Overall sizes of chamotte brick. The properties of chamotte brick, its varieties, characteristics and features of the correct masonry. How to make refractory brick. Structure

- Brands chamotte brick

- Main characteristics

The usual "red" brick is not intended for use in furnaces and furnaces. At a temperature of 1200ºС compressed into the brick, the burned clay melts, and cooling, begins to crumble. And although in an ordinary household oven, the temperature does not rise above 800ºС, which does not require use when they are constructed fireproof materialsIn practice, cast iron plates and iron doors are rarely stronger, so the use of at least in places of contact with them a special refractory brick more than justified.

If necessary, submit relative export documents and the original certificate. Warm and beautiful after-sales service.

Our main products are refractory and thermal insulation materials, heating elements, industrial ceramics. They are available in various sizes and forms. Our products enjoy a good reputation due to excellent quality and maintenance in the domestic and international markets.

Stamps and sizes

We can quickly offer our offer if you kindly send a request with the following factors: drawing, measurement. Operating temperature, application and quantity. Welcome your inquiry and hopes to provide satisfactory products and services for you. The shooting system is a system for firing dry bricks, which consist of a tunnel oven, furnaces and work equipment. Choir wall structure: from the inside and outside, this is a shaft brick, brick light-insulating, aluminum silicate heat insulation material, and red brick.

Distinctive features of chamotte brick

Among all numerous types of refractory bricks, it is chamoten that has the greatest strength. Therefore, it is more often used for the construction of furnaces of furnaces, fireplaces and other elements of the heating system, which have direct contact with fire, as well as for the construction of chimneys.

At a certain distance, an expansion clearance should be installed from each other to provide a free flexible part of the furnace. It is mainly heavy oil, light diesel fuel, natural gas, coal gas and coal coal. The drying system dries a wet brick through the drying chamber and the drying trolley that prepare for the burning of bricks. The heat source of the drying chamber is from the roasting furnace, the heat source will be sent to the drying chamber through the pipeline through the heating fan, the moisture formed during the drying process will be unloaded with a moisturizing fan.

It is able to withstand a temperature of 1600ºC, so recently it began to apply it for lining pyrolysis boilers. Responsive craftsmen were correctly judged that having an increased resistance to the temperature chamotte brick will take the main heat blow to himself, protecting the metal boiler and extending its service life.

In accordance with the structure, the drying chamber can be divided into a single-layer dryer, a small dryer and a large section dryer. The drying trolley is used to load wet bricks. In accordance with various functions, we have a moisture separator, a fan, a fan for smoke removal, a cooling fan and a fan for combustion. The fan provides heat supply and the release of moisture, and also provides air supply, moisture removal and smoke removal of the roasting furnace and cooling the furnace.

Reducing in smoothness or chammess on average 0-1, 5

Ferry machine, locomotive, pusher and cooler ensure a safe handle in the oven.

Excellent behavior when drying

Preparation of red after oxidation. Ideal for manual latch, machine or laminated use. Designed for excellent drying, including solid and dry items. This shamulated land allows you to avoid deformations and cracks that may arise.- Ideal for the technology of glazed land.

- In accordance with the technique used, several hardness are offered.

For the production of chamotte brick, chamotte powder and refractory clay are mixed. The composition of chamotal brick is from 60 to 80% of the chamotte powder, depending on its variety. To give the product a high strength, its manufacturers add coke or graphite filling, and large grains of quartz are added to the achievement of a beautiful appearance in chammed brick.

Gram, which can be very thin and thick, can be selected from 0 to 20 mm. Find the shape in the bag weighing 25 kg and a monophonic big bag. Baked quality clay adapted to all your needs, tariffs that meet your expectations are quite normal, since you are in the store of refractory shaft.

Fast drying, you have a lot of time to use it. For a safe purchase for us, high-quality products are calculated to more regularly use refractory chamotte promotion and concrete too. You need a "board for" the use of high-temperature refractory cements, DON blend to contact us.

The resulting mixture is burned across special technology, and the retreat from it is unacceptable. If the mixture is reappeared into the furnace more necessary, a vitreous film will appear on the roasted bricks. It gives the bricks a special strength, but at the same time almost completely disappears the ability of its surface to be adopted with laying solution, so it will not be possible to fold something worthwhile from such bricks.

Guaranteed reactivity, you can pass the contact shape and even add a photo of your stove if you have any doubts. Discover all shames and concrete. Depending on raw materials, bricks are characterized by the following moments. High density in their microstructure, good resistance to thermal impact and resistance to thermal deformation. Chamotte bricks are used in various industries. For use in the carbon monoxide atmosphere, the range includes a very low metal brick and baked at high temperatures.

The brick underseded in the furnace has a property to actively absorb and keep moisture, losing its strength. It is possible to fold from it without any problems anything, but the brick in such a laying will quickly crumble.

It is possible to distinguish chamotany from other types of brick products by straw-yellow color with reddish splashes and a grainy based. If you still have doubts, you can be ridiculously hit it. If this is really high-quality chamotte brick, then on such a blow it will be called metal sound. You can not be afraid of smashing it with a random blow, since it is distinguished by enviable strength.

Durrat - Tight Bricks Shamot

The range also includes sorting with high wear resistance and slag resistance. They are resistant to many acid attacks, including acidic reactions and sulfur connections, even if the dew point is not exceeded. That is why they are used in the construction of chimneys and for acid-resistant gaskets.

High wear resistance and chlorine allow you to benefitly use in installations with fluidized bed and heaters in the cement industry, if the raw materials or fuel have the corresponding voltages. An essential requirement of refractory materials, in addition to heat resistance, is the invariability of the volume, which means the weak expansion coefficient to ensure the stability of the design or coatings. In addition, as needed resistance to mechanical loads, minimal porosity to resist the attack of substances in contact or circulating gases, and sometimes a certain chemical nature, or to resist the reaction or reaction with the action of molten substances.

Back to the category

Chamotte brick stamps

Different types of chamotte bricks have different sizes, physico-technical characteristics and thermal conductivity. To distinguish them, manufacturers use labeling. Today, many brands are made, the main of which is:

The chemical composition is always simple; One of these materials is salt: kaolin; Most of them are oxides: silicic acid, aluminum oxide, magnesium oxide, calcium oxide, rare earth oxide, then carbon and carbide. Piston acids. - silica. - Anhydrous silica is in several varieties: the most common quartz, tridimitis, rarely crystobalitis. Three varieties exist in two altropy forms of α and β, resistant to low and one at high temperatures; At the conversion temperature, the extension coefficient jump occurs.

But inside each brand there are many varieties that differ in each other, size, weighing and thermal conductivity. For example, Mark Sha, the most popular in the construction of household furnaces and fireplaces, is divided into:

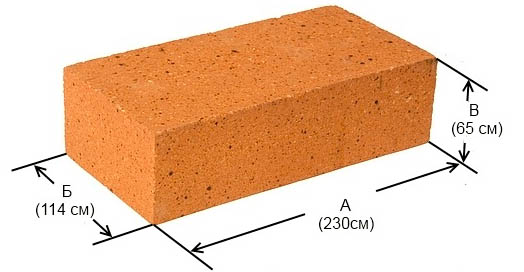

- Sha-2 with dimensions of 230x114x65 mm;

- Sha-5, with dimensions of 230x114x65 mm;

- Sha-6 narrow, dimensions 230x114x40 mm;

- Sha-8, 250x124x65 mm;

- Sha-9, 300x150x65 mm;

- Sha-10, 350x150x75 mm;

- Sha-22 wedge of the end, 230x114x65x55 mm;

- Sha-23 clin end, 230x114x65x45 mm;

- Sha-24 wedge end, 250x124x75x55 mm;

- Sha-44 wedge of the edge, 230x114x65x55 mm;

- Sha-45 wedge of the edge, 230x114x65x45 mm;

- Sha-46 wedge of the edge, 250x124x75x55 mm;

- Sha-94 slab chamotone, 460x230x65 mm;

- Sha-95 chamotel plate, 575x170х80 mm;

- Sha-96 chamotel plate, 600x230x90 mm.

Back to the category

Marking and Conditions for GOST

Transformation Temperatures: quartz α ⇄ quartz β at 570 ° C by change of volume 1, 35%; Crystallite α at 225 ° with a change in volume of 3%; Tididimitis α ⇄ β at 117 ° C by changes in volume 0, 45%. Figure 1 shows a graphical representation of this behavior.

Three varieties also have different density: Quartz β 2, 65, crystobalitis β 2, 83, tridimitis β 2, the transformation of one variety in the other occurs with great difficulty and especially slow, so that the limits of the existence fields are not well defined in the sense of cooling. Polymorphism of silicon dioxide is schematically shown in Figure 2. If quartzites are valid in nature, it will happen that during temperature passes where polymorphic transformations occur, will occur sharp changes The material must contain only a stable phase at a temperature at which it must remain in the aggregation state to withstand wonderful mechanical stresses that are required in these materials.

Main characteristics

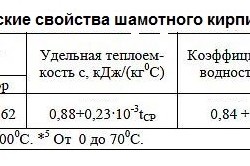

Table properties of chamotte brick.

Most often, the chamotte brick is produced in the form of standard rectangles with dimensions of 230x113x65 mm, since it is that size is optimal for brick masonry. With such sizes, the number of seams in the masonry is considered optimal, and the masonry itself is as smooth as possible.

Bricks are usually grinding manually and compressed in piston or hydraulic presses. Quartzite impurities, together with the added calcium, form easily fused silicates, which at the cooking temperature form a liquid, which, like a veil, surrounds the β-quartz granules, which make up the mass. This quartz melts in liquid to saturation; It is unstable at this temperature, seeks to become stable, that is, in crystobalite. Now, for chemical LawThe stable form has a lower solubility than unstable, so the solution saturated with respect to quartz β becomes more complex than precipitation of crystobalite in crystalline form.

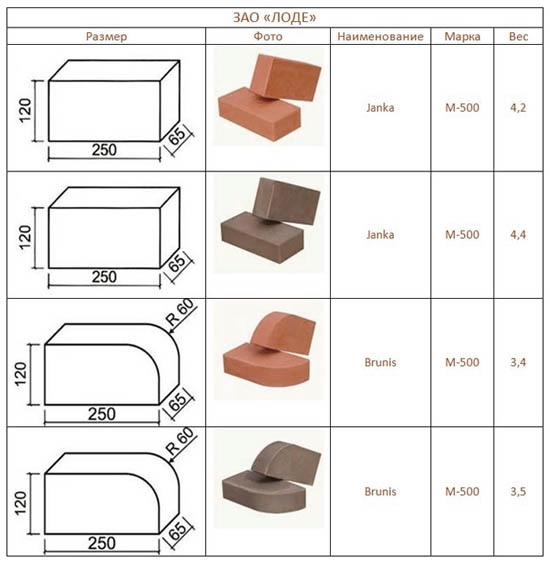

But, going towards consumers, manufacturers produce this product and other forms and sizes. You can find chammatory brick in the form of a trapezoid, arch, or wedge, so its use allows you to lay out the furnaces complex geometric shapeBy making them a kind of chief of the interior. Contributes to this and his beautiful appearanceTherefore, the owners laid out of chamotte brick stove can afford the luxury do not plaster her.

The solution, no longer saturated, quartz still melts, which turns into crystobalitis and falls into a precipitate. The main composition of lime and impurities is to form a liquid in which polymorphic transformations can occur at a relative speed, while in a solid state they are too slow, this liquid allows you to form continuous laying of crystals, both from concrete and after cooling, Need to ensure the required strength of the complex.

Usually as a melting point, the temperature at which the pyramid from the material is 5 cm per -1, 5 decreases to half its height under its own weight. The melting point in the silica-oxide of aluminum depends on the proportions of the two connections. All impurities reduce the melting point: Molecular equivalent amounts of bases have an "equal effect on the federation of clay", assuming that all bases are in a state of combination with silicon dioxide or are subject to such temperatures as these combinations.

Stability K. high temperaturesAs well as to the aggressive chemical environment and alkaline effects, it provides a chamotal brick located in its composition of aluminum oxide. The porosity of the material depends on the concentration of this component, and its thermal conductivity depends on the porosity.

The more porous brick will be, the more time it will be needed to warm up. But this brick has a property to accumulate heat, i.e. He will cool too slower. However, porosity has an opposite effect on the strength of the material: the porosity is higher, the strength is lower.

For such an unclean clay, this formula loses the value: even physical factors, such as the degree of subtlety, the uniformity of the distribution, etc. Special influence on the softening temperature. At this temperature, the molecule is likely to be divided into silicon dioxide and free aluminum oxide.

This indicates the recombination of these two substances, possibly with the formation of sillimanitis. Best Material There will be kaolin, but its price makes it prohibited for this purpose. Clay is purified by coating in water, electrically or dry in air flow. It is necessary to melt clay with materials that without retractions form an indisputable skeleton, which prevents the formation of cracks or clay deformations. As a slimming with the help of clay bakes at high and terrestrial temperatures, or burnt material from use, land with vertical grinding circles.

This is due to the fact that strength directly depends on the density of the brick. In the most frequently used brands, the density ranges from 1700 to 1900 kg / m. In addition to strength, the density affects the heat-insulating and moisture-absorbing properties, on and on their adhesion with laying solution. In order to determine which brick has a greater porosity, it is enough to hold in the hands of products of different brands.

It can be used as a slimming of quartzite grounding, quartz sand, to the detriment, however, the modeling is usually performed from the refractory and strength of the product, the slices are then compressed between metal forms, but the methods of work differ significantly depending on objects and factories. Drying is performed either by installing on the furnace or oven special. Cooking is produced in reverb furnaces or ovens in round rooms or even in pebble furnaces; Gasification gas heating is the most used.

The smaller his weight, the higher his porosity.

Despite the undoubted advantages of chamotte bricks, be prepared for the fact that the master-sticker you hired will be convinced you to refuse to use it when building a furnace or fireplace in your home. The increased strength of chamotte products is the increased strength of chamotte products, because of which to customize it under the desired dimensions - the occupation of time consuming and tedious.

In addition, the masonry must be performed not on the usual, but on a special refractory solution, the preparation of which also takes time. For those grief masters, who chases earnings to the detriment of the quality of work performed, such delays - the time spent.

"\u003e Anton Mikhailovich DergachevFireproof alumina or chammed brick distinguishes special strength from other species, the best features and an acceptable price. Used to erect various industrial and household facilities (fuel chambers, fireplaces). A brick from a special aluminosilicate clay is made (70%), with the addition of graphite and coke powders.

Refractory brick It has positive characteristics, including:

- relatively small mass;

- high refractory - up to 1690 ° C;

- significant heat capacity and inertia (heats over and slowly cooled);

- wide variety of forms and values. For example, standard size refractory brick SB-8 - 114x230x40 mm, and Sha-9 - 150x300x65;

- resistance to temperature differences and negative impact ambient;

- aesthetics - the ability to give different shades and textures.

Disadvantages: Due to significant strength, there are problems with sharp, the cost is higher than that of the usual red type.

Classification and characteristics

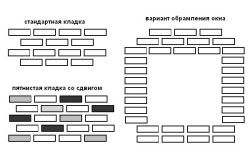

Technical features, the mass and sizes of chamotte brick are governed by GOST 8691-73, 390-69. In form, it is not only rectangular, but also a wedge-shaped, trapezoid, edge. Products of complex geometry are used to masonry rounded structures and arches. By porosity, such a refractory brick is divided into: especially dense, dense, highly detached, compacted, ultrawork, lightly. The more this indicator, the longer heated and slower cooling. The refractory chamotte material is distinguished by the processing method: folded, burned or debugging. It depends on its moisture absorption.

Permissible temperature and physico-chemical composition determines the brand. The letters in it indicate the maximum thermal load and class, and the numbers are the value and shape. For example, Chamotte Brick Sha-8 has dimensions of 65x124x250 mm, can be used in conditions up to 1400 ° C. If a fireproof product It is marked with only one "sh" and a digit, then it is manufactured by that. Some other values, according to GOST, are shown in the table:

Most often are bricks with dimensions of 65x120x250 or 65x114x230 mm.

Important parameter - density. It depends on the species. The apparent (calculated) value for conventional bricks from the chamot varies in the range of 1.9-2.1 g / cm3, for lightweight - 0.4-1.3. Directly with these indicators is associated with porosity, which should not exceed 30%. At the same time, than it is less, the stronger the refractory material. Its mass depends on overall dimensions and composition features and ranges from 2.4 to 6 kg.

Application

Thanks to good qualities, refractory brick is used in different branches of the economy and for household needs. And the brand often affects the area. So, the spl is characterized by high refractority and thermal resistance, necessary for the lining of steel-based buckets. Another brand - the ACSP, is considered a domain, SHA - refers to the combatant, that is, it is used to build and repair the mountains and furnaces for wrinkling cast iron.

Special additives (such as Corunda Powder) introduced into refractory materials improve characteristics. The resulting brick goes to the arrangement of boiler arches, pipes, furnaces for burning solid or other fuel. Marks Sha and SB are more common in private construction, as well as in industry. For example, Sha-5 brick is ideal for fireplaces, stoves. It, along with options for other sizes, due to the resistance to the effects of the environment, is applicable to the arrangement of chimneys, fively.

It is important to remember that the laying is carried out by a special solution. It should be in its composition fire-clay And the crushed brick. The layer thickness depends on future temperature loads (than they are higher, the thinner it is recommended to apply). In the chemical, metallurgical and other industries, Sha and SB products are used to create various installations (fuel chambers, boilers).

Cost of refractory chamotte brick