The best sandy gravel mixture. How to compact building crusp

- Types of rubble and specifications

- Seal ratio: Purpose

- How to determine the seal coefficient?

Crushed stone is a common building material that is obtained by crushing the rock solid. Raw materials are obtained by conducting explosive work during career developments. The breed is crushed into the corresponding fractions. At the same time, the value has a special coefficient of sealing crushed stone.

Granite is the most common, since the frost resistance is high, and the water absorption is low, which is so important for any construction design. Estimacy and strength granite rubble Complies with standards. Among the main fractions, rubble can be noted: 5-15 mm, 5-20 mm, 5-40 mm, 20-40 mm, 40-70 mm. The most popular is the crushed stone fraction 5-20 mm, it can be used to keep various works:

- construction of foundations;

- manufacture of ballast layers of trails and railway tracks;

- supplement to building mixes.

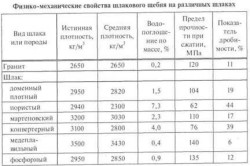

The seal of rubble depends on many indicators, including its characteristics. Should be considered:

- The average density is 1.4-3 g / cm³ (when the seal is calculated, this parameter is taken at one of the main).

- Beshechy determines the level of the material plane.

- All material passes sorting by fractions.

- Frost resistance.

- Radioactivity level. For all works, you can use rubble grade 1, and the 2nd class can only be used for road.

Based on such characteristics, a solution is made, which material is suitable for a certain type of work.

Types of rubble and specifications

Crushed stone for construction can be used different. Manufacturers are offered different types of its properties that differ from each other. Today, the type of raw crushed stone is accepted to divide on 4 large groups:

- gravel;

- granite;

- dolomite, i.e. limestone;

- secondary.

For the manufacture of granite material, the corresponding breed is used. This is a nonmetallic material that is obtained from solid rock. Granite is a frozen magma, which has a lot of hardness, processing it is difficult. The crushed stone of this species is manufactured according to GOST 8267-93. The most popular is a crushed stone having a 5/20 mm fraction, as it can be used for a variety of works, including the manufacture of foundations, roads, platforms and other things.

Gravel crushed stone is a building bulk material, which is obtained when crushing the rocky rock or breed in careers. The strength of the material is not as high as the granite rubble, but the cost of it is lower as the radiation background. Today it is customary to distinguish between two types of gravel:

- crushed varieties of rubble;

- gravel river and maritime origin.

According to the gravel fraction, class 4 large groups: 3/10, 5/40, 5/20, 20/40 mm. Used material for cooking various construction mixes As a filler, it is considered indispensable when mixing concrete, construction of foundations, tracks.

Limestone crushed stone is made of a mining sedimentary breed. As it is clear from the title, the raw materials are limestone. The main component is calcium carbonate, the value of the material is one of the lowest.

The fractions of this rubble are divided into 3 large groups: 20/40, 5/20, 40/70 mm.

It is applicable for the glass industry, in the manufacture of small reinforced concrete structures, in the preparation of cement.

Secondary crushed stone has the lowest cost. Make it from the construction trash, for example, asphalt, concrete, brick.

The advantage of rubble is low cost, but according to the main characteristics, it is very inferior to the rest of three types, therefore it is rarely applied and only in cases where the strength of great importance does not have.

Back to the category

Seal ratio: Purpose

The seal coefficient is a special regulatory number defined by SNiP and GOST. This value shows how many times the crushed stone can be seal, i.e. Reduce its outdoor volume when traaming or transportation. The value is usually 1.05-1.52. According to existing standards, the seal coefficient may be as follows:

- sand and gravel – 1,2;

- construction sand - 1.15;

- keramzit - 1.15;

- gravel crushed stone - 1,1;

- soil - 1.1 (1.4).

An example of determining the sealing coefficient of rubble or gravel can be given as follows:

- It can be assumed that the density of the mass is 1.95 g / cm ³, after the seal was performed, the value was 1.88 g / cm³.

- To determine the value, it is necessary to divide the actual level of density to the maximum, which will give the coefficient of the seal of the rubble 1.88 / 1.95 \u003d 0.96.

It should be noted that the project data does not usually indicate the degree of seal, but the so-called skeletal density, i.e. During calculations, the level of humidity, other parameters of the building mixture, must be taken into account.

The coefficient of the seal of rubble is a dimensionless value that characterizes the degree of decrease in the external volume of the material as a result of a tamping or natural seal during transportation. This parameter and order of its accounting during construction work is governed by the current GOST and SNiP, in particular GOST 8267. Its value depends on the material brand and is 1.05 - 1.52. For example, the sealing coefficient of the granite rubble is, on average, 1.1, at the schsps - 1.2.

What requires a seal coefficient

This parameter is required for:

- calculating the mass of the acquired material;

- definitions of material shrinkage during construction work.

Knowing, for example, the sealing coefficient of 20-40 seal can be determined by a mass of material, multiplying the existing volume (car, truck body, containers, etc.) on bulk density and seal coefficient.

Also, the seal coefficient is required to calculate the required amount of materials for the site planning. For example, when crushed 5-20, with a thickness of the layer, 20 cm we get:

1 * 0.2 * 1600 kg / m3 (rubble density) * 1,2 \u003d 384 kg per 1 m2 area, where 1.3 is a seal coefficient of 5-20.

It must be remembered that the coefficient of seal depends on the rubble fraction than it is larger, the less. Thus, the coefficient of sealing the rubble 40 70 fraction is higher than 5 20, which must be taken into account when designing construction work. When calculating it is necessary to consider that in the project, as a rule, it is not indicated by the degree of seal, but, so on. Skeleton density. This means that when calculating it is necessary to take into account the level of humidity and other parameters of the material.

Methods for determining the seal coefficient

The coefficient of the material seal is determined by the manufacturer and is indicated in the passport, accompanying each batch. Often there is a need to determine the coefficient of sealing rubble when traaming and at the construction site. The measurement is performed using a densector under the condition of the content in the material not more than 15% of the particles whose size exceeds 10 mm. The accuracy of the definition is 90 - 100% of the standard density according to GOST.

The material seal is determined by the testimony of the resistance when the tip is immersed - a conventional or truncated cone, depending on the type of mixture. The indicator is determined to deviate the arrow of the instrument indicator.

The measurement is made by strictly vertical immersion of the device cone in a mixture with the necessary pressure. Each point is measured 3-5 times with a distance between a 150 mm immersion site. Next, from the results of measurements is determined average value. Using the graph attached to the device and the average data obtained is determined by the coefficient of the seal of the crushed stone during the trump.

The best option is the acquisition of rubble directly from the manufacturer, bypassing intermediaries. It is beneficial from the point of view of prices, supplies, quality, as well as the availability of all the necessary documentation with the rubble parameters based on the data of laboratory studies.

Crushed stone - common building material produced by crushing mountain breeds or artificial materials. One of the parameters defining the operational properties of the material is the seal collaffic. This is a dimensionless value that characterizes the degree of reduction in the external volume of a bulk substance during transportation or tamping with special tools. Knowledge of the coefficient will allow you to purchase the required amount of material and avoid the destruction of the bulk layer during the load due to insufficient seal.

Find any standard value for this case is difficult because it is influenced by many factors:

- the height of which was made of the material;

- the length of the path and quality of the road;

- transport feature;

- the fraction and the testicle of rubble (the teaching grains are stacked with a large number of voids, compared to cuboid).

When delivering significant batches, the difference between volumes - loaded and delivered is quite significant. The seal coefficient is indicated in the supply contract. According to GOST 8267, this value should not exceed 1.1.

Sealing coefficient of rubble at the construction site: the value and method of its determination

- bulk material with grains of different shapes. When using a material for laying a preparatory layer, it is necessary to reduce the amount of voids that reduce the degree of resistance to the loads. Therefore, the tamper is a mandatory procedure for the maintenance of roads and foundations. The seal coefficient of rubble for road construction is regulated by SNIP 3.06.03-85:

- for grades with strength 800 and more fractions 40-70 mm and 70-120 mm, the seal reserve coefficient is 1.25-1.3;

- for brands with strength 300-600 - 1.3-1.5.

The level of rubble seal is determined using a densector - tool with a tip in the form of a truncated or conventional cone. The tool selection is determined by the characteristics of the material being checked. Check process:

- the densemer is vertically adjusted to the surface;

- with pressure immersed in a compacted mixture;

- the magnitude of the seal is determined by the deviation of the arrow;

- at each point, 3-5 measurements are performed;

- the distance between the measurement points is approximately 15 cm;

- the results obtained are summarized and found the average.

Attention! If the seal was carried out with a violation of technology - only on the upper layer, and not layerly, then the coefficient will not correspond to the actual degree of seal.

How to seal rubble with your own hands?

Manual tamping is relevant when performing small amounts of work, since it requires significant physical effort. Options for simplest devices:

- Bar 100x100 mm and length depending on human growth. The optimal option is the length of the bar before the chest. The amount of section can be increased to 150x150 mm. At the top Mount the handles made of metallic rods or wooden bars. The lower edge of the bar is bubble with a galvanized sheet. The principle of operation is very simple: the timber is raised to the highest possible height and are lowered to the trambeum surface. The Tambrovka Square is not too big, but this seal option is the most economical and simple.

- A more efficient option - a metal headband attached to wooden bruusperforming the role of the handle.

- The most durable is the design made entirely of metal. Working with such a tool is effective, but is complicated by the vibrations that metal, in contrast to the wood, is not reputed.

For the tamping of a bulk material on a spacious platform, on which there are no buildings and plantations using a car. The brought material is evenly spilled over the surface with robbles or shovel, and then driving through the territory in different directions. The resulting ruts fall asleep with rubble.

Seal rubble vibroplitoy

With this equipment, you can perform quite large volumes of work in places where the use of rollers is difficult or impossible. Plates differ by mass, vibration strength, paw area, engine type. By weight, the aggregates are divided into:

- Light - approximately 75 kg. Used for thin sandy layers in the device of flower and tracks.

- Universal - up to 200 kg. Used for ground and asphalt tamping.

- Agel - up to 400 kg. In demand for working with rubble.

Equipment management type: manual or remote. In the first case, the speed of work is small.

By type of engine distinguish:

- Electric plates. Used in places where there is access to an electrical power source. These are usually small aggregates that can work on thin layers.

- Gasoline models. Compared to the previous type of equipment, have a large mass, engine power, performance and cost. Significant plus is the lack of necessity in the source of power supply.

- Diesel unit. Reliable, high-performance, with a large resource.

Another distinction is the number of directions in which the model moves:

- single equipment can only move forward, its plus is a larger working period, compared with reverse options;

- reversable vibrating plates can move and forth.

Effective Method of Tamble Rubble - Outline

If it is necessary to obtain the maximum dense base, the method of collapication is used.

Definition! Oblonging is laying the base using a crushed stone of various fractions. At the same time, the voids between the grains of large size are filled with fine-mellular rubble.

Stages of construction:

- laying grains of fractions 50-70 or 80-120 mm;

- sealing by vibrating or rink;

- failure of rubble shallow fraction;

- seal;

- adding material with even smaller grains;

- seal

For the most dense base, three collapsing is carried out. To reduce grain friction shed water. Outlinking can be used in road construction, manufacturing products of products and structures.

GD Star Rating

a WordPress Rating System

Crushed stone is a popular building material, due to which it is possible to solve many problems in the field of construction. The process of obtaining material is carried out using crushing of the mountain solid. The extraction of raw materials is carried out by the method of explosive work during career development.

After that, the breed is crushed to the desired fraction. In addition, the crusher is assigned a certain seal coefficient. Consider more, for which this parameter is needed and how to determine it.

Chemble is an extremely popular material. Thanks to him, it is possible to build very durable and reliable designs. But in progress, many people do not take into account the construction of such a parameter as the seal coefficient.

It is he who plays a special role during a shrinkage of the house. If the process of measuring this parameter passed incorrectly, it will affect the durability of the built building. As a result, shrinkage will occur and cracks will go on the surface of the house.

What the crushed stone differs from gravel, you can learn from this

The seal coefficient is an immeasurable number, which indicates the degree of reduction in the external volume of the bulk component when it is transported or tamping. Apply the seal coefficient to sandy gravel mixtures, sand and crushes.

What crushed stone is needed in different cases

The soil seal with rubble is used in the case when it is necessary to build a certain home. Thanks to technological process It is possible to fulfill all the tasks and not get the appeal of the subsequent layers. If the sealing process is incorrect, then over time, the crossbank layer and the rammed soil will give a cage. As a result, slots will be formed on the surface.

What is the significant difference between gravel and rubble indicated in this

The rambling rubble is mandatory events for those who wish to get durable and qualitative foundation When erected expensive and buildings. To perform the rambling, you need to use special equipment. We use a rink or vibrating plate more often. If there are small volumes, the material will be touched manually.

Check the quality of the package performed is necessary using a special instrument. These events are considered mandatory, otherwise poor-quality rambling entail a lot of trouble. During the measurement, it is necessary to determine the degree of traam. This is done with the method of dynamic sensing.

To carry out the weight of the event to determine the coefficient on its own very difficult. As a rule, people seek help in a special laboratory. It is necessary to apply static equipment in cases where need operational control over all the values \u200b\u200bof the sealing solutions is needed.

It is possible to apply this method not only when determining the coefficient for rubble, but also for sand, other bulk materials. But at the same time, in the test mixture there should be no particles with a greater capacity of 10 mm. The percentage of their content may not exceed 15%. The equipment can show reliable results with an error of 0.9-1 from the standard of density of GOST 22733.

How many rubble is part of a light concrete indicated

The process of determining the seal level is carried out taking into account the air tip shore, as well as taking into account the resistivity. Depending on which the mixture is used during construction, a truncated or ordinary cone can act as a tip. It is possible to determine the seal coefficient by the level of deflection of the arrow of the indicator when the ring is deformed.

Learn about what is it possible in this article.

The procedure itself to determine the coefficient of the seal of rubble is not long and simply. It is necessary to take a densemer in the hands and bring it vertically to the surface. After that, lower the tip in the mixture with pressure. As a result of the actions described, the instrument will extract and mark the indicators received. For a specific point, it is necessary to make measurements 5 times. A step between points should be equal to 15 cm. After conducting such experiments, the indicators compare and build a specific schedule according to which the necessary coefficient is determined.

What it is indicated in the description of the article.

The density coefficient is a very important indicator, thanks to which it is possible to build houses, roads and not worry that a shrinkage will happen after a while. The process of determining this parameter does not imply anything difficult. If you can get to the densemer, then there should be no problems.

Coefficient of sealing (trimming) of PGS, sand, rubble, soil.

Seal coefficient (purchase) - This is a regulatory number, which is determined by the gtales and on the bottom, which takes into account how many times the bulk material (namely, the PGS, sand, crushed stone, soil, etc.) compressed (therefore, it has decreased and its external volume) during transportation and tamper. Its value varies in the range of 1.05 - 1.52: The seal coefficient is taken into account from the volume of the rash material (soil, PGS, sand, crushed stone, ceramzite, etc.), as well as the sealing mechanism (tamping). Much important is the quality of inert material. For example, the PGS (sand-gravel mixture) may contain different gravel content (from 10% to 90%), and hence to change TOfILE Based on this, the data in the table is provided with average.

The coefficient of the seal is called a dimensionless number, showing the degree of reduction in the external volume of the bulk grain building material With its transportation by transport or traam. Used applied to sandy gravel mixtures, sand, rubble, soil.

Each type of rubble has its markings specified in the adopted standard (GOST 8267-93). It describes the methods for determining the seal coefficient. Manufacturers must specify this parameter in the marking of the rubble of one or another type. The degree of seal is also determined by experts experimentally. Results can be obtained within 3 days. The magnitude of the seal of rubble is measured and expressed by methods. This uses static and dynamic denneters. Expenses for measuring the value of the coefficient in the laboratory conditions are significantly lower than right on the construction site.

Why do you need to know the value of the seal coefficient?

Knowledge of the exact value of ku (coefficient of sealing the rubble) is required to determine: a) the mass of the purchased construction material; b) degree further shrinkage rubble in construction work. In both cases, errors can not be allowed.

The mass of rubble (in kg) can be calculated by moving the values \u200b\u200bof 3 quantities:

- volume of filling (in m3);

- specific gravity (in kg / m3);

- the seal coefficient (in most cases ranges from 1.1 to 1.3).

Specialists use the tables of the average mass of rubble depending on the fraction. For example, in 1 m3 Crushed stone fits 1500 kg fraction 0-5 mm and 1470 kg - fractions 40-70 mm.

Work with bulk materials is connected with such a magnitude as bulk density. Its accounting is obligatory in the process of construction, laying of rubble, calculating the composition of concrete. Its value is determined by the experimental way with the help of special vessels (up to 50 l). For this, the mass difference is empty and filled with a crushed vessel, it is divided into the volume of the vessel itself.

Otrugtzovka - dense laying of rubbed base with the help of grains of various fractions. The essence of the technology is filled with large voids between large grains of small pieces.

Trubovka - One of the mandatory conditions for strengthening the foundation of roads or the foundation bases of buildings. It is carried out using special equipment (mechanical rink, vibrating plate) or manual traam. The quality of the seal is monitored by a special device. The amount of seal (traam) can be defined by several methods. In particular, the method of dynamic sensing.

Seal coefficient Also used when calculating need quantity bulk materials for laying a rubble site. Let the thickness of the styling - 20 cm. What amount of dropout do we need for 1 m2 of the site? Multiplying the volume of the plot on specific gravity (1500 kg / m3) and on the seal coefficient (1,3), we obtain 390 kg.

It should be remembered that the various fractions of rubble have a different seal coefficient. This parameter is gaining great importance when performing designer based on rubble.