Weight cube rubble 20 40 granite. What is the volumetric weight of the crushed stone of different fractions? Fraction, shape, water absorption

Under the crushes they understand the stone obtained as a result of grinding mountain breeds, PEMZ, bricks, domain slags. From technical characteristics This material depends on how durable and reliable will be built, erected with its participation.

Average density Rubble when crushing on the fraction is 1.6 t / m 3 (for a bulk form). When calculating the required amount, most conveniently operated by the volume weight of the bulk type rubble (in the dry state). So, on average, 1 cubic meter of bulk material will weigh 1.6 tons.

Asphalt cement sticking to the aggregator is somewhat more complicated than a new asphalt cement. This is primarily due to the effect of asphalt on atmospheric oxygen during use and weathering. A typical range of particle size distribution for reduced asphalt coating.

Physico-mechanical properties of restored asphalt coating. Asphalt cement consists of predominantly high molecular weight aliphatic hydrocarbon compounds, but also small concentrations of other materials, such as sulfur, nitrogen and polycyclic hydrocarbons with a very low chemical reactivity. Asphalt cement is a combination of asphaltenes and maltentes. Asphalt are more viscous than resin or oils, and play an important role in determining the viscosity of asphalt.

By the size of fractions, crushed stone is classified into groups:

- I - the dimensions of the fraction up to 5 mm (screening). The storage grade varies within 100-400, the content of dust particles - up to 25%.

- II - fractions Size 5-20 mm ( request material). Dust-containing minimum. Strength of 1400-1600 and 800-1200;

- III - the dimensions of the fraction of 20-40 mm. Building materials related to this group enjoys the greatest popularity. The dust content does not exceed 35%, while the strength of the material reaches 1000.

- IV - 25-60 mm. In construction, this material is used quite rarely. The content of dust particles does not exceed 0.25%, while the storage grade varies in 1000-1200 converters;

- V - 40-70 mm. Dive-containing - up to 0.68%. Strength - within 1000-1200.

There is a crushed stone of fractions 70-120, 120-150 and 150-300 mm (Booth). It is used in decorative purposes (decoration of pools, reservoirs, fences).

The oxidation of the pressed asphalt causes the oil to convert into resins and resins to convert into asphalt, which leads to hardening and more viscous binder. Rogers. "Ontario's experience with restored materials for use in aggregates." Presented at the International Conference of the Road Federation, Calgary, Albert, Magni. The use of bitumen and concrete material in a grainy and on Earth. . The supply of mineral building materials is one of our basic advantages, regardless of the number you need.

The main properties of rubble:

- Beshech. In the testicle (elongation and flatness of Kherehen), the material is classified into 3 groups:

I - up to 15% - cuboid;

II - up to 25% - extended;

III - up to 35% - normal.

- Frost resistance. Crushed stone can have frost resistance classes, starting with F15 and ending with F400. Construction uses material with a frost resistance of F300 and more.

- Strength. The high-strength type includes material with the characteristics of M1200-1400, to a durable - 800-1200, medium-strength - 600-800, low strength - 300-600.

- Radioactivity. This parameter is closely related to the quality of the building material. In private construction, crushed stone I am a class of radioactivity (up to 370 BC / kg), in road construction II class (no more than 740 BCs / kg) is used.

- Density. The average density of the material is 2600 kg / m 3.

We deliver them to you in small quantities, freely inclined or stored in a container to large quantities with the delivery of the corresponding bulk materials. Of course, we also provide you with a large number of mineral building materials for self-assembly in our factories.

Please note: We do not store all the above building materials at all our factories, and then the factory number, so you can see if the desired building material is available at the appropriate factory. Attention: Special prices for direct deliveries are free.

What is the proportion of rubble?

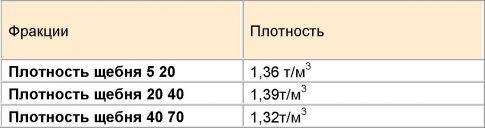

Often this characteristic, as a density with respect to this material, is not used incorrectly. As is known, the density of rubble is equal to 2600 kg / m 3, but there is such a concept - a bulk density. Under the bulk density, we understand the weight of 1 cubic meter of building materials in natural condition - Taking into account the voids between the grains. The volumetric weight of the rubble directly depends on the fraction and density. The larger the stone fraction, the lower the bulk density. This indicator is especially important in the production of concrete mortar.

You have special requirements for building materials that are not listed, or you need them in large quantities, no problem! Roughly speaking, this is usually allocated to free-member and cohesive bulk materials. Depending on the product available various brands, basic colors or bulk materials, such as sand or sand.

Building materials for decorative design - Now check the availability of the desired products!

To make your choice, select the perfect and ready-to-use product for your project and insist the quality of such properties such as frost and resistance to weathering, as well as effective efficiency against weeds. Basal split is an example of a bulk material that is suitable not only for practical construction projects, such as the substructure on terraces, but also very attractive for decorative purposes. Take a look at our wide range of various bulk materials and make sure that the versatility of the products.

There is a dependence - the higher the degree bulk densityThe smaller the cement is required. Also important is the indicator and during the transportation of building materials. Knowing this amount, you can easily steer the necessary vehicle capacity and warehouse capacity.

The density or proportion of rubble is 5-20 mm - 1.35 t / m 3, for fraction 40-70 mm -1.52t / m 3, for a fraction of 25-60 mm - 1.37 t / m 3, for dropping 0 -5mm - 1.41 t / m 3, fractions 20-40 - 1.35 t / m 3.

Varieties and application

Alacata solution for dissolution must perform a plurality of quality criteria to withstand all external adverse effects. A ready-to-use solution for plastering, which you can use for the water permeable grout of plaster surfaces, for example, in the garden, inlet or on the terrace, is convinced of its resistance to atmospheric influences and high load capacity. The volumetric material is resistant to abrasion, effectively prevents the formation of weeds in the joints and easily transfers random driving vehicles.

Why is the volumetric weight of the rubble of different types differ?

The following characteristics have direct impact on this indicator:

- Type of material. For example, the proportion of the touched stone is 800 kg / m 3, and slag and marble - 1500 kg / m 3.

- Form and size of fractions. These parameters affect the volume of volume. At the same time, the lambs of rubble is the greatest value. Cuboid forms of material have a high seal, lamellar and needle - contribute to creating voids, which leads to significant consumption of material, for example, when creating concrete solutions. For dense filling, it is necessary to use a low-body material (up to 15%), for the "pillow" and the iltumps fits crushed stone with a leachy of 25-50%, forming a large number of voids.

Groups of gravel products and sand. Here you will find an explanation of various groups of products, from the production of gravel and sand. Since the applications of sand in the construction sector are diverse, there is also a number of terms in which the specific sand fitness is expressed directly.

Building plaster and sands are used. For the production of construction gravel and sands from gravel and sand sand from a sediment, raw materials are processed by washing and seven. During the washing process, separated components are removed, such as IL, clay, clay or woodcase particles. At sifting, the resulting material is divided into different grain size classes, which are then used as needed.

Adygea (Republic) Altai (Republic) Altai Territory Amur region Arkhangelsk region Astrakhan region Bashkortostan (Republic) Belgorod region Bryansk region Buryatia (Republic) Vladimir region Volgograd region Vologodskaya Oblast Voronezh Region Dagestan (Republic) Jewish Autonomous Region Transbaikalsky Krai Ivanovo region Ingushetia (Republic) Irkutsk region Kabardino-Balkarian Republic Kaliningrad region Kalmykia (Republic) Kaluga region Kamchatsky Krachay Karachay-Cherkess Republic Karelia (Republic) Kemerovo region Kirov region Komi (Republic) Kostroma Krasnodar region Krasnoyarsk region Kurgan region Kursk region Leningrad region Lipetsk region Magadan region Mari El (Republic) Mordenia (Republic) Moscow Moscow Region Murmansk region Nenets autonomous District Nizhny Novgorod region Novgorod region Novosibirsk region Omsk region Orenburg region Oryol region Penza region Perm Krai Primorsky Krai Pskov region Rostov region Ryazan region Samara region St. Petersburg Saratov region Sakha (Yakutia) (Republic) Sakhalin region Sverdlovsk region North Ossetia - Alania (Republic) Smolensk region Stavropol region Tambov region Tatarstan (Republic) Tver region Tomsk region Tula region Tyva (Republic) Tyumen region Udmurt Republic Ulyanovsk region Khabarovsk region Khakassia (Republic) Khanty-Mansiysk Republic Autonomous Okrug Chelyabinsk Region Chechen Republic Chuvashskaya republic Chukotka Autonomous Okrug Yamalo-Nenets Autonomous Okrug Yaroslavl region

This includes, for example, frost resistance and thawing agents, a fraction of the swelling components of organic origin, the content of water-soluble chlorides or the content of separated components. Gravel and sand for road, deep and road construction, the construction of landfills.

The cuttings are either deliveries that do not meet the increased requirements for noble slabs, or all the delivery, at which the bottom and upper nominal screen width are not directly nearby. They can be made by direct screening or by assembling neighboring grains.

Crushed stone is auxiliary building materialand characterized by quite frequent use in various situations. The specific direction of application of rubble depends on its origin, fraction and some other parameters.

Granite rubble medium fraction

The most widespread crushed stone from the granite of the middle fraction with a particle size of 20-40 mm. Due to these by the following factors:

Table of the most important scales of units and individual scales

If several chips are combined. Your crane is a high-quality large block that will provide you with constant availability. Density indicates. How harder is heavier or lighter than the water of the same body. Concrete blocks apart: hollow block with recesses.

Precast beams for solid ceilings. Round concrete pipes without legs. Wastewater and septic tanks. The wire ropes of the wiring harnesses must be laid when: the braid is damaged, strong wear is noticeable, corrosion scars appear, there are folds, wrinkles or fuses, teeth, butt damage or clamp are detected.

- The material of the origin of rubble (granite) is characterized by strength, resistant to negative environmental factors and high-load resistance.

- The 20-40 mm fraction successfully combines the advantages of rubble small fraction and large.

- The cost of this type of material is also quite medium.

The foregoing allows us to use this type of rubble in the production of concrete and reinforced concrete products, when preparing pillows for road construction or under the foundation.

Stop cable should also not be used if one of the two next numbers of visible wires is detected in the worst point. Chains should not be used in lifting, if. A whole chain or a member has an extension of 5% or more, or a chain or part of it is rigid, or the initial thickness of the limb decreased by more than 10% anywhere. Ropes and chains should not be loaded beyond their maximum permissible load.

Calculation of the seal coefficient

In the case of stop ropes and chains with more than two threads, only two threads can be considered reference. When using stop ropes and chains as possible permissible loads Must be calculated in accordance with the appropriate angle of inclination. Invalid tilt corners of more than 60 °. In such cases, it is necessary to always take into account the carrying ability of one thread.

Weight rubble

Since crushed stone refers to bulk materials, usually, its measurement is carried out in volume measures, that is, in cubic meters. In some cases, we need to better know the weight of rubble more or less.

- During transportation;

- When planning the outcome weight of the reinforced concrete product;

- When calculating the loads on the soil and other structures rendered by a cushion from rubble.

Weight rubble depends on various factors:

When lifting items with sharp edges, the ropes and chains must be protected from damage using mild intermediate layers, such as wood. If stretch cables and chains are diverted several times around the load, the windings must lie close to each other without intersecting.

When using lifts, use ropes that do not twist. Plastic shells or coated cables should not be used. Loads should not be loaded by lifting ropes. The formation of cable loops should be avoided. Bending ropes at the edges or on rollers of small diameter reduces load capacity. In such cases, cables with higher bearing capacity should be used. With a strong frost load bearing capacity significantly decreases. Wire ropes must be protected from humidity.

- Material of origin;

- Fraction size;

- Water absorption coefficient.

Since the granite crushed stone of the middle faction is the most popular, and consider it in more detail.

Determining weight factor is the material of origin. For example, a cubic meter of a tumped rubble (porous, light materialIt will weigh about 800 kg, and the same cubic meter from sandstone is 1.3 tons. If we consider the granite crushed stone of 20-40 interested in us, the weight of 1m3 will be about 1,400 - 1 500 kg.

Care I. maintenance Also include lubricant. Heavy contaminated cables must be cleaned from time to time. Wire ropes must be checked at regular intervals to ensure their operational safety. Special attention should be paid to parts of the ropes that pass through cable pulleys or which are located near the pendants of the rope or rope devices.

Weight rails of tower rotational road systems

Chains should not be tied. Before use, twisted chains must be rotated. Turning chains should not be repaired, clinging together with wire or with the help of the wire. Screws are held together. It is intended for applications in which special requirement is not required.

In other words, the more denser the source material, the hardest it will be crushed stone.

The next important factor is the size of the fraction. What it is less, the less emptiness between the particles. Thus, rubble completely fills the volume, and the cubometer of small rubble will weigh more than the cubometer is larger, but to a certain limit. If the fraction refers to large, then the voids between the particles are compensated by the weight of the particles themselves and general weight Rubble in the cubic meter is growing again.

It is used in all types of work for which special cement is not required, namely. Pre-mixed concrete precompanied and reinforced concrete structures Paving, runways and bridges Channels and water pipes Prefabricated blocks and elements Brickwork cement floor. Due to its excellent workability, rapid evolving resistance and high resistance is especially recommended.

Heavy concrete concrete in the marine environment Concrete sidewalks in general and, in particular, those placed on high-performance equipment, and those that have quick transit qualifications. Constructions with sliding formwork concrete during periods of low temperature. . To achieve solutions and concrete with sufficient strength, durability and volume stability, it is recommended to strictly follow all current specifications using.

The fraction of 20-40 mm considered by us is medium, and it is its weight in the cubic meter that will be minimal. For granite rubble It will be approximately 1,400 - 1,410 kg.

Secondary weight factors

The leachy of particles is less affected by weight, but still noticeable. The amount of emptiness in the crushed stone with high brees will be greater than the rubble with low indicator. Accordingly, it will be less than the average.

Use well-balanced, clean and secure units. To avoid using aggregates with a delayed shape and very small sands, as they increase the need for water in mixtures, which reduces the resistance and impermeability of the solution or concrete and increases the risk of cracking.

It is recommended to use as much water as possible, for which it is vital to use the plasticizing additive of the average radius of action and avoid using very liquid mixtures, since it reduces the resistance and impermeability of the material and increases the risk of cutting cracks.

Similarly, the high coefficient of water absorption increases the weight of rubble due to the addition of the weight of absorber water.

Important clarification

Please note that the specified numbers are averaged. If you're important to know accurate weight The rubble used, it is necessary to resort to a special procedure for weighing bulk bodies, which allows you to determine the weight adjusted for all possible factors.

Reducing construction terms Rapid on to be preloaded before and after load.

- Increase security if the dosage is saved.

- Increase durability by reducing the porosity of the paste.

This is a granular material of inorganic, natural or artificial origin, intended for construction purposes. The main function of the unit is the creation of a solid concrete frame with a minimum interval. We distinguish the aggregates depending on their origin, bulk density, size and grain size.