Cement sandy solution M150 consumption. Construction mixture on cement-sand-based

Dry mixture M-150 cement universal Used when performing work on plastering various surfaces (walls, ceilings) under painting, shtatleving and gluing wallpaper. The M-150 dry mixture is used for concreting, repair of reinforced concrete products and structures (stairs, floors), when performing assembly and masonry work. The most preferred bases for applying a dry mixture M-150 (layer 5-50 mm) are concrete, cement-lime, cement-sand, brick bases.

Dry construction mixture M-150 cement universal meets the requirements of GOST 28013-98.

Structure:

- Portland cement PC 400 D0, PC 500 D20 (GOST 10178-85, GOST 30515-97);

- Sand dry, fractionated, combined composition of fractions 0.1-1.25 mm (TU 5711-002-05071329-2003).

| Technical characteristics of material | ||

| No. p / p | Name of the indicator | Norm for brand |

| 1. | Color | grey |

| 2. | Required amount of water per 1 kg of dry mixture, l | 0,17-0,19 |

| 3. | Viability (at least), min. | 120 |

| 4. | Water-holding ability (at least),% | 92 |

| 5. | Compressive strength in 28 days, MPa | 15,0 |

| 6. | Coupling strength when separating, MPa | 0,5 |

| 7. | Frost resistance, cycles | 50 |

| 8. | Consumption, kg / m? | 1,8 |

| 9. | Layer thickness, mm | 5-50 |

Preparation of the foundation:

- the base should be structurally durable, dry, diverse, without fat pollution, lubricating oils, paints and other substances that reduce adhesion;

- Sowing and fragile surface areas should be removed;

- plots covered with moss, algae or amazed by fungus, it is necessary to clean the steel brush and treat fungicidal preparations;

- The grave surfaces before applying should be moisturized or projected into several layers (with drying each layer).

Preparation of mortar mixture:

- in clean cold water (from +15 to +20? C) gradually add a dry mixture (dosage for manual application 10 kg of a mixture of 1.8-1.9 liters of water), thoroughly stirring to the disappearance of lumps and the formation of a homogeneous mass;

- withstand 5 minutes for the ripening of the mixture, then mix without adding water;

- The finished mixture is suitable for use during 120 minutes, when thickening the solution, it is possible to re-stirring.

Performance:

- Works are carried out in dry conditions (air temperature and base from +5 to +30? C, relative humidity no more than 80%);

- Before applying the solution, fill large flares and cracks;

- we apply a solution onto a working surface, throwing a cylma or spitting with a spatula, then grow up with the rule and plot;

- with external work, with a layer thickness of more than 30 mm, it is necessary to use a plaster mesh;

- Before applying each subsequent layer, make sure that the previous layer is completely dry;

- equal and strew the upper layer of the applied mixture;

- 24 hours after applying the last layer, the surface can be grinding, painting, bold, finishing work;

- Full strength is achieved in 28 days.

ATTENTION!

The mixture contains cement and when interacting with water gives an alkaline reaction. When working with a dry mixture it is necessary to protect your eyes and skin. When a mixture in the eye contacts, rinse with water and refer to the doctor if necessary.

Storage and packaging:

- Dry mixture M-150 is packaged in branded four-layer paper bags of 40 and 50 kg;

- Warranty shelf life in branded packaging in dry conditions at least 6 months from the date of manufacture, specified on the package.

Buy and use dry mix M150

If you started the construction, then for the implementation of installation and masonry and finishing work, you will need to restore the mortar, which is best seen based on the cement-sandy dry mixture M150. The advantages of this building materials are indisputable: versatility, economical consumption, high quality and reliability, thanks to the correspondence of GOST 28013-98. Luxstroy, which has been many years of sales in the construction market and specializing in various dry mixtures, offers a large selection of this high-quality and indispensable building material: packaging of various packaging (40 or 50 kg) and at competitive prices.

To date, building markets offer a huge variety of different building materials, but the dry mixture of M150 is one of the most popular and sought-after. It is a universal tool for preparation and decoration, plaster and leveling of any surfaces: walls, ceiling and floor. Dry mixture M150 is also used for masonry tiles, for concreting and repairing stairs, overlap and other reinforced concrete structures, To finish slopes when installing windows and doors. It is unthinkable and carrying out any other installation or masonry work without this assistant. In addition, the mortar, induced using this cement-sand mixture, is easily applied and grabbed on almost any surfaces, be it a concrete base, cement-limestone and cement-sandy, as well as a brick surface. Simple use and rapid drying (within 24 hours) of this material will reduce the time of any building process.

The economical consumption of this building material (1.8 kg / m2 with a sufficient thickness of the applied solution is 5-50mm) and quite reasonable prices for a dry mixture of M150, especially in Luxstroy, also identified a high demand for this construction products. Applying it, you will save time and strength to carry out any installation and construction work, capital or current repairs.

High quality and excellent strength characteristics, which are inherent in this material due to the special composition and manufacturing technology, ensure reliability, safety and durability of the surfaces and the entire constructed structure as a whole.

Distinctive characteristics of dry mix M150

This bulk material of gray is made from Portland cement PC 500d0, PC 400 D20 with sand, various impurities and modifying polymer additives that improve the quality and binding properties of the construction mixture. Depending on the compliance with a specific GOST (10178-85 or 30515-97), a dry mixture of M150 can be made from Portland cement MARODs of PC 400 D20 or 500 d0 PC with the addition of dry, fractionated sand (composition of fractions combined 0.1-1.25 mm. TU 5711-002-05071329-2003)). To guide a homogeneous dense and elastic mortar solution, it is enough to mix 1 kg of mixture and 0.17-0.19 liters of cold (T \u003d 15-200C) water and withstand 5 minutes.

The special technology of manufacturing and the optimal ratio of the components of the construction dry mixture M150 makes it frost-resistant, high-strength (with a compression of 15 MPa, stretching 0.5 MPa), reliable and durable. In addition, our dry mixture M150 will give your new coating excellent heat and sound insulation qualities. And due to low hygroscopicity and water-retaining capacity, at least 92%, the induced mortar for two hours retains elasticity and is suitable for use, preventing premature hardening.

Features of using a dry mix M150

Work is better in dry conditions at air temperature 5-300c. Apply the finished solution is necessary on the purified from dust and dirt, as well as from the residues of the old coating and building materials, if possible, on a dry and degreased smooth surface. In the conditions of increased dampness to avoid the reproduction of microbes, the propagation of rot and mold. The base before applying the building solution must be pre-cleaned with a steel brush and treat fungicidal drugs. If the surface is very absorbing, then before applying the solution based on the cement-sandy dry mixture M150, it is necessary to moisten and breach in several layers to increase the setting and increase the reliability and durability of the new coating.

If there are large cracks, they must be filled with this solution, and then you can align the surface, applying several layers and evenly distributing the mixture with a spatula or mounting grid. Each new layer of solution based on a dry mixture M150 is applied after complete drying of the previous one. 24 hours after applying the last layer, the surface can be painted or hugged.

Handicapped with a dry mixture of M150 should be very careful, avoiding it from entering the skin and the more in the eye, for it contains cement and when the water is connected, it gives an alkaline reaction. It is best to use auxiliary tools and work in gloves.

In the list of the most common materials on construction sites cement mixtures consist. The basis for them is cement and sand, but for improving properties, various additives (plasticizers) are introduced into the composition. The CPS is applied almost at all stages - from the installation of the foundation until the walls are plastered. The dry mixture is only necessary to dilute with water in the proportions specified on the container, and to withstand a few minutes to the correct state. It is easy to use it made it so popular.

The cement-sand mix is \u200b\u200ba basic building material for filling the foundations, wall masonry; Alignment of floors, plastering surfaces and seam close.

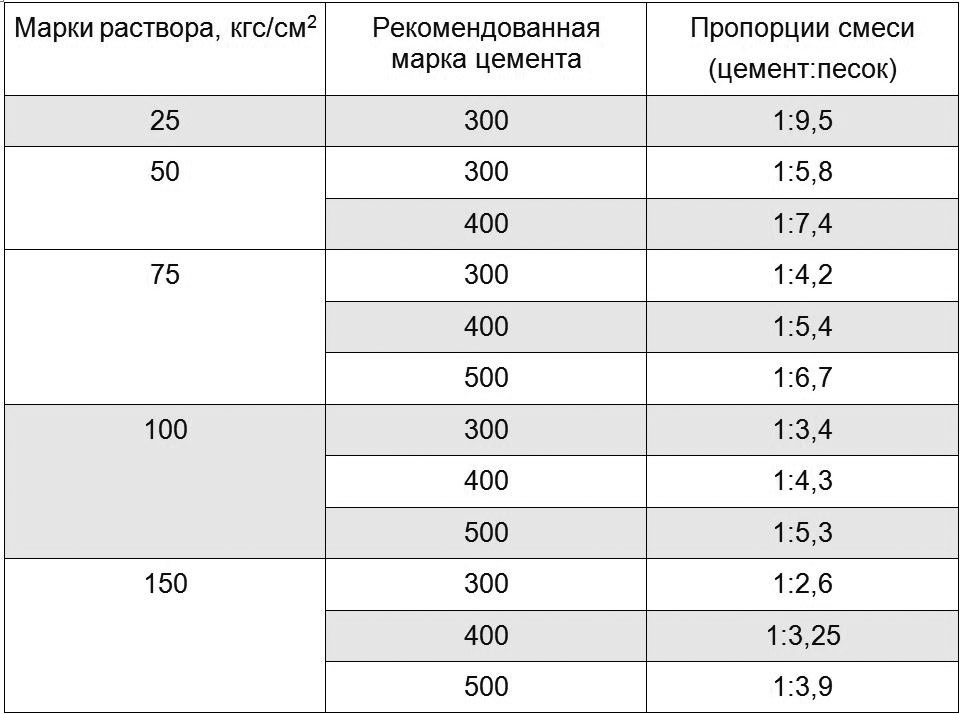

The brand is determined based on the specific type of work:

Plasticizers expand the range of applications. Thanks to additives, adhesion changes (the degree of grip of heterogeneous surfaces), water repellent properties, mechanical stability of the finished CPS. Their presence affects the price of the material towards its increase.

GOST and Marking CPS

The technical parameters of dry cement-sand mixtures are governed by the provisions of GOST 28013 (1999). The classification was carried out by:

- density (lungs, heavy);

- quantity binders (Simple - one, complex - several);

- assignment (plastering, masonry, fill).

For solutions based on the mixture, GOST regulates:

- humidity;

- density;

- temperature range;

- plastic;

- relax.

The solidising mass is assessed by:

The solidising mass is assessed by:

- density;

- strength;

- frost resistance.

Marking M200 indicates that 1 cm³ hardened mixture can withstand a static load of 200 kg.

The container in which the CPS faces must convey the consumer full information about the composition, method of application and storage time. The manufacturer must indicate specifications cement sand mix:

- material class;

- brand concrete for compressive strength (MPa);

- used additives (view, quantity);

- maximum fraction of aggregate (mm);

- the volume of water to obtain the finished mass (L).

In addition, the manufacturer itself is displayed on the container, weight, release date, expiration date.

The use of CPS

This is a cement-sand plastering mixture. The composition includes cement, river sand And lime. By 10 kg of dry matter, 2 liters of water is added. The price is low, as little cement is used.

Produced in several modifications. Accordingly, it is suitable for plastering, filling seams, mounting and masonry work inside and outside buildings.

Installation and masonry M200 - the best way For walls. In universal composition it is suitable for ribbon foundations. The third version of the cement-sand mix is \u200b\u200bplaster.

4. M300.

4. M300.

The M300 cement-sand mix (sandbetone) is intended for concreting work requiring the high strength of the finished layer. It is used as the main material for filling the foundation or concrete screed, flooring in places with a large crossway. It consists of cement and sand of various fractions, it is used both inside buildings and outside. The cost of the bag of sand-cement mixture M300 weighing 50 kg is about 140 rubles.

This is the most durable, frost-resistant and plastic sandbetone for bases, floors, carrying structures, exterior sites, reinforced concrete products. Cement prevails and many plasticizers are added, which makes the cost M400 high.

Any amount of money voiced for a bag does not make sense until the amount of consumption is specified. And he can differ in the same area at times, it all depends on the layer thickness. The flow rate of 1 m² of dry cement-sand mixture is in the range of 1.7-1.9 kg. But manufacturers indicate it at the rate of 1 mm thick.

For processing square meter Surfaces with a 2-mm layer will take about 3.6 kg, and 5-millimeters - about 9 kg. As practice shows, when pouring floors, a layer of 10 mm is consumed 21-22 kg of cement-sand mixture per 1 m². Based on this situation, 20 m² will take more than 400 kg of Peskobeton M300. Therefore, in order to save money, many individual developers do not use the factory composition, and they prepare it on their own.

Types of solutions

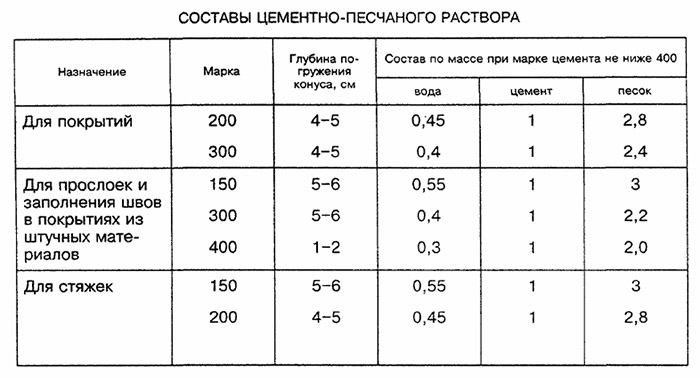

1. The CPS for the tie of the residential premises.

The solution should be brand 150 or 200. To achieve these parameters, you can take the cement M500 and sand in proportions - 1: 3 or cement M400, but already in a 1: 2 ratio. It is advisable to add 800 g of fiber bulk to 1 cubic meter.

2. Watching surfaces.

3. Laying walls.

In this case, special attention should be paid to the purity of sand, if necessary, sift it. Only with this condition, the binding and aggregate will turn into a homogeneous mass that reliably captures bricks. The proportions vary from 1: 3 to 1: 6. On 1 part of the cement, 0.8 parts of the water relies.

How to prepare a building mixture?

There is an erroneous opinion that it is good enough to mix sand, cement and water so that it turned out the right consistency. In fact, the first stage is important - mixing the binder and aggregate. It is the uniform distribution of cement that will be a pledge of a good solution. In the basic dry cement-sand mixture you can also pour dye to obtain different colors. After a homogeneous sandy cement mass is obtained, a liquid is gradually poured.

If there is a concrete mixer, the water is first poured into it. Next is added cement, the composition is communicated to a homogeneous state and only after that the sand is poured.

Experienced builders have their own secrets:

- If there is little cement, the strength in the frozen form will be weak, and the hardened amount of the binder makes the solidified cement-sandy mixture of fragile.

- You can strengthen the sand, but the plasticity will decrease.

Medium rates

In many cases, developers prefer to use ready-made dry mixtures. Purifying water according to the instructions, in a few minutes you can get the right solution. Easy to use and high-quality ingredients, including the necessary additives, speak in favor of the CPS. The cost is determined by the brand, the cheapest - M100, and expensive - M400. The weight of the packaging is also important: the price of 1 kg in a bag of 25 kg will be higher than 50 kg. For large construction, cement-sandy mixes are fusing in container up to 1 t.

Below is the average cost of various types of CPS presented in the Russian market.

| Manufacturer | Weight, kg | Price, ruble |

| M400 | ||

| Dauer Z-40 | 50 | 220 |

| M300 | ||

| Reference | 40 | 135 |

| Maks. | 50 | 125 |

| Luix. | 40 | 110 |

| Dauer Z-30 | 50 | 150 |

| Rusean | 40 | 140 |

| Stone Flower | 40 | 115 |

| Eco | 40 | 100 |

| Real | 25 | 95 |

| MKU | 40 | 90 |

| Mixmaster | 25 | 81 |

| Polygran | 25 | 78 |

| M200 | ||

| Dauer Z-20 | 25 | 85 |

| Maks. | 50 | 125 |

| Stone Flower | 50 | 135 |

| Master Harz | 50 | 160 |

| Solution Cherlets | 25 | 90 |

| M150 | ||

| Reference | 40 | 150 |

| Maks. | 50 | 125 |

| Luix. | 40 | 110 |

| Dauer Z-15 | 50 | 131 |

| Rusean | 40 | 145 |

| Perfekta. | 50 | 160 |

| Real | 25 | 95 |

| MAGMA | 30 | 130 |

| Kamix. | 25 | 110 |

| Mixity | 25 | 93 |

| Petrol | 25 | 87 |

| M100 | ||

| Maks. | 40 | 106 |

When you go directly to the construction of any design, then after drawing up the project, you must go shopping in search of high-quality materials. To perform various masonry work, the concreting of floors, the construction of walls of bricks, eliminating cracks and other flaws It is worth using a dry cement-sandy mixture.

But in order to save its money, it is necessary to determine in advance the required amount of building material. Here you need to calculate the flow, which, in turn, depends on the type of construction.

The mixture, which contains dry sand and cement, today is very in demand. The reason for such popularity is explained by the simplicity of preparation, low cost and effective result.

To get the necessary solution, you just need to add water in the desired proportion. However, today you can purchase a product, as part of plasticizers. It is from the type of these components that will depend on the characteristics of the finished solution.

Manufacturers use chemical additives in the cooking process, since it is possible to improve the properties of the mixture and the perfect compliance of the composition for certain conditions of application.

The result of adding these components will increase such qualities:

- adhesion;

- waterproof;

- resistance to wear;

- resistance to frost.

The video describes the proportions for cement sandy mixture:

All existing cement-sand mixes have a variety of destination. They can be involved to combat quietwesters, when installing a different nature, for filling the floor, brick masonry. Between all the present types of this product, there is one main difference - these are indicators of strength. For example, the M100 brand is characterized by the composition of cement and sand, the ratio between which will be 1: 3.

In the laboratory conditions, the presented product is capable of withstanding the load on the hydraulic press to 100 kg / cm2 for 28 days. Thanks to this, it can be actively used to close the cracks or just for masonry bricks. As for the flow, it can be calculated using the data on the mixture that the manufacturer indicates.

If we talk about plasticized mixtures, then they are often called as "cast concrete" or "rough leveling agent for the floor." To make such a material use the cent of the brand is not lower than M200. If this condition does not observe, the solution will start sliding from the walls and spread to the floor.

In essence, a plasticized mixture is all the same cement and sand (1: 3), but with the addition of plasticizer. Why do these additives need? Thanks to them, it is possible to dissolve the resulting solution to the consistency of the liquid sour cream. As a result, it is possible to reduce water consumption and improve spreadability.

The presence of a plasticizer provides excellent hardening, without cracking, which can be formed during shrinkage. In addition, it is important to add a spoon of washing powder into a mixture. If you put a tablespoon of powder on the bucket of the solution, then it is possible to achieve the same effect that when using a mixture with a plasticizer. But many manufacturers' factories use plasticizers in a certain proportion to prevent the process spreading the finished composition.

Now it is worth considering the consumption of a cement-sand mix of a certain brand and for specific cases. The average consumption of dry cement-sand mixture will be 1 m2 of about 1.7-1.9 kg. In this case, the fundamental factor is the thickness. If you need to process 1 m2 of the surface with a layer thickness of 2 mm, the material consumption can be 3.6 kg. With a thickness of 5 mm - 9 kg.

In practice, the situation is as follows: when pouring the floor, the thickness of which will leave 10 mm, the material will leave 21-22 KSH / M2. Taking into account this data, it can be concluded that 400 kg of Peskobeton M300 will go to 20 m2.

Now consider the types of materials and their consumption:

Features of calculation

Regardless of what purpose it is necessary to use the mixture, to obtain 1 m3 requires a sand cube. To create a concrete screed, required amount Cement is calculated taking into account the proportion of 1: 3. Thus, for obtaining necessary mix You need to take 465 kg of sand. To perform a screed, still construction mixtures M150 and M200 are used, for obtaining cement M400 and M500, the consumption of which will be 490 and 410 kg per m3.

On the video - cement sandy mixture, GOST:

When the construction of walls is underway with the help of a sandy-cement mixture, then the traditional is considered the proportion of 1: 4. Thus, 1 m3 will be enough 350 kg. If masonry is underway silicate brick, then the flow will be less - 0.22 m3. For the construction of bearing walls requires to use higher grades cement. When lime is present in the solution, then it is necessary to use the proportion of 1: 3. Read more about the flow rate of cement sand mixture on 1m2 is written.

The process of adding water is carried out "to the eye" according to how thick the consistency you want to get. Also, a lot depends on the characteristics of the material at the time of calculating the consumption. In this case, viscosity, density and drying time play not the last role.

The cement-sand mixture is today one of the most sought-after building materials. But a wide range of these products very often complicates the process of choosing a suitable composition. It is also very important to take into account the consumption of the mixture, because it is its own for performing certain works. Perhaps you will be interested to know what. The link describes.

In the area of \u200b\u200bconstruction, dry mixes are in virtually all major technological stages. Quite often they are used in the repair (restoration). The specificity of this or that composition is largely determined by the type of binder. The theme of this article is their species, characteristics and indicative price of products. The general TU at the CPS is set out in detail in GOST No. 31357 of 2007.

The main components of such compositions are sand and cement. The number that stands after the LITERA "M" means the load (kg / cm2), which can withstand the hardened layer. It is necessary to consider that this indicator is indicative, since much depends on such factors as the correctness of the preparation of the solution from the mixture, compliance with the technology of work and a number of others. For example, for the M150 CPS, it approximately equals 150 kg / cm2.

Characteristics:

- Composition and proportion. In some CPS (for example, M100, M150) should not be organic impurities.

- The ability to hold water (GOST determines at least 90%).

- Frost resistance (expressed in cycles).

- Grappling time.

- The coefficient of overlap (should not be 10).

- Consumption of cement-sand mix on 1m2.

- The thickness of the applied layer.

1. If there are mixtures with similar characteristics on sale, before you buy a specific composition, you need to analyze the ratio of the last two indicators - thickness and consumption (kg / m2). Practice shows that the acquisition of the CPS at a higher price in total expression is more cost-effective.

2. Manufactured by the manufacturer consumption on M2 oriented to a professional, and high-class. Therefore, when evaluating the feasibility of buying a CPS also take into account. The actual consumption of plaster, the solution on the masonry or the screed will be more about 8-12%.

Varieties

Used for the preparation of cement-sand plaster solutions. In addition to the main components there is lime in it. Because at the expense of it, the share of cement is reduced, M100 is characterized by a smaller cost. Such formulations, except plaster, are used to level the base and eliminate small defects of surfaces (cracks, cracks, chosen).

Used for the preparation of cement-sand plaster solutions. In addition to the main components there is lime in it. Because at the expense of it, the share of cement is reduced, M100 is characterized by a smaller cost. Such formulations, except plaster, are used to level the base and eliminate small defects of surfaces (cracks, cracks, chosen).

This brand is considered universal and used when conducting various technological operations. The cement-sand mixture M150 is equally well suited for the preparation of plastering, masonry. It is used in the arrangement of screeds, various repair workoh. In principle, in everyday life, M150 will replace any other. If you correctly determine the required characteristics of the cement mortar, the change in the ratio of components can be achieved to improve certain properties of the final product. The relevance of these compositions is influenced by their acceptable cost.

Characteristics M150:

- Recommended layer thickness (mm) - from 5 to 50.

- Consumption per m2 is about 16.5 kg (1 cm).

- Time (hour): Camping cement mixture - 2, hardening - 24.

Buying a ready-made masonry solution of the brand 150, you need to see what additives are available in its composition. For example, whether it corresponds to the requirements for frost resistance. It is also important and the thickness of the layer for the consumption recommended by the manufacturer on M2.

These cement-based mixtures are often called mounting and masonry. The M200 CPS is produced in several modifications, each of which is focused on a specific application - preparation of plaster, masonry solution, for a screed and even foundation. The resulting artificial stone (layer) is characterized by sufficient strength. Approximate consumption (with a thickness of 5 mm): 7.5-8.5 kg / m2.

The data of the mixture in everyday life is called sandbetone or foundation CPS. Their price is somewhat higher, and the scope of use is not as large as the compositions of M150. Mixtures cement-sand are used where such a characteristic, as durability, is one of the main. It is advisable to buy for masonry solutions when installing block structures, arraying for massive screeds and the like. But for M300 plasters does not fit. Approximate consumption on the screed - 19.5 kg.

Self-preparation

Several factors affect the proportions. First, the prescriptions of the solution; secondly, cement marks; Thirdly, the dates of his release. For some reason, many forget about the latter. It is necessary to consider that when storing cement, even under the appropriate conditions, it gradually loses its original properties. It is taking into account this that his share should increase somewhat, depending on the storage term. Therefore, all values \u200b\u200boccurring on the Internet are only approximate, not taking into account all the features of the preparation of the composition.

1. For screeds.

As a rule, cement grades 400 or 500 are taken. In the first case, the proportion is 1 to 2, in the second - 1 to 3. Reduce the likelihood of cracks in the hardened layer, it is possible by adding fibrovolock to the CPS to the CPP for the calculation of 0 , 7-0.9 kg / m3 of the mixture.

2. For masonry.

The quality of work is largely determined by the seam thickness. In this regard, much depends on how carefully prepared (succeeded) sand. Therefore, on 1 part of the cement, it is usually taken from 3 to 5 parts of this bulk material.

Mixing mix must be done in small quantities. Wizards first try quality on separate bricks, experimental by determining needed proportion For the available binder and sand. At the same time, the approximate consumption of cement on the masonry becomes also understood. This allows you to slightly optimize spending.

3. Cement mortar For plaster.

It is enough to take the binding brand M200-M300. The recommended proportion is 1 to 3.

Nuances of manufacturing CPS

1. The quality depends not only on the proper selection of components (by brand, grain), but also on the thoroughness of mixing. Manually achieve this almost impossible, even if ready and ready (shop) mixture. In everyday life it is advisable to use the nozzle to the perforator (e / drill). This adaptation is not a deficit, and its price does not exceed 210 rubles.

2. Attempts to reduce the consumption of cement by increasing the fraction of the sand will not lead to anything good. It will decrease the elasticity of the solution, cracks will appear, chips, the fittings are screamed in the screed - and this is not a complete list of "surprises". Manipulated with the ratio of components can be only within the recommended proportions.

3. When storing cement for six months, it loses its properties by approximately half. In such cases, proportions should be changed.

4. Do not forget about the water. Its excess leads to a decrease in the strength of the artificial stone and increases its curing time.

The cost of mixtures largely depends on the ratio of components and the type of additives that change the individual characteristics of the composition.

* Data on cement-sand mixtures averaged, in relation to the Moscow region. Recommended consumption is indicated individually for each composition.

** For packages 50 kg.

A mixture of universal M150 consumption is only 18 kg per m2 with a layer thickness of 10 mm. Recommended solution thickness of a solution from 5 to 50 mm. Without plaster grid You can apply a layer to 30 mm.

Manufacturer Lyubertsy plant cement-sand mixtures LLC "Center Building materials"(TsS.M.). This product is certified and has a steadily high quality. Characteristics of sandboxes CSM / CSM are an order of magnitude higher than popular materials " Stone Flower».

The universal mixture M 150 is designed to perform masonry aligning - plastering, concreting, repair work, stools and seams, styling paving slabs.

Cement-sand mix Universal M150 is made from high quality cement, construction sand Using mineral and organic additives improve its characteristics.

Advantages of dry mixes CSM:

- High-adhesive ready solution M-150 allows you to get a plaster layer with a thickness of up to 30 mm

- For work inside and outside

- Economical flow

- Ecology

- High resistance to low temperatures

- Parp permeability

- Great strength

- Weather resistance

Preparing the foundation

To reduce the consumption of dry universal mixture M150 and obtaining high-quality coverage, it is necessary to conduct preliminary training surfaces. Bases with a porous structure (PENSY, gas-silicate blocks) severely needed carefully processing primer or moisturize. This is allowed to reduce water consumption that leaves the solution to the base.

Preparing the building composition

In a predetermined container with a mixture of universal M150 pour water, according to the flow rate indicated on the package. The kneading can be performed by manual or machine to obtain a homogeneous jelly-shaped mass. The resulting solution after 5 minutes must be reused. After that, cement-sand consistency should be spent within 45 minutes. When the prepared universal mortar mortar, the M150 cannot be added to the water, simply mix it just once again.

Sequence of work

Before applying the leveling layer, it is necessary at the relics of the same mixture to close all the irregularities (cracks, depressions, chips). The universal solution is attacked on the base using a cell or spatula. The twined mass M150 is pulled by the rule before obtaining a flat surface. The average flow of dry mix on a layer of 10 mm per sq.m. It is 18 kg. Pulling is made using a metal or plastic grater. On the foundation obtained can be applied decoration Materials After 72 hours. After complete drying. Polished cement plaster can paint, glue wallpaper, put ceramic tiles etc. If the leveling of the base with a mixture of universal M150 is performed for several passes, then it is necessary to wait when the previous layer dries. All work should be produced at a temperature of +5 to + 30c and relative air humidity not more than 80%

The warranty period for the storage of the mixture of universal M150 is 0.5 years, subject to the storage of sandboxes in a dry room and factory packaging. It refers to paper three-layer bags of 40 and 50 kg.

Technical data

- Mix color - gray

- The viability of the solution is 45 minutes

- The number of cycles for frost resistance - at least 50

- Blend Universal M150 Consumption per m2 - 18kg / cm

- Clutch - 0.5MPa

- Compressive strength - 1.5 MPa (after 28 days)

- Recommended application thickness - from 5 to 50 mm

Price list with wholesale prices on cement-sand formulations.