The volumetric weight of rubble 20 40. What is the density of the granite rubble and its proportion? How to determine the exact weight of a cubener cubic meter

Crushed stone is a building stone resulting from grinding mountain breedsas well as from pums, bricks, metallurgical waste. From technical characteristics The quality of the obtained concrete, its brand, etc., the quality of the obtained concrete, its brand, and other parameters, are played by a very important role or bulk density of rubble.

Secondary crusher This crusher is usually designed to repeated crushing the primary crusher of smaller size or deviation from the primary crusher. The deposition is very thin material in the drain of water and stormwater, originating from natural, mechanical and human disorders. The sediment particles originate from weathering and erosion of rocks or unconsolidated deposits and are transported, suspended or precipitated with water or air. Consists of clay, sludge and sand.

Separation. The trend of large aggregate is separated from concrete and accumulate on the one hand, since concrete passes from unlimited ends of trays, conveyor belts or similar devices. The contents of the shell The content of the shell particles in a large filler passing through a sieve of 10 mm and held on a sieve 5 mm.

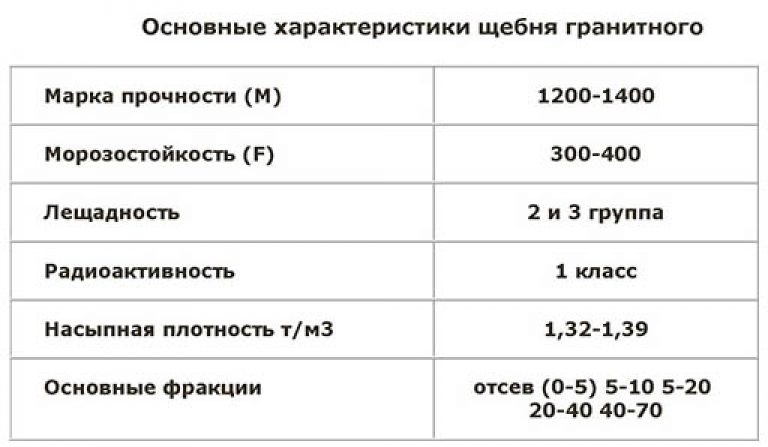

What depends on the density of the granite rubble?

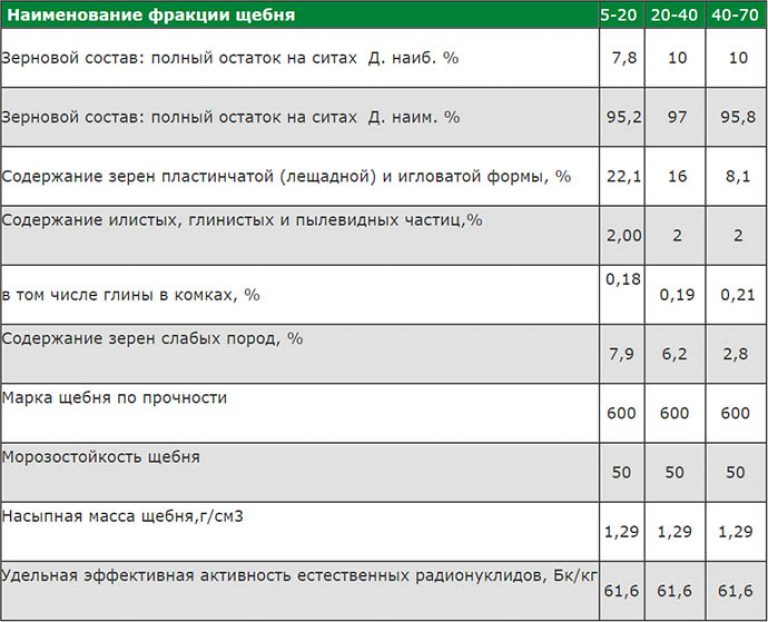

What is the density of the substance known from the school course of physics is the ratio of the mass of matter to its volume. The density of granite is 2,600 kg / m3, however, the above-mentioned turning table of the main fractions gives other indicators;

Table 1. Density (specific weight) of various rubble fractions

Impact load shock load material, such as aggregate or concrete, when it is released or discharged during placement. Shrinkage. The properties of the solution in a portland cement concrete, which is subjected to shrinkage, since it dries as a result of hydration and evaporation.

The proportion of granite

Eloquent grain of rocks from 002 mm to 06 mm. A single unit aggregate having a major fraction of particles lying between narrow sizes. The site of the land or water area, where the physical or physical location or activity of any object or activity or all disturbed and undisturbed lands are within the legal limits of ownership.

As you can see, the density of the rubble fraction 20-40 is 1.35 t / m3 or 1350 kg / m3 - almost two times less than the density of granite in an unfinished state. Such a big difference is formed at the expense of aircraft, due to which the indicator itself is bulk density. The fraction of crushing plays a big role - how it is smaller than the higher the specific weight. Therefore, the density of rubble is 20-40, due to the smaller amount of aircraft is higher than the density of rubble 40-70, large-scale construction stone. It should also be borne in mind that, density granite rubble Indicated in a dry state.

The importance of the incomplete density of rubble

Slip Resistance The property of the paved surface, which ensures resistance to the drift. Slurry printing surface treatment of the road using a mixture of fine aggregate and emulsion in the form of a suspension on the existing coating. Test for resistance to sodium. The test method used to determine the characteristics of the freezing of the unit.

Soil unconsolidated material on the immediate surface of the earth, which serves as a natural plant growth medium. Solubility. The tendency to dissolve the aggregate with liquid. Special provisions section of the draft application application, which addresses special specifications that trading participants must comply with the submission of their tender documents.

As for the term "specific weight", the density of the substance is often understood under it, although, in terms of physics, it is different concepts. Specific gravity - This is the ratio of weight to the volume of the substance. Due to the fact that on the surface of the Earth, the weight is almost equal to the mass, then the proportion equal to density. Accordingly, the proportion of rubble 10-20 is 1.35 tons / m3, i.e. 1350 kg in one cubic meter.

What is the density of granite rubble and its proportion?

The proportion of the mass ratio of this volume of aggregate to the mass of equal volume of water. Stability. Property that allows a combination of aggregate particles to remain stable and maintained bearing abilities With different types of load. Stakeholders all persons, agencies, bodies, companies, etc. Interested in this issue.

Standard proctor. A test that defines the maximum dry density for specific soil types. Certain sealing densities for fillings are often based on a percentage of a standard coccant for a certain moisture content. Standards Efficiency levels established by law or legislation.

There are other parameters affecting the bulk density of the granite rubble:

- The view and, accordingly, the density of the rock from which crushed stone is mined. Depends on the place of production.

- Terms of storage of rubble.

- Form or leggings of rubble.

- The percentage of water absorption.

- Material moisture.

For example, in a dry state, the proportion of 20-40 rubble on the tables is 1.35 tons / m3. When water absorbed 0.5% its weight, respectively, will increase this indicator.

Sterilization. Delete for any reason access to a potential aggregate site for extraction. Storage of stocks of an aggregate product on a large embankment for subsequent use, sale or disposal. Emergency accumulation of material storage practice for subsequent use, sale or disposal.

Storm water. This part of the storm flow, which naturally not seeps in the ground or does not evaporate, and flows through the daily stream, flow, pipes, and other features of the storm sewage system. Storm drainage system. Created and natural elements that function together as a system for collecting, transporting, holding, holding, locking, holding, detentions, infiltration or removal of stormwater.

Significantly affects the relief of grains of rubble, his testicle. The highest sealing indicator has cuboid grains containing up to 15% of rickened and lamellar grains. With the large content of needle and lamellar grains, the density decreases. Such a crushed stone has the highest drawdown and water absorption, requires special conditions when stored and transport.

Stripping the loss of adhesion between asphalt and aggregate due to sensitivity to moisture. Surface humidity Free humidity is preserved on the surfaces of the aggregate particles, which becomes part of the mixing water in concrete mix. Varnished coating. The use of light spraying of the asphalt emulsion with low viscosity on the existing surface road coat To ensure the connection between the starting coating and the subsequent asphalt concrete.

Temporary windows schedule for certain aggregate operations and mineral mining activities to minimize the impact on environment. The upper layer of soil is the topmost layer of soil, which is usually characterized by dark, organically enriched materials.

The importance of the incomplete density of rubble

In the production of concrete there is a dependence - the higher the bulk density or, for example, the proportion of the rubble fraction 20-40, the less cement is used. The parameter of the bulk density is important for transportation and storage - determining the transfer of transportation and warehouse capacity. The parameters of the obtained concrete depend on the accuracy of the information, characteristics. building structures, fare.

Resistance to damage from impact. This is closely associated with the lack of fragility. The coefficient of uniformity is the test to determine the ratio of the sieve, at which 60% of the filler passes against the size of the sieve at which 10% passes. The result is expressed as a number; The higher the number, the more coarse and thin elements of the material are mixed.

Vermiculitis. The unit, somewhat similar to perlite, which is used as a placeholder in light roofs and decks. It is formed from mica, hydrosilicate with the possibility of expansion when heated with education light material With insulation quality. It is used as bulk insulation, as well as the unit in insulating and acoustic plaster and in an insulating concrete.

Laboratory measurements are carried out for the exact value of the bulk density. For example, to determine the proportion of rubble 40-70, this material is filled with a certain measure of volume, as a rule, a barrel with a volume of up to 50 liters. Weighing is made empty and filled containers, the difference of readings is divided into volume. The result obtained is reflected in the certificates of the accompanying material.

Voids in the cumulative mixture. Spaces between aggregate particles. This can be additionally determined by sorting into a coarse, medium or thin, depending on the natural composition of the material and the percentage of the detection of particles on a 36-millimeter sieve.

Fraction, shape, water absorption

Washing the practice of cleaning the unit with water to remove an excess amount of small particles. Water absorption The ability of the filler to absorb water 1 - 2% for ordinary road units. Water quality Chemical, physical and biological characteristics of water, as a rule, in relation to its suitability for a specific purpose.

The density determines and after grinding and drying the unit of material, which eliminates the presence of emptiness. This determines the real density of rubble and its porosity. For example, if the share of rubble 5-20 is 1300 kg / m3, then the result obtained according to this technique will be about 2500 kg / m3.

Water table top surface or groundwater height in aquifer, which is closest to the surface of the earth. The amount of the unit you need is determined by the area that you want to cover, to which depth and type of material you want to use.

Therefore, if you want to apply them at a depth of 50 mm, one ton will cover 14 square meters. For pedestrian walkways, it is usually enough 35 mm, and in this case, 1 ton will be sufficient to cover approximately 20 square meters. This can be done either with the help of a roller, or over time it will be compact while driving. The compacted vacuum cleaner weighs 2 tons on cubic meter. The minimum recommended depth for the movement of the vehicle is 75 mm, which means that 1 ton will cover 7 square meters.

You can and independently determine the exemplary bulk density of rubble, for which any capacity is needed, the volume of which is either well known or is easily determined by multiplying the length of the width and height. Further, as in the laboratory, the packaging is weighted empty and filled with material, the difference obtained is the net weight of rubble. The result obtained must be divided into volume, and you will learn an approximate share of the material. A more accurate result is given only laboratory research.

For a pedestrian motion, 50 mm depth is enough, allowing 1 ton to cover 10 square meters. These materials are formed when removing asphalt sidewalks for reconstruction, grinding, or gain access to buried utilities. The asphalt coating is usually removed by milling or removing full depth. Grinding implies the removal of the surface of the sidewalk with milling machinewhich can remove a thickness of up to 50 mm in one pass. In most cases, the broken material is selected and loaded into truck-loaders with a front loader and is transported to the central processing unit.

Crushed stone 20-40 refers to the medium-complete, this brand is considered one of the most sought-after in private, road and industrial construction. When calculating quantity required material, volume of warehouse premises and carrying capacity of transport for its transportation by the main indicator of the bulk (bulk) weight, taking into account its mass in natural condition, including pores and emptiness. Its value is necessarily indicated in the supplied certificate along with the rest of the performance, if desired, it is experimental.

Granite rubble medium fraction

Although most old asphalt sidewalks are processed at central processing enterprises, asphalt coatings can be crushed in place and included in granular or stabilized basic courses using self-propelled grinding machine. Hot on-site and cold recycling processes in place have turned into continuous trains operations, which include partial removal of the depth of the road surface, mixing the regenerated material with enriching additives and placement and sealing the mixture obtained in one pass.

Specific and volumetric concept

At perfectly tight bodies, they coincide, in other cases the difference is to take into account the volume of the interior and emptiness. In practice, the volume (bulk) weight in most building materials is less specific to the magnitude of the porosity (for building rubble From dense and solid rocks, its value rarely exceeds 7%). Practically, it reflects the weight of the material that is combined from a height of 100 mm into a container equal to 1 l (at home the container is weighed before and after filling, its dimensions make it easy to find the exact volume). All calculations are carried out exclusively for rubble in a dry state.

Additional information on the utilization of asphalt coating can be obtained from the following organizations. National association of asphalt concrete coatings. Association for the processing and disposal of asphalt. Excess asphalt concrete is removed in landfills or sometimes to the right.

Excess grainy material or soil or even garbage can sometimes be introduced into the old stocks of sidewalks. This is especially true for the recycling of the road surface on the spot. These include its use as a substitute for the aggregate and additives of asphalt cement in the recycled asphalt coating in the form of a grainy base or a substabase, a stabilized base filler or in the form of embankments or filler.

Thus, the proportion is an absolute (perfect) value, volume - practical. In construction, the second term is often replaced by the concept of bulk density. For rubble with the size of fractions of 20-40 mm, the difference between it and the true (starting breed without pores and voids) reaches 50% and higher, this is due to the large amount of air involved between individual grains. Accordingly, the smaller the particle size, the higher the volumetric weight.

Asphalt concrete agglomerate and asphalt cement application. Asphalt for hot mixing. This product is subsequently included in the mixture for asphalt concrete mixtures as aggregate-based mixers. Hot recycling in place is the process of repairing, which is performed as a single or multiple operation using specialized equipment for heating, scarification, rejuvenation, styling and sealing. Before actual recycling is not required processing.

The asphalt of cold mixing. The process of recycling in a cold location includes specialized factories or processing trains, due to which the existing surface of the road surface is crushed to a depth of 150 mm, is processed, mixed with asphalt-concrete emulsion, is placed and compacted in one pass.

The indicator refers to auxiliary, but it plays an important role in calculating the number of building materials and selection of proportions. Knowing the size of a concrete structure, it is easy to find the required weight of solid large-scale filler. The desired value is determined by multiplying its volume on the proportion of the rubble and the coefficient of the seal (for bulk crushed rocks, its average value is taken equal to 1.3, the manufacturer is more accurate). Similarly, the lifting capacity of vehicles for transportation or required storage warehouses is carried out.

Determination of the quality of granite rubble

The use as an embankment or filling material within the same path of the path can also be a suitable alternative to the disposal of excess asphalt concrete, which is generated by a specific highway project. Between the asphalt concrete mixtures there may be significant differences in aggregate quality, size and consistency.

Both grinding and crushing can cause some deterioration in the aggregate. Studies on road surfaces in California, North Carolina, Utah and Virginia showed that before and after grinding it can be expected that the proportion of the road surface passing through a sieve of 36 mm will increase with a predetermined range from 41 to 69 percent to a distance from 52 to 72 percent.

The value of the specific gravity is influenced:

- The true density of the initial breed. 1 m3 of a whole piece of cliff weighs almost 2 times the same material in a fragmented state. This indicator cannot be determined with high accuracy at home, oriented to the values \u200b\u200bspecified by the manufacturer. In practice, it differs even in the same rocks, with an equal grade of the strength of the crushed stone or gravel 20-40 mm (or another fraction) from different quarries will weigh differently.

- Fraction size - numerical differences in specific weight for different marks It's small, but the smaller the grain, the more dense they fit together and the better the concrete is better.

- The water absorption coefficient, which is dependent on many factors: from porosity and roughness to the form of particles (needle and incorrect is better absorbed and kept moisture on the surface even under the condition of a highly qualified internal structure).

- Beshechy - the higher the proportion of fractions with the right and cubic form, the less air is involved and the more he weighs.

The material quickly gains moisture, to change the bulk weight, a sufficiently light blotch under the rain. For this reason, all calculations and practical actions are carried out with a pre-prepared filler - maximum purified from foreign impurities and dry.

The weight of the fraction of 20-40 mm for different species rubble

| Variety of rubble | Value value,% | True material density, kg / m3 | Volumetric weight, kg in 1 m3 |

| Granitis | 19 | 2650 | 1350 |

| Gravine | 15 | 2600 | 1470 |

| Limestone | 20 | 2800 | 1300 |

| Secondary | 25 | 1800 | 1250 |

| Slag | 2950 | 1500 |

The figures presented are averaged, the specific gravity of 1 m3 of the granite rubble fraction 20-40 reaches 1400 kg / m3 (even higher at the gabbro-diabasic brands). They can be used under preliminary calculations, for private construction and small-sized structures, the error will be small. But when working with large volumes of crushed stone or gravel, repels exclusively from the value specified in the certificate.