The average density of the material depends on it. Cheat sheet on information systems and technology. Structural properties of building materials

True material density r and - physical value determined by the ratio of mass m., g, homogeneous material to its volume V. a, cm 3, in absolutely tight state, i.e., excluding pores and emptiness, namely:

p and \u003d. m./V. a, g / cm 3. (1.18)

Completing of the work. To determine true density stone material From the selected and thoroughly mixed medium samples, 200 ... 220 g. Slices of selected sample are dried in a drying cabinet at a temperature of 110 ± 5 ° C to constant mass, then thin in a porcelain mortar. The resulting powder is sieved through a sieve No. 02 (cell size in the light - 0.2 × 0.2 mm). Having a molding in a porcelain cup with a mass of about 180 g sizzy powder, it is dried again, and then cooled to room temperature in the desiccator, where the powder is stored before the test.

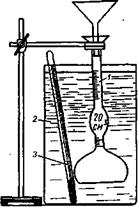

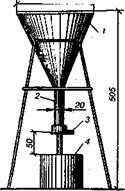

The true density of the solid material is determined using a lester size (Fig. 1.1), which is a glass flask with a capacity of 120 ... 150 cm 3 with a narrow neck, somewhat expanding in the middle part. On the neck of the flasks above and below the spherical broadening, two features are applied, the volume between which is 20 cm 3. The neck is graduated, the division price is 0.1 cm 3.

Fig. 1.1. Volume meter le chaitor:

1 - volume meter; 2 - vessel with water;

3 - Thermometer

The volume is filled to the lower zero line with a liquid, inert with respect to the powder of the material: water, anhydrous kerosene or alcohol. After that, the part free from the liquid (above the zero line) is carefully wiped with a tampon of filter paper. Then the volume is placed in a glass vessel with water having a temperature of 20 ° C (the temperature in which the scale was graded). In the water, the volume meter remains all the time while the test is being tested. So that the volume is in this position does not pop up, it is fixed on the tripod so that the entire graded part of the neck is in water.

From the prepared sample in the desiccator, with an accuracy of 0.01 g, 80 g of material are rested and poured with a spoon through a funnel into the device in small portions until the fluid level in it rises to the line with a division of 20 cm 3 or to the line Within the upper graduated part of the device. The difference between the final and initial levels of fluid in the volume processer shows the volume of the powder, rushes into the device. Powder residue weighed. The mass of powder, rushed into a volume meter, will be equal to the difference between the results of the first and second weighing.

True material density is calculated by the formula

r and \u003d ( m. – m. 1)/V. A, (1.19)

where m. - mass of the material of the material before the experience, r;

M. 1 - the remainder of the hitch, r;

V. A is the volume of the liquid displaced by the sample material (the volume of the powder in the volume processer), cm 3.

The true density of the material is calculated with an accuracy of 0.01 g / cm 3 as the average arithmetic results of two definitions, the discrepancy between which should not exceed 0.02 g / cm 3.

The results of the determination of the true density of the material are recorded in the log for laboratory and compare with the data given in Table. 1.2.

T a b l and c and 1.2. True and average density of materials

Ministry of Education and Science of the Russian Federation

Ugra State University

Faculty of Engineering

Department "Construction technologies and structures"

The main properties of building materials

(density, voidness, porosity, water absorption, humidity, strength, softening, frost resistance).

at the rate "Materials science (building materials)"

for specialties:

"Economics and Management at the construction enterprise" (060800)

Khanty-Mansiysk

|

General provisions ............................................................................. | ||

|

Structure of laboratory work ............................................. | ||

|

General classification of the main properties .................................. | ||

|

Laboratory work number 1 Determination of true and medium density ........................... ... | ||

|

Determination of the true density of the brick .......................................... | ||

|

Determination of the average density of materials ......................... ... .. | ||

|

Sample material of the right shape ....................................... | ||

|

Sample incorrect form…………………………………….…... | ||

|

Laboratory work number 2 ................................................................ | ||

|

Determination of the bulk density of materials ............................. | ||

|

Wallout ..................................................................... .. | ||

|

Theoretical part……………………………………………………. | ||

|

Laboratory work number 3. Porosity and water absorption building materials………….. | ||

|

Theoretical part……………………………………………………. | ||

|

Laboratory work number 4. Determining the moisture content of building materials ...................... | ||

|

Theoretical part……………………………………………………. | ||

|

Laboratory work number 5. Strength of building materials ....................................... | ||

|

Theoretical part……………………………………………………. | ||

|

Part 1. Determination of the strength in compression and the coefficient of constructive quality ................................................. .... | ||

|

Part 2. Definition of the softening coefficient ................ ... .. | ||

|

Theoretical part……………………………………………………. | ||

|

Part 3. Determining the strength of bending ............... ... | ||

|

Laboratory work number 6 Frost resistance ............................................................... .. | ||

|

Determination of the stamp on frost resistance ................................. ... | ||

|

Theoretical part……………………………………………………. | ||

|

Control questions………………………………………………….. | ||

|

Bibliography…………………………………………………….. |

The purpose of this work is the acquisition of work skills with laboratory equipment, the development of modern methods for determining the main properties of building materials and the ability to estimate the correctness of the results obtained.

1. General provisions

Students who have studied the content of work on the relevant work are allowed to perform laboratory work. methodical instructions and submitted a report to work with the necessary laboratory logs. The report summary is drawn up in accordance with the structure of laboratory work.

1.1. Structure of laboratory work

1.1.1. Name of the topic of laboratory work. It should be performed clearly and stand out from the main text.

1.1.2. The purpose of the laboratory work is the name of the defined property; The method used in operation; Evaluation of the correctness of the results obtained.

1.1.3. Theoretical part. The main definitions of the properties of building materials studied in this work are given, the outcrimal formulas, units of the dimension of the defined constants.

1.1.4. Materials and equipment, reagents.

Sets out the course of work in a fairly brief form with an indication of the sequence of operations.

1.1.6. Laboratory magazine.

All experienced data obtained on their foundation are made to it and the calculated values \u200b\u200bobtained on their basis. The laboratory log is designed in such a way that the table method of calculation can be carried out.

1.1.7. Calculated part.

The calculated part is present when it is necessary to conduct auxiliary calculations, the explanations that are not included in the laboratory log.

1.1.8. Transcue.

It is concluded about the correctness of the results obtained by comparing them with the standard values \u200b\u200bof the constants defined in the laboratory work given in the special literature or those specified in Guest.

General classification of basic properties:

– physical properties (density, porosity, water absorption, humidity, thermal conductivity, frost resistance, etc.);

– mechanical properties (strength, hardness, abrasibility, impact resistance, etc.);

- Deformative properties (plasticity, elasticity, creep, etc.);

– chemical properties (alkali resistance, acid resistance, bioscistance, etc.);

- technological properties (weldability, clove, plasticity, sintering, etc.).

Laboratory Work number 1.

Definition of true and medium density

THEORETICAL PART

The density is the mass of material in a unit volume.

Depending on the degree of compaction of the particles of the material distinguish:

True densitywhen a unit of material is in an absolutely dense state (without pores and emptiness)

rI \u003d, g / cm3, where

rI - true density, g / cm3;

m - the mass of the material in an absolutely compacted state, r;

Va - the volume of material in an absolutely dense state;

V - material volume in natural condition;

VP is the pore volume prisoners in the material.

Middle density, or just a density when the mass of material in a unit of volume is in a natural state (with pores and voids)

rO \u003d, g / cm3, where

mo - Material Material in Natural State, G.

Bulk density When the mass of the material in a unit of volume is in a bulk state (interzraine voids are included in the bulk volume);

rN \u003d, g / cm3, where

rN - bulk density, g / cm3;

mN - bulk mass, g;

VN - bulk volume, cm3.

The bulk density is determined both in the loop-sucking state and in the compacted. In the first case, the material falls asleep in the vessel from a certain height, in the second, it is compacted on the vibrationboard (30-60 seconds). From the foregoing it follows that in a unit of volume for this material

m\u003e Mo\u003e MN and RI\u003e RO\u003e RN

Relative density is a dimensionless value equal to the ratio of the average density of the material to the density of water at 4 ° C, equal to - 1 g / cm3

d - relative density;

rO - average density, g / cm3;

rV is the density of water at 4 ° C, 1 g / cm3.

This value is taken into account in some empirical formulas.

Purpose of work:included with the essence of the concepts of "density" True and average and methods for their determination for samples of the correct and improper geometric shape. Learn to evaluate the correctness of the results.

1. Definition of true brick density

Materials: Snapped in a powder of ceramic brick weighing about 70 g, distilled water.

Instruments and devices: Scales laboratory technical, standard volume meter (flask le chaitor), glass wand, glass (porcelain) glasses with a capacity of 100 and 500 cm3; Dry napkin.

Progress

1. The sample of fine bricks (particle size should be less than the size of the pores in the brick) weighing about 70 g placed in a glass and weighed on technical scales with an error of not more than 0.05 g.

2. In the volume meter (Fig. 1.1) pour water to the bottom risks applied to the extension on the throat of the flasks. The throat of the volume is to dry the filter paper (or cloth). Then the brick powder from a weighted glass carefully with the help of a glass sticks to pour it into a volume meter until the water level rises to the top label (the loss of the powder is not allowed). The volume of the filtering powder VP is equal to the volume between the upper and lower marks of the size of the size (20 or 10 cm3) and is indicated on the size.

3. The mass of the brick powder (g), filled into the volume meter, to determine, weighing the powder residue in the glass M2 and calculate it as the mass difference (M1-M2)

ρ \u003d (M1-M2) / VP

|

Figure 1.1. Volume meter le chateel

1 - volume meter; 2 - vessel with water; 3 - thermometer.

All results to put in the laboratory log.

Laboratory Journal

|

true mass |

powder volume |

powder mass in size |

True density |

|||

2. Definition of medium density of materials

2.1. Sample material of the right form

Materials: concrete (or solid) sample cube; a cube of a tree with 1 edge 4 ... 5 cm; Sample of foam in the form of parallelepiped weighing 10 ... 30 g

Instruments and devices: Laboratory scales technical, measuring rules, caliper.

Progress

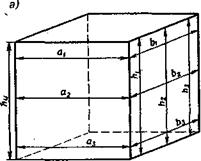

1. Samples of concrete cubes (solution), wood and foam mester to measure a line with an error of 1 mm or a calipercule with an error of 0.1 mm. Each face of a cubic or close to it is measured in three places (A1, A2, A3, B1, B2, B3, H1, H2, H3) in width and height, as shown in Fig. 1.2.And, and for the final result, the arithmetic average of three measurements of each face is taken. On each of the parallel planes of the sample of the cylindrical shape, two mutually perpendicular diameters (d1, d2, d3, d4) are carried out, then measure them; In addition, the diameters of the middle part of the cylinder (DS, DB) are measured in the middle of its height (Fig. 1.2., b.). For the final result, the average arithmetic six diameter measurements are taken.

The height of the cylinder is determined in four places (H1, H2, H3, H4) and the final result is taken by the arithmetic average of four dimensions.

Samples of any form with a side of up to 100 mm measured with an accuracy of 0.1 mm, a size of 100 mm and more - with an accuracy of 1 mm.

2. Determine the mass M of concrete, solution, wood and foam. Samples weighing less than 500 g are weighed up to 0.01 g, and weighing 500 g and more up to 1 g.

The data obtained is in the laboratory log.

| |

Fig. 1.2. Sample size measurement scheme

but – cubic shape; b. - cylindrical form

Laboratory Journal

|

material |

sample sizes, cm |

True density |

||||||||

D. |

||||||||||

2.2. Sample of irregular shape

Materials: a piece of bricks of an irregular shape weighing 50 ... 70 g; Melted paraffin, density RP \u003d 0.93 g / cm3.

Instruments and devices: Scales laboratory technical with a device for hydrostatic weighing, brush.

Progress

1. Weigh the sample - m, g;

2. With the help of a tassel to cover the paraffin sample to save in its opening volume;

3. Weigh the sample coated with paraffin, pre-cooling it to room temperature - M1, r;

4. Conduct hydrostatic weighing coated with paraffin sample M2, r (Fig. 1.3.).

Weighing to spend up to 0.01

Experience repeat three times.

|

All results to put in the laboratory log.

Fig. 1.3. Weighing sample on hydrostatic scales

Laboratory Journal

|

mass sample, g |

paraffin |

density |

||||||

m2. |

||||||||

Calculated part

Determination of the sample volume by the method of hydrostatic weighing is made on the basis of the Archimedes Act: "The body immersed into fluid acts an ejecting force equal to the weight of the fluid in the amount of this body."

Therefore, the mass of a sample suspended in water will be easier masses of a sample suspended in air, on pushing force

A \u003d (m1-m2) g, n

A - the power of Archimedes;

g - Acceleration of free fall, m / s2.

Vo. P. * RV \u003d M1-M2 þ Vo. p. \u003d, but Vo. p. \u003d V + VP þ

Þ V \u003d Vo. P.- VP \u003d.

Laboratory work number 2.

1. Determination of the bulk density of materials

Materials: quartz sand.

Instruments and devices: Scales laboratory technical, standard funnel, ruler, measuring cylinder with a capacity of 1 liters.

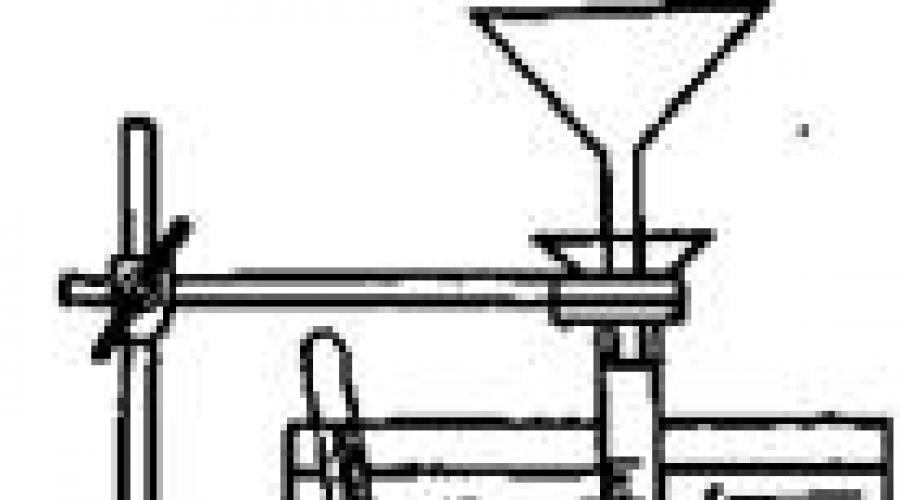

Progress

1. Weigh the measuring cylinder - M1 g;

2. In the standard funnel installed on the pallet, fall asleep sand with a closed gate (Fig. 1.4.);

3. One reception by opening the shutter, fill the measuring cylinder to the sand before the formation of a cone above its edges;

4. Remove the excess sand by conducting a ruler along the top of the cylinder forming;

5. Weigh the measuring cylinder filled with sand - M2.

Weighing to produce up to 1 g.

Experience repeat three times.

|

Fig. 1.4. Standard funnel

1 - body; 2 - tube; 3 - catch; 4 - measuring cylinder

Laboratory Journal

|

material |

measuring cylinder |

cylinder with sand, |

sand mass |

bulk density |

||||

volume |

weight |

|||||||

For the final result, adopt the average value of 3 experiments.

2. Empty

THEORETICAL PART

Emptiness is the proportion of inter-rigid voids in a bulk volume of material.

Estimated formula:

where

where

PU is void, share or%;

Vput is the volume of voids in a bulk volume of material, cm3;

V - material volume, cm3.

Emptiness is expressed in%:

Emptiness is the most important characteristic of the correctness of the selection of the grain composition of aggregates for concrete, on which the consumption of binder (cement, bitumen, etc.) depends. In practice, void lies within 26.5 ... 47.6%.

2.1. Determination of the volatility of bulk materials

Purpose of work: Determine the voidness of sand and rubble. Establish the dependence of the emptiness from the magnitude of the grains of a bulk material. Assess the correctness of the results obtained.

Materials: quartz sand, fraction (0.63 - 0.315) - 2 l; Crushed stone granite, fraction (10-5) - 10 liters.

Instruments and devices:dimensional cylinders with a capacity of 1 l and 5 l; Standard funnel; line; trade scales; pallet.

Progress

1. Determine bulk density sand in accordance with the previous part of the work;

2. Weigh a blank cylinder, with a capacity of 5 l - m1, g;

3. Fill the crushed stone into the cylinder of the scoop from a height of 10 cm before the formation of a cone above the edges, putting it pre-onto the pallet;

4. surplus rubble cut the line to the clove with the edges;

5. Weigh the cylinder filled with rubble - M2, G.

Weigh up to 1 g. Central quartz sand density and granite rubble Take from table 1 applications.

Definition repeat three times.

Laboratory Journal

|

material |

cylinder |

cylin-dra, |

material |

bulk density, |

density |

emptiness |

||

For the final result, adopt the average value of the voids of their three definitions.

Laboratory work number 3.

Porosity and water supply of building materials

THEORETICAL PART

Porosity and water supply of materials are closely connected with each other. Water absorption increases with increasing porosity. Therefore, these properties are conveniently considered in parallel.

Porosity is the proportion of material filling.

Total porosity (or just porosity):

,

,

where VPP is the pore volume in the material.

Porosity is expressed as a percentage:

From the magnitude of the porosity and its character, the most important characteristics of the material are dependent: density, strength, thermal conductivity, durability, etc.

Porosity in the material is characterized by both open and closed.

Open pores increase the water absorption and water permeability of the material and worsen its frost resistance.

An increase in closed porosity due to open increases the durability of the material, reduces its thermal conductivity.

Water absorption - Property of material absorb and hold water.

Quantitative characteristics of this property:

Mass water absorption - this is the ratio of the mass of the absorbed material of water under certain GOST conditions to the mass of dry material in%:

Volumetric water absorption - This is the ratio of the mass of the absorbed material with the material under certain GOST conditions to the volume of material in a dry state in%:

bm - mass absorption;

bV - bulk water absorption;

mN - the mass of material saturated with water under standard conditions, r;

m - the mass of air-dry material, r;

V is the volume of air-dry material, cm3.

The ratio between mass and volumetric water absorption:

Volumetric water absorption is numerically equal to open porosity:

Having determined water absorption in terms of volume and porosity of the material, you can easily calculate the closed porosity:

Pzakr \u003d (P-Potch)%

The saturation coefficient of pores water is the ratio of water absorption by volume to porosity:

It changes from 0 (all the pores are closed in the material) to 1 (all the pores are open).

The larger the KN, the higher the proportion of open pores relatively closed.

Purpose of work:determination of porosity, water absorption and saturation coefficient of pores with water on the example of ceramic bricks. Evaluation of the correctness of the results obtained.

Materials: ceramic bricks.

Instruments and devices:scales laboratory technical, caliper, ruler, bath with water.

Progress

1. Dry bricks (3 pcs) to constant weight at a temperature of 105-110 ° C (the difference of the results of 2 consecutive weighing is not more than 0.2%). Weighing to produce after complete cooling of bricks - m, g;

2. Measure the geometric dimensions of bricks with an accuracy of 0.1 mm;

3. To saturate bricks with water at a water temperature of 15-20 ° C, for 48 hours, at a water level by 2-10 cm above the top of the edge of the bricks;

4. Watching bricks with a damp cloth, immediately weigh them - MN, G.

Weigh up to 1 g.

The value of the true density of ceramic brick take out of work number 1.

Laboratory journals

Water absorption

|

brick mass |

geometric brick dimensions, |

water absorption |

|||||||

|

mass |

volumeful |

||||||||

|

water |

|||||||||

POROSITY

|

density |

porosity |

coef. saturation pore water |

|||||

|

open |

closed Pzak \u003d Pottle,% |

||||||

|

true | |||||||

For the end result, take the average value of 3 definitions.

Laboratory work number 4.

Determination of humidity of building materials

THEORETICAL PART

Humidity is the ratio of the mass of water currently contained in the material, to its mass in a dry state, in%.

Estimated formula:

mVL - mass of wet material, g;

m - Mass of dry material, G.

Purpose of work: Determination of sand humidity. Evaluation of the correctness of the result.

Materials: quartz sand.

Instruments and devices:fucks, drying cabinet, excitator, technical scales.

Progress

1. Weighing bins - M1, g;

2. Weighing bins with wet sand - m2, g;

3. Place the bins with sand in the drying cabinet, the drying time depends on the mass of the sample material;

4. Cool bins with sand in the desiccator and weighed - M3, r;

5. Drying to produce to constant weight.

For the final result, adopt the arithmetic average of 3 parallel definitions, provided that the relative deviation of the individual result from the average value does not exceed 5%.

Laboratory Journal

|

mass Bekbe |

mass of the Bekbe with dry sand, g |

humidity |

||||

|

value humidity |

Counting deviations of a separate result from the average value.

Calculation part:

|

humidity |

Deviations of a separate result |

|||

|

absolute |

relative |

|||

OUTPUT.

CONTROL QUESTIONS

1. List the properties of materials that characterize the characteristics of the physical condition of building materials.

2. Compare mass and volumetric water absorption for test materials. What is the value - or more for compared materials? Answer Motivate.

3. How is the strength of the material with water absorption, with porosity?

4. If in the material to reduce water absorption, then how will it affect the medium density of the material, on the true density, on the thermal conductivity coefficient?

5. How to change the thermal conductivity coefficient, if the frost resistance of the material has increased?

6. Name the magnitude of the average and true density for concrete, for ceramic brick, for wood and for any polymer material.

7. What can the materials of the exterior structures of buildings and structures in the winter can be destroyed?

8. From what parameters the frost resistance of structural materials depends?

9. How is the thermal conductivity with porosity in building materials?

10. In concrete, medium density is reduced by certain operations. How will this affect the strength of the material and its durability?

11. Give examples of materials characterized by high fire resistance, refractory.

12. What is the dimension of the coefficient of thermal conductivity, frost-resistance?

13. List the indicators that determine the mechanical properties of materials.

14. What types of strength characterize concrete, wood? Which units is the strength?

15. Give examples of materials that have high deformation properties. What parameters are the deformative properties of materials?

16. What is the abrasibility? Give examples of materials with high and low abrasability.

ATTACHMENT

Table 1.

True I. average density Some building materials

|

Material |

True density, kg / m3 |

Average density, kg / m3 |

|

Limestone: shechechians Volcanic tuff Ceramic brick: ordinary hollow porous Wood pine Foams Stool construction perceptible lightweight overall Gypsum and Gypsum Products silicate slag trepal Mineral wool Foam concrete and aerated concrete Penosilikat Foamglo Solutions: lime lime-cement cement Slagobeton granulated fuel Fibrololite: magnesian cement |

Table 2.

Porosity and water absorption of ceramic bricks

|

View of ceramic |

Average density |

Porosity,% |

Water absorption,% |

|

Ordinary Conditionally effective Effective |

frost resistance

For building materials, these are the most important properties characterizing the material. Knowing density can be assumed which strength, thermophysical properties, frost resistance.

Define the density as a mass of a unit of volume, as a rule, is a mass of 1 cm 3 or 1 m 3.

If weigh the unit of the volume of porous and absolutely dense of the same material, we will get different masses, and the difference will be the greater, the more pores in the material. Therefore, in construction practice distinguished true densitywhen the material is laid in absolutely dense volume, there are no pores, between parties solid body No gaps (g / cm 3):

The density of the material in a unit of volume with pores and loosers characterizes middle density Or, as it used to be called, the volume mass (g / cm 3):

If the material without pores and non-rotations, its average density is true. So, at metals, glass, dense plastics, deep stone rocks The true density is equal to the average. W. porous materials part of the volume occupy pores, so the mass is less . Volume In the natural state is equal to the volume of the solid body and the amount of pores (see 3):

For bulk materials determine bulk Density when the unit of volume is filled with grainy or powder materials, in the grains of which there may be pores, and may not be, but there are always air interlayers between the grains, for example, a container with cement, sand or rubble. In this case, there remain looseness between bulk grains or particles - emptiness and therefore, the bulk density is always less than the average and all the more true density.

It is indicated in the same units - g / cm 3 or kg / m 3:

Relative The density D expresses the density of the material relative to the density of water. As a rule, it corresponds to the average density:

The porosity is common The material is defined as the ratio of the volume of pores to the volume of material in a natural state, is indicated in the fractions of a unit or in%:

If the pore volume is not known, the total porosity is determined by density. To do this, you need to know the true and middle density:

where the density ratio of the true to the middle there is a density coefficient:

Porosity along with the density coefficient is one whole, unit:

In the case of the pores, there may be open and closed, separate, where water can not penetrate the material during immersion in it. How to find out if there are some pores or not?

It is easy to determine the open porosity, immersing the material into the water. And, knowing the total porosity, determine the difference closed:

.

.

Open porosity is determined by water absorption. It is equal water absorption In terms of volume, which is calculated by the difference of masses of wet and dry material:

The larger in the material closed pores the less moisture can hold the material during wetting, the higher it will be higher frost resistance I.heat insulating Properties.

According to openly reported capillaries, water fills the voice space, reducing thermal insulation, frost resistance and even strength.

Water absorptiondenote the letter W and determine as in volume (  equally

equally  ) and by mass

) and by mass  . By mass determine and humidity Materials in%:

. By mass determine and humidity Materials in%:

Attitude  . Water absorption by weight can be more porosity, but it cannot exceed the porosity.

. Water absorption by weight can be more porosity, but it cannot exceed the porosity.

By the number of absorbed water calculates saturation coefficientequal to the ratio of water absorption in volume to the total porosity of the material:

Open porosity is specifically created if the material is needed when the sound wave is weakening in the capillaries maze. For this purpose, materials are specially perforated, create an open porosity. For thermal insulation, on the contrary, closed pores with fixed air are needed, since the air is the lowest thermal conductivity.

The larger in the material of pores or the thinner of the grinding of the material, the more contact with the air is becoming its surface - specific surface area(The surface in cm 2, which comes on 1 g of substance), which has a significant effect on the properties of the material. The higher the specific surface area, the higher the sorption properties of the material - the ability to absorb moisture from the air and when cooled to form condensate. This property is called hygroscopicity, and such materials - hygroscopic.

Sorption or adsorption occurs in any material due to the unsaturation of the energy of the extreme molecules of the solid body, but in dense materials or coenproofs with a slight specific surface, sorption abilities are insignificant. In hygroscopic materials, for example, in wood in humid air, humidity may increase to 30%, in cellular concrete - up to 7-8%, which will affect the thermal conductivity (if the materials are not dried).

The thinner of the capillaries, the higher them can climb moisture and moisturize the design. This phenomenon is called capillary suction. It is dangerous for the walls, therefore, there is always a waterproofing material between the foundation and wall.

Moisture in the material can get 3 ways: with capillary suction; via capillary filtration or water permeability when water presses from above; via capillary condensationWhen adsorbed moisture in the form of a pair inside the wall with a decrease in temperature turns into water and can be frozen there.

Satisfied with moisture and when it changes it in the air, the striking, the material is experiencing humidity deformations, occurs shrinkage, When saturated moisture - swelling. The alternation of drying and moisturizing porous materials is accompanied by alternating deformations that accelerate the cracking and destruction of the material.

The greater the material can absorb moisture, the more he has a shrinkage, the more its structure will suffer when drying and during freezing in rich water.

Shrinkage for some building materials (mm / m):

Frost resistance - The ability of the material to withstand alternate freezing in rich water and thawing in water. Water during freezing increases in volume by more than 9%, the formed ice crystals break the thin walls of the capillaries, and the material is destroyed by peeling the surface more saturated with water. Frost resistance is quantified with cycles and is marked: F25, F50, F100, F200, F50, F100, F200, F300 or more, i.e. By how many freezing cycles, the samples were withstood without loss of strength not more than 5% or loss of mass no more than 3%. One cycle is freezing until the samples are completely freezing and thawing them in water.

Brick and porous concrete have a small frost resistance, since there are few closed pores in their structure, many reporting capillaries (large water saturation). And the material saturated with water has a low frost resistance.

Rich moisture material reduces its heat shielding properties. The best heat insulator under normal conditions is a dry fixed air that can be in closed pores or isolated cells. All insulation contain small closed pores. Coefficient of thermal conductivity Air is equal λ \u003d 0.023 W / (M ° C), while water - 0.58 W / (m ° C), ice - 2.3 W / (M ° C). Therefore, all thermal insulation materials are saturated with air, made with cellular or fibrous, and they need to be protected from moisture.

Fire resistance- The property of the material to resist the action of fire for a certain time. This property depends on the ability of the material to ignite and burn. Building materials on fire resistance are divided into: non-aggravated (brick, concrete, steel, stone), challenges (asphalt concrete, fibrolite, impregnated with antipyrin wood), combustible (wood, plastics, rubberoid). For some materials determine Teten resistance, i.e. the temperature at which the performance of the material is preserved without its deformation. So, for metals there is a flow temperature when softening and significant deformations begins, - it has become 600ºС. The design at such a temperature is not capable of performing its functions. Aluminum alloys are 150-200 ° C.

Linear temperature coefficientexpansions (CLTR) matters when fluctuations in temperature for materials working jointly under load. In seasonal or daily change in temperature, different deformations occur in different materials. So, in reinforced concrete steel reinforcement has a CLTR 10 · 10 -6 degrees -1, the same coefficient and in concrete, so they work synchronously, not peeling. If instead of steel reinforcement, it is two times higher instead of steel reinforcement, one of the material from the other will occur, the design will be weaker, cracks will go along the concrete. Temperature deformations at daily fluctuations of the temperature reaches 0.5-1 mm / m, which is particularly undesirable on linear multi-meter structures, so long structures are cut in temperature or deformation seams.

When creating new composite materials, this factor is one of the conditions required for execution. Another condition is the chemical compatibility of the components: the materials should not respond to each other. So, when reinforcing cement concrete with fiberglass, glass should be alkali, then fiberglass will work as fittings, and not to enter into chemical interactions with cement stone.

Full-text search:

Home\u003e Cheat Sheet\u003e Construction

The concept of "material consumption"

"Material intensity" -Conditions of effective materials that are determined

signs.

operating and technical and aesthetic properties - pleasant and complex. Simple Properties can not be divided into others. For example, the simple properties of "Mass", "Length" of materials cannot be represented by other simpler properties.

Sophisticated Properties can be divided into several less complex or simple properties. For example, functionality is a complex property determined by the set of operational and technical properties. Economy is composed of technical and economic characteristics, reflecting the cost of production, the use and operation of construction material during the entire settlement service life. Complicated properties include quality and integral quality.

Application of qualimetry principles to assess the quality of building materials

an acquaintance with his methodological foundations should be taken into account the following provisions: 1) the assessment of the quality of the building material depends on what purpose and for what conditions this assessment is made, therefore the same material may have several different quality estimates. Before assessing the quality assessment, it is necessary to establish all the necessary conditions and the purpose of the assessment; 2) Quality should be considered as a hierarchical set of material properties located at different levels. Each property of one level depends on a number of other properties of a lower level; The quality assessment of the material depends on the indicators of its properties.

Conducting qualimetric analysis implies the implementation of several main stages, of which the most responsible - construction of the tree of properties, i.e., the image of the entire set of material properties in the form of a multi-level structure.

"Figure" of the tree may vary depending on the type of material, the purpose of the assessment and other factors ..

A quantitative assessment of the quality of compared building materials (products) can be obtained as an average weighted arithmetic of relative estimates of properties TO i. , from By consideration of their weight M. i. ,. We will receive a comprehensive assessment of the quality of the material, which characterizes its ability to meet all the functional and aesthetic requirements for the material in accordance with its purpose. If all indicators are summed up without exception, the result obtained gives the most complete assessment of the integral quality of the material TO ∑

To σ \u003d k i x m i

When evaluating the results, that of comparable building materials is the best for integral quality, which indicator TO ∑ will be more important.

The main properties of building materials and products

Functional properties

Functional properties include: structural(medium and true density, porosity), Hydrophysical (hygroscopicity, water absorption, moisture product, water-resistance, water permeability, humidity), thermophysical (thermal conductivity, heat-capacity, frost resistance, fire resistance, refractory), complex (durability,

reliability, compliance).

Structural properties of building materials

Density Call a lot of material volume of material. Distinguish between the average, true and bulk density.

Average density - Mass of the unit of material volume in the natural state, i.e. with pores and voids. The average density ρ 0, kg / m 3, g / cm 3, calculated by the formula

where t - Material mass (sample) in dry state, kg or g; V-the volume of material (sample) in the natural state, m 3 or cm 3.

The mass of the material is determined by weighing the samples on the scales of various types.

The determination of the volume depends on the shape of the sample. Samples are correct (cube, parallelepiped, cylinder) and irregular geometric shape. In the first case, the sample volume is determined by calculations on geometric sizes. For example, for cube V \u003d.aBC, Where a, b, C - Dimensions of the parties of the cube. If the sample of the wrong shape (piece of brick), then the sample volume is determined by the volume of the displaced fluid (the archimedes law).

The average density for the material is not a magnitude constant. Artificial materials can be obtained from the required average density. By changing the structure, you can get a heavy concrete with a density of up to 2500 and a particularly lightweight density of less than 500 kg / m 3.

True density , kg / m 3, g / cm 3 - the mass of the unit volume of the material in absolutely dense state (without pores and voids). Calculate it according to the formula according to STB 4.211-94

where V A. - Absolute material volume, m 3 or cm 3.

True density - This density of the substance from which the material consists is therefore the true density of the material is a physical constant characteristic.

In dense materials, the numerical values \u200b\u200bof the true and average density are the same. For example, in steel p 0 \u003d p and \u003d 7850 kg / m 3. In porous materials, the true density is greater than the average. For example, a ceramic brick r o \u003d 1600 ... 1900, and r and = 2500 kg / m 3.

The density of the material is largely affected by its durability. The average density of materials directly affects the efficiency of construction, as well as the complexity of transportation and installation. Reducing the average density of building materials while maintaining the necessary strength and durability is the path to a decrease in the material consumption of construction, an increase in its feasibility efficiency.

Porosity Material P. - This is the degree of filling the volume of the material by pores. The porosity of the value complements the density to one or up to 100% and is determined by the formula = V. p / V. , Where

V. p - praises V- The volume of material in the natural state, i.e. Together with the pores.

Transforming this formula, we obtain 100%, or 1-RO)

Porosity is expressed as a percentage (GOST 12730.1-78). The porosity of building materials fluctuates in a wide range: from 0 (steel, glass) to 90 ... 95 (foam and poroplasts); Heavy concrete is 5.-. 15%.

The coefficient of density of the CPV - the degree of filling material with a solid substance: CLV \u003d ro.I. PI

In the amount of P + CPL \u003d 1 or 100%, i.e. The dried material consists of a solid frame, providing strength and air pores.

Pores (from Greek. poros. - The output, hole) in the material is gaps, cavities between the elements of the material structure filled with air or water. Pores occur in materials at various stages of their preparation (in artificial materials) and formation (in natural materials), from here and pores are artificial and natural. Form, dimensions and pore structure are different.

Larger pores in products or cavities between slices loose-made bulk material (sand, gravel, crushed stone) are called voids.

Depending on porosity, low-pore (structural materials - p 50%) are distinguished.

For loose (bulk and fibrous) materials (sand, crushed stone, cement, mineral and glass), as well as for materials with artificial voids (hollow ceramic bricks and stones, concrete and reinforced concrete plates with technological voids) The ratio of the volume of voids to the total volume of the material is called void.

Hydrophysical properties of building materials

Gigroscopic - Property of porous material absorb water vapor from air

Humidity (W. ) - This is the amount of water in the material. There are absolute humidity (g) and relative (%). Relative humidity is calculated by the formula

where t. from - Mass of dry sample, r; t. in - Mass of a wet sample,

For moisturizing, the materials change their properties increase the density, thermal conductivity and reduces the strength.

Therefore, when storing and transporting building materials, GOST requires them to protect them from moisturizing.

Water absorption Call the property of materials to absorb and hold water. Water absorption is determined by the standard procedure, immersing material samples into water with a temperature of 20 ± 2 ° C and withsting them in water a certain time. Water absorption can be determined with respect to the mass of dry material or with respect to the natural volume of material. Differ water absorption by weight - W. and by volume - W. and calculate them by formulas (in%):

where t. from - mass of dry sample, r; t. n. - Mass sample saturated

water, g; V- Sample volume in a natural state, cm 3.

The water absorption of the material is usually less than its porosity, since the pores can be closed or very small and the water does not penetrate into them, and in very large pores the water is not held. In highly porous materials (wood, mineral wool and fiberglass-nice plates) water absorption can be more than 100%; Volumetric water absorption is always less than 100%.

To saturate water, the sample is immersed in water gradually or withstand it in boiling water (STB 4.2306-94).

As a result of water saturation, the properties of materials change significantly: thermal conductivity increases, density, and in some materials (for example, the tree) also volume.

We establish the dependence between water absorption and by volume

Indicators of water absorption of building materials are different. For example, water absorption by weight of granite 0.1 ... 0.8%, ceramic tiles For floors - 1 ... 4, heavy concrete - 2 ... 3, ceramic bricks - 8 ... 15, heat-insulating gas-silicate materials - 50 ... 75%.

Moisturizing and saturation with water adversely affects the strength of materials, reducing it.

Water resistance The material is called its ability to resist the destructive action of moisture. Quantitatively water resistance of the material is estimated to the softening coefficient to p. The latter is equal to the ratio of the strength of the material saturated with water R. n. , To the strength of the dry material R C: K p \u003d R n / r s.

The softening coefficient ranges from 0 (in clay unconditioned materials) to 1 (from steel, bitumen). Materials with a softening coefficient greater than 0.8 are called waterproof.

The water resistance is an important characteristic of building materials that are used in hydraulic structures. Water resistance can be improved artificially, reducing hydrophilicity, reducing the wetting of materials with water, as well as applying hydrophobic coatings.

High hydrophobicity and water resistance of some materials allow them to be used as waterproofing materials (bitumens, polymer films).

Moisture report - The property of the material to give water in the presence of appropriate conditions in environment (increase temperature, air movement, reduce air humidity).

POWER PERFORMANCE Call the body's ability to pass water under pressure. The magnitude of the water permeability is characterized by the amount of water that has passed over 1 h through 1 cm 2 of the area of \u200b\u200bthe test material (sample) at constant pressure. Materials are especially dense, i.e. In which the true and average density is equal (metal, glass), are waterproof.

The water permeability is characterized by the CF filtering coefficient (m 2 / h). Filtration coefficient is inversely proportional to the waterproof material.

Architecture, work by mathematics, biology, geology, anatomy ... distinguish from the animal and by flat nails and by Smile, I. by Mind, I. by religion, etc. But ...

Crib by Stories (5)

Cheat Sheet \u003e\u003e HistoryParties of a specially organized prosecutor's office (from 1722); " Crib by domestic history"3) were formed by the central ..., sculpture and architecture This period was influenced by European classicism. " Crib by domestic history "...

Crib by Information systems and technology

Cheat Sheet \u003e\u003e InformatikaServer and mobile processors built by architecture Intel X86. RISC processors ... server and mobile processors built by architecture Intel X86. RISC processors ... through GSM networks. Openness architecture By The structure controllers are divided into ...

Crib by Administrative law (1)

Cheat Sheet \u003e\u003e State and LawOlga Vladimirovna Kostkov Crib by administrative law Allel, 2010, 64 ... documentation; b) training and retraining of specialists in the field architecture and urban planning; c) Formation and maintenance of the State Fund ...