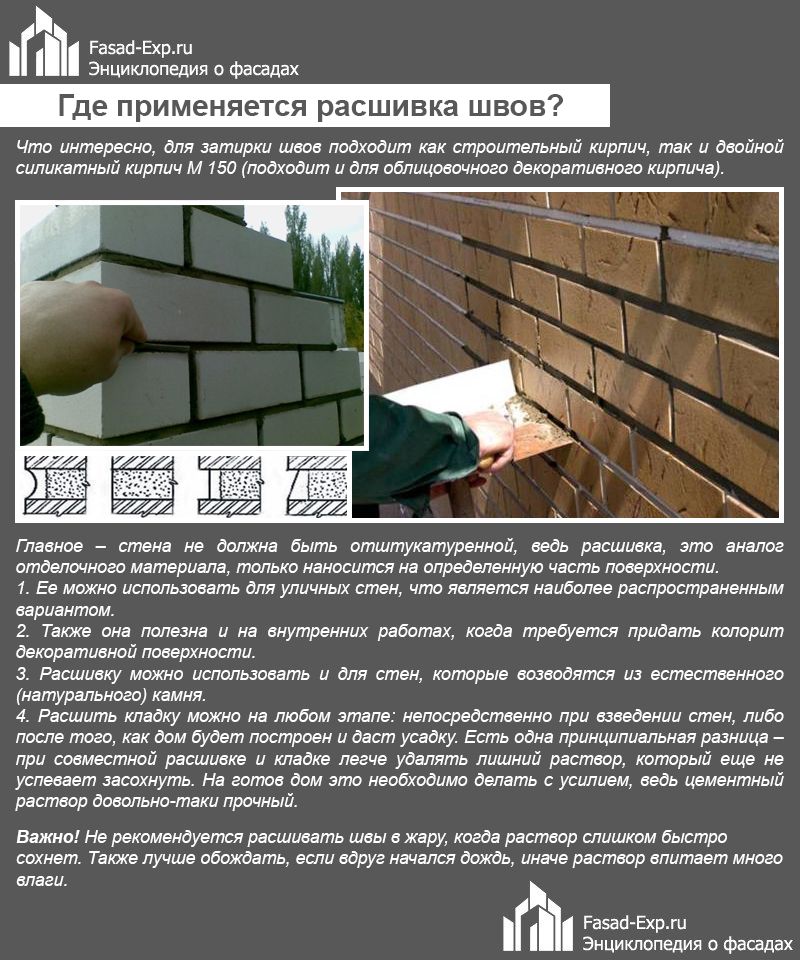

The material for the construction of a country house is often brick. It looks very elegant, while possesses and mass useful properties - For example, it retains warmth in the finished structure. And even finishing brick also brings considerable benefits, besides, it also performs aesthetic function. And to make the house more prettier, you can add the walls extra decorative elements. For example, putting seams brick masonry It looks spectacular, and it brings, as it turned out, considerable benefits.

Why is it needed?

The grout of the brickwork seams is the leveling of the seam bricks formed during the masonry process, their decorative design, possibly applying an additional layer of a solution of another color, which effectively emphasizes the correctness of the lines and the accuracy of the masonry itself. This is a peculiar way of finishing walls, thanks to which they will become more expressive and neat. Grout combines in a single whole seams horizontal and vertical, formed during brick masonry.

Brick masonry seams are needed not only to decorate the facade of the house. It makes a laying more resistant to weather conditions, increases its tightness, increases the life of the entire structure. That is, increases the density and strength of the laying seam and allows you to make the definition of its drawing.

On a note! Statting of the seams is not always able to improve the appearance of the masonry. If the work on the construction of the brick wall was carried out negligently and inactively, then the curvature of the seams and walls, the unacceptable pieces of surplus cement and other disadvantages will not fix the best and neatly applied mixture for the grout.

The main objectives of the use of grouting or batch boxes.

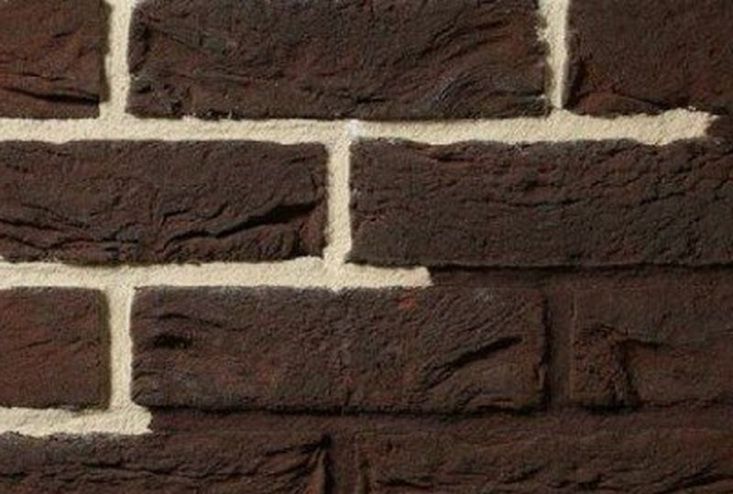

- Improving the appearance of the facade of the house. The use of mixtures for grouting having various shades (and the color scheme is rich enough for them), it is able to emphasize the accuracy of the brickwork. Frequently use contrasting shades, for example, in combination with dark bricks, it looks good light color and vice versa.

- The grout will protect against the moisture of the seams of the cement mortar, which will significantly improve the timing of its service, as well as at home and walls as a whole.

- Indicators of the heat and sound insulation of walls laid out of the brick, thanks to the grout of the seams increase significantly.

Where can the extending be used? After all, it is not always possible to see at home with such a finish, which means that theoretically, can I do without it? Grout is necessary if the walls of the brick house will not be facing or plastering.

Tip! If the walls of the house will be drawn up with the help of seams, then during masonry it is necessary to use only whole and neat bricks without flaws. And the seams between individual bricks must be one thickness, although some masters make horizontal slightly thicker vertical - this is a kind of designer move. In general, according to the requirements of SNiP, the thickness of the suture layer of the brick laying should be as follows: vertical seams from 8 to 15 mm, horizontal - from 10 to 15 mm.

Shutdown seams is suitable for bricks of any kind - construction, facing. The main thing is that the bricks themselves are beautiful if work is planned to be grouting precisely with aesthetic purpose. It looks very good on the facade walls of the house, and inside indoors. Also an excellent option may be putting the seams of masonry from natural stone.

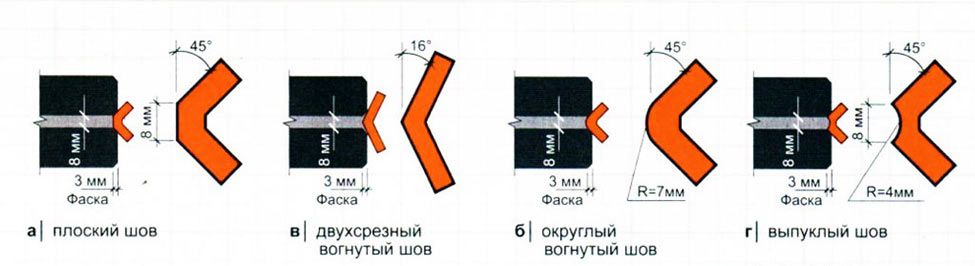

Methods of grout

Grouting of brickwork seams can be carried out in several ways. From this will depend on the effect, which will be given to the walls of the structure. We will get acquainted with the most popular of these ways.

Table. Methods of grouting seams.

| Name | Characteristic |

|---|---|

| Flush | This is the easiest way to grout seams and make it possible even without a special narrow spatula. The rapid solution laid in the slit, or the usual cement mortarwho protruded abroad bricks are simply removed by the Clavma from the wall. After that, the seam is processed by a rigid brush. |

| Concave | In order to make this kind of stamps of the seams, it will take a small spatula (wearing the name "extending"), which will be performed on the filling of the seams with a mixture and its seal. It should not be long to be able to fill them and vertical, and horizontal seams. Cement mortar from the masonry is cut into the flush, and then it is passed on it with a special extext spatula. According to the same technology, work is made with a special solution applied inside. |

| Convex | In this case, the spatula must be arcuate, it is applied to the seam outside the arc part, and the free space is filled construction mixture. Then the spatula is simply moving further along the seam, the process of applying the mixture continues. |

| Rectangular | But the rectangular way of grouting is more complicated. About 5-6 mm of solution are taken out from the seams (sometimes even dried), and then the gaps between the bricks are again condensed with a new solution. It looks like the finish is beautiful, but it is undesirable for facade work, as it takes the water badly. |

| Sleeve | An ideal outpan option for those houses that are built in the regions with a harsh climate. In this case, the solution inside the seams is cut into acute cells not exactly, but at a sharp angle of about 3-4 mm. |

What is used for grouting

What may be needed for grouting seams between bricks? Not much, as it might seem. First, you need a solution for grouting, the creation of which we will talk a little later. Secondly, you need and tools with which all work will be made.

For grouting seams will need:

- spatula (Kelma);

- "Turntable" for a perforator or a building mixer;

- the perforator itself directly to work with the "turntable";

- small sieve for sifting sand;

- capacity for mixing the solution;

- the extension of this size so that its width is equal to the width of the seam between the two bricks. If the vertical and horizontal seams have different widths, then you will need two types of this device.

Note that there are also the main tools that may be used. But in some cases they can not at all come in handy. For example, if you do not plan to make a curly gap, you can simply remove the fresh surplus of cement during masonry by Kelma.

Cooking mortar

The color of the grout solution is determined after the masonry is fully completed. But in general, the color gamut can be chosen even at the stage of selection of bricks. It is better to buy the most suitable materials suitable for each other in color, they must be harmonized among themselves, and not to cause a desire to immediately take a look from the wall at home. But often designers are experimenting with a combination of two bright contrasting colors, and such experiments are often very impressive and beautiful.

On a note! If the combat of the right color was not, then the seams can be lost and conventional cement-sandy solution. In any case, it will look nice, as it has a grayish natural color that is harmonizing with all other shades.

To prepare the mixture itself, with which it will be put on the seams on the brickwork, the following components will be needed:

- high quality cement - 4 buckets;

- clean small sand - 2 buckets;

- dry finished mixture for the preparation of the grout solution;

- clean water is about 6 liters.

Note: The volumes of materials are indicated approximately, but will allow approximately calculated costs.

To prepare a solution, you need to carefully sift the sand with a small sieve, remove large fractions from it and possible trash. One part of the entire sifted material further needs to be mixed with two parts of dry cement, after which some water is added to this composition and everything is mixed to the state of a thick mixture of homogeneous consistency with a building mixer. Then the mixture is added for the grout, water, again everything is thoroughly mixed.

The finished mixture needs to be broken. After the solution will swell a little, absorbing the liquid, it is mixed again. All, the solution is ready for use.

Quick MIX Series VK 01 - Masonry solution with a track for facial brick

The process of grouting seams of brick masonry, maybe monotonous, but rather simple. To carry out it for any person, so the owner of the country site will be able to cope with this task independently.

On a note! Work on the grout of the seams is important only when the brickwork is fully completed. Otherwise, there is a risk to ruin all your works. At the same time, it is important to take into account the weather conditions during the work, humidity and quality of materials used for grouting - all this will significantly affect the quality of all work.

Step 1. Masonry seams mold must be made according to a clean and prepared surface, it is desirable even that the cement solution is already dried. First of all, the surface of the seams is cleaned with a brush from garbage.

Step 2. Then washed with seams of ordinary clean water From the hose. In addition, this procedure will make it so that the brick itself does not pull water from the cement mixture.

Step 3. Create a solution for grouting in all the rules.

Attention! If a ready-made mixture is used for grouting, then it is necessary to prepare it as written on the package. The above instruction is just an approximate landmark.

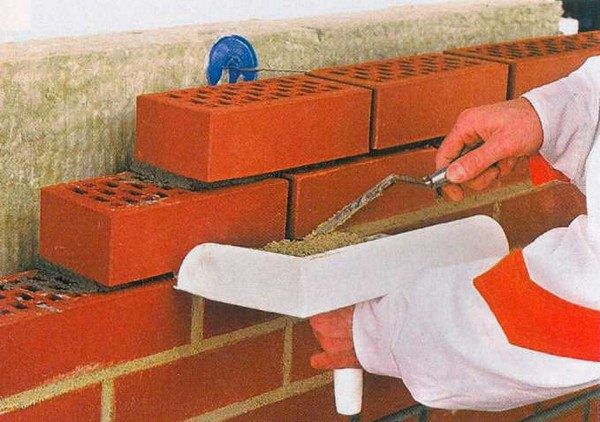

Step 4. The prepared mixture is placed on a large spatula, which is then attached close to the seam. Using a narrow bunch, the mixture is accurate, but quickly applied to horizontal seams, in the process slightly pressing the gap inwards to remove air from the cavity.

Step 5. Vertical seams are convenient to fill out, if you keep a little mix in the palm of your hand. By the way, the builders advise first to fill out vertical seams and only then go to horizontal.

Step 6. After filling in the seams of grouting, its residues are removed with a brush. Works are completed.

Attention! After applying the solution on the seam, it is important to immediately remove its surplus, if any. Otherwise, they sacrificed and spoil all the works. And you can form the shape of the seams when the solution slits a bit.

Video - way of grouting seams bricks

Stout seams of old masonry

Shutters can be made not only in fresh masonry. With this method, you can improve the appearance and old brick building. It is especially important if the solution in the gaps has already become collapsed, which deteriorates the thermal insulation of the entire structure.

If the seams are made on the old brickwork, it is necessary to first remove the part of the old solution (about 1-2 cm). This is done with the help of chisel and hammer. Also, wash the remaining of the old solution using a special apparatus acting on the masonry of a powerful stream of water (for example, mini-sink of high pressure).

The solution prepared as described above is applied in the usual way inside the gaps. It is important to monitor that during the work of the work the solution did not hit the vertical surface of the brick - there may be stains.

It is impossible to choose without understanding that this is an architectural element when it is necessary and what requirements for it are extended. Only with this data can be selected the optimal brick for the base, take into account all the parameters and operational characteristics.

And finally, several tips and secrets that will help improve the quality of the works.

Brickwork stamped seams - one of the most durable ways to design the appearance of the facade brick wall. It looks very impressive, and all work is easy to spend independently without resorting to the help of specialists. And this is undoubtedly a huge plus.

("Config" :( "IDPartner": 29 "," SiteID ": 163))