The largest brand of cement. How is the marking of cement deciphered? Recipe for the preparation of cement mortar

Read also

Cement is binder, without which it is impossible to do when pouring the foundation. By mixing it with fillers such as gravel, sand, water and crushed stone in certain proportions, you can get a monolith that can withstand severe loads.

How to understand brands of cement?

To sort out technical specifications and components of this building material and understand which of its types is best suited for the planned foundation, you need to learn how to decipher the markings from numbers and letters on bags of cement.

We have the following types of refractories. Technical data such as density, type of refractory concrete, alumina content for calculation comparison or equivalence are given in the following link. Information about procedures and technical data sheets. We have various refractory mortars and dry ready for gluing refractory brick, refractory tiles in some applications and for gluing metal board ceramic fiber furnace body.

We can make prefabricated parts with refractory concretes already cured from the factory to increase their performance. Ceramic fiber cones for flow channels. We advise you to choose a specific option or equivalence. We advise you to expand the boards in place.

Old GOST from 1985

According to the old GOSTs on the packaging first they write PC or SPC, which means Portland cement or Portland slag cement. PC is a mixture in which calcium silicates predominate. The lion's share of the concretes used in the world is produced on the basis of Portland cement. ShPTs - a mixture that contains additives in the form of slag. There is also magnesia, alumina, acid-resistant and other types of material used for the construction of structures in specific conditions.

Here are some of the preparations various types concrete. Concrete dense traditional preparation. First, the material is mixed to dryness, and then the minimum water is added and added as you order the mixture without exceeding the maximum. Mix for 3 - 5 minutes, pour the mixture using a pencil or naming vibrator.

Then cover the concrete with wet bags to allow it to cure and remove the frame after 24 hours. First, the material is mixed in a dry state, and then a minimum of water is added and the mixture is added as needed without exceeding the maximum.

Second element on the package after the letters is a three-digit number - from 300 to 600. It means the brand of cement according to the strength of the sample obtained from this mixture. For example, M 400 means that the test specimen withstood a load of 400 kg per cm 2 .

Third there is an element that carries information about the content of active mineral additives as a percentage (for example, D10 - additives 10%). The content of additives should not exceed 20%.

Avoid adding more water than indicated as it will affect the quality of the material. Mix for 5-7 minutes to homogenize the material. Empty as quickly as possible to prevent porosity once it has been sealed with vacuum bags or wet papers to ensure maximum curing. Mix for 4-8 minutes to homogenize the material. Empty as soon as possible to avoid porosity once it has been sealed with vacuum bags or wet papers to ensure its maximum degree of cure.

Fourth the element reports that this building material is B - fast-hardening (for example, PC 400 D20 B), N - normalized, SS - sulfate-resistant, BC - white cement, VRTs - waterproof, etc. The abbreviation PL indicates the presence of plasticizers. This is the so-called hydrophobic cement, which can be stored even in conditions of high humidity.

According to their special characteristics, it can be. Low heat of hydration White. Gray cements have a very distinctive color due to which they are also known as Portland cements. Portland Cement Cement Excellent performance, higher 3 day resistance allowing to fail or run down in less time than other cements, optimal setting and durability in the construction of concrete slabs, columns, locks, dalas, foundations, sewers, plumbing and prefabricated of all types.

This cement is compatible with all common building materials such as sand, gravel, marble, quarry, etc. As well as pigments and additives, provided that they are used with care and dosages recommended by their manufacturers. This gives concrete mixtures greater cohesion, adhesion and workability even in the presence of problematic aggregates. Reduces bleeding and segregation of concrete mixes.

Last group of numbers- information about the GOST of building materials (for example, GOST 10178-85).

New GOST from 2003

First comes the name of the composition: CEM I - means pure cement without additives, CEM II - composition containing additives. The second type of CEM II, in turn, is divided into two groups A and B. A is understood as a mixture with an additive content of 6-20%, B - 21-35%. The next letter carries information about the type of additive: P - pozzolan, Sh - granulated slag.

Its use is recommended for all jobs and especially for those in which the concrete elements will be exposed to damp environments, as it provides protection against foundations, walls and ceilings, giving excellent results in moisture protection. This prevents saltpeter and mildew, flattened or painted walls and ceilings from detaching due to moisture, and prevents electrical installations and rods from deteriorating.

It is recommended for all jobs and especially for the construction of dams, canals, municipal drainage and underground works. White This cement has the same characteristics as any other Portland cement, its whiteness permanently makes any additional treatment at the end of the job unnecessary, and its maintenance is simple and economical. It is the final, integrated, defined and uniform appearance, either in its natural white color or in the desired color tone. The completed work will have greater strength, as they do not risk separating the parts that make up the finish.

The next indicator is digital. It reflects the compressive strength class 28 days after the foundation is poured. Strength can vary within 22.5-52.5. Next comes the subclass, which reflects the compressive strength of the material in the range from 2 to 7 days. N - normally hardening (22.5 - strength class), B - fast hardening (32.5-52.5 - strength). The last is information about GOST. So, the marking of cement CEM II / A-SH 32.5B GOST will have a decoding - fast-hardening Portland cement with a slag additive - 6-20%.

It can be used for structural, architectural and adhesive uses. Mortar, also called pantry cement, is Portland cement mixed with finely divided inert materials. In other words, it is cement with sand and water; and what distinguishes it from reinforced concrete is the absence of coarse aggregates. Mortar Designed to produce mixtures of plasticity and optimum workability and with sufficient resistance to use in masonry work such as: joining or gluing blocks, partitions, bricks, stone and brickwork; flattened, perverted, sullen, repellers and resans; solid, insoles and pavements.

Grade of cement for the foundation

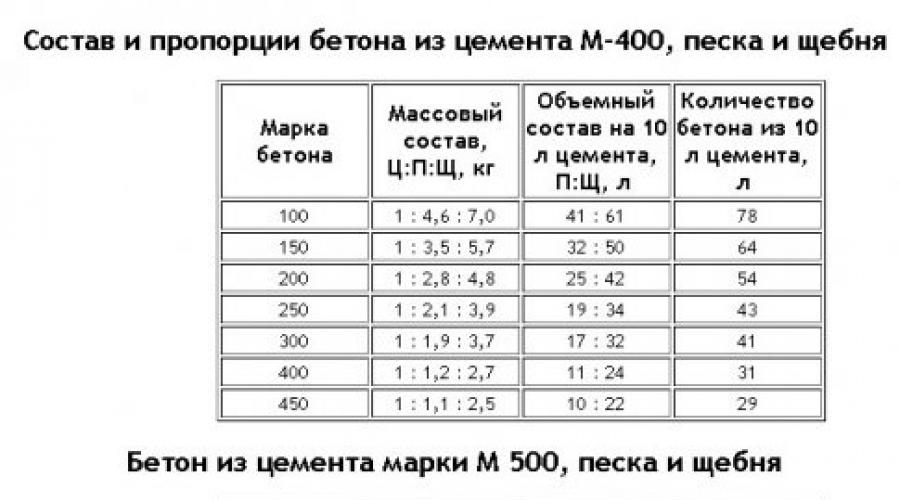

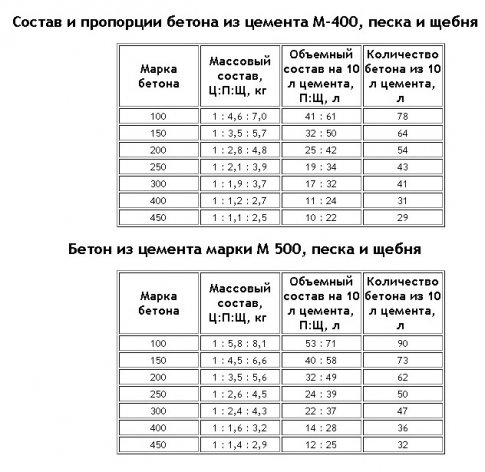

If you plan to build a foundation on dry ground, the best choice there will be ordinary Portland cement grade 400 or M500. For example, for the manufacture of concrete M350, PC M 500 will be required. In this case, the proportions of the solution will be as follows: for 1 part of cement - 4 parts of crushed stone, 2 parts of sand. Water is added in an amount equal to half of 1 part of dry PC.

Preparation of solution M25

It should not be used when constructing structural elements. White Blue Cross Cement White Blue Cross Cement is made from carefully selected materials that guarantee its superiority over similar products. This is "White Prefect", whether used alone or mixed. Its high quality is preferred by architects and builders. Its main properties are: Whiteness and luminosity: can be used alone or with the addition of dyes to diversify the range of uses and finishes.

- In low-rise individual construction, cement M400 and PC M400 D20 are used. This is the best value for money. The foundation built using this material will meet high requirements for frost resistance and moisture resistance.

Cement M500 and PC M500 D20 - the best option for the construction of foundations for industrial buildings (hypermarkets, multi-storey buildings, hangars, etc.). PC M500 D20 has found wide application in the construction of structures in areas with high humidity.

Mechanical resistances: very high and homogeneous, which allows it to be used with a large number of aggregates. Plasticity: it provides sufficient mobility and great ease of molding. Durability: due to strict quality control during its development. Imperviousness: A feature that makes it excellent for covering swimming pools.

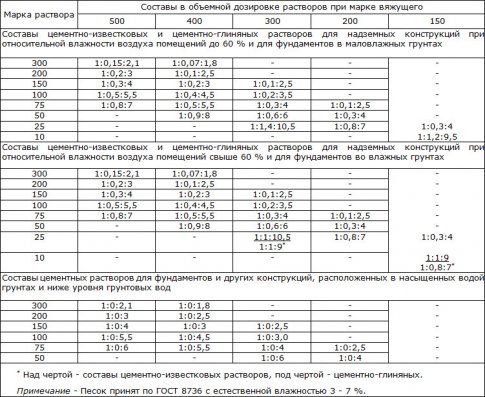

Mortar for masonry

All these properties allow the product to be used in a wide range of applications in architectural work, where the durability and reliability of its finish can be appreciated. Its main properties: Mechanical resistance: high and uniform. Due to their reliability, they have a positive impact on the specific design, which is reflected in higher performance. Waterproofing: After carefully handling, transporting, placing and finishing the concrete, it helps to reduce the number of pores in the concrete, reducing the penetration of corrosive substances such as sea salts, black water, salty soils, etc. Heat of Hydration: Our characteristic clinker, together with additional cementing agents, generates less heat during hydration, which is why the cement is classified as low heat of hydration, which minimizes thermal expansion and greatly reduces the occurrence of cracks.

- When choosing a brand of cement, be sure to consider total weight the future structure and the load on the foundation, as well as the geology of the site (the level and nature of the soil), the type of basement and underground part of the building (tape, piles, the presence / absence of a basement).

- To build a foundation for a house from a bar or log, a mixture of M250 or M300 is enough, for the construction of a prefabricated panel building - M200.

Foundations for brick houses, buildings made of prefabricated reinforced concrete and other wall materials of significant weight should be arranged using more durable concrete (M350 and higher).

Segregation, Bleeding, Plasticity and Cohesion: The fineness and better particle size distribution of our cement results in less blood flow and less segregation in the concrete resulting in greater cohesion with the aggregates. Eco-friendly: this product reduces the emission of greenhouse gases such as carbon dioxide that contribute to climate change on our planet. Thus, Cruz Azul confirms his position in favor of the defense environment, by optimizing the use of natural resources.

The jobs done with this product are characterized by their durability, reliability and cost reduction. Recommended for all types of engineering and architectural work, as well as for general use. The mixture of these raw materials goes through strict quality control and makes it the best cement available on the market. Recommended for major engineering and architectural work, for general use and for work in areas exposed to aggressive and heavily polluted soils.

- On rocky and sandy soils, it is better to use concrete M200-250. In construction on loam and clay, M350 concrete is used with a higher coefficient of water resistance and frost resistance.

- If a basement is planned in the house, the base should be poured with M350 concrete and additional external waterproofing measures should be taken.

- In the case when the construction of the building will be carried out in areas where groundwater with a significant salt content is present, when choosing cement, pay attention to its sulfate resistance. You can use a ready-made sulfate-resistant mixture or purchase modifying additives and pour them in at the stage of preparing the solution.

How to identify a brand?

As a rule, this can be done according to special designations printed on the packaging. But in some cases, when, for example, the packaging is damaged, it is possible to determine the brand of cement experimentally.

Its main properties are: Mechanical resistances: high and uniform, have a positive effect on the design of the concrete mixture, which is reflected in a higher productivity. Higher impermeability: reduces the number of pores in concrete, which reduces the penetration of aggressive substances such as sea salts, sewage, salty soils, etc. increased resistance to sulfate attack and reaction liquor Added: Chemical composition The clinker and the quality of the pozzolan make it a very resistant cement for environmental chemical attack.

For this, you will need mortar, sand, water, weights with weight designation, cap, steaming chamber, molds for cement.

We mix the concrete mortar, adhering to the ratio of cement and sand - 1: 3. In this case, the coefficient of water-cement ratio should be at least 0.4 (400 g of water per 1 kg of the mixture).

Heat Hydration: Develops when heated during hydration. It produces concrete with greater volumetric stability, which minimizes decomposition and significantly reduces the appearance of cracks. Fineness and distribution of particles: this gives the concrete excellent workability, less segregation and bleeding, and greater cohesion of the mixture. The resulting finishes are smoother. Ecology: Thanks to careful production and composition, this cement contributes to the care of the environment.

Together, these properties make it a very reliable cement that gives concrete high mechanical and chemical resistance. The work performed with this product is characterized by high durability, reliability and cost reduction. Cement mortar Cruz Azul Cement mortar Cruz Azul is a product intended for work and masonry. The strict quality control that goes through during its development gives the user a high level of reliability to use in all their work. This the best option, and its cost is less than using a mixture of gray cement and lime.

The resulting solution is poured into molds measuring 4cmx4cmx16cm.

We cover the samples with a cap. Carefully monitor the maintenance of a sufficient level of humidity (place a container of water next to the molds). Leave the samples under the hood for a day.

Remove the sticks and send to the steaming chamber. Check the strength of the samples for bending - place a bar on two supports, while the center of the bar should remain free. Place 1 weight in the middle until the sample begins to collapse. Remember this weight. Using a special formula and the obtained indicator, determine the compressive load and cement grade.

Its main properties are: Excellent plasticity: characteristic of our mortar cement due to the retention of water and air content. Excellent performance: simple application reduces operating time. Excellent Adhesion: Reduces mixing of waste and greatly reduces spatter on face, clothing and pre-finished work areas. High quality finish: provides imperviousness for the highest durability of the work. Pleasant color and texture: allows architects and users in general to use them alone or with stains to expand the range of visible facades.

R-daily=P / S * 98 (MPa)

Where R- force, measured in kg/s; R- daily - strength in megapascals; S- surface area sq / cm. To conduct a more complete check of the characteristics of cement, devices such as a granulometer (allows you to determine the fractional composition), IATs-04M devices or contraction meters (to determine the activity of the binder composition), etc. are used.

Dosage: Add only sand and water in suitable proportions. All these properties allow for a wide range of applications, as well as a significant reduction in labor costs, without compromising the resistance, durability and reliability of its finish.

General Portland cement with addition

Today Portland cement is standardized and there are eleven types on the market. The gypsum acts as a handle retarder, avoiding the immediate hydration reaction of the cement. This type of cement has less permeability due to the addition of pozzolana.

Portland cement made from slag

Cement portland connection with gilding. This type of cement is recommended from reinforced concrete structures to laying and coating, but is not suitable for applications in very aggressive environments.Today high-quality cement is the key to a great repair or construction. After all, it is a kind of binder, without which any construction business cannot be dispensed with.

Starting, repairing a room or building a structure, many of us do not even think about which brand of cement to prefer. And it should, because all its types have their advantages and disadvantages.

Let's get acquainted with the various types of cement and the need to use them in various jobs.

main element

There are also M600 and M700, they are used mainly in the defense industry. When buying cement, you should know its decoding of letters and numbers.

DXH indicates the percentage of additives. So, D10 indicates that this cement also contains 10% additives - substances that give it certain properties, for example, resistance to low temperatures, rapid solidification, resistance to salt water, etc.

If it is free of impurities, then the indicated marking will look like this - D0. This is all the so-called Portland cement. But it happens that the percentage of additives exceeds 20%. Then we are talking about slag cement, which is called slag Portland cement.

AA is an indicator of the index of properties. If the SS will stand in their place, then this indicates that he is able to withstand the destructible action. It is used in the construction of hydraulic structures that will be in aggressive salt water, which contains sulfate minerals.

But there are other meanings of various impurities:

- PC - ordinary sulfate-resistant cement;

- SPC - Portland slag cement, the one that is made from inexpensive raw materials;

- BC - white cement, finishing work is performed with it;

- VRTs - does not let moisture through, sets quickly (from 4 to 10 minutes);

- H - a product that has the correct ratio of components;

- PL - cement, which increases the plasticity and workability of the mortar and concrete mixtures, increases their frost resistance;

- GF is hydrophobic, does not react to moisture. By the way, it can be transported over long distances. In addition, it is very plastic and frost-resistant;

- B - means the one that hardens quickly(used for urgent matters);

- But this is all classic labeling. And today, product manufacturers have begun to call it in a new way.

Changed titles

Today, manufacturers adhere to and produce:

- CEM I 32.5B - Portland cement (hardens quickly, its strength is 32.5);

- CEM II / V-Sh 22.5N - Portland cement with a slag capacity (fortress - 22.5);

- CEM II / A-I 32.5N - the same brand, only with the capacity of the rock containing lime, the characteristic is the same;

- CEM V / A-K (Sh-3-I) 32.5B - an astringent diluted with additional ingredients: granular ash, calcareous rock. Differs in that it instantly seizes;

- CEM III / A 32.5N - cement, which is characterized by a significant capacity of granular ash. The product hardens well;

- CEM IV / A (P-Z-MK) 32.5N - mainly contains a dusty mixture of volcanic ash, pumice, tuff and more;

- CEM V / A (Sh-3) 32.5N - this name implies the capacity of ash residues in granules in the composition of the mixture, which, when used correctly, sets perfectly.

According to GOST, cement can be:

- SSPTs 500-D20-PL - hardening material resistant to sulfates, which is sold under the brand name M500. It also contains about 2% mineral additives, which makes it more plasticized;

- SSSHPTs 400 - slag cement is also resistant to sulfate minerals and salts, produced under the name M400;

- PPC 300 - super strong cement, capable of hardening both in liquid and in any humid environment;

- NTs-20-M500 TU 46854090 - cement with excellent performance characteristics, has a huge self-stress in 28 days;

- PCB 2-400-D20-PL GOST 965-89 - light beige free-flowing powder, containing second-rate additives, marked on the bag with the number 400, has good plasticity, which makes it easy to stack;

- GOST 10178-85 involves the production of two types of this binder building material:

- PC 400-D20-B-PL - cement made from clinker, gypsum and additives, together with calcium silicates, which predominate in it. By the way, it is the most common in the world and is used in all kinds of construction and finishing works, it is produced under the brand name 400, it is easy to operate, quickly hardens;

- ШПЦ 400 - slag capacity binder, with the same strength as the M400.

A wide selection of this product is produced according to DSTU B V.2.7-46:2010:

- PTS I-400R-N - concrete production cement M400 from clinker and uniformly containing composition;

- PC II / A-Sh-400R-PL - slag-containing cement with a ratio of 6% -20%;

- PC II / A-K (Sh-V) -400 - the same material with the addition of limestone;

- PC II / B-K (Sh-Z) -400 - Portland cement with granulated slag and ash;

- ShPTs III / A-400 - purely slag-containing binder powder;

- PTSTS IV / B (P-Z) -400 - pozzolanic cement with an admixture of ash;

- KTs V / A (Sh-Z) -400 - composite cement with slag and ash.

You can find more information about cement grades and decoding on the video:

We define the brand

Sometimes it happens that the cement brand information stamped on the bag is damaged or poorly visible. In this case, do not rush to despair. Capacity can also be determined experimentally.

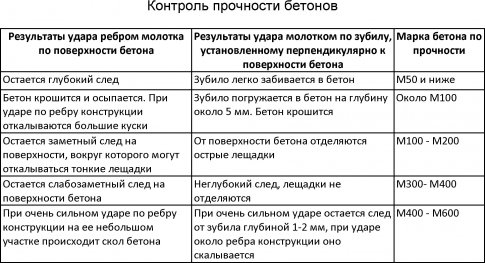

To do this, you need to take a hammer and hit the surface or hit the chisel with a hammer, which must first be fixed perpendicular to it.

If in the first case you see a deep mark, and in the second case, the chisel easily “fits” into the concrete, then the cement is fragile, most likely it is M50 or lower.

If it crumbles and shatters into tiny pieces, or when it hits the side of the structure, huge fragments break off or the chisel gets into the concrete by about 5 mm - this is the M100 brand; a decent imprint is preserved on top, from which narrow, flat-shaped pieces can fly off.

There are a large number of varieties of sand, differing from each other in their characteristics and having different applications. all characteristics of quarry sand.

When building a foundation, it is imperative to take into account the proportion of sand and cement, only then will a solid and reliable structure be obtained. you can get acquainted with the necessary proportions.

For finishing walls and ceilings with decorative plaster, it is not necessary to invite specialists, you can do it yourself. Learn how to do it by clicking on decorative plaster with your own hands.

Sharp such pieces are also separated from the surface, then you are dealing with the M100-M200 brand; on the cemented surface, an almost imperceptible or shallow trace, but the pieces do not separate - M300-M400.

At the maximum blow with a hammer on the edge of the structure, concrete breaks off from its small area or on the surface after a powerful blow an imprint from a chisel with a depth of 1-2 mm is imprinted, and upon impact near the side of the structure, it breaks off - M400 - M600.

Which brand is better to choose?

In any case, before buying one or another brand of cement, you need to know what it is for, during which construction works he will be needed.

Choosing one or another of its types, it is necessary to calculate what will be the pressure of the base of the structure, what is the level of groundwater, what will be the basement and whether the underground part is supposed.

So, in one-story private buildings, the M400 and PC M400 D20 are most used. It is inexpensive and of good quality. A base built with this bonding material is guaranteed to be resistant to frost and airtight.

Cement M500 and PC M500 D20 - quoted for large structures(hypermarkets, high-rise buildings, hangars). HRC M500 D20 is popular among builders who build houses on plots with excessive dampness.

To lay the foundation of a wooden building, M250 or M300 is suitable, for the construction of a building from prefabricated panels - M200. More solid reinforced concrete structures, brick buildings, as well as other wall materials that are heavy, require the use of a slightly stronger product - M350 and more.

When building a building on loam and clay, you will need a frost-resistant and impermeable M350, on deposits of stone and sand - M200-250.

When laying a basement at home, you need to purchase cement grade M350. In addition, you should take care of external waterproofing.

When constructing a building on a site with groundwater that contains a significant amount of salt, preference should be given to cement that has a sulfate-resistant quality. And you can buy modifying additives and add them at the stage of preparing the solution.

Summing up

As you can see, the choice of cement is large. But, unfortunately, it is a perishable product. With a very long storage, it loses its activity. Its main enemies are humidity and carbon dioxide, which is present in the atmosphere. Therefore, it is not recommended to buy it for future use.

But if, nevertheless, you are forced to do this, then do everything to save it and protect it from all kinds of influences.

Do not put packages of cement underground, where it is often damp. Do not store outdoors, especially in the rain. Even a canopy will not help protect them from moisture. The only salvation in this case is polyethylene.

If they pack cement well, then if the product cannot be completely protected from dampness and petrification, part of it can still be preserved. After all, it hardens, as a rule, along the edges, but in the middle of the package it will not be immediately damaged by moisture. It can be applied anywhere.

Of course, the quality of such a product will be lower than what is indicated on the container, but it may well fit on the farm. Approximately, if you need to lay tiles for paths on a mixture of sand and cement, or prepare mortar or concrete for pouring flimsy structures.

At the same time, in order to replenish the properties of the lost brand, You can increase the percentage of Portland cement in the concrete mixture. Just know that judicious use of any brand of cement can save you money, but is very important, and save you from working on mistakes.