Thermal insulation materials for the walls inside. Insulation technology in a frameless way. Durability and service life.

Read also

Protecting your home from cold and dampness is not so difficult. If you are tired of overpaying fabulous sums for trying to reach a comfortable temperature by heating with electrical appliances, then it's time to deal with the problem of warming the room. Correctly selected materials and high-quality installation are a guarantee of comfort in a house or apartment.

Colored acrylic, silicate or silicone plaster... These ribs are characterized by a synthetic polymer backing. It differs in this type of plaster: silicate, silicone and acrylic. Compared to mineral fuels, the vapor permeability of acrylic plaster is significantly lower. The structure of the plaster is closed, which is weatherproof. Acrylic plastered buildings can be washed with low pressure water detergents. main feature silicate plaster- very good conductivity for water vapor and high resistance to alkaline reactions.

Saving payments due to competently performed insulation is significant, so you should not neglect it. However, some features of future work must be found out in advance.

Wall insulation from the inside: problems

Disputes about whether it is necessary to insulate the interior walls of a room have been going on for a long time and with varying success. Some agree that only installation from the inside will bear fruit. Others believe that wall insulation work should be carried out exclusively from the facade, since this is the most effective method achieve the desired result. For residents, who, for various reasons, cannot sheathe the outer walls with special materials, the only way out is to do thermal insulation inside the building.

Disputes about whether it is necessary to insulate the interior walls of a room have been going on for a long time and with varying success. Some agree that only installation from the inside will bear fruit. Others believe that wall insulation work should be carried out exclusively from the facade, since this is the most effective method achieve the desired result. For residents, who, for various reasons, cannot sheathe the outer walls with special materials, the only way out is to do thermal insulation inside the building.

Therefore, this gypsum is highly resistant to microorganisms. It is advisable to use it in areas of high humidity where low diffusion resistance is required. The paintwork of the building remains bright and clean for a long time. Water accumulates on the surface with dew drops on the surface of the sink. This effect protects the base and successfully reduces the build-up of atmospheric dirt on the building surface. Acrylic, silicate and silicone plaster is supplied as a ready-to-use compound.

In what cases is it impossible to carry out work on external insulation from the outside?

- The house is an architectural monument, and the facade is recognized as a historical value.

- Inconvenient location of walls and lack of space between them.

- Living in high-rise multi-storey buildings makes insulation work impracticable.

- Bans by local authorities on all kinds of changes to the facades of buildings located in the central districts of the city.

- The apartment is located near an elevator shaft or staircase.

If installed incorrectly indoors, the walls will freeze, and maintaining a comfortable temperature for living will be accompanied by various problems. Internal insulation work is easy to do at any time of the year with your own hands, it won't take very long.

They can be used for concrete slabs, traditional renders, plaster ceilings, chipboard and drywall, etc. The choice of matting material also depends on the final surface requirements. The surface texture of coarser or less granular plaster appears smoother or softer, and a special solution can be made. According to the type of texture, the plaster is divided into three groups. Accordingly, the tool can form a raised or flattened surface, smaller or denser grains, fish scales, circles, and other shapes.

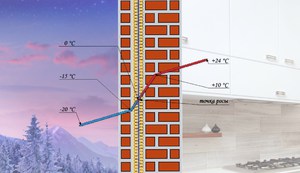

Dew point

In the cold season, when the temperature in the apartment differs from the outside, under the wall after installing the insulation condensation may appear on the inner surface. The dew point according to Building Codes and Rules (SNiP) occurs at a temperature of 10.7 ° C. Until the moment of thermal insulation, it is inside the wall. And after the work carried out, the condensate begins to move under the insulation, leading to the appearance of dampness and mold, which negatively affects the health of residents and requires the prompt elimination of the problem.

In the cold season, when the temperature in the apartment differs from the outside, under the wall after installing the insulation condensation may appear on the inner surface. The dew point according to Building Codes and Rules (SNiP) occurs at a temperature of 10.7 ° C. Until the moment of thermal insulation, it is inside the wall. And after the work carried out, the condensate begins to move under the insulation, leading to the appearance of dampness and mold, which negatively affects the health of residents and requires the prompt elimination of the problem.

They contain grains that, during a stroke, fill wood patterns such as round, vertical, horizontal, in plaster, depending on the direction of the plaster. The grains contained in it serve for drawing patterns, as is the case with runners. The mint is rubbed into the pebbles, the outer layer of the product, and a dense stone gravel mosaic is exposed.

The use of more than one system mesh in the thermal insulation process has unfortunate consequences. Do not use foreign substances in the insulation system. Unfortunately, this practice often happens, but it is a violation of building rules. First of all, it should be borne in mind that the appearance of an insulated house depends not only on our aesthetic knowledge, but also on the compliance with the requirements of the system manufacturer.

The gradual destruction of the wall itself and the deterioration of the quality of the insulation layer due to exposure to moisture leads to even greater heat loss. If in outside wall there are door and window slopes, then to prevent the appearance of condensation, they are also carefully insulated. By freezing, the water will enlarge all possible crevices.

There is a way out of this situation - a careful approach to the choice of material for insulation. In him there must be no seams during installation so that moisture cannot penetrate into the room. Be sure to pay attention to such specifications as vapor permeability and moisture absorption. The lower they are, the more attractive the insulation for installation inside the apartment.

Hot water is prepared at the heating point of the water-water system with a water heater. The name of the plumbing system is adjusted by a typical dignity. Devices. House exits come from waste water. A sewerage system is installed inside. The interior of the house is equipped with an entrance and an electrical distribution board, which is equipped with a three-phase automatic fuse. To improve the energy efficiency class of the house to A or A, additional measures can be easily integrated into the built-in concept of the house.

When it comes to thermal insulation, it is commonly said that materials that can protect your home from external temperature fluctuations can help maintain a constant temperature regime in your home. To qualify as a heat-insulating material, it must have a low heat transfer coefficient. What materials does the thermal insulation material have? This is one of the most important elements of any design, and it needs to be thought about even during design. High quality wall insulation has some special features.

Indoor dew point countermeasures

What can be done to keep the inside warm and how to protect the walls from condensation?

- Choose a material with low vapor permeability. Moisture should only leave the room outside, not inside.

- For apartments with installed plastic windows use forced ventilation when air from the outside enters through an opening in the frame or ribbed seals in the ceilings. Built-in micro-ventilation significantly reduces humidity.

- Before installing the insulation, the walls are treated with compounds to protect against mold and mildew. As soon as the layer is dry, you can proceed with the thermal insulation.

- Elimination of cold bridges. The load-bearing walls are connected to the walls inside the premises and ceilings; it is these places that cannot be insulated with an improvised method. A vapor barrier material comes to the rescue.

When heating the walls of the house, and this must be done with high quality, it is necessary to ensure a favorable temperature inside the house in winter, and in summer the temperature of the house should be constant. The thermal insulation material must breathe, that is, it must generate vapors that easily pass through the facade of the building. The material must be free from moisture, mold or condensation. Your home should be protected from mechanical stress and should extend its lifespan. This should improve the energy efficiency of the home, reduce the energy demand for heating and cooling, and save money and the environment.

Insulation for walls inside the apartment

Consider the main materials that the modern construction market offers for insulation and the features of their application.

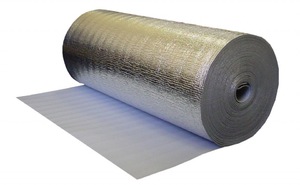

Foamed polyethylene or penofol

Sheets are used, foil-treated on one side to reflect heat into the room. Experts recommend installing them so that there are 2 gaps between the sheet, room decoration and the inner wall... These requirements are very complex and it is not always possible to fulfill them. The gaps cease to be airtight, the dew point shifts and moisture penetrates into the insulation. It is best to use Penofol in combination with other heat insulators.

Sheets are used, foil-treated on one side to reflect heat into the room. Experts recommend installing them so that there are 2 gaps between the sheet, room decoration and the inner wall... These requirements are very complex and it is not always possible to fulfill them. The gaps cease to be airtight, the dew point shifts and moisture penetrates into the insulation. It is best to use Penofol in combination with other heat insulators.

The insulating material should create a healthy and comfortable indoor climate, thereby increasing the value of your property. The construction market has a very large range of construction products, but for the right choice and installation of thermal insulation material, it is necessary to find out in detail what properties of materials and how they differ from each other. The question of what kind of insulating material is best for everyone who insulates a private house. This is due to the fact that there is a very large number of materials, and there is little information about them.

Styrofoam or expanded polystyrene

The board is glued to a wall pre-treated with a primer with waterproofing properties or liquid glass... This is done to prevent moisture from entering the room. Before pasting the foam with wallpaper, putty is applied to a pre-installed mesh. The material has many advantages, in particular, it is easy to process and has a light weight.

The board is glued to a wall pre-treated with a primer with waterproofing properties or liquid glass... This is done to prevent moisture from entering the room. Before pasting the foam with wallpaper, putty is applied to a pre-installed mesh. The material has many advantages, in particular, it is easy to process and has a light weight.

Wall cladding materials are divided into several main categories, they can be organic or inorganic. Modern frame houses is a practical and reliable home with an attractive appearance... For those who want to build comfortable houses at an affordable price, houses with a frame structure are the optimal solution. Builders have identified several basic methods for warming the walls of a house. All installation work is carried out schematically, when the facade is finished, wind protection is provided, the frame is filled with heat-insulating material and a vapor barrier is provided.

Due to its properties, the foam does not allow the dew point to absorb moisture, therefore, the installation does not require a vapor barrier. For sealing joints use polyurethane foam, which is applied to the surface of the plate. After all the work, the material is plastered and covered with plasterboard. Manufacturers often produce sheets with specially processed edges at the junction. This makes installation very easy and the slabs are laid flat. The disadvantages are increased flammability, in which substances harmful to health are released and low noise insulation.

In modern construction works several types of carcasses are used, namely wood and metal. For many years, wood has been considered the main building material. The main advantage of wood is that it is strong enough, usually processed, has low heat transfer and low weight. The metal frame is made of very thin and light steel structures. The base is nothing but galvanized steel profiles, so the zinc can be increased up to 100 years.

When heating the walls of a house, it is very important that the insulation materials are correctly selected. Since there are quite a few new, modern thermal insulation materials on the market, they have become very popular. During thermal insulation, the choice of thermal insulation material is a very responsible and serious process. The materials used are modern and are ideal for insulating frame houses. You need to make sure that the walls of your home are properly heated and that your home is warm.

Polyurethane foam

The material is sprayed with special equipment. A lathing made of timber is preliminarily attached to the wall, on which polyurethane foam is applied, in addition, it serves as a support for sheathing with drywall sheets. The material foams on the wall and hardens quickly. It does not allow moisture to pass through, so no additional vapor barrier is required during application. The dew point is isolated because polyurethane foam has good adhesion and water does not get inside. Fast curing and excellent sealing are other advantages of using polyurethane foam. Spraying is used for walls of various configurations, without forming seams.

The material is sprayed with special equipment. A lathing made of timber is preliminarily attached to the wall, on which polyurethane foam is applied, in addition, it serves as a support for sheathing with drywall sheets. The material foams on the wall and hardens quickly. It does not allow moisture to pass through, so no additional vapor barrier is required during application. The dew point is isolated because polyurethane foam has good adhesion and water does not get inside. Fast curing and excellent sealing are other advantages of using polyurethane foam. Spraying is used for walls of various configurations, without forming seams.

To defeat the enemy, you must know him well. Again, let's pay attention to the physical origin of sound - waves or vibrations. Air vibrations or structural vibrations can easily be transmitted through walls or ceiling planes that re-fill the indoor air. This is exactly what we hear with our ears. It is important to stop this chain of wave propagation. It uses wave-absorbing soundproofing materials. By rotating a structure that is rigidly attached to another part or plane without insulation, it turns it into a sound source.

Warm plaster

This relatively new, spectacular looking material has appeared on the insulation market quite recently. It is a mixture of cement mortar, where sand is replaced by expanded clay crumbs, sawdust, pumice powder, expanded vermiculite. The last aggregate is made from rock by heat treatment. Due to its antiseptic properties such plaster is used indoors without fear of infection with mold and mildew. It is also ideal for external wall insulation. However, many agree that such plaster should be used only as a final insulation stage.

This relatively new, spectacular looking material has appeared on the insulation market quite recently. It is a mixture of cement mortar, where sand is replaced by expanded clay crumbs, sawdust, pumice powder, expanded vermiculite. The last aggregate is made from rock by heat treatment. Due to its antiseptic properties such plaster is used indoors without fear of infection with mold and mildew. It is also ideal for external wall insulation. However, many agree that such plaster should be used only as a final insulation stage.

In favorable weather, the human voice easily throws an unsurpassed partition, which transmits its movements to the ceiling, and the neighbor above us hears everything we talk about. Basic principles of sound insulation. Local soundproofing is ineffective. This means that the sound features we talked about earlier cannot be eliminated by insulating one wall. You need to think about everything: ceiling, walls, floor insulation.

The main points of wave transmission are the fasteners. It doesn't matter if we have provided a separate suspended ceiling frame or floor divider. If it all connects solid without spacers or screws to the wall, the sound insulation is slightly improved and the cost doubles. Protect everything only with special soundproofing pads.

Ceramic based paint

Another option for liquid insulation. Among the advantages are incombustibility and a high adhesion coefficient. Having chosen this material, you can not be afraid that there will be a reduction in living space, even if you apply several layers of mortar. Wallpaper can be glued to the surface dried within 12 hours.

Another option for liquid insulation. Among the advantages are incombustibility and a high adhesion coefficient. Having chosen this material, you can not be afraid that there will be a reduction in living space, even if you apply several layers of mortar. Wallpaper can be glued to the surface dried within 12 hours.

Soundproofing is essential for sealing. Before covering the walls, check for cracks and, if you find, fill them with silicone or acrylic. In the fight against noise, it is important to create a heterogeneous structure of different density materials. This sandwich prevents sound waves from creating a resonant effect on the wall. If the sub-partition is insulated from the floor partition and the intermediate section is filled with wool, a heterogeneous wall structure will exist in the bulkhead through the intermediate or retractable partition.

The single-motor swing wall transfers them to the wool, which "quenches" them, and the surface of the drywall or acoustic panel does not vibrate at all. It is also important to deal with noise inside the room, i.e. don't let the planes reflect the sound, because we can feel like a barrel. The relief effect is destroyed by both fabrics on uneven or porous surfaces. Carpet covering on the floor, upholstered furniture, curtains also perfectly absorb sound waves.

Recently, ceramic bubble paint application not considered an effective technique in terms of wall insulation from the inside. Its application will shift the dew point temperature, which will entail the appearance of fungus and wet spots on the finish. Like warm plaster, it is good as an additional layer of insulation when the outside walls are already insulated. Otherwise, it is better to take a closer look at other materials.

Under the roof ceiling we can have acoustic ceilings. These are special sound absorbing panels that absorb sound waves in a heterogeneous porous or condensed surface and structure. The most effective way to deal with upstairs noise is to negotiate with neighbors to insulate the floor under their floor. The soundproofing layer must be laid on the floating floor. The more you work with your neighbors, the less you will fight on your territory.

Provide warmth to the home and space to prevent heating costs - important for both the apartment owner and the family home. Experts agree that in order to choose the most economical solution, there must be high quality insulation materials and ensure that they line up not only the walls, but also the foundation of the house - it even lost about 20 percent through the underground part of the building. in all the heat. In addition, to perform the work of insulation, it helps prevent deformation of the structure, which may be due to frozen soil.

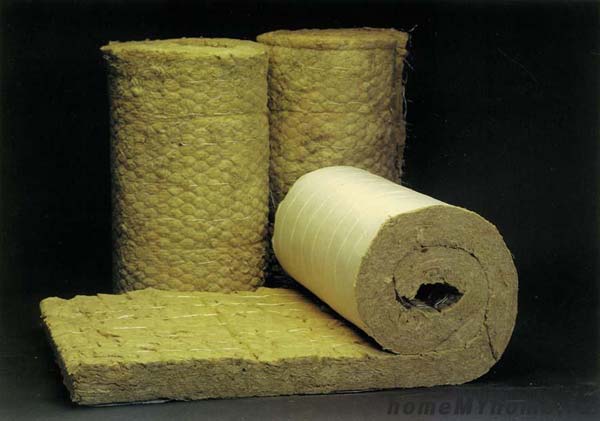

Mineral wool

Poorly suitable for internal insulation, as it has a low moisture resistance. It is best to choose a material with a high density, but no one will give a guarantee that it will be dry. Property mineral wool"Breathing" and letting in air leads to condensation, dampness and mold. Therefore, if it is impossible to use other heaters, careful installation is required with a decrease in vapor permeability. But it is best to choose other materials to avoid the risk of mold and consequent destruction of the insulating layer.

Poorly suitable for internal insulation, as it has a low moisture resistance. It is best to choose a material with a high density, but no one will give a guarantee that it will be dry. Property mineral wool"Breathing" and letting in air leads to condensation, dampness and mold. Therefore, if it is impossible to use other heaters, careful installation is required with a decrease in vapor permeability. But it is best to choose other materials to avoid the risk of mold and consequent destruction of the insulating layer.

The farther, the more popular home insulation is expanded polystyrene. This material is fully customizable and brick and wood old and new or refurbished building construction. People gather polystyrene on positive qualities - inflated and pressed granules do not absorb moisture, polystyrene is resistant to bending and compressive strength, has low thermal conductivity, lightweight and easy to install.

Expanded polystyrene is not durable, inexpensive, no negative consequences for health and environment- it does not emit toxic substances during operation and use. It can withstand temperatures ranging from -50 ° C to 70 ° C or even 75 ° C. Insulated foundations, some experts believe, are much simpler than walls because you won't do the finishing. First of all, land to be collected from the foundation and prepare them - smear the foundation wall with bitumen and gasoline mixture or coated with a welded bitumen coating.

Cork cover

It is made of balsa wood - a type of oak. This is the most environmentally friendly insulation. Its use guarantees good sound insulation. Cork is used not only as insulation interior walls, but also the decoration of the room. The warm surface of the wood is very pleasant to touch with your hands. Various shades and textures are suitable for the most respectable premises. Another plus of the cork cover is that the small thickness does not reduce the internal area of the housing.

It is made of balsa wood - a type of oak. This is the most environmentally friendly insulation. Its use guarantees good sound insulation. Cork is used not only as insulation interior walls, but also the decoration of the room. The warm surface of the wood is very pleasant to touch with your hands. Various shades and textures are suitable for the most respectable premises. Another plus of the cork cover is that the small thickness does not reduce the internal area of the housing.

Experimental solutions for wall insulation from the inside

In individual cases, when the use of thermal insulation materials is impossible, it remains only to resort to experiments that will help solve the problem of constant humidity and cold from the inside.

The main disadvantages of wall insulation from the inside

When performing work on warming a room, you should remember about the features.

Armed with high-quality and environmentally friendly materials, you can carry out insulation work from the inside with your own hands. It will take effort, but a comfortable microclimate in the apartment will be a good reward for your efforts.

Choosing the right insulation for the walls inside the house in the country is not as easy as it seems to many. In this review, we will assess the advantages and disadvantages popular types, let's analyze comparative characteristics each of them, we will consider how to organize warm rooms in the country, so that the house is comfortable. Indeed, if you plan to visit this place out of season, that is, during the cold season, you should make sure that there is complete comfort, regardless of the temperature.

House elements requiring insulation

Heaters: options, advantages, disadvantages

Different heaters for walls inside the house in the country will differ in characteristics, ease of installation and price. We will consider the most popular options that may well be suitable for a country house.

Penoplex is the most popular material

This is a well-known foam. Its sheets of standard meter height and width are either 0.5 or 1 m. It is convenient to work with it, since the sheets keep their shape.

But at the same time, it will not be possible to get rid of the joints of the material, and if they are not sealed, then no matter how many layers you mount, the cold will penetrate through the walls. Installation technology is simple, and there are different options for it. It can be glued with the help of a special composition of the board directly on the walls, you can lay them in pre-mounted niches. The latter option is suitable if you plan to decorate the room with facing plates.

This insulation is suitable for walls, ceilings and floors. The most important thing is to seal the joints. It is also important that the insulation layer is at least 100 mm, for this it is better to use a two- or even three-layer scheme. In this case, the next layer must be laid so that the joints of the previous one overlap with a whole sheet.

Advantages:

- Price;

- Ease of installation;

- High energy saving properties.

Flaws:

- The need to lay in several layers;

- Mandatory sealing of panel joints.

Foamed polyurethane - a new word in insulation

This is a new generation of insulation, for its installation, or rather, application, you need to use a special spray.

It is also important to consider that this instantly hardening composition will not withstand any cladding on itself and, so on top of it, you need to mount finishing panels, lining or drywall sheets.

Installation technology: first, the formwork is organized, then the formed space is foamed with the composition, after which it is imperative to lay hydro and vapor barrier.

Advantages:

Flaws:

- The need to equip an additional wall;

- Obligation to install the formwork;

- The cost of the work.

Mineral wool - a universal solution

This versatile insulation is widespread in our country. It is convenient and quick to insulate a country house with it, and you do not need to involve additional hands - all the work can be done independently.

Installation of mineral wool is carried out in a crate. When using matte mineral wool, instead of rolls, installation is greatly simplified, since it has the necessary rigidity. When installing the battens, it is important to pay attention to the fact that the distance between the strips should be 3-5 cm less than the width of the panel - this will help the material, thanks to its cotton structure, to fill all the cracks. The thickness of the lathing bar should correspond to the layer of insulation that will be installed.

Lathing device for mineral wool

Advantages:

- Price;

- Ease of installation;

- Thermal insulation qualities.

Flaws:

- When working, it is necessary to use special clothes, glasses, a respirator, since small particles of fibers can irritate the skin and cause discomfort.

Dry bulk materials

For insulation, you can also use bulk materials, for example, expanded clay and ecowool. Non-standard options include backfilling with moss, pine or spruce needles, hay, sawdust. These methods are environmentally friendly and safe for the environment, but their installation is carried out mainly for floors and ceilings, moreover, mice like to live in natural insulation.

Insulation specifications

All heaters have their own technical characteristics that can affect the ease of installation and their heat-saving properties, for the right choice you should familiarize yourself with them.

Varieties and properties of mineral wool

The class of mineral wool includes glass wool, stone, slag. They all have one general characteristics- these are the finest fibers, which, due to their structure, can guarantee a high level of thermal insulation.

- Glass wool has fibers 5-15 microns thick and 15-50 mm long;

- Slag wool and stone wool, fibers 4-12 microns thick, up to 16 mm long.

All mineral wool is highly hygroscopic, so it is important to use waterproofing during installation. Safety rules must be observed when working with mineral wool.

Penoplex technical indicators

It is a comfortable insulation in all respects, its main characteristics are:

- Minimal water absorption;

- Long service life;

- Compression resistant;

- Ease of installation and processing, you can cut it with an ordinary knife;

- High environmental friendliness, although freons are used in its production, they are absolutely harmless to humans;

- Zero reactivity, none construction material will not react with penoplex.

Properties of polyurethane foam

In a rigid (solidified) form, polyurethane foam has the lowest thermal conductivity of all heaters, and it does not need such a large layer as for mineral wool or foam.

In addition, this type of insulation is very light, you do not need to use additional devices to fix it, it is simply sprayed onto the surface. Such a monolithic coating guarantees the absence of cold bridges, the material is environmentally friendly and durable.

Article