Porous materials in construction. Physical properties of building materials

To categoriarity: Choice of building materials

Properties of building materials

Physical properties include the following parameters: density, porosity, water absorption, moisture production, hygroscopicity, water permeability, frost resistance, thermal conductivity, sound absorption, fire resistance, refractory and some others.

Density

The material density is medium and true. Average density Determined by the ratio of body weight (brick, stone, etc.) to the entire volume occupied by them, including the pores and emptiness available in it, and is expressed in the ratio of kg / m2.

True density- This is the limit of the relationship of the mass to the volume without taking into account the voids and pores available in them.

In dense materials, such as steel and granite - the average density is almost equal to true, in porous (brick, etc.) - less than it.

Porosity

This characteristic is determined by the degree of filling the volume of the material by pores, which is calculated as a percentage. Porosity affects such properties of materials such as strength, water absorption, thermal conductivity, frost resistance, etc.

In the size of the pores, the materials are separated on fine-sized, in which the pore sizes are measured in hundredths and thousands of millimeters, and large-pore (pore sizes - from the tenths of a millimeter to 1-2 mm). Porosity building materials fluctuates in a wide range. For example, glass and metal it is equal to 0, it has a brick - 25-35%, the MIP is 98%.

Moisture report

This property of the material characterizes the ability to lose moisture in its pores. The moisture date is calculated by the percentage amount of water that the material loses per day (with the relative humidity of the ambient air of 60% and its temperature is 20 ° C).

Moisture studio is of great importance for many materials and products, for example wall panels and blocks that in the construction process usually have increased humidity, and under normal conditions, due to water, water is dry - water evaporates until the balance between the moisture content of the wall material and the humidity of the surround air is established, that is, while the material does not reach the air-dry state .

Water absorption

Water absorption is the ability of the material to absorb and hold in their pores moisture.

In terms of volume, water absorption is always less than 100%, and by weight there may be more than 100%, for example in thermal insulation materials. The saturation of the material with water impair its basic properties, increases thermal conductivity and average density, reduces strength.

The degree of reduction in the strength of the material under its limitization is called water resistance and is characterized by the softening coefficient.

Materials with a coefficient of softening of at least 0.8 are apparent. They are used in the structures in water, and in places with high humidity.

Gigroscopic

Gigroscopicity is the property of porous materials to absorb moisture from the air. Hygroscopic materials (wood, heat insulation materials, semi-dry pressing bricks, etc.) can absorb a large amount of water. In this case, their mass increases, the strength is reduced, dimensions change.

Fire resistance

Fire resistance is the property of materials to resist action high temperatures. According to the degree of fire resistance, materials are divided into non-government, challenges and combustible. Failure materials (brick, concrete, steel) under the action of fire or high temperatures are not ignited, not smoldering and not charred, but can be very deformed. Empty-facilible materials (fibergolite, asphalt concrete, etc.) are smoldering and charred, but after removal of the source of fire, these processes are terminated. The combustible materials (wood, rubberoid, plastics, etc.) flamm or smoldering and continue to burn or smoldering and after removal of the source of fire.

Fireproof

Fireproof - the property of the material is to resist, not deforming, long-term exposure to high temperatures. According to the degree of refractory, materials are divided into refractory, withstanding the effect of temperatures up to 1580 ° C and higher ( chamotte brick); refractory, withstanding the temperature of 1350-1580 ° C (refractory brick); Lightweight, softening or collapsed at temperatures below 1350 ° C (ceramic brick).

Mechanical properties

The mechanical properties of the material include its strength, elasticity, plasticity, fragility, impact resistance and hardness.

Strength

The strength is the ability of the material to resist the destruction under the influence of the external forces causing internal voltages in it. The strength of the material is characterized by the strength of the strength at three types of impact on it - compression, gesting and tension.

The strength is the property of the material to resist the destruction under the action of stresses arising from the action of external forces (loads).

In the designs of building materials, exposed to various loads, test the voltages of compression, stretching, bending, cut,, impact. Most often they work on compression or stretching.

Various materials in different ways resist various types of stresses. So, natural stones, concrete, bricks are well resist compression and significantly worse stretching. Steel and wood work well both on compression and tensile.

By magnitude, the voltage of the central compression or stretching is equal to the strength per 1 cm2 cross section material. The voltage of the central compression or stretching is calculated by dividing the load on the initial cross-sectional area:

The strength of building materials is characterized by the so-called tensile strength or tensile strength, i.e., with a voltage corresponding to the load causing the destruction of the material sample.

The depth primary rocks include: granite, dioritis, seinite. They have high density, have high strength and large volumetric mass.

The erupted rocks include: basalt, diabases that are dense rocks, as well as pumice and tuffs that have a small volumetric mass due to heavy porosity.

Secondary breeds were formed as a result of the destruction of the erupted and other breeds under the influence of temperature fluctuations, the action of water and wind. Destruction products moved by water flows to significant distances precipitated in places of less intense flow of water and in reservoirs in the form of layers.

Minerals soluble in water and their destruction products subsequently deposited from aquatic solution. This formed, for example, gypsum. The sedimentary rocks also consists of minerals and products of the vital activity of organisms inhabiting water pools. These breeds include: limestone, chalk, seven, etc.

The modified rocks were formed as a result of deep changes of the erupted and sedimentary rocks under the influence of high temperatures or greater pressures, so these breeds differ significantly from the initial. These breeds include: marble, gneus, shale.

Elasticity

Elasticity is the ability of the material after deformation under the influence of any loads to take the initial shape and size. The greatest voltage at which the material still has elasticity is called the elasticity limit. Elastic materials include rubber, steel, wood.

Hardness

Hardness - the ability of the material to resist the penetration of another, more solid. This property of materials is important when furnaces and road coatings.

Fragility

Fragility - the property of the material under the action of external forces instantly collapsed without noticeable plastic deformation. Fragile materials include bricks, natural stones, concrete, glass, etc.

Plastic

Plasticization - the property of the material is changed under the load and dimensions without formation of breaks and cracks and save the changed shape and dimensions after removing the load. This property is opposite to elasticity. Plastic materials include bitumen, clay dough, etc.

Resistance to impact

Resistance to impact - the ability of the material to resist the destruction under the action of shock loads. Fragile materials are badly resist.

The strength is the ability of the material to resist internal stresses resulting from the action of external forces (loads).

Under the action of external forces, the material is deformed. The deformations can be elastic if they disappear after removing the load, and residual, if after removing the load, they remain.

Elasticity is called the property of the material to restore its shape (solid) and volume (liquid and gases) after the termination of the forces caused by the deformation. At enough large loads Solid bodies lose elasticity and deform plastic. Small deformations of solid elastic bodies are proportional to the applied load.

Deformation with sufficient se development leads to the destruction of the material. At the same time, for the material in a fragile state, the destruction occurs when the limit value of the elastic deformation is reached, and for the plastic material - when it is reached by two limit states: the transition of elastic deformation into plastic and transition from plastic deformation to the destruction of the material.

The material voltage is the internal force of the interaction per unit area. The magnitude of the voltage at each point of the section is a measure of the internal forces arising in the material as a result of deformation caused by external forces.

The voltage corresponding to the load at which the material destruction occurs is called the material strength limit (Table 2). Depending on the type of deformation under load, the tensile strength, bending, tension, etc. differ.

The tensile strength of RVM compression, RMR bend, tensile the tension is determined by the ratio of the destructive force to the cross-sectional area of \u200b\u200bthe sample.

IN building structures And their elements allowable voltage is only part of the strength of the material.

The stricter reserve coefficient at static load is: for plastic materials 2.4-2.6; For fragile 3-9.

With a shock load, the plastic material has a reserve factor of 2.8-5. (TPSH ^ A 1 (W, where (TSHMH is the largest stresses arising in the material under the action of external forces.

The coefficient of constructive quality KI (strength-mass coefficient) is rather not the limit of compressive strength (MG1a) to the value of the material density in natural condition (kg / m3). For example, for concrete SC \u003d 0.006, for brick masonry - 0.003, for plastics -0.1-0.2, for high-grade steel -0.13, for granite - 0.04-0.09.

Fragility is the property of the material under the action of external forces to collapse immediately, not detecting any significant deformations. Fragile materials (cast iron, concrete, glass, granites, marbles, ceramic tiles And others) badly resist the blow.

Plasticity is the ability of the material under the action of the load to change its shape and without signs of destruction to fully maintain it after removing the load.

Unlike fragile, plastic materials are destroyed only after a significant residual deformation (for example, small-carbon steel, copper, bitumens).

Hardness is the property of the material to resist the penetration of solid bodies into it.

Chemical properties

The chemical properties of the material characterize its ability to react with different substances. For example, the ability of binding materials to react with water, to withstand the effects of aggressive substances in the environment.

Solubility is the ability of the material to dissolve in one or another solvent. A measure of material solubility under these conditions is the concentration of its saturated solution.

If the material under the action of the solvent worsens its properties of P &ces, the solubility is a negative factor. If solubility is used as an integral part of the technology in the manufacture of mastic, the solubility becomes a positive factor.

Corrosion resistance is called the ability of the material to maintain its properties under the conditions of the aggressive environment. The aggressive media includes water (fresh and sea), gases, solutions of acids, alkalis and salts, as well as organic solvents.

Acid resistance - the ability of the material to resist the action of acids without changing its properties. Acid-resistant acids have salts of strong acids (nitrogen, hydrochloric, silica), some polymeric materials, as well as special ceramic tiles.

The alkaliiness is characterized by the ability of the material to resist the action of alkalis, while maintaining its properties. Pigments applied in the device of mosaic and xylolite flooring, as well as the floors of the type of breccia (ocher, umbra, etc.) are considered to be shagless.

Glow resistance - material ability not to react with gases ambient. Materials used in facing works must be mainly resistant to carbon dioxide gas prying.

If silicon dioxide (silica) prevails in the material, the material is considered a resistant to acid attitude, the software interacts with the main oxides, for example, with calcium oxide. When basic oxides are dominated in the composition of inorganic material, it is usually unstopping to acids, it does not destroy alkalis.

The chemical properties of the material characterize its ability to chemical transformations under the influence of the substances with which it is in contact, as well as some physical (for example, heating, irradiation, electric current) and biological (microorganisms, fungi, etc.) of influences. From the chemical properties of materials for the builder, the main - corrosion resistance of materials in building structures and their chemical activity. The latter property is important, for example, for materials used as a binder (for example, cement, synthetic resins).

Corrosion is the destruction of solid bodies, which is caused by the chemical and electrochemical processes occurring in them when interacting with the external environment. Not only metals are subject to corrosion destruction, but also stone materials, concrete, plastics, wood.

The main aggressive agents causing corrosion of building materials are: Fresh and salty water, mineralized soil water dissolved in the rainwater gases (SO2, SO3, N02) from industrial enterprises and cars. In industrial enterprises, the corrosion of building materials often cause stronger agents: solutions of acids and alkalis, molten materials and hot gases.

The special type of corrosion is biocorrosion - the destruction of the material under the action of living organisms (for example, fungi, microbes). Biocorrosion is not only rotting organic Materials (Woods, bitumen, etc.), but also the destruction of concrete and metal products of the vital activity of the microorganisms settled on them.

Changing the structure I. chemical composition Plastics under the influence of the external environment is called "aging". The most harmful effects on plastics have solar irradiation, air oxygen and elevated temperatures.

Corrosion of building materials is dangerous not so much with chemical changes in the material as associated changes in the physicomechanical characteristics of materials.

Chemical activity of such building materials like binding stiffs or mineral additivesDepends not only on their composition and structure (i.e., from the activity of the components of their molecules), but also from the fineness of grinding. The reason for this is that chemical processes proceed either with direct contact of these substances with each other (i.e., on their surface), or when substances dissolved (dissolution occurs also from the surface). Thus, the greater the surface of the substance, the more active in chemical terms. The surface increases with increasing the degree of grinding of its particles.

The degree of grinding of the substance is characterized by a value called the specific surface. The specific surface is the total surface of all particles of the mass of the substance (cm2 / g). The specific surface area of \u200b\u200bthin-fat materials reaches large values \u200b\u200b(cm2 / g): ordinary portland cement - 2000 ... 2500, and a thin-fat rapid-hardening - 3000 ... 4000. The greater the specific surface, the faster the cement particles interact with water and, accordingly, faster cement harden.

Properties of building materials

Building materials, like all the items around us and phenomena, have a number of signs and characteristics that appear to a greater or lesser extent. By the combination of these signs and characteristics, reflecting the properties of materials, judge the quality of products.

Of all the variety of properties inherent in each object or material, only those that determine the suitability of products are selected when using direct intended purpose. For example, for concrete, such properties are important as durability, density, durability, water permeability, thermal conductivity. Some other characteristics, in particular the color, are no value for construction concrete. Vice versa color for finishing materials - This is the main property, and the thermal conductivity of the secondary.

All properties of building materials are divided into the following groups.

Physical properties. This group consists of the parameters of the physical condition of materials and properties that determine the ratio of materials to various physical processes. The first is the density and porosity of the material, its chemical, phase and mineral composition, the degree of grinding of powders, to the second - hydrophysical properties (water absorption, humidity, water permeability), thermophysical (thermal conductivity, heat capacity, temperature expansion), resistance to physical corrosion (water resistance, Frost resistance) and some others.

Mechanical properties. This group includes characteristics reflecting the ratio of material to the action of mechanical loads: strength, hardness, deformability, elasticity, plasticity, fragility, abrasibility.

Chemical properties. This group includes properties that characterize the stability of the material to the destructive chemical impacts of the environment (corrosion resistance), as well as the ability of the material to chemical transformations (for example, the ability of cement after indulging with water spontaneously solidify to a durable campaneous body).

For numerical definition of properties, the results of testing standard samples of building materials are used. Test methods regulate State standards (GOST), the requirements of which should be strictly implemented at all construction sites.

Standards contain comprehensive product quality requirements: technical conditions, types and basic product parameters, test methods, acceptance rules, labeling, transportation and storage. Compliance with the properties of materials specified in the standards parameters - the key to high quality products.

The properties of materials depend on their composition and structure. The chemical, mineral and phase composition distinguish. The chemical composition expressed by the percentage of different oxides affects chemical resistance, fire resistance, mechanical properties material.

Mineral composition shows which minerals and in what ratios are in the material. Thus, the composition of granite is determined by the content of breeding minerals - polespota, quartz, mica and horny deception. Similarly, the characteristics of the mineral composition of the clinker are used to evaluate the properties of cements. If the material has a polymineral composition, its properties depend on the quantitative relationship between minerals, since the individual characteristics of the minerals of unequal. Consequently, when creating artificial building materials, it is possible to consciously manage their properties.

The phase composition of the material also has a big impact on the properties. In the solid phase, crystalline and amorphous components are isolated. The crystalline state of the substance is more stable. The amorphous form compared to crystalline is characterized by a large margin of potential energy, and therefore amorphous substances in a chemical ratio are more active. For example, quartz (crystalline form of silicon oxide) is able to interact with lime only at temperatures above 170 ° C, and opal (amorphous form of silicon oxide), which is part of the diatomite, tremble, reacts with lime already when normal temperature. The high chemical activity of the amorphous form is used in the manufacture of portland cement clinker, creating a certain amount (6 ... 15%) of the vitreous phase in its composition. This allows you to increase the strength of cement. In the structure of porous material, such as concrete or construction solutionMix the solid phase forming its frame, and the pores that can be filled with air and water. When freezing a saturated water material, water goes into ice, increasing in volume. As a result, in the framework, i.e. In the pore walls, large tensile stresses arise, which lead to the destruction of the material.

Construction Materials. Lectures. 31

General information about building materials.

In the process of construction, operation and repair of buildings and structures, construction products and structures of which they erected are subjected to various physical and mechanical, physical and technological impacts. From the engineer-hydraulic engineering required with knowledge of the right to choose the material, products or design that has sufficient resistance, reliability and durability for specific conditions.

Lecture №1 General About building materials and their basic properties.

Building materials and products used in the construction, reconstruction and repair of various buildings and structures are divided into natural and artificial, which in turn are divided into two main categories: the first category includes: brick, concrete, cement, timber, etc. When erecting various elements of buildings (walls, overlaps, coatings, floors). To the second category - special purpose: waterproofing, thermal insulation, acoustic, etc.

The main types of building materials and products are: Stone Natural Building Materials of them; Binding materials are inorganic and organic; forest materials and products of them; hardware. Depending on the purpose, the conditions for the construction and operation of buildings and structures, appropriate building materials are selected, which have certain qualities and protective properties from the impact on them of a different external environment. Given these features, any building material must have certain construction and technical properties. For example, the material for the outer walls of the buildings should have the smallest thermal conductivity with sufficient strength to protect the room from the outer cold; Material of the structure of hydrochromelic purposes - waterproof and resistance to alternate humidification and drying; The material for the coating is expensive (asphalt, concrete) should have sufficient strength and low abrasibility to withstand the load from transport.

Classifying materials and products, it must be remembered that they must have good propertiesand qualities.

Property- The characteristic of the material manifested in the process of its processing, application or operation.

Quality- A set of material properties that determine its ability to meet certain requirements in accordance with its appointment.

The properties of building materials and products are classified by three main groups: physical, mechanical, chemical, technologicaland etc .

TO chemicalthe ability of materials to resist the action of a chemically aggressive medium, which causes metabolic reactions leading to the destruction of materials, changes in its initial properties: solubility, corrosion resistance, resistance to rotting, hardening.

Physical properties: medium, bulk, true and relative density; Porosity, humidity, moisture production, thermal conductivity.

Mechanical properties: limits of strength in compression, stretching, bending, shift, elasticity, plasticity, rigidity, hardness.

Technological properties: Convertibility, heat resistance, melting, hardening and drying rate.

Physical and chemical properties of materials.

Average densityρ 0 Mass medals volume V. 1 absolutely dry material in a natural state; It is expressed in g / cm 3, kg / l, kg / m 3.

Bulk density of bulk materialsρ n. Mass medals volume V. n. dried freely fused material; It is expressed in g / cm 3, kg / l, kg / m 3.

True densityρ mass medals volume V.material in absolutely dense state; It is expressed in g / cm 3, kg / l, kg / m 3.

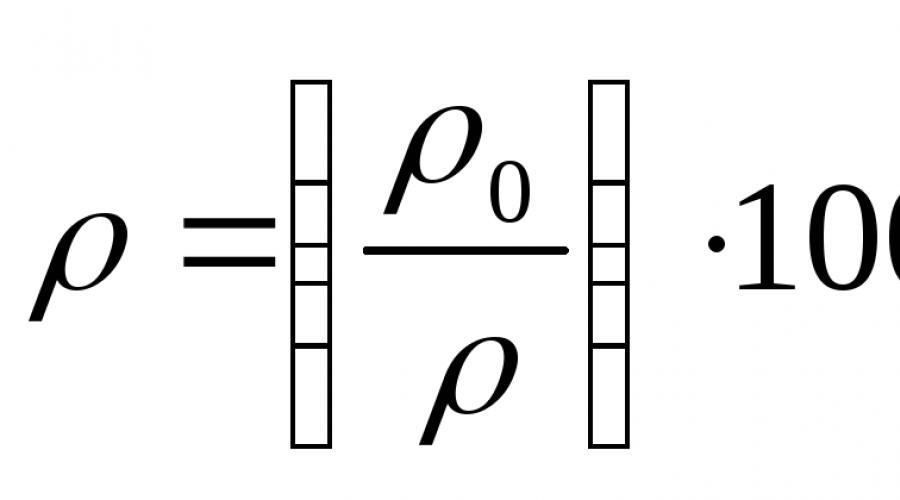

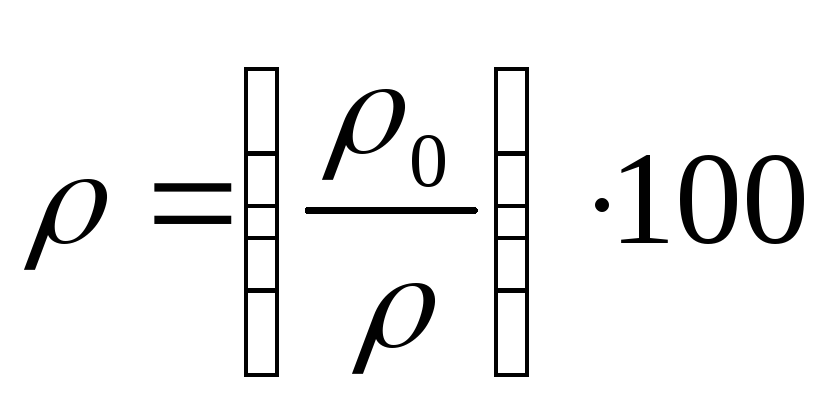

Relative densityρ(%)

- degree of filling material of the material of the solid substance; It is characterized by the ratio of the total volume of solid V. In the material to the entire volume of the material V. 1

or ratio of medium density of material ρ

0

to its true density ρ:, or  .

.

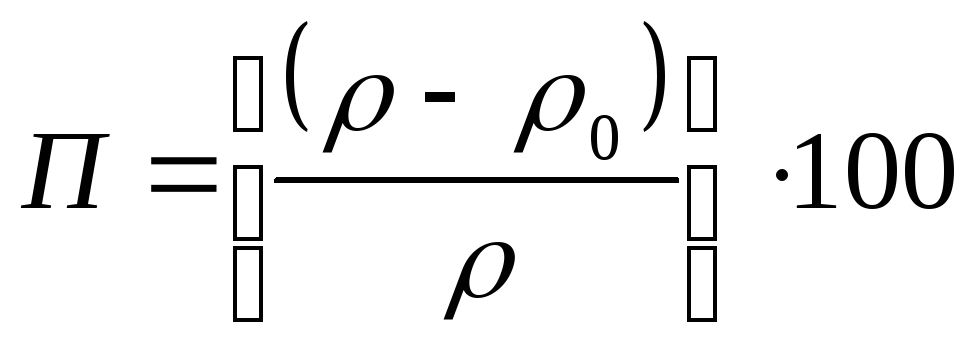

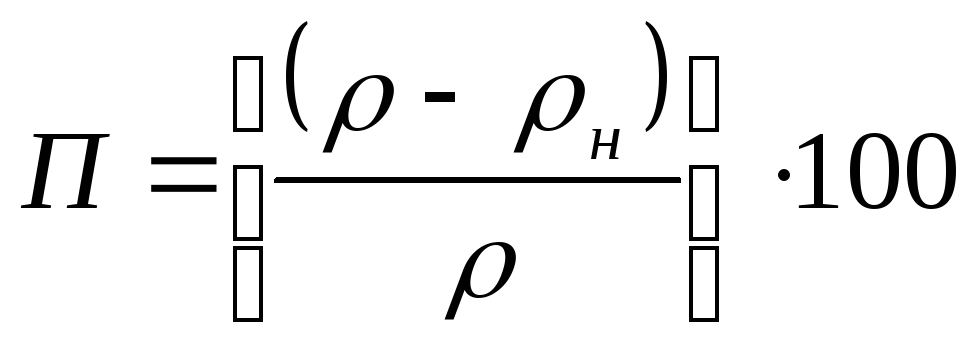

PorosityP - The degree of filling the volume of the material by pores, voids, gas-air inclusions:

for solid materials:  For bulk:

For bulk:

Gigroscopic - The ability of the material to absorb moisture from the environment and thicken it in the mass of the material.

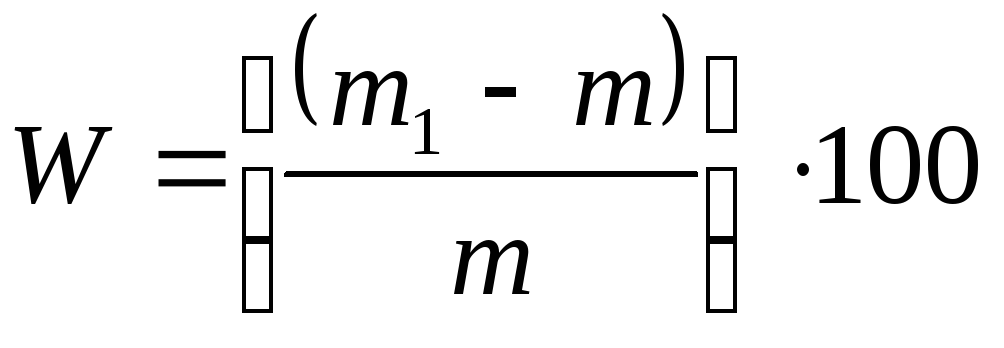

HumidityW.

(%)

- the ratio of the mass of water in the material m. in =

m. 1

-

m.

to the mass of it in absolutely dry condition m.:

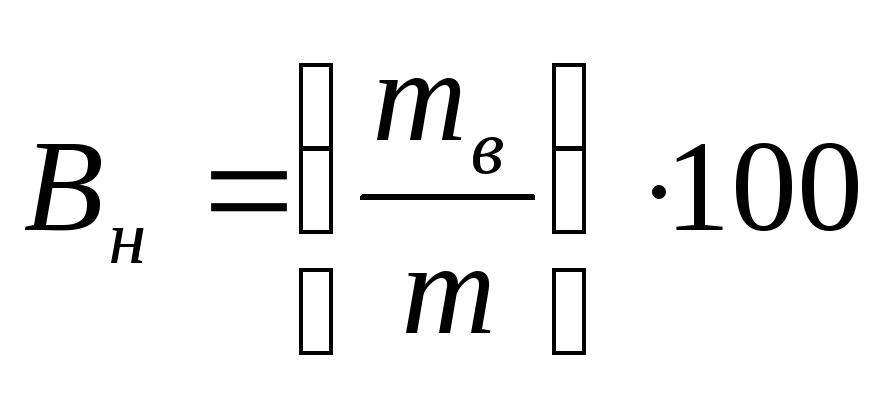

Water absorptionIN - characterizes the ability of the material when contacting with water to absorb and hold it in its mass. Distinguish between mass IN m. and volume IN about Water absorption.

Mass water absorption(%)

- the ratio of mass absorbed water material m. in to the mass of the material in a completely dry condition m.:

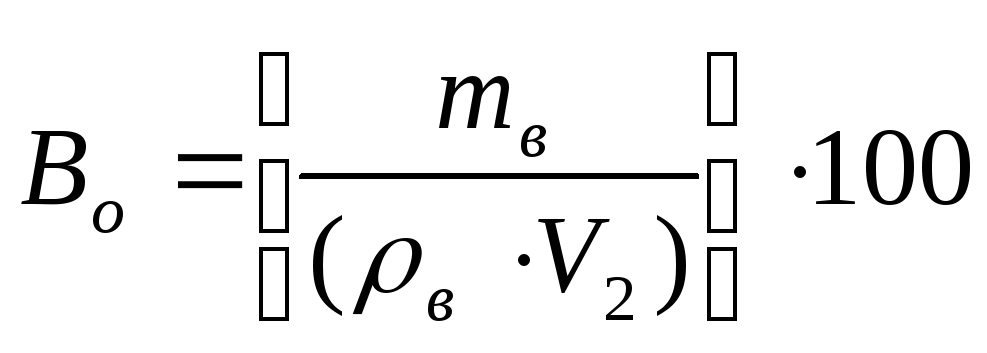

Volume water absorption(%)

- The ratio of volume by absorbed water material m. in /

ρ

in

to his volume in a water-saturated state V. 2

:

Moisture report - The ability of the material to give moisture.

Currently, the nomenclature of building materials is very diverse. For the same structures or their elements, various materials can be applied. Choose the best and cheapest is not always easy. For wall materials, for example, belong: timber, brick, natural stone, concrete and reinforced concrete, saman, etc. However, for specific purposes, the material must be selected that most satisfying functional purpose Walls (residential premises, manufacturing workshop, warehouse, engineering structure, etc.), as well as economic requirements.

When choosing a material, it is necessary to take into account its ability to react to individual or combined factors - mechanical, external environment, temperature and its oscillations, chemical reagents, technological operations, etc. This material ability to respond to the specified factors is called its properties.

The rational use of building materials is possible only if the knowledge of its physical, mechanical, chemical, technological and artistic and decorative properties.

The physical state Building materials are quite fully characterized by medium and true density, as well as porosity. It is known that most building materials have a porous structure, an exception is glass, metals and some others. The ratio of body weight or substance in a natural state together with voids and pores to the entire volume occupied by them is customary to be called an average density, in contrast to the true density, representing the mass ratio to the volume when the volume is reduced to the point in which the density of the body or substance is determined without Accounting emptiness and pores available in them.

For bulk materials, there is a concept of "bulk density" - this is the ratio of mass of grainy and powdered materials to the entire volume occupied by them, including the space between particles. Units of these quantities: grams per cubic centimeter (g / cm 3), kilogram per liter (kg / l), ton on cubic meter (T / M 3), kilogram per cubic meter (kg / m 3). The technique mainly use a kilogram unit into a cubic meter (kg / m 3). Indicators of the density of building materials serve indirect estimates of porosity, water absorption, frost resistance, thermal conductivity and strength.

Usually, weight or volumetric water absorption is determined, which are the ratio of the difference between the weights of the water-saturated and dry samples by weight or volume of the dry sample, respectively.

The porosity of the material is estimated by the relative value showing what part of the material is occupied by internal pores. It fluctuates widely - from 0 to 98%.

Porosity can be open and closed. Open pores are most dangerous - they communicate with the environment and among themselves, which allows them to fill with water in saturation conditions. And this leads to an increase in water absorption and, as a result, to reduce the strength and frost resistance, an increase in thermal conductivity and water permeability. True, open porosity improves the sound-absorbing properties of the material.

Some building materials (brick, cement, concrete, timber, etc.) have hygroscopicity, i.e., the ability to absorb water vapor from air as a result of adsorption and capillary condensation. An increase in the hygroscopic humidity of the material leads to the deterioration of its main properties, as mentioned above.

Changing the strength of material as a result of water saturation is estimated coefficient softening - the ratio of the strength of the material saturated with water, to the strength of the dry material. This coefficient characterizes the water resistance of the material and it varies from 1 (metals, etc.) to 0 (splashing clay).

Power permeability is the property of the material to pass through itself under pressure. It is estimated filtering coefficientequal to the amount of water, m 3 passing through the plate material with an area of \u200b\u200b1 m 2, a thickness of 1 m in 1 hour with the difference in hydrostatic pressure at the plate boundaries in 1 m water column. In order to reduce the water permeability, builders use more dense materials with closed, closed porosity or protect the structures with waterproofing materials.

The ability of the material to pass through its cracks and pores in the presence of a pressure difference of gas or steam is called gas or vapor permeability. Some materials are presented with full gas-tightness requirements, for example, to the materials of the gas storage. But wall materials, on the contrary, should have a certain permeability. The wall must "breathe", i.e. A natural ventilation should be carried out through it. However, to protect thermal insulation from moisturizing the wall and overlapping from wet rooms should be protected from steam penetration.

Many porous organic and inorganic building materials at moisture swell, i.e. Increase in size, and during drying - decrease. There is a so-called shrinkage or sleeping. Multiple moisturizing and drying often leads to destruction as a result of fatigue of porous materials.

Very important physical characteristics of a number of building materials are their frost resistance. This is the ability of the material in a water-saturated state to withstand a certain amount of alternating freezing and thawing cycles.

The frost resistance of building materials largely depends on porosity, density and water resistance. Roofing, walls and other materials in the structures and finishes of buildings and structures under operating conditions are exposed to water saturation and freezing. When the water transition to the ice, its expansion occurs by about 9%, which leads to the destruction of the pores of the material. Multiple freezing and thawing is sometimes able to withdraw the structure in a short time. It is possible to increase the frost resistance by improving the structure of the material, a decrease in porosity, exclusion of water saturation, etc.

The heat engineering properties of building materials include: thermal conductivity, heat capacity, refractory, fire resistance, linear temperature expansion coefficient.

Thermal conductivity is the property of the material to pass through its thickness heat flux from one surface to another. For materials such as thermal insulation, walls and some other thermal conductivity is one of the main indicators of their quality. The thermal conductivity of porous materials depends primarily on the index of porosity and its character - open, closed, through, reporting. The temperature, temperature and, of course, the nature of the material itself, affect the magnitude of thermal conductivity, is influenced by the thermal conductivity. his substore composition. The thermal conductivity is estimated by the thermal conductivity coefficient - W / (m 0 s). Here are some examples, the coefficient of thermal conductivity of copper is 403 W / (m 0 s), and the steel has only 58, in heavy concrete -!, 5, light concrete - 0.5, mineral wool - 0.08, etc. The lowest thermal conductivity in the air is 0.023.

The heat capacity is the ability of the material to absorb heat. It is estimated by the specific heat capacity - the amount of heat required for heating 1 kg of material 1 0 C.

Refractory - the property of the material is to resist, not melting and not deformed, long-term exposure to high temperatures (from 1580 0 s and above). Fireproof materials Apply for inner lining industrial furnaces. The refractory materials are softened at temperatures above 1350 0 S.

Fire resistance - the ability of the material to maintain physicomechanical properties in a fire for a certain time. It depends on the ability of materials to burn. According to this performance, building materials are divided into: non-aggravated (brick, concrete, metals, etc.), challenges (fibergolite; Some fiberglass; wood, impregnated with flame retardant compositions, etc.), burned (wood, bitumen, plastics, etc.).

The linear temperature expansion coefficient characterizes the body's ability to deform when the temperature changes. The various coefficients of linear expansion of the components of the conglomerate or composite materials can lead to their destruction. In order to avoid cracking of the buildings of a large length, they are cut into temperature seams.

TO mechanical propertiesbuilding materials include their strength and deformative characteristics, hardness and abrasion.

Strength - The ability of the material to resist by external or internal loads without destruction. It is assessed by the strength of the strength in a particular form of deformation (compression, stretching, bending, twist, etc.) and is equal to the ratio of the destructive force to the initial cross-sectional area (the unit of measurement of PA or MPa). The strength of the material depends on numerous factors: density, porosity, structure, humidity, shape, and sample sizes, loading rates, etc.

DeformativenessmATERIALS This property change its dimensions and shape under the action of external load or internal stresses.

Deformation can be elastic (reversible) and plastic (irreversible, residual). Elasticity This feature of the material is to restore the original shape and dimensions after the termination of the load. The plasticity of the solid is called its ability to change the shape and dimensions under the action of the load and maintain the resulting shape and dimensions after removing the load.

Hardnesscalled the ability of the material to resist the penetration of another more solid body into it. It is determined by the structure of the material. When choosing materials for floors, road surfaces and in a number of other cases, their hardness needs to know. From hardness depends abrasion Materials.

The density is the value of the equal ratio of the mass of the substance to the volume occupied by it; It is expressed in kilograms per cubic meter (kg / m3).

The true density is the limit of the mass ratio to the volume of the body or substance, without taking into account the voids and pores existing in them.

Bulk density - The ratio of mass of grainy materials, materials in the form of powder to the entire volume occupied by them, including the space between particles.

The average density is a physical value determined by the ratio of body weight or substance to the entire volume occupied by them, including emptiness and pores available in them.

The relative density is the ratio of the density of the body or substance to the density of the standard substance under certain physical conditions.

Porosity ratio of pore volume to external volume

(Dimensional) material. It is expressed in percent.

Porosity determines the main properties of materials: durability,

frost resistance, gas permeability, water permeability, etc.

Water absorption - material ability to absorb

and hold water. Water absorption is determined by mass difference

sample material in saturated water and absolutely dry

and express in the percentage of the mass of dry material.

Water absorption in volume B0 is equal to the mass of water absorbed

a sample during its saturation, attributed to the volume of the sample.

Water absorption of material in volume less than 100%, and water

the absorption is absorbed by very porous materials - more than 100%,

The ratio of the strength of the material saturated with water to its

in a dry state is called the coefficient

soft. The numerical value of this coefficient varies from 0 to 1.

With a softening ratio of more than 0.8 building material

it is considered waterproof, with a coefficient of less than 0.7 - native

and structures with big humidity.

Moisture product - the material of the material to give moisture when

environmental change. Moisture student is characterized by

dried material drying per day with relative humidity

ambient air 60% and temperature 20 ° C.

The moisture content of the material in percent is determined by the content of moisture referred to the mass of the material in a dry state.

The water permeability is the ability of the material to pass water under pressure. The water permeability is characterized by the amount of water passed in 1 hour after 1 cm2 of the surface of the material at constant pressure. The degree of water permeability of the material depends on its density and structure.

Adhesion - the ability of the material to stick together with the surface of another body. It is quantitatively characterized by the specific work spent on the separation of tel. Adhesion - an important property of paintwork polymer coatings, anticorrosive compositions, waterproofing and roofing emulsions and suspensions, etc.

Frost resistance - the ability of the material in a saturated water condition to withstand multiple alternate freezing and thawing without visible signs of destruction and reduction of strength.

Frost resistance is characterized by the amount of weathered freezing cycles, determined to reduce the strength of the material by no more than 25% and the mass loss of no more than 5%.

The frost resistance of the material is checked by repeated freezing of the samples at a temperature of -15 ...- 20 ° C and the subsequent thawing in water at a temperature of 20 ... 25 ° C.

The thermal conductivity of the material to transmit heat through its thickness from one surface to the opposite due to the temperature difference.

Heat capacity - the property of the material to absorb heat when heated and give it when cooled; characterized by the heat capacity coefficient equal to quantity Heat in the joules required for heating 1 kg of material at 1 ° C.

The heat capacity assigned to a unit of mass is called specific heat. The heat capacity of the material allows to preserve the heat resistance of buildings.

The gas permeability is the ability of the material through the thickness of the gas or air. The volume of the gas passing through the material layer is directly proportional to the area of \u200b\u200bthe wall, the time of gas flow, the pressure difference and the thickness of the wall is directly proportional.

Sound permeability is a matter of material to skip air and shock sounds. Fencing structures of buildings are estimated on soundproofing ability: Quantitative measure - Decibel. Soundproofing of walls is characterized by an indicator of permeability from air sound, and between the interhesive floors - an indicator of sound insulation from air and shock sounds. For residential buildings An indicator of sound insulation from the air sound of the inter-wines and inter-floor floors should be at least 1 decibella, and the sound insulation indicator from the impact noise of intermediate floors - 0 (zero) decibel.

Fire resistance- material support to resist

action without loss of necessary strength structures

and operational qualities. Fire resistance-time limit

in the clock, during which the design performs its functions

in a fire. Fire resistance limit depends on fire

materials, as well as on availability and reliability of their protection against

fire action. According to the degree of fire resistance, materials differ on

non-government, challenged and combustible. Non-aggravated materials

do not ignite, do not smash and are not charred. Epoprietia

materials are hardly ignited, smoldering or charred. Combustion

my materials are ignited or smolder.

Strength - the ability of a solid to perceive in

the radiated limits are the impact of external forces without signs of

ways. The strength of the material is characterized by the strength limit

on compression, bending and stretching.

The elasticity is a matter of material to deform under the influence

yoney physical influencesassociated with the emergence of internal

renny forces and fully restore the original condition

after eliminating these impacts.

Plasticity - the ability of the material under the influence of

efforts to change their sizes and form without

cracks and save them after removing the load. Plastic

the same material may be different

bridges from temperature. Plastic materials include bitumen,

clay and cement dough, polymer pastes and mastics, etc. -

Fragility - the ability of the material instantly collapsed

under the action of external forces without noticeable plastic deformation.

For fragile materials, a significant difference between

limits of compressive strength and tension. Fragile materials

badly resist shock. The fragility of the material changes in

dependence on moisture, temperature, the rate of increasing, the existing load.

Hardness - the ability of the material to resist penetrate

kania into it another solid body.

The hardness of fragile materials is determined by the method of scratching

according to the mineralogical scale of the Moos, where as the standards adopted

hardness of the following materials; 1-Talc, 2-GIPS, 3 -Calcitis,

4 - Fluoritis, 5 - apatite, 6 - orthoclases, 7 - quartz, 8 - Topaz, 9 -

corundum, 10-diamond.

The abrasability is the ability of the material to decrease in mass and volume under the action of abrasive efforts.

The resistance of material abrasion is determined on abrasion circles or sandblasting machine. Typically, such tests are subjected to materials for the device of floors, stairs, road coatings, airfields, etc.

Corrosion resistance - the ability of the material does not enter into reactions with other substances, while changing its initial properties; The most important indicator is the ability of the material to resist the effects of acids, alkalis, salts, gases.