Mass of the volume of material volume in a natural state. The main properties of building materials

Ministry of Education and Science of the Russian Federation

Ugra State University

Faculty of Engineering

Department " Construction technologies and designs "

The main properties of building materials

(density, voidness, porosity, water absorption, humidity, strength, softening, frost resistance).

at the rate "Materials science (building materials)"

for specialties:

"Economics and Management at the construction enterprise" (060800)

Khanty-Mansiysk

|

General provisions ............................................................................. | ||

|

Structure of laboratory work ............................................. | ||

|

General classification of the main properties .................................. | ||

|

Laboratory work number 1 Definition of true I. middle density………………………... | ||

|

Definition true density Brick .......................................... | ||

|

Determination of the average density of materials ......................... ... .. | ||

|

Sample material of the right shape ....................................... | ||

|

Sample incorrect form…………………………………….…... | ||

|

Laboratory work number 2 ................................................................ | ||

|

Determination of the bulk density of materials ............................. | ||

|

Wallout ..................................................................... .. | ||

|

Theoretical part……………………………………………………. | ||

|

Laboratory work number 3. Porosity and water absorption building materials………….. | ||

|

Theoretical part……………………………………………………. | ||

|

Laboratory work number 4. Determining the moisture content of building materials ...................... | ||

|

Theoretical part……………………………………………………. | ||

|

Laboratory work number 5. Strength of building materials ....................................... | ||

|

Theoretical part……………………………………………………. | ||

|

Part 1. Determination of the strength in compression and the coefficient of constructive quality ................................................. .... | ||

|

Part 2. Definition of the softening coefficient ................ ... .. | ||

|

Theoretical part……………………………………………………. | ||

|

Part 3. Determining the strength of bending ............... ... | ||

|

Laboratory work number 6 Frost resistance ............................................................... .. | ||

|

Determination of the stamp on frost resistance ................................. ... | ||

|

Theoretical part……………………………………………………. | ||

|

Control questions………………………………………………….. | ||

|

Bibliography…………………………………………………….. |

The purpose of this work is the acquisition of work skills with laboratory equipment, the development of modern methods for determining the main properties of building materials and the ability to estimate the correctness of the results obtained.

1. General provisions

Students who have studied the content of work on the relevant work are allowed to perform laboratory work. methodical instructions and submitted a report to work with the necessary laboratory logs. The report summary is drawn up in accordance with the structure of laboratory work.

1.1. Structure of laboratory work

1.1.1. Name of the topic of laboratory work. It should be performed clearly and stand out from the main text.

1.1.2. The purpose of the laboratory work is the name of the defined property; The method used in operation; Evaluation of the correctness of the results obtained.

1.1.3. Theoretical part. The main definitions of the properties of building materials studied in this work are given, the outcrimal formulas, units of the dimension of the defined constants.

1.1.4. Materials and equipment, reagents.

Sets out the course of work in a fairly brief form with an indication of the sequence of operations.

1.1.6. Laboratory magazine.

All experienced data obtained on their foundation are made to it and the calculated values \u200b\u200bobtained on their basis. The laboratory log is designed in such a way that the table method of calculation can be carried out.

1.1.7. Calculated part.

The calculated part is present when it is necessary to conduct auxiliary calculations, the explanations that are not included in the laboratory log.

1.1.8. Transcue.

It is concluded about the correctness of the results obtained by comparing them with the standard values \u200b\u200bof the constants defined in the laboratory work given in the special literature or those specified in Guest.

General classification of basic properties:

- physical properties (density, porosity, water absorption, humidity, thermal conductivity, frost resistance, etc.);

– mechanical properties (strength, hardness, abrasibility, impact resistance, etc.);

- Deformative properties (plasticity, elasticity, creep, etc.);

– chemical properties (alkali resistance, acid resistance, bioscistance, etc.);

- technological properties (weldability, clove, plasticity, sintering, etc.).

Laboratory Work number 1.

Definition of true and medium density

THEORETICAL PART

The density is the mass of material in a unit volume.

Depending on the degree of compaction of the particles of the material distinguish:

True densitywhen a unit of material is in an absolutely dense state (without pores and emptiness)

rI \u003d, g / cm3, where

rI is true density, g / cm3;

m - the mass of the material in an absolutely compacted state, r;

Va - the volume of material in an absolutely dense state;

V is the volume of material in a natural state;

VP is the pore volume prisoners in the material.

Middle density, or just a density when the mass of material in a unit of volume is in a natural state (with pores and voids)

rO \u003d, g / cm3, where

mo - Material Material in Natural State, G.

Bulk density When the mass of the material in a unit of volume is in a bulk state (interzraine voids are included in the bulk volume);

rN \u003d, g / cm3, where

rN - bulk density, g / cm3;

mN - bulk mass, g;

VN - bulk volume, cm3.

The bulk density is determined both in the loop-sucking state and in the compacted. In the first case, the material falls asleep in the vessel from a certain height, in the second, it is compacted on the vibrationboard (30-60 seconds). From the foregoing it follows that in a unit of volume for this material

m\u003e Mo\u003e MN and RI\u003e RO\u003e RN

Relative density is a dimensionless value equal to the ratio of the average density of the material to the density of water at 4 ° C, equal to - 1 g / cm3

d - relative density;

rO - average density, g / cm3;

rV is the density of water at 4 ° C, 1 g / cm3.

This value is taken into account in some empirical formulas.

Purpose of work:included with the essence of the concepts of "density" True and average and methods for their determination for samples of the correct and improper geometric shape. Learn to evaluate the correctness of the results.

1. Definition of true brick density

Materials: Powder shrouded ceramic brick Weighing about 70 g, distilled water.

Instruments and devices: Scales laboratory technical, standard volume meter (flask le chaitor), glass wand, glass (porcelain) glasses with a capacity of 100 and 500 cm3; Dry napkin.

Progress

1. The sample of fine bricks (particle size should be less than the size of the pores in the brick) weighing about 70 g placed in a glass and weighed on technical scales with an error of not more than 0.05 g.

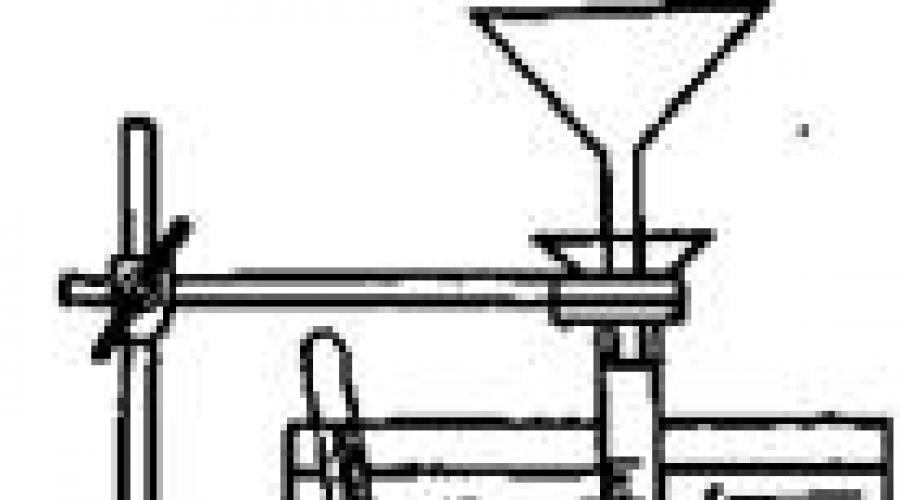

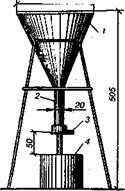

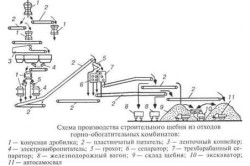

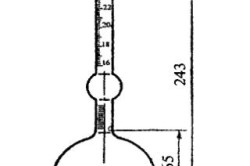

2. In the volume meter (Fig. 1.1) pour water to the bottom risks applied to the extension on the throat of the flasks. The throat of the volume is to dry the filter paper (or cloth). Then the brick powder from a weighted glass carefully with the help of a glass sticks to pour it into a volume meter until the water level rises to the top label (the loss of the powder is not allowed). The volume of the filtering powder VP is equal to the volume between the upper and lower marks of the size of the size (20 or 10 cm3) and is indicated on the size.

3. The mass of the brick powder (g), filled into the volume meter, to determine, weighing the powder residue in the glass M2 and calculate it as the mass difference (M1-M2)

ρ \u003d (M1-M2) / VP

|

Figure 1.1. Volume meter le chateel

1 - volume meter; 2 - vessel with water; 3 - thermometer.

All results to put in the laboratory log.

Laboratory Journal

|

true mass |

powder volume |

powder mass in size |

True density |

|||

2. Definition of medium density of materials

2.1. Sample material of the right form

Materials: concrete (or solid) sample cube; a cube of a tree with 1 edge 4 ... 5 cm; Sample of foam in the form of parallelepiped weighing 10 ... 30 g

Instruments and devices: Laboratory scales technical, measuring rules, caliper.

Progress

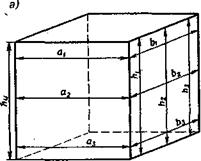

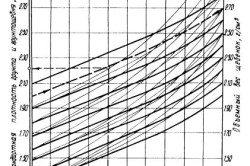

1. Samples of concrete cubes (solution), wood and foam mester to measure a line with an error of 1 mm or a calipercule with an error of 0.1 mm. Each face of a cubic or close to it is measured in three places (A1, A2, A3, B1, B2, B3, H1, H2, H3) in width and height, as shown in Fig. 1.2.And, and for the final result, the arithmetic average of three measurements of each face is taken. On each of the parallel planes of the sample of the cylindrical shape, two mutually perpendicular diameters (d1, d2, d3, d4) are carried out, then measure them; In addition, the diameters of the middle part of the cylinder (DS, DB) are measured in the middle of its height (Fig. 1.2., b.). For the final result, the average arithmetic six diameter measurements are taken.

The height of the cylinder is determined in four places (H1, H2, H3, H4) and the final result is taken by the arithmetic average of four dimensions.

Samples of any form with a side of up to 100 mm measured with an accuracy of 0.1 mm, a size of 100 mm and more - with an accuracy of 1 mm.

2. Determine the mass M of concrete, solution, wood and foam. Samples weighing less than 500 g are weighed up to 0.01 g, and weighing 500 g and more up to 1 g.

The data obtained is in the laboratory log.

| |

Fig. 1.2. Sample size measurement scheme

but – cubic shape; b. - cylindrical form

Laboratory Journal

|

material |

sample sizes, cm |

True density |

||||||||

D. |

||||||||||

2.2. Sample of irregular shape

Materials: a piece of bricks of an irregular shape weighing 50 ... 70 g; Melted paraffin, density RP \u003d 0.93 g / cm3.

Instruments and devices: Scales laboratory technical with a device for hydrostatic weighing, brush.

Progress

1. Weigh the sample - m, g;

2. With the help of a tassel to cover the paraffin sample to save in its opening volume;

3. Weigh the sample coated with paraffin, pre-cooling it to room temperature - M1, r;

4. Conduct hydrostatic weighing coated with paraffin sample M2, r (Fig. 1.3.).

Weighing to spend up to 0.01

Experience repeat three times.

|

All results to put in the laboratory log.

Fig. 1.3. Weighing sample on hydrostatic scales

Laboratory Journal

|

mass sample, g |

paraffin |

density |

||||||

m2. |

||||||||

Calculated part

Determination of the sample volume by the method of hydrostatic weighing is made on the basis of the Archimedes Act: "The body immersed into fluid acts an ejecting force equal to the weight of the fluid in the amount of this body."

Therefore, the mass of a sample suspended in water will be easier masses of a sample suspended in air, on pushing force

A \u003d (m1-m2) g, n

A - the power of Archimedes;

g - Acceleration of free fall, m / s2.

Vo. P. * RV \u003d M1-M2 þ Vo. p. \u003d, but Vo. p. \u003d V + VP þ

Þ V \u003d Vo. P.- VP \u003d.

Laboratory work number 2.

1. Determination of the bulk density of materials

Materials: quartz sand.

Instruments and devices: Scales laboratory technical, standard funnel, ruler, measuring cylinder with a capacity of 1 liters.

Progress

1. Weigh the measuring cylinder - M1 g;

2. In the standard funnel installed on the pallet, fall asleep sand with a closed gate (Fig. 1.4.);

3. One reception by opening the shutter, fill the measuring cylinder to the sand before the formation of a cone above its edges;

4. Remove the excess sand by conducting a ruler along the top of the cylinder forming;

5. Weigh the measuring cylinder filled with sand - M2.

Weighing to produce up to 1 g.

Experience repeat three times.

|

Fig. 1.4. Standard funnel

1 - body; 2 - tube; 3 - catch; 4 - measuring cylinder

Laboratory Journal

|

material |

measuring cylinder |

cylinder with sand, |

sand mass |

bulk density |

||||

volume |

weight |

|||||||

For the final result, adopt the average value of 3 experiments.

2. Empty

THEORETICAL PART

Emptiness is the proportion of inter-rigid voids in a bulk volume of material.

Estimated formula:

where

where

PU is void, share or%;

Vput is the volume of voids in a bulk volume of material, cm3;

V - material volume, cm3.

Emptiness is expressed in%:

Emptiness is the most important characteristic of the correctness of the selection of the grain composition of aggregates for concrete, on which the consumption of binder (cement, bitumen, etc.) depends. In practice, void lies within 26.5 ... 47.6%.

2.1. Determination of the volatility of bulk materials

Purpose of work: Determine the voidness of sand and rubble. Establish the dependence of the emptiness from the magnitude of the grains of a bulk material. Assess the correctness of the results obtained.

Materials: quartz sand, fraction (0.63 - 0.315) - 2 l; Crushed stone granite, fraction (10-5) - 10 liters.

Instruments and devices:dimensional cylinders with a capacity of 1 l and 5 l; Standard funnel; line; trade scales; pallet.

Progress

1. Determine the bulk density of sand in accordance with the previous part of the work;

2. Weigh a blank cylinder, with a capacity of 5 l - m1, g;

3. Fill the crushed stone into the cylinder of the scoop from a height of 10 cm before the formation of a cone above the edges, putting it pre-onto the pallet;

4. surplus rubble cut the line to the clove with the edges;

5. Weigh the cylinder filled with rubble - M2, G.

Weigh up to 1 g. Central quartz sand density and granite rubble Take from table 1 applications.

Definition repeat three times.

Laboratory Journal

|

material |

cylinder |

cylin-dra, |

material |

bulk density, |

density |

emptiness |

||

For the final result, adopt the average value of the voids of their three definitions.

Laboratory work number 3.

Porosity and water supply of building materials

THEORETICAL PART

Porosity and water supply of materials are closely connected with each other. Water absorption increases with increasing porosity. Therefore, these properties are conveniently considered in parallel.

Porosity is the proportion of material filling.

Total porosity (or just porosity):

,

,

where VPP is the pore volume in the material.

Porosity is expressed as a percentage:

From the magnitude of the porosity and its character, the most important characteristics of the material are dependent: density, strength, thermal conductivity, durability, etc.

Porosity in the material is characterized by both open and closed.

Open pores increase the water absorption and water permeability of the material and worsen its frost resistance.

An increase in closed porosity due to open increases the durability of the material, reduces its thermal conductivity.

Water absorption - Property of material absorb and hold water.

Quantitative characteristics of this property:

Mass water absorption - this is the ratio of the mass of the absorbed material of water under certain GOST conditions to the mass of dry material in%:

Volumetric water absorption - This is the ratio of the mass of the absorbed material with the material under certain GOST conditions to the volume of material in a dry state in%:

bm - mass absorption;

bV - bulk water absorption;

mN - the mass of material saturated with water under standard conditions, r;

m - the mass of air-dry material, r;

V is the volume of air-dry material, cm3.

The ratio between mass and volumetric water absorption:

Volumetric water absorption is numerically equal to open porosity:

Having determined water absorption in terms of volume and porosity of the material, you can easily calculate the closed porosity:

Pzakr \u003d (P-Potch)%

The saturation coefficient of pores water is the ratio of water absorption by volume to porosity:

It changes from 0 (all the pores are closed in the material) to 1 (all the pores are open).

The larger the KN, the higher the proportion of open pores relatively closed.

Purpose of work:determination of porosity, water absorption and saturation coefficient of pores with water on the example of ceramic bricks. Evaluation of the correctness of the results obtained.

Materials: Ceramic bricks.

Instruments and devices:scales laboratory technical, caliper, ruler, bath with water.

Progress

1. Dry bricks (3 pcs) to constant weight at a temperature of 105-110 ° C (the difference of the results of 2 consecutive weighing is not more than 0.2%). Weighing to produce after complete cooling of bricks - m, g;

2. Measure the geometric dimensions of bricks with an accuracy of 0.1 mm;

3. To saturate bricks with water at a water temperature of 15-20 ° C, for 48 hours, at a water level by 2-10 cm above the top of the edge of the bricks;

4. Watching bricks with a damp cloth, immediately weigh them - MN, G.

Weigh up to 1 g.

The value of the true density of ceramic brick take out of work number 1.

Laboratory journals

Water absorption

|

brick mass |

geometric brick dimensions, |

water absorption |

|||||||

|

mass |

volumeful |

||||||||

|

water |

|||||||||

POROSITY

|

density |

porosity |

coef. saturation pore water |

|||||

|

open |

closed Pzak \u003d Pottle,% |

||||||

|

true | |||||||

For the end result, take the average value of 3 definitions.

Laboratory work number 4.

Determination of humidity of building materials

THEORETICAL PART

Humidity is the ratio of the mass of water currently contained in the material, to its mass in a dry state, in%.

Estimated formula:

mVL - mass of wet material, r;

m - Mass of dry material, G.

Purpose of work: Determination of sand humidity. Evaluation of the correctness of the result.

Materials: quartz sand.

Instruments and devices:fucks, drying cabinet, excitator, technical scales.

Progress

1. Weighing bins - M1, g;

2. Weighing bins with wet sand - m2, g;

3. Place the bins with sand in the drying cabinet, the drying time depends on the mass of the sample material;

4. Cool bins with sand in the desiccator and weighed - M3, r;

5. Drying to produce to constant weight.

For the final result, adopt the arithmetic average of 3 parallel definitions, provided that the relative deviation of the individual result from the average value does not exceed 5%.

Laboratory Journal

|

mass Bekbe |

mass of the Bekbe with dry sand, g |

humidity |

||||

|

value humidity |

Counting deviations of a separate result from the average value.

Calculation part:

|

humidity |

Deviations of a separate result |

|||

|

absolute |

relative |

|||

OUTPUT.

CONTROL QUESTIONS

1. List the properties of materials that characterize the characteristics of the physical condition of building materials.

2. Compare mass and volumetric water absorption for test materials. What is the value - or more for compared materials? Answer Motivate.

3. How is the strength of the material with water absorption, with porosity?

4. If in the material to reduce water absorption, then how will it affect the medium density of the material, on the true density, on the thermal conductivity coefficient?

5. How to change the thermal conductivity coefficient, if the frost resistance of the material has increased?

6. Name the magnitude of the average and true density for concrete, for ceramic brick, for wood and for any polymer material.

7. What can the materials of the exterior structures of buildings and structures in the winter can be destroyed?

8. From what parameters the frost resistance of structural materials depends?

9. How is the thermal conductivity with porosity in building materials?

10. In concrete, medium density is reduced by certain operations. How will this affect the strength of the material and its durability?

11. Give examples of materials characterized by high fire resistance, refractory.

12. What is the dimension of the coefficient of thermal conductivity, frost-resistance?

13. List the indicators that determine the mechanical properties of materials.

14. What types of strength characterize concrete, wood? Which units is the strength?

15. Give examples of materials that have high deformation properties. What parameters are the deformative properties of materials?

16. What is the abrasibility? Give examples of materials with high and low abrasability.

ATTACHMENT

Table 1.

True and average density of some building materials

|

Material |

True density, kg / m3 |

Average density, kg / m3 |

|

Limestone: shechechians Volcanic tuff Ceramic brick: ordinary hollow porous Wood pine Foams Stool construction perceptible lightweight overall Gypsum and Gypsum Products silicate slag trepal Mineral wool Foam concrete and aerated concrete Penosilikat Foamglo Solutions: lime lime-cement cement Slagobeton granulated fuel Fibrololite: magnesian cement |

Table 2.

Porosity and water absorption of ceramic bricks

|

View of ceramic |

Average density |

Porosity,% |

Water absorption,% |

|

Ordinary Conditionally effective Effective |

Physical properties are determined by the parameters of the physical condition of materials under the influence external environment and the conditions of their work (action of water, high and low temperatures, etc.).

The true density is the value determined by the ratio of the mass of a homogeneous material T (kg) to the volume occupied by it in an absolutely dense state, i.e., without pores

The dimension of the true density is kg / m3 or g / cm3. The true density of each material is a constant physical characteristic that cannot be changed without changing it chemical composition or molecular structure.

So, the true density is not organic Materials, natural and artificial stones consisting mainly of silicon, aluminum and calcium oxides is 2400 ... 3100 kg / m3, organic materials consisting mainly of carbon, oxygen and hydrogen - 800 ... 1400, wood consisting Basically from cellulose, - 1550 kg / m3. The true density of metals fluctuates in a wide range: aluminum - 2700 kg / m3, steel - 7850, lead - 11300 kg / m3.

In building structures, the material is in a natural state, i.e., the volume occupied by them necessarily includes and pores. In this case, the concept of medium density is used to characterize the physical condition of the material.

The average density is the value determined by the ratio of the mass of a homogeneous material T (kg) to the volume occupied by them in the natural state Fe (M3)

The average density is an important physical characteristics of the material varying depending on its structure and humidity wide limits: from 5 (porous plastic) to 7850 kg / m3 (steel). The average density has a significant effect on mechanical strength, water absorption, thermal conductivity and other properties of materials.

The degree of filling material by pores. Porosity - the value is relative, expressed as a percentage or fractions of the material volume.

The porosity of building materials ranges from 0 (steel, glass) to 90 ... 98% (foam)

The porosity of the material is characterized not only from the quantitative side, but also by the nature of the pores: closed and open, small (size in hundredths and thousands of millimeters) and large (from the tenths of a millimeter to 2 ... 5 mm). By the nature of the pores, the ability of the material to absorb water. So, polystyrene foam, the porosity of which reaches 95%, has closed pores and practically does not absorb water. At the same time, a ceramic brick having porosity is three times smaller (i.e. about 30%), thanks to the open nature of the pores (most pores are reportable capillaries) actively absorbs water.

The magnitude of porosity significantly affects the strength of the material. Building material is the weaker resist the mechanical loads, thermal, shrinkage and other efforts, the more pores in its volume. Experienced data show that with increasing porosity from 0 to 20%, the strength is reduced almost linear.

The amount of strength also depends on the size of the pores. It increases with their decrease. The strength of fine-porous materials, as well as materials with a closed porosity higher than the strength of coenproof and with open porosity.

For bulk materials (cement, sand, gravel, crushed stone) calculate bulk density.

The bulk density is the value determined by the ratio of the mass of the material T (Kr) k occupied by them in the loose state VH (M)

The value of Va includes the volume of all particles of the bulk material and the volume of spaces between particles called voids. If the granular material is known for the pH bulk density and the average density of RS grains, then it is possible to calculate its voidness A - the relative characteristic expressed in the fractions of the unit or in percent

In physical meaning, the concept of porosity and voidness are similar. In the manufacture of concrete, they seek to use bulk aggregates - sand, crushed stone or gravel with minimal voidness. In this case, to fill emptiness, less cement and concrete will need cheaper.

Very often, in the course of operation, building materials and structures are exposed to water, and the properties of materials are changed. Quantifying the properties of the material in this case, the following concepts allow.

Water absorption of materials, depending on the nature of porosity, can vary widely. WM values \u200b\u200bare for granite 0.02 ... 0.7%, heavy concrete - 2 ... 4, brick 8 ... 20, lungs thermal insulation materials With open porosity - 100% or more. Water absorption in terms of WQ does not exceed porosity, since the volume of water supplied water can not be greater than the amount of pores.

The values \u200b\u200bof W0 and WM characterize the deadline when the material is no longer able to absorb moisture. In real structures, the material may contain a certain amount of moisture obtained with a short-term moistening with droppore water or as a result of condensation in the pores of water vapor from the air. In this case, the condition of the material is characterized by humidity.

Humidity - the ratio of the mass of water currently in the TV material, to the mass (less often - to the volume) of the material in a dry state

Humidity may vary from zero when the material is dry, up to the value of WM corresponding to the maximum water content. Moisturization leads to a change in many properties of the material: the mass of the construction structure increases, the thermal conductivity increases; Under the influence of the inclusion of water, the strength of the material decreases.

For many building materials, humidity is normalized. So, the mooler of the ground chalk - 2%, wall materials -5 ... 7, air-dry wood - 12 ... 18%.

Water resistance - the property of the material to maintain strength when it is saturated with water. The criterion of water resistance of building materials is the softening coefficient - the ratio of strength in compression of a material saturated with water, RB to the strength when compressing dry material

Materials in which the softening coefficient is greater than 0.75, called waterproof.

Waterproofability - the property of the material to resist the penetration of water under pressure. This property is especially important for concrete, perceiving water pressure (pipes, tanks, dams). The waterproofability of the concrete is estimated by a brand of W (W-2 ... W-8), denoting the maximum one-sided hydrostatic pressure, in which the standard sample does not pass water. For waterproofing materials, water resistance is characterized by time, after which the water seepage appears under certain pressure through the material sample (mastic, hydroisol).

Gigroscopicity is the property of capillary and porous material to absorb moisture from the air. With an increase in the relative humidity of air and a decrease in temperature, hygroscopicity increases.

Gigroscopicity adversely affects the properties of building materials. Thus, the cement during storage under the influence of air moisture is hydrated and commemorated, while its brand decreases. Extremely hygroscopic wood, from moisture she swells, rushes and cracks.

The characteristic of hygroscopicity adopted the ratio of the mass of the absorbed moisture with the relative humidity of air 100% and the temperature of +20 ° C to the mass of dry material.

Frost resistance - the property of a material in a saturated water condition to withstand a multiple number of cycles of alternate freezing and thawing without visible signs of destruction and a significant reduction in strength and mass. Frost resistance is one of the main properties characterizing the durability of building materials in structures and structures. As is known, water in the pores of the material, when moving to ice, increases in the amount of about 9 ... 10% and causes tensile voltages. Rhythmic alternating ice crystallization in the pores followed by thawing leads to additional internal stresses. Micro and macrobrees may occur with possible destruction of the structure and reduced strength.

For testing for frost resistance, standard samples of materials or whole small-piece products (for example, brick) are first saturated with water, and then frozen at a temperature of minus 15 ... 20 ° C. The samples are then removed from the freezer and thawed in water room temperature. Such freezing and thawing is one cycle. Frost-resistance brand (F10, F15, F25, F35, F50, F75, F100, F150, F200, F300 for stone materials) is characterized by the number of freezing and thawing cycles, which stood material, with a permissible reduction in the strength or decrease in the mass of the samples.

High frost resistance has dense materials that have low porosity and closed pores. Materials porous with open pores and, accordingly, large in do-absorption are often non-versions resistant.

When exposed to static or cyclic thermal factors, the material is characterized by the thermophysical properties. They are important for thermal insulation and heat-resistant materials, materials of enclosing structures and products hardening during thermal processing. These include heat capacity, thermal conductivity, thermal expansion, fire resistance and refractory.

The heat capacity is the property of the material to absorb during heating and give a certain amount of heat during cooling. The heat capacity is the measure of the energy required to increase the temperature of the material.

The heat capacity attributed to the unit of mass is called specific heat C and measured in J / (kg ° C). The specific heat capacity is the amount of heat required for heating 1 kg of material 1 ° C. In organic materials, the heat capacity is usually higher than that of inorganic, J / (kg ° C): Woods - 2.38 .. .2.72; steel - 0.46; Water - 4,187. Water has the greatest heat capacity, therefore, with an increase in moisture content, their heat capacity increases. The numerical characteristics of heat capacity are used when calculating the heat-resistance of the enclosing structures. In addition, the values \u200b\u200bC should be known to calculate the cost of fuel and energy for heating materials and structures during winter work.

Thermal conductivity - the property of the material to transmit through its thickness heat flux resulting from the temperature difference on opposite surfaces. This property is important for building materials used in the device of enclosing structures (walls, coatings and overlaps), and materials intended for thermal insulation. The thermal conductivity of the material depends on its structure, chemical composition, porosity and pore character, as well as humidity and temperature at which heat is transmitted.

The thermal conductivity is characterized by a thermal conductivity coefficient indicating how much heat in j is able to skip the material through 1 m2 of the surface at the thickness of the material 1 m and the temperature difference on opposite surfaces 1 ° C for 1 hour. The thermal conductivity coefficient, W / (M * ° C), equal: for air - 0.023; for water - 0.59; for ice - 2.3; For ceramic brick - 0.82. Air pores in the material sharply reduce its thermal conductivity, and water moisturizing strongly increases it, since the thermal conductivity coefficient is 25 times higher than that of the air.

With increasing temperature, the thermal conductivity of most building materials increases, which is explained by the increase in the kinetic energy of molecules, the stories of the material

Thermal expansion is the property of the material to change the size when heating and cooling. For the numerical characteristics of such a phenomenon, the temperature coefficient of linear extension (TCCR) is used, which shows how the material is expanding to the material when the temperature is increased by 1 ° C.

TCCR values \u200b\u200bare, ° C ~ 1: for concrete (10 ... 12) - 10 6, steel 10 10 ~ 6, woods along the fibers - (3 ... 5) 10 6. TCPR polymer building materials in 10 .. . 20 times more.

Due to the thermal and shrinking deformations in the buildings of a large extent, unacceptable through the operating conditions of the skewers, cracks or ruptures can be formed. That this does not happen, arrange temperature and shrinkage (deformation) seams that, as it were, cutting the structure. The distance between the seams is prescribed, taking into account the thermal expansion of the materials.

Fire resistance - the property of the material to withstand without destruction exposure to high temperatures, flames and water in a fire conditions. The material in such conditions either burns, or cracks, is strongly deformed, destroys the loss of strength. Fire resistance distinguishes the materials non-government, challenges and combustible.

Failured materials under high temperatures are not affected by ignition, degeneration or charring is brick, concrete, etc. However, some non-aggravated materials - Maramor, glass, asbestos cement - with sharp heating are destroyed, and steel structures are strongly deformed and lose strength.

Empty-plated materials under the influence of fire or high temperature are slowly flammable, but after removing the source of fire, their degeneration or burning stops. Such materials include fibrololite, asphalt concrete, impregnated with antipyrin wood.

The combined materials under the influence of fire or high temperature are burning and continue to burn after removing the source of fire. It is wood, wallpaper, bituminous roofing and polymeric materials, etc.

The fire resistance limit is a period of time (minutes or hours) from the start of fire before the emergence of the limit state. Loss consider the limit carrier ability, i.e., the collapse of the structure; The occurrence of through-cracks in it, through which combustion and flames can penetrate on the opposite surface; Invalid surface heating, opposite to the action of fire, which can cause spontaneous fire from other parts of the structure.

Fireproof - the properties of the material to withstand a long exposure to high temperature (from 1580 ° C and higher), not deformed and not softening. Fireproof materials (Dynas, Shamot, Chromomagnezit, Corundum) used for the inner lining industrial furnacesare not deformed and not softened at a temperature of 1580 ° C and higher. The refractory materials (refractory chimney brick) withstand without melting and deformation temperature 1350 .. J580 ° C, low-melting (ceramic construction brick) - up to 1350 ° C.

The acoustic properties of materials are properties associated with the interaction of material and sound. Sound, or sound waves are mechanical oscillations propagating in solid, liquid and gaseous media. The builder is interested in two aspects of the interaction of sound and material: to what extent the material spends through its thickness - sound conductivity and to what extent material absorbs and reflects the sound falling on it - sound absorption.

When a sound wave falls on a protective surface, sound energy is reflected, absorbed and carried out by a solid body.

The sound absorption coefficient depends on a number of factors: the level and characteristics of the sound (noise), the properties of the absorbing material, the methods of its location relative to the rigid surface (ceiling, wall) and measurement methods.

Sound absorption depends on the nature of the surface and porosity of the material. Materials with a smooth surface reflect most of the sound falling on them, so indoors with smooth walls The sound, repeatedly reflected from them, creates constant noise. If the material surface has an open porosity, then sound oscillations, entering into the pores, are absorbed by the material, and not reflected.

The essence of the physical phenomenon occurring during the sound of sound with a porous body is as follows. Sound waves, falling on the surface of such a material and penetrating further in its pores, excite air fluctuations in narrow pores. At the same time, a significant part of sound energy is consumed. The high degree of air compression and its friction about the pore wall cause heating. Due to this, the kinetic energy of sound oscillations is converted to thermal, which is dissipated in the medium.

The sound of sound contributes to the deformation of the flexible skeleton of sound-absorbing material, for which sound energy is also spent; This contribution is especially noticeable in porous fibrous materials with an open reporting porosity with its total volume of at least 75%.

Sound conductivity depends on the mass of the material and its structure. The material is the less sound, the more its mass: if the mass of the material is large, then the energy of the sound waves is not enough to pass through it, because for this it is necessary to bring material into oscillation.

Giving the soundproofing properties of the fence is based on three main physical phenomena: reflection of air sound waves from the surface of the fencing, absorption of sound waves by the material of the fence, shocking of the shock or air noise due to the deformation of the structural elements and the materials from which it is made.

The ability to reflect sound waves is important for outdoor building fences. In this case, massive structures with a smooth outer surface apply to increase the reflection of air sound waves.

For interior premises The high reflecting ability of the fence (partitions) is insufficient, since the reflected sound waves will enhance the noise in the most noisy room. In this case, multilayer structures are used, which includes elements from sound insulation materials, the effectiveness of which is estimated by a dynamic modulus of elasticity. As sound insulation gaskets, porous fibrous materials made of mineral or glass wool, wood fibers (wood fiber plates), fringe of porous grains (ceramzit, slag, etc.) are used.

A low dynamic modulus of the elasticity of sound insulation materials (up to 15 MPa) and the presence of air in the pores contribute to a decrease in the level of shock and sound noise. In this case, the reduction in the intensity of the sound occurs due to the deformation of the elements of the structure of sound insulation materials and partially due to sound absorption.

Under the concept of "True density of rubble" means the mass of this unit of volume without taking into account the available pores and emptiness, in a true density state. This value is determined whether it is determined according to a given formula and is used after that in the calculations of the determination of the porosity of the material. Crushed stone by crushing solid rocks of various fractions and has a very good clutch with components concrete mixes. Crushed stone in the form of grains is applied in different areas Construction.

Types of crushed stone: A - cuboid, b - acutely angular, in - wedge-shaped, g - teaching.

A concrete is produced on granite rubble, and products from such concrete are used as a spript in road covering and in the production of asphalt concrete. Such a concrete is used in the construction of structures responsible to which high strength requirements are presented.

Determination of the density of rubble

Among the inert materials, granite crushed stone still retains leading positions.

None of the types of large aggregate with another composition cannot compete with a strong stone rock formation of magmatic origin. There are interdependence of the main characteristics of rubble.

Than in the granite rubble is better density indicators, the higher the characteristics such as density and frost resistance. Construction technologies, as a rule, differ for nonmetric material several types of density, which is customary to determine the three species:

- true;

- medium;

- bulk.

In turn, the true density such as rubble and gravel can be found in several ways, namely: picnometric and accelerated.

Back to the category

Determination of true density with a pycnometric method

This method used to determine the density implies mass measurement and volume unit for pre-prepared, dried and crushed, material. To determine the true density of this rock breed In the geological sample, a special laboratory test is preparing. Crushed stone for obtaining the result is laid in the crusher, and after processing, crushing products in it are dispersed. To determine the true density, crushing to thin powder is also used and then drying at 105-110 ° C to obtain a constant mass. The degree of grinding of the rock can be different and depends on the standard for each material. To determine, you will need:

- picnometer with a capacity of 100 ml, corresponding to GOST 22524;

- desktop scales: Dials must correspond to GOST 29329, and laboratory - 24104;

- porcelain cup for weighing according to GOST 9147 or a cup according to GOST 25336;

- porcelain or cast iron mortar;

- excitator, corresponding to GOST 25336;

- sulfurous concentrated acid according to GOST 2184;

- calcium chloride or calcium chloride (anhydrous) according to GOST 450;

- drying cabinet;

- sand or water sauna;

- lab 60x100 laboratory grill crusher or 50x150;

- metal brush;

- sito №0125 GOST 6613.

Available fractions are subject to a fear of material, 2 identical samples from each type of fraction are taken to study the material, otherwise the result will be inaccurate. The weight of each closed sample will depend on the size of the separate fraction of rubble. So, for a fraction from 5 to 10 mm, 1 kg is taken, from 10 to 20 mm - 1.5 kg, from 20 to 40 mm - 2.5 kg, from 40 to 70 mm - 5 kg, and if there are grains, more Large fractions, they are pre-before the sample fence, they will be crushed to reach ~ 70 mm or a little less.

To prepare a crushed stone for testing and determine its true density with the help of a pycnometric method, a crushed stone with a metal brush is thoroughly cleaned from dust and dirt, then it is crushed in a laboratory special crusher to a grain size of no more than 5 mm. This mass is stirred and taken from it 150 g, after that it is crushed again and taken from there 30 g. This sample should be crushed to the state of dust, mixed, and at the same time the particles should not be ready for readiness to exceed 0.125 mm. Thus, the crushed stone is placed in a pre-prepared cup of porcelain or a special glass designed for laboratory weighing.

In this laboratory glassware, the samples taken very carefully dry and cooled after that before reaching the values \u200b\u200bof temperature close to room. Most often in laboratory conditions, cooling, keeping the object of experience over pairs of concentrated sulfuric acid, in other cases they cool experience over anhydrous calcium chloride.

When all the conditions are executed in order to determine the true density, it takes 2 hits of 10 g each of them, then they suck in the pycnetter, pre-prepared for this, dry and clean. After that, the distilled water is poured there, taking it to this experience in the amount required to make it filled with nothing more than half of the total volume of the pycnometer. The content is boiled on a water or special sandy bath, for an accurate result must pass from the beginning of boiling at least 15-20 minutes, it is necessary to completely remove air bubbles from the mixture. In this case, it should be in the inclined position in relation to the main plane. Also, air bubbles, which are inevitably arising from the connection of water and rubble powder, can be removed by holding the picnometer for some time in the desiccator over the vacuum.

When all the air from the crushed stone, mixed with purified with distillation with water, is removed, the picnometer is required to wrap and cool, and having the same water characteristics additionally fills up to the label, which its level corresponded to boiling, the device after this procedure is weighed. After weighing, the picnometer is completely exempt from its contents, is thoroughly washed, filled to the same level of similar purified water and is weighed again. In order to experience more accuracy, two parallel characters are conducted by the terms of experience.

The true density of rubble fractions is thus defined as the arithmetic average between the two dimensions and is calculated by the formula.

The formula for calculating the true density of rubble is used as follows:

r \u003d MR8 / (M + M¹-m²) (1.11), where:

- r is the true density of rubble, in g / cm³;

- r8 is the density of water, which is accepted by default per 1 g / cm³;

- m is a mass of powder samples selected to determine the true density of rubble, which is dried to a constant mass in r;

- m¹ - Mass of a picnometer with distilled water, in grams;

- m² - a mass of a pycnometer with a mood and distilled water after removed by boiling air bubbles, in grams.

Back to the category

Accelerated definition of true density rubble

When using this method, the value that is known as the true density of the breed and grains of rubble is determined by the calculations of the total mass of the pre-crushed and after this dried material. In this case, to accurately determine all the parameters, the device is used for this. Requires the following equipment and materials:

- device le chaitor;

- laboratory scales GOST 24104 or desktop dial according to GOST 29329;

- for weighing: Porcelain Cup GOST 9147 or Glass 25336;

- exicitor GOST 25336;

- drying cabinet;

- sulfuric acid GOST 2184;

- calcium chloride (calcium chloride anhydrous) GOST 450;

- sieve, hole size 5 mm, GOST 6613;

- metal brush.

A well-chopped crushed stone prepared similarly to the previous method of definition, pour into a porcelain cup or a laboratory glass designed specifically for weighing. It is dried until it is dried to achieve a constant mass, to reach this parameter, the material is cooled to the value close to the value of the room temperature, with the help of the desiccator. Cooling can be carried out above sulfur concentrated acid or anhydrous calcium chloride. Two sakes are selected from the dried powder, 50 g in common weight each.

To begin with, the device is filled with water until the level of the bottom of the existing marks is reached, it is possible to determine this level using the lower meniscus. After that, inside the devices through the funnel in each place the prepared hitch with small portions. Pouring continue until the bottom of the water from the markup of the lower division under the action of the crushed rubble will leave up to 20 ml or any selected division, which is in the upper part of the scale. To remove an extra accumulated air, during the process, the device is slightly shaken.

Determine the desired density of the material in this case by weighing the part of the crushed stone taken, which did not enter inside. The discrepancy between the two results in the final calculations should not be greater than 0.02 g / m³. If the discrepancy turned out more, the third definition is made to then take into account 2 of the nearest to each other values.

After that, the arithmetic arithmetic 2 closest values \u200b\u200bis taken as a result. In the event that the need arises to determine the density of rubble or gravel, which is a mixture of fractions, the value for each fraction is determined separately.

True material density r and - physical value determined by the ratio of mass m., g, homogeneous material to its volume V. a, cm 3, in absolutely tight state, i.e., excluding pores and emptiness, namely:

p and \u003d. m./V. a, g / cm 3. (1.18)

Completing of the work. To determine true density stone material From the selected and thoroughly mixed medium samples, 200 ... 220 g. Slices of selected sample are dried in a drying cabinet at a temperature of 110 ± 5 ° C to constant mass, then thin in a porcelain mortar. The resulting powder is sieved through a sieve No. 02 (cell size in the light - 0.2 × 0.2 mm). Having a molding in a porcelain cup with a mass of about 180 g sizzy powder, it is dried again, and then cooled to room temperature in the desiccator, where the powder is stored before the test.

The true density of the solid material is determined using a lester size (Fig. 1.1), which is a glass flask with a capacity of 120 ... 150 cm 3 with a narrow neck, somewhat expanding in the middle part. On the neck of the flasks above and below the spherical broadening, two features are applied, the volume between which is 20 cm 3. The neck is graduated, the division price is 0.1 cm 3.

Fig. 1.1. Volume meter le chaitor:

1 - volume meter; 2 - vessel with water;

3 - Thermometer

The volume is filled to the lower zero line with a liquid, inert with respect to the powder of the material: water, anhydrous kerosene or alcohol. After that, the part free from the liquid (above the zero line) is carefully wiped with a tampon of filter paper. Then the volume is placed in a glass vessel with water having a temperature of 20 ° C (the temperature in which the scale was graded). In the water, the volume meter remains all the time while the test is being tested. So that the volume is in this position does not pop up, it is fixed on the tripod so that the entire graded part of the neck is in water.

From the prepared sample in the desiccator, with an accuracy of 0.01 g, 80 g of material are rested and poured with a spoon through a funnel into the device in small portions until the fluid level in it rises to the line with a division of 20 cm 3 or to the line Within the upper graduated part of the device. The difference between the final and initial levels of fluid in the volume processer shows the volume of the powder, rushes into the device. Powder residue weighed. The mass of powder, rushed into a volume meter, will be equal to the difference between the results of the first and second weighing.

True material density is calculated by the formula

r and \u003d ( m. – m. 1)/V. A, (1.19)

where m. - mass of the material of the material before the experience, r;

M. 1 - the remainder of the hitch, r;

V. A is the volume of the liquid displaced by the sample material (the volume of the powder in the volume processer), cm 3.

The true density of the material is calculated with an accuracy of 0.01 g / cm 3 as the average arithmetic results of two definitions, the discrepancy between which should not exceed 0.02 g / cm 3.

The results of the determination of the true density of the material are recorded in the log for laboratory and compare with the data given in Table. 1.2.

T a b l and c and 1.2. True and average density of materials

Brick density is a physico-technical characteristic, or a physical value that is a mass content of a substance (or material) in a certain amount of volume.

In this article, we will deal with what terms such as medium and true density mean. Here will also be provided with an instruction, following which you can determine the density of the building brick.

General requirements for testing over bricks

First of all, the tests should be carried out in a room in which the air temperature is equal to (20 ± 5) ° C. Samples of a whole product or halves should be used as a test material.

When drying, the sample or sample is adjusted to a certain condition, in which the difference of indications between the two last weighing during the drying process does not exceed a clearly regulated error.

In addition, the break between the two weighing should be the period in time, not less than specified in the norms:

- for sample or - 4 h;

- for sample - 2 h.

Drying is produced in special equipment at a set temperature of 1055 ° C, such equipment can serve as electrical cabinet.

The established regulatory maximum errors of weighing samples and samples, depending on their mass in grams, in which the mass is considered constant:

- 20 g and less - 0.002;

- 20 g..1000 g - 1;

- 1000 g..10000 g - 5;

- 10,000 g and more - 50.

The density of silicate brick kg: M 3 \u200b\u200bis determined no earlier than a day after the completion of the processing in autoclaves.

Definition of medium density

Brick has such a characteristic as the average density, which, in fact, is, the ratio of the mass of the substance M (kg) to the same volume occupied by the same volume (m 3), together with voids and pores: M / Vest. According to the average density of the material, it is possible to judge its thermal conductivity, since this is the value inversely proportional to porosity.

Required testing inventory:

- Drying electrical cabinet Suitable TU 16-681.032 The main requirement for the drying cabinet is an automatic temperature adjustment within 100..110 ° C.

- Metal measuring line that meets the requirements of GOST 427.

Preparation of samples for testing

You need to choose at least three samples to determine the average density.

Directly testing

The volume (V) of each sample is determined by its geometric dimensions, measured with the maximum permissible error of no more than 1 mm. To determine each linear sample size, it is measured in three places - along two ribs, and in the middle of the face. The measurement result is considered the arithmetic average of three dimensions.

Samples before driving to constant mass, purified from different contaminants, on the like dust.

Cord Sample will reach a constant mass - this will be the mass (M), taken into account when further calculations.

Processing obtained results

The average density (ρ CP) of the sample in kg: M 3 \u200b\u200bis calculated by the formula:

where V is the sample volume, see 3.

As you already guessed, the arithmetic average of the mean values \u200b\u200bof the average density for each sample we will take for the representative value of the average density for the entire batch of the building material, and the calculation accuracy should be up to 10 kg: m 3.

Both the initial data and the results of the calculation of the average density are closely entering the testing log specifically for this.

True density

The definition of the true density of the brick is a more complex process that requires more special devices.

Testing inventory:

- Drying electric cabinet, according to TU 16-681.032 032. The main requirement for the drying cabinet is an automatic temperature adjustment within 100..110 ° C.

- Scales corresponding to GOST 24104.

- Thermostat capable of maintaining the temperature in 20.0 ± 0.5 ° C.

- The vacuum excitator, made in Embodiment 1 according to GOST 25336, supplemented with an oil or water jet vacuum pump, according to GOST 25662, capable of creating a vacuum 532 pa (or 4 mm mercury column).

- The desiccator made in Embodiment 1 according to GOST 25336, equipped with a concentrated acid H 2 SO 4, according to GOST 4204, also use anhydrous calcium chloride, which is normalized according to GOST 450.

- Several pycnetters of the 50-100ml-type PZh2 type, type PZh3 and PT according to GOST 22524. The cone is attached to each of them, according to GOST 8682.

- Agated or porcelain mortar with pestle.

- BUKS GLAYS according to GOST 25336 or porcelain cups according to GOST 9147.

- Sieve, Mesh N 1 and mesh N 0.063 according to GOST 6613.

- Sand or water bath.

- Distilled water according to GOST 6709 or any other, inert with respect to the material of the test samples, liquid.

Terms and Definitions

The desiccator is a thick-walled vessel made of plastic or glass, which supports the necessary experience, usually close to zero, air humidity. The lid, to ensure tightness, is lubricated with a special lubricant at the point of contact with the case.

Use this unit for such purposes:

- For slow drying in room temperature

- To ensure favorable conditions for storing hygroscopic compounds that require gravimetry, and it is important to prevent saturation of experiments by an unknown volume of water from the surrounding atmosphere.

- For some purposes it is possible to create a vacuum inside the excitator.

In the desiccator, there is a lattice porcelain pallet, installments installed on it. At the bottom of the vessel, there is a hygroscopic substance for removing moisture residues, or a special solution that maintains the level of the necessary partial pressure of water vapor.

Picnometer - a device, a quoted volume and special shape made of glass, used by physicists and chemists to determine the density of gaseous, liquid and solids. According to some data, invented him in 1859, the well-known scientist Dmitry Ivanovich Mendeleev.

To determine the density, weigh the substance that fills the pycnometer to a certain mark on the neck or until the uppermost point of the capillary, which corresponds to the nominal volume of the pycnometer. Density solid body It is determined by immersion in a pycnometer filled with liquid.

The main advantages of determining the density with the help of a pycnometer are:

- the measurement accuracy is sufficiently high - up to 10..5 g / cm³;

- it is allowed to use a small amount of substances - 0.5..100 cm³;

- the minimum area of \u200b\u200bthe open surface of the fluid, which makes it possible to eliminate the possibility of evaporation and absorption of moisture from the atmosphere.

Preparatory work before testing

- Either construction brick, facing brick density which must be defined, or double silicate brick M 150 - the procedure is the same.

The true density is determined on the samples of the material from which products obtained at least from three different samples consist. - To prepare samples:

- From each sample from the middle and outside two, about the same, a piece of their total mass should be at least 200 g.

- These pieces are crushed to the size of the size of approximately 5 mm.

- The price of quartwing is made by the mass of which over 100

- The jacket is crushed in agateau or porcelain mortar until it goes completely through the grid N 1.

- After that, the rental method makes a hitch, the mass of which is over 30 g

- The jacket is crushed into the mortar until it passes completely through the grid N 0.063.

- The prepared powdered sample of the material of the samples is dried until the sample mass becomes constant. After drying the sample, it is cooled to room temperature in a desiccator over anhydrous CaCl 2 calcium chloride or concentrated H 2 SO 4.

Stage of testing

The density is determined parallel to two samples selected from the sample, the mass of them is about 10 g each.

The selected jamming is poured into a clean, dried pycnometer, which is weighed after drying. A pycnometer is weighing together with experimental powder, after which the inert liquid is poured into this special vessel (usually water) so that the pycnometer is filled with about half of its volume.

In order to remove air from the sample material as well as from the liquid, the picnometer along with the contents are placed in a vacuum excitator, and it is located there until the bubbles stop out. Also, when using water as an inert fluid, it is possible to remove air by boiling a pycnometer with a content of about 15..20 minutes, slightly tilting it, on a water or sandbar.

The liquid to fill the picnometer should not contain air bubbles, if this condition does not comply with the homogeneity of the composition of the liquid by removing all gaseous substances from it.

When the air is removed - PG3 type picnometer is completely filled with liquid, and PZh2 and PT fixtures are filled to a certain tag. The vessel is placed in the thermostat tuned at a temperature of 20.0 ± 0.5 ° C, and it is maintained there at least 15 minutes.

After the expiration of 15 minutes, the PZH3 type picnometer is closed with a plug with a hole, so that the liquid completely filled the capillary, and its excess was removed. After that, the vessel is carefully wiping, and the drop of fluid from the capillary is removed by filtering paper.

In PZh2 type pycnetters and PT, the fluid level is brought to the label of Lower Meniska.

When the fluid level will freeze at a constant mark - the picnometer is weighed.

After the pycnometer weighed it cleaned from the fact that inside, it is thoroughly washed and filled with the same liquid, after which the entire air is removed from it, then kept in the thermostat, bring it to a constant level and again weighed.

Stage processing obtained results

The true density (ρ and) of the sample material is measured in (g / cm 3) by the formula

As well as in determining the average density, the representative value of the true density of the samples is taken by the arithmetic average between the results of determining the true density of the test material for two hits. Calculations lead up to 0.01 g / cm 3.

With all this, the discrepancy between the two results of parallel tests should not be higher than 0.02 g / cm 3. With greater discrepancies, all stages need to be repeated again.

As well as in determining the average density, the initial data, and the results of the calculation of the true density are closely entering the test journal specifically for this.

reference Information

Below is the density of brick kg: m 3:

- ceramic brick density kg: m 3:

- – 1600-1900;

- hollow - 1000-1450;

- facing - 1300-1450;

- red brick density kg: m 3:

- density clinker bricks kg: m 3 - 1900-2100;

- full-time - 1600-1900;

- – 1000-1450;

Tip: To determine the density of bricks, you are best to contact the laboratory, as in order to make it with your own hands, you will need high-precision expensive equipment, if you decide to use less accurate handicraft analogues of the desired equipment, then the price for this pleasure can be pretty High - the unreliability of the data obtained.

In this article, we looked at what the density of such material as a brick, and how to determine it. (See also Article) Look at the Voice Video: This article has theoretical information, and having reviewed the video, you may be better perceived, as it looks in practice.