What are self-tapping screws, product sizes. Standard sizes of screws - screws.

The modern construction sphere, like many others, does not stand still, developing rapidly. New, increasingly efficient and unusual solutions offer the market for fasteners to their customers.

Saws - a thing without which it is impossible to do in construction.

If you need to hang the shelf or wardrobe, collect furniture, or you have taken a global decision on the construction of your own home - in any case, in the process you will need this small, but universal and multifunctional item.

Previously, at the request of the buyer, stores offered standard products, now among the diversity of forms and sizes you can get lost, and it is not always possible to immediately determine which of them is optimally suitable for you.

Self-tapping screws acquired a narrower specialization, and there are varieties created specifically for use in one sphere.

For example, in modern stores, products for working with such materials are offered:

- Plasterboard;

- Wood;

- Plastic;

- Roof;

- Plasterboard.

And many others. To know the standards and sizes of the tree screws, it is important to choose the most suitable tool for yourself.

Self-timers standards

They need to become familiar with them in order to start navigate the assortment of fasteners and choose the best option to meet your needs.

Among European standards, manufacturers choose:

- DIN - the German standard, which is developed by the National Standardization Organization of Germany, representing its national interests of the state;

- ISO - international standards.

In many ways, these two standards coincide among themselves. Most buyers before purchasing goods, will be interested in its compliance with these standards.

Among the domestic GOST is popular, the rules of which are largely coincided with adopted in Europe.

In the description of the goods, sellers must indicate their compliance with the above standardization rules. The effectiveness of templates is tested all over the world, and they are equal to the manufacturers of most states.

Self-sizes of wood screws

You need to pay attention to this parameter, pushing out the purpose of acquiring the tool.

The size of such criteria is determined:

- The diameter that makes up the arrangements of the product thread. They are different, and their number is quite wide - from the smallest 1, 6 to the largest 12, 0 (in millimeters). All dimensions are standardized. It must be remembered that not all types of self-samples are produced in all data diameters - some types are presented in limited sizes, since, judging in a very large or small simply no need. For example, the tools for a metal profile are only in two values \u200b\u200b- 3, 5 and 3, 9. Products for drywall - from 3.5 to 4, 8 mm;

- Length is also normalized. If the screw or self-tapping screw has a secret head, this criterion is determined for it at full length, and if we convex, measure the distance from the lower edge (head) to the tip of the tip, by the rod. The dimension range for this parameter is also varied - from 7 to 300 mm.

Self-tapping screw - this is a fastener, which is designed for installation of finishing and building materials low hardness and density. To such materials you can attribute a tree as well as a variety of artificial materials. With the help of such products, the installation of fiberboard, chipboard and OSP are realized. They can also be used to attach plastic and drywall. In this case, many people walk on shopping in search of self-tapping for sheets of plasterboard, not even suspecting that in reality such elements are the screws on a tree, the size of which is 3.5 x25 mm.

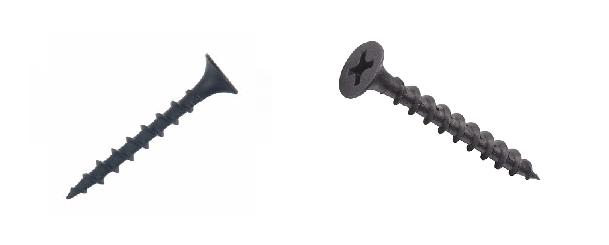

Self-tapping screws GOST 11473 can produce two types: with large or fine threads. As a material, carbon steel with further applying phosphate is used. Due to this, it is possible to protect the product from corrosion and increase the clutch of the surface of the fastener hats with facing materials.

What is GOST roofing screws for metal with a drill

You can distinguish a wood fastener from other self-tapping screws on a cone-shaped head, the form of which resembles a cross. This allowed to carry out fasteners, performing complete drowning in the material. Such an advantage allows you to get the perfect surface on which any irregularities are missing.

The video describes the sizes of the tape summers:

An unclean step of the thread allows you to reduce friction product about the material, thanks to this, the screwing process can be carried out using a screwdriver or screwdriver. If you are going to use a tree tapping screws, the thickness of which is 4 mm and more, then for this it is worth taking care of the holes in advance. You can perform them using 2.5 mm drill. In the absence of such a hole, you will turn out to be twisted with you, but over time, the material will not stand the expansion and give cracks.

Self-tapping screws GOST 11473 is a material that can be equipped not only with a carvings, but also a special shape of the head. This feature of the structure allows you to screw the product into the material and drown hats in it, which are practical not towering above the surface.

On the video, it is described, what are the sizes of the tree screws:

If you decide to go to the store and buy the necessary fasteners, then you should adhere to a clear rule, according to which the purchased wood screws will allow you to get high-quality and durable fastening. When choosing a hardware, consider the basis to which the installation of the material will be performed. If you need to fasten plastic or sheets of drywall to the base of wood, then the vehicle screws are the most suitable option. When installing a wooden material to a metal surface, it is not necessary to do without self-tapping screws for metal.

The coma of the listed advantages of the tree screws, there is another very important.

Since such products are used when performing finishing works, they all have a hidden or counted head. After the self-tapping screw is screwed into the material, there will be no different performances on the surface. This allows you to seize the fastening section of imperceptible.

Self-tapping screws are popular products, without which it is very difficult to perform fasteners today. finishing materials To the base of the tree. When this product is selected, it is necessary to take into account the conditions in which the self-tapping and attached material will be operated. If it is a bathroom or kitchen, then buy the screws with a layer of phosphate with the layer applied to them. Then you can be absolutely calm, because any corrosion is not terrible.

The main elements in construction and repair, which ensure the stability of the structure, are considered conventional self-tapping screws. The development of technologies allows you to improve the structure of the part, creating new types of fasteners for any materials. Due to this, it is possible to choose the appropriate Self-tapping screws on a tree or metal. I have an idea of \u200b\u200bthe basic advantages of using the part, understanding their differences, you can mostly connect the materials for construction or repair, which guarantees an increase in the life of the object.

Basic information and benefits of use

The main feature of the screws is the presence of a special thread along the entire length of fasteners and a rather sharp end. Such properties allow you to freely penetrate the texture of the building material without changing its shape and without causing cracks on the surface. Details for wood are most widespread. The distance between the thread lines is quite large in order to fasten with each other are not too solid materials, while maintaining their structure.

Self-storm parameters range from several centimeters. As a rule, the length of the screw varies from 1.1 cm to 20 cm. In the work with the last models, they use a screwdriver, since ordinary screwing with a screwdriver is considered a time-consuming process.

All self-tapping screws are manufactured according to GOST 1145. The norms adopted in the 80s are still valid, due to which the products of different consumers are identical, qualitative and characterized long time Services. A wide range of products and constant demand from consumers is explained by the presence of significant advantages. Chief advantages include:

- Relief repair I. construction work, in particular, the procedures associated with the fastening of materials.

- Protection of materials from deformation when fixing.

- The presence of different heads that are suitable for a certain type of surface.

- Budget value.

- Resistance to the harmful effects of water.

The popular area of \u200b\u200buse of details is the creation of furniture, construction of wooden frames, repair of the room decoration, the manufacture of wood structures.

Adopted classification of screws

According to state Standard 1145-80 Self-tapping screws are made of three types of raw materials. In the process of manufacturing these fasteners, use:

- Low carbon steel;

- Carbon steel;

- Corrosion-resistant steel.

To improve the technical characteristics, the outer surface of the part is covered with galvanized or chrome-plated compositions.

By parameters and target target fasteners are:

Each of the presented part groups has its own characteristics that regulate the main areas of use.

State Standard Standards

Major norms of mass, technical and qualitative characteristics Specified in GOST 1145-80. The document dictates the permissible shape of the hat, the size of the inner surface, the optimal length of the "body", etc. The name of the self-press provides for the indication of the specific execution of fasteners, the size of the diameter, the thread parameters, the material group, the volume of the external coating.

According to the document being established, fasteners are allowed to produce from 0.7 cm to 10 cm. Each category is divided into subgroups for which certain magnitudes of the head diameter are characteristic.

Saws to GOST.

The current standard consists of four parts. The first contains the schemes of several versions. Self-tapping screw can have a flat or in-depth countersunk head, with a leg completely or partially covered with threads. The drawings prescribe the designation of the main elements of these screws to which it is necessary to pay separate attention in the process of production and quality verification. Important parameters include:

- External diameter and thread step;

- Sizes hats;

- Slot characteristics (number, radius and depth).

A separate position in the standard is prescribed by the mass and permissible deviations of this parameter from the established norm.

The main coding involves the use of numerical characteristics of characteristics, thanks to which the process of finding the desired model for the purchase is accelerated. Example marking has the following type of screw 2-3x20,016 GOST 1145-80. The first digit determines the version of the part of the part, the number 3 indicates the optimal diameter of the Hat, and The value of 20,016 indicates the thickness of the fastening element, taking into account the possible coating. This practice of accounting allows you to quickly find the screws needed for a specific surface.

Conclusion

The durability of the structure is determined by how high-quality its individual elements are fixed. It is recommended to pick up the self-sufficiency of this type and type that is suitable for a certain type of treated raw materials. When choosing fastening parts, pay attention to the purpose of their use, the sizes of the cap, the material used in the process of the production of tools.

From the length of the screw and the parameters of the inner deepening of the head depends on the method of fixing building materials. Details Over 15 cm are screwed into place in place, pre-drilled drill.

Such practice allows you to qualitatively connect the elements, while maintaining the integrity of the surface being processed. During work with self-draws, the basic security rules are held, since any error can spoil the appearance of wood, wooden panels, boards.

Video: Self-tapping screws - Features

Roofing tapes on a tree are considered an indispensable element in construction and installation work. The name of these parts sounds like a vehicle self-sufficiency (or SVFS), but apply them to secure metallic, metal-plastic planes, plasterboard, sheets of GLK, roofing boards. How to choose a self-tapping screw or metal, and which screws are used in working with other materials - practical instruction for everyone!

Types and specifications of tree screws

The technical range offers customers a sufficient number of types of Self-tapping screws in GOST 11473.. This is provoked by the manifold of construction and repair work and the materials used.

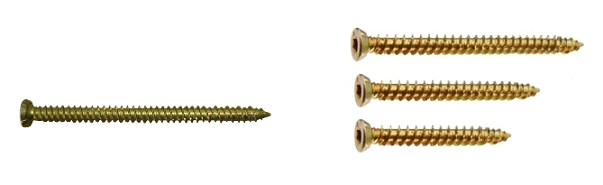

The main differences of each species can be defined visually in the color of the product, the length of the screws on the tree and the diameter, the shape of the head and other characteristics:

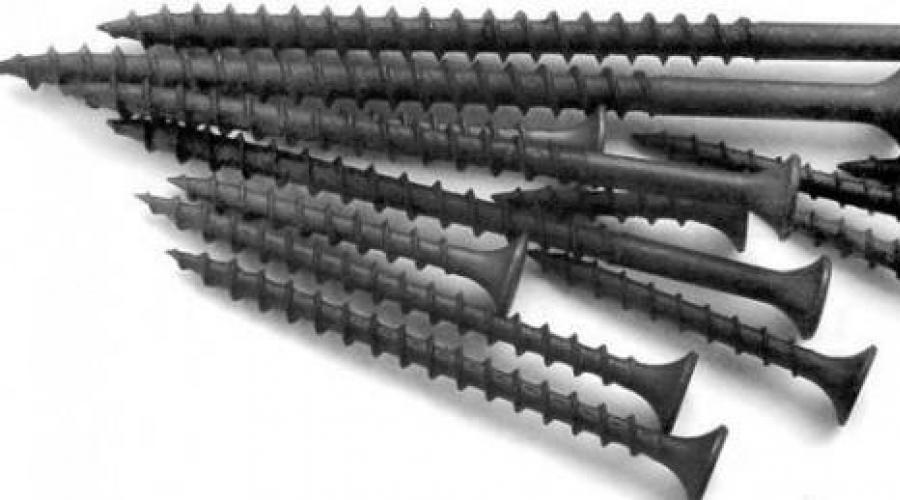

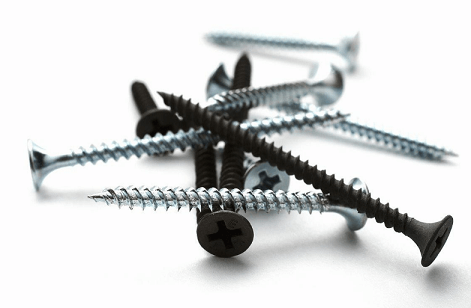

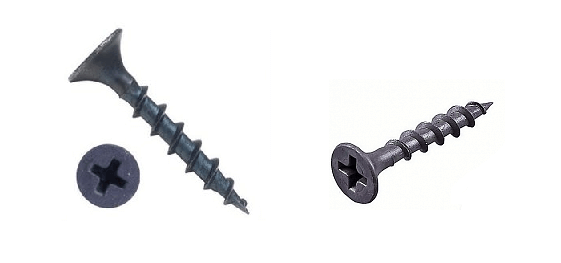

- Oxidated (phosphatated) Selfless black color has the following external description: large carving for comfortable woodwork 35-48 mm, length up to 150 mm, secret hat. This is the optimal choice for a lightweight, fast and reliable fastening on the tapping screws of paintings, design objects or decorations of a wood interior.

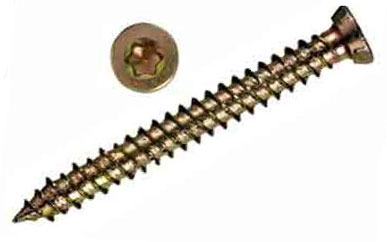

- Self-tapping screw or yellow-fashioned species is the self-tapping screws, thanks to the brass coating, they are recommended to use in rooms with high humidity.

- Self-tapping screws are white. Their description in matters of corrosion resistance is similar to a yellow-fashioned form, but the reason is in a special coating with a thin layer of zinc. Both types (yellow and white) are defined in construction, as universal, since the length and diameter from 35 mm and above, attached to any material and in any environment, or a screwdriver is needed for installation, or a shock on a drill.

Varieties

According to the production classification for self-tapping screws, the main distinctive features include:

- Thread step;

- Self-timber weight;

- The length of metiza;

- External thread diameter;

- Shape and type of head.

These distinguishing features help to choose the optimal quality and convenience of self-samples for the profile or to work with various materials. And also correctly calculate the consumption of screws for a specific construction and repair task.

Color

There is a color sign:

- Hardware of black;

- Yellow-closed (brass);

- White (galvanized).

Head

The shape of the head and the type of slot are the requirements of the installation and facade of repair, i.e. They are improved in order to perform fasteners as quickly as possible, and the methis itself did not attract attention, was almost imperceptible.

- Conical heads secret may have a cross-shaped slot or straight. The last view for fastening the board does not like to use builders, because The edges of the slot are susceptible to rapid erasure.

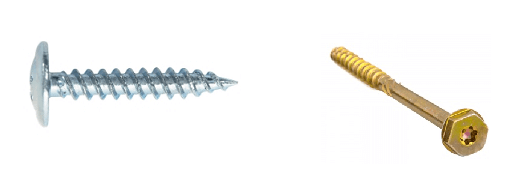

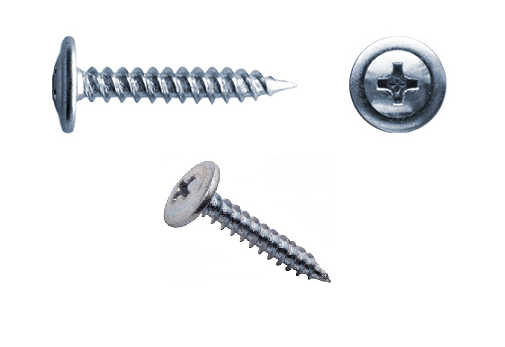

- Hardware with a tree head in the form of a press sunderate to the category of semi-man. May be complemented rubber gaskets For greater tightness.

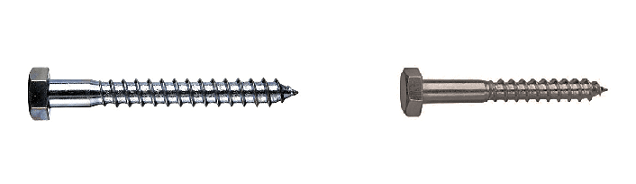

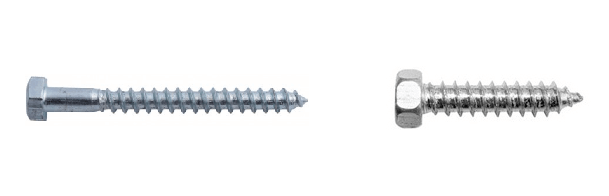

- Self-tapping screws with a hexagon head - their thickness and weight are superior to standard species, i.e. can withstand more kilograms of weight load. As convenient advantages, builders call the fact that the hex screws with a hexagon head and cruciform slot are quite easily screwed into a screwdriver, a drill and even a conventional horn key.

Thread Length

There are two main types of hardware for thread:

- Along the entire length of self-press (i.e., from the hats to the tip);

- From the tip of 2/3 of the part of the metric (the remaining 1/3 of the self-sufficiency before the hats is perfectly smooth).

If the first view provides maximum fastening reliability, then the second is chosen for serious works with wood to set the space for a natural increase in dimensions with temperature and humidity drops.

size table

You can view and select the desired wood screws in size in the table.

Each of the above species described its overall scale, i.e. First, you should decide on a specific type of methome, and only then watch the sizes on the table:

| Code and Size |

under Blowing on |

|

| 5 D. | 8d. | |

| KDH - 3 x L | 0,59 | 1,22 |

| KDH - 3.50 x L | 1,01 | 1,84 |

| KDH - 4 x L | 1,05 | 1,81 |

| KDH - 4.50 x L | 1,51 | 2,68 |

| KDH - 5 x L | 1,39 | 3,08 |

| KDH - 6 x L | 2,06 | 3,12 |

- Phosphatated hardware start counting in size of a diameter of 3.5 mm to 4.8 mm, and in length - from 16 to 152 mm;

- Brass and galvanized hardware with cruciform slot and a secret head in diameter from 3 to 6 mm, and in length - from 12 to 200 mm;

- For yellow or white hardware with direct slot indicate the diameter of the head in parallel with the diameter of the self-press: the minimum combination is 4 * 2, and the maximum - 16 * 8 mm;

- The hexagon head due to the maximum fastening load has relatively large dimensions: in diameter from 5 mm to 12 mm, and along the length of the methome - from 30 to 300 mm;

- Hardware with pressshabhibr at a length of only 13-75 mm, and by the diameter of the base - 4.2 mm;

Usal scope

Various overall proportions of fastening elements and their manufacturing materials allow you to apply to solve almost any construction and repair task.

Phosphatated, with secret heads

This screw with a diameter of 35 mm. It is perfectly attached to such a self-tapping screw to the wall, which allows it to apply it to arrange the design of the room. A wide dimension scale will make it easily choose the necessary dimensions of the dowel for self-drawing.

Suitable for the walls of the walls, ceiling, roofing sheets of GLCs on a wooden crate or (if you choose black screws) for fastening plywood, boards, osp. A step in 20 millimeter will allow to keep the sheets firmly, and the effect of imperceptibility is easily easily drowning the head of hardware for the layer of conventional putty.

Infix structural tapping screws

With crosses

Such a screw is used for finishing works in internal or external repairs. On the shape of the screw of the self-press (ie, the tall of metiza) can be found self-tapping models (like a boura self-built) and simply honed end. The length is also small, medium or large species. Strengthen the fixation of methiza in the plane is recommended by special dowels under the self-sufficiency.

Easily mounted on any surface, on the boards, GCL or metal surfaces, for which they received particular popularity and versatile status. But, due to the additional anti-corrosion processing of brass or zinc, are more expensive building materials.

With hexagon head

Such self-tapping screws are used as the most reliable on the weight load mounting screw for fastening the lag, bars, carrier rails, heavy wooden board, GLC, etc. Of course, how the screws are reinforced, such a screw will cope with the holding of severe large-sized household devices, water heaters, etc.

With pressshabie

This screw is used to fasten the tree thin sheet material, GLK. There may be a large thread or small.

Confirmate - Furniture Self

In contrast to the traditional self-press of acute, in this form, the main feature is a stupid end. On furniture methiza secret head With a cross-shaped slot, as well as a rare threaded notch. Used for assembling furniture, fixing sheets of chipboard, MDF, plywood and other wooden planes, regardless of the weight of the element.

Roofing selflessness

Roofing tools are always characterized by a more complex design. Roofing screws are no exception. This is a combination of screws and traditional self-pressing: a round with a slot under a screwdriver or hexagon-dried turnkey head and a sharp tip.

Length - up to 150 mm, diameter - up to 6.3 mm. It is made of high carbon stainless steel. Apply for fixing all types roofing materials Regardless of weight and destination.

With rare carvings

Self-timber with rare carvings are ideal for working with wooden canvases. The most popular dimensions in diameter x 35 mm, and in length - depending on the thickness of the fastened surfaces.

With frequent carvings

Choose self-tapping screws to work with metal sheets follows with more frequent threads, due to the density of the material.

Screw on wood for professionals Heco Topix

The abundance of brilliant fasteners on the shelves of construction stores pleases the eye, but makes it gets awkwardly at the showcase of each person professionally not associated with the sale of fasteners. The appointment of half of the screws is incomprehensible, but ask the seller as something awkward ... Let's try to understand the variety of screws - the screws presented in the modern market. After 5 minutes, you will find out with surprise that everything is much easier than it seems.

Screw - selfselography. Where confusion arises from

What is the difference between the screw from the self-press? I propose to look in B. GOST 27017-86which gives the following definition of a screw:

Screw - fastening product in the form of a rod with an outer special thread, a threaded conical end and head on the other end forming the thread in the hole of the combined wooden or plastic product.

As follows from the document dated 1986, the use of this type of fastener assumed a preliminary drilling of the opening and limited the material of the fastened elements with wood or plastic. For this type of screws, brass is used, low-carbon steel (ST1, ST2, ST3, 10CP) or corrosion-resistant steel without electroplating coatings. As a fastening product, classic screw is minor, but today everything is still found as a cheap alternative to self-draws.

Saws is a new round of the evolution of fasteners. Formally, it corresponds to the definition of the GOST, which we led above, but has significant constituctural differences (shape of the slot, turn, thread and tip) and is made of high-quality steels with corozion-resistant coatings.

As it follows from the name, the screws can independently cut the thread and is used without pre-drill holes. Self-tapping screw is not only a tree and plastic, but metals, concrete, brick, etc. Given the diversity of fasteners it is useful to know their size and classification. Below are convenient tables to each of the types.

Example decryption

Screw 1 - 4 × 25 GOST 1145-80

Screw with a diameter of 4 mm, 25 mm long made of low carbon steel, without galvanic coatingStandardized marking looks like this, but in practice everything is much easier. On the box that you take from the shelf will be written only the appointment of self-tapping and their size.

Standard Self-Sizes - Screws

The size of the screw-screw is determined by only two values: long and diameter.

Universal screws

Made usually with incomplete thread. Used for wood, chipboard, etc. Soft materials. Self-tapping properties are low. According to standards GOST 1144-80, 1145-80 , 1146-80 Available with diameters 1.6, 2.0, 2.5, 3.0, 4.0, 5.0, 6.0, 8.0, 10.0 mm and length 13, 16, 20, 25, 30, 35, 40, 45, 50, 60, 70, 80, 50, 60, 70, 80, 60, 70, 80, 100, 110, 120 mm.

| Ø, mm. | length, mm. | Ø, mm. | length, mm. | Ø, mm. | length, mm. | Ø, mm. | length, mm. | Ø, mm. | length, mm. |

| 2.5 | 10 | 3.0 | 10 | 3.5 | 10 | 4.0 | 13 | 5.0 | 16 |

| 13 | 13 | 13 | 16 | 20 | |||||

| 16 | 16 | 16 | 18 | 25 | |||||

| 18 | 18 | 18 | 20 | 30 | |||||

| 20 | 20 | 20 | 22 | 35 | |||||

| 22 | 22 | 22 | 25 | 40 | |||||

| 25 | 25 | 25 | 30 | 45 | |||||

| 30 | 30 | 40 | 50 | ||||||

| 40 | 45 | 60 | |||||||

| 50 | 70 |

Self-tapping screws, chipboard, fiberboard, plastics

One of the most common self-tales. Used when mounting in a dowel. It happens with galvanized coating (white) or with galvanized and chromatic passivation (yellow), sometimes processed by phosphate.

| Ø, mm. | length, mm. | Ø, mm. | length, mm. | Ø, mm. | length, mm. | Ø, mm. | length, mm. | Ø, mm. | length, mm. | Ø, mm. | length, mm. |

| 3.0 | 10 | 3.5 | 10 | 4.0 | 12 | 4.5 | 16 | 5.0 | 16 | 6.0 | 30 |

| 12 | 12 | 16 | 20 | 20 | 40 | ||||||

| 16 | 16 | 20 | 25 | 25 | 45 | ||||||

| 20 | 20 | 25 | 30 | 30 | 50 | ||||||

| 25 | 25 | 30 | 35 | 35 | 60 | ||||||

| 30 | 30 | 35 | 40 | 40 | 70 | ||||||

| 40 | 35 | 40 | 45 | 45 | 80 | ||||||

| 40 | 45 | 50 | 50 | 90 | |||||||

| 45 | 50 | 60 | 60 | 100 | |||||||

| 50 | 60 | 70 | 70 | 120 | |||||||

| 70 | 80 | 80 | 140 | ||||||||

| 90 | 160 | ||||||||||

| 100 | 180 | ||||||||||

| 120 | 200 |

Schurphan Cool with Hexagon Head

DIN 571 and GOST 11473-75. Designed for fastening lags, rails and other tasks in which reinforced fixation is necessary. As a rule, galvanized is produced.

| Ø, mm. | length, mm. | Ø, mm. | length, mm. | Ø, mm. | length, mm. | Ø, mm. | length, mm. |

| 6.0 | 30 | 8.0 | 40 | 10 | 40 | 12 | 100 |

| 40 | 50 | 50 | 120 | ||||

| 50 | 60 | 60 | 140 | ||||

| 60 | 70 | 70 | 160 | ||||

| 70 | 80 | 80 | 180 | ||||

| 80 | 90 | 90 | 200 | ||||

| 100 | 100 | 100 | 230 | ||||

| 120 | 120 | 120 | 250 | ||||

| 160 | 140 | 140 | 280 | ||||

| 180 | 160 | 160 | 300 | ||||

| 180 | 180 | ||||||

| 200 | 200 | ||||||

| 220 |

Screws for mounting to metals

Screws on DIN 7981, DIN 7982, DIN 7982

We are visually similar to universal, but differ in the materials of the manufacture, an angle of entering and an angle of the thread profile (up to 60 degrees).

| Ø, mm. | length, mm. | Ø, mm. | length, mm. | Ø, mm. | length, mm. | Ø, mm. | length, mm. | Ø, mm. | length, mm. | Ø, mm. | length, mm. |

| 3.5 | 13 | 3.9 | 13 | 4.2 | 13 | 4.8 | 16 | 5.5 | 16 | 6.3 | 16 |

| 16 | 16 | 16 | 19 | 19 | 19 | ||||||

| 19 | 19 | 19 | 22 | 22 | 22 | ||||||

| 22 | 22 | 22 | 25 | 25 | 25 | ||||||

| 25 | 25 | 25 | 32 | 32 | 32 | ||||||

| 32 | 32 | 32 | 38 | 38 | 38 | ||||||

| 38 | 38 | 38 | 45 | 45 | 45 | ||||||

| 45 | 45 | 50 | 50 | 50 | |||||||

| 50 | 50 | 60 | 60 | 60 | |||||||

| 70 | 70 | 70 | |||||||||

| 80 | 80 |

Screws on DIN 7504

Structurally almost completely identical to the pointed screws for metal DIN 7981., 7982 , 7983 (See Table above). The key difference is the tip that performs the function of the drill.

| Ø, mm. | length, mm. | Ø, mm. | length, mm. | Ø, mm. | length, mm. | Ø, mm. | length, mm. | Ø, mm. | length, mm. | Ø, mm. | length, mm. |

| 3.5 | 13 | 3.9 | 13 | 4.2 | 13 | 4.8 | 16 | 5.5 | 22 | 6.3 | 22 |

| 16 | 16 | 16 | 19 | 25 | 25 | ||||||

| 19 | 19 | 19 | 22 | 32 | 32 | ||||||

| 22 | 22 | 22 | 25 | 38 | 38 | ||||||

| 25 | 25 | 25 | 32 | 45 | 45 | ||||||

| 32 | 32 | 38 | 50 | 50 | |||||||

| 38 | 38 | 45 | |||||||||

| 50 |

Self-timber for sheet metal and metal-based products

Self-tapping screws

They are commercially as with a drill (for metal up to 2 mm thick) and a sharp tip (designed for metal up to 0.9mm). Standard diameters 4.2 (4.0) mm and Length - 13, 14, 16,

18, 19, 22, 25, 32, 41, 51 mm.

Self-timber with a half-cylindrical head ("Klop")

Similarly, the predecessor can be acute and with the drill. The dimensional line of this self-market is missing and occurs in the only size of:

With a sharp tip - 3.5 x 11

With tip-drill - 3.8 x 11

Saw Hex Head

Designed to work with sheet metal without prior preparation of the opening. Provide enhanced mount. From one manufacturer to another, variations of the size of the products of this segment of the fasteners are possible. The tables below are the most popular.

With a sharp tip.

For metal sheets up to 0.9 mm.

Coo Drill (DIN 7504-K)

For metal a large thickness (5mm or more). The length of the tip - the drill determines the max. Sheet metal thickness.

| Ø, mm. | length, mm. | Ø, mm. | length, mm. | Ø, mm. | length, mm. | Ø, mm. | length, mm. |

| 4.2 | 19 | 4,8;5,0 | 14 | 5.5 | 19 | 6.3 | 19 |

| 21 | 19 | 25 | 25 | ||||

| 25 | 25 | 32 | 32 | ||||

| 32 | 38 | 38 | 38 | ||||

| 45 | 51 | 45 | |||||

| 51 | 64 | 51 | |||||

| 64 | 76 | 64 | |||||

| 76 | 76 | ||||||

| 90 | |||||||

| 102 | |||||||

| 127 | |||||||

| 152 |

Self-tapping screws for plasterboard

It is made with a secret conical reduced head, a cross-shaped slot, a two-way thread of a variable profile and a sharp tip. The size of the fasteners for mounting on a wooden frame or a metal profile with a thickness of less than 0.9 look like this: Ø 3.9 mm with lengths 19, 25, 30, 45 mm .

Self-tapping screws for mounting plates and sheets of chipboard, fiberboard, plywood

As a rule, these are galvanized screws (FLugel) size 5.0 x 36

Meet with countersunk conical head and notches for the delaying hole ( DIN 7504P.) Size:

Roofing selflessness

When installing the roof it is advisable to apply standard galvanized screws. They are not corrosion. The table with dimension line looks like this:

| Ø, mm. | length, mm. | Ø, mm. | length, mm. | Ø, mm. | length, mm. | Ø, mm. | length, mm. |

| 4,80 | 20 | 5,50 | 19 (20) | 6,30 | 19 (20) | 7,00 | 122 |

| 29 | 25 | 25 | 142 | ||||

| 35 | 32 | 32 | 162 | ||||

| 38 | 38 (40) | 38 (40) | 177 | ||||

| 50 | 51 (50) | 50 | |||||

| 60 | 64 (62) | 60 | |||||

| 70 | 76 (78) | 70 | |||||

| 80 | 100 | 80 | |||||

| 115 | 90 | ||||||

| 130 | 100 | ||||||

| 150 | 130 | ||||||

| 180 | 150 | ||||||

| 235 | 175 | ||||||

| 200 | |||||||

| 235 |

Release roofing selflessness with painted heads. Paint creates additional protection against exposure to external factors. And they do not spoil the exterior of the roof, since "chosen" in color.

Special screw screws and screws

Confirmates

Confirmate or Euro-screw is a separate category of fasteners. It is designed to build furniture panels. Made with various protective - decorative coatings (more often galvanized). The step of the thread is rare. Task - pull the details to each other. The head has a characteristic difference. For minting, a special hexagon is needed.

Screws on concrete

Screwd in advance drilled hole. The perforator is not recommended. Hence the complexity of the process. Before screwing, you need to drop the machine oil - it will make it a bit easier for the procedure. The look of fasteners, which is called "forever." Hold high loads (up to 100ks). There are: Ø 7.5 mm. Length: 50, 70 (72), 80, 90, 100, 120, 130, 140, 150, 160,180, 200, ... mm.

Window Selfness

Preparation of the opening is not required. Work as "amplifiers" of windows and have the following dimensions: Ø 3.9 mm, lengths: 13, 16, 19, 22, 25, 32, 35, 40 (38), 45 mm.

Frame screws

Large screws with high strength. Screwd up in a dowel and sometimes come with it.

Adjustment screws

A characteristic feature is the second thread. The first thread (usually smaller) is necessary for mounting to the base, the second serves to mount the substructure.

Screws are popular for screws ∅6 mm and length: 60, 70, 80, 90, 100, 110, 120, 130, 145 mm.

Screws for scaffolding

Screws-nails

Screws for suspensions

Very comfortable in everyday life, for example, on such a fasteners, you have been hanging a children's swing in the corridor of the city apartment for several years. Time for installation and removal - literally 1 second! The single standard on the size of this element does not exist and each production generates a dimensional line at its own discretion.

Cheat sheet homemade master

The following tables will help to navigate when choosing the required fastener.

We distinguish the product by the type of thread

Self-tapping screws differ in the frequency of turns. Small step allows you to apply fasteners for metal parts. Rare thread screws are designed for materials having low density. This includes: asbestos, plaster, plastic, and so on. By appearance You can classify the screws as follows:

|

Pitch thread |

Special purpose |

|

Universal screws. Designed to attach objects from any materials (are the most common). |

|

|

Frequent, |

Designed to attach to metrophrophyl thickness up to 0.9 mm thick without applying dubile (needed preliminary preparation holes |

|

Self-tapping screws to attach parts made of soft materials (wood, plastic plastic, asbestos, and so on) without the use of dowels. |

|

|

Middle, S. |

Self-tapping screws to reinforced concrete or brick objects of buildings by drivening in a dowel. |

|

Asymmetric |

Self-tapping screws for fastening elements of modern wood furniture, chipboard, plywood, etc. (pre-drilling hole with a diameter of 4.5 or 7 mm, respectively). |

|

Alternating with notches |

The screws for attaching to reinforced concrete or brick details of the buildings without a dowel (braided), (screwed into a hole with a diameter of 6 mm at a depth of 15 mm exceeding the submersible portion of the self-press). |

All the way in a hat

In the shape of the Hat, you can determine the purpose of the self-press. The relationship between these parameters is shown in the table:

|

View of the Hats |

Features and target |

|

Counted |

After screwing, the hat is completely interpreted in the fixed object without a protrusion. |

|

Profile - Polusfer. |

It is firmly held by the attached part thanks to the increased area of \u200b\u200bthe presser hat. |

|

Profile - half presser with a small press washer |

It has a larger area of \u200b\u200bthe working surface of the hat and its high height. Used when installing sheet materials. |

|

Small secret |

It has a small work area and a gender transition from the hat to the trunk with a carvings. When installing is fixed both in the stationary object and in the attached part. Allows you to apply much greater effort in the mount process than in the case of a conventional secret hat. |

|

Profile - Polusphere with Big Press |

It has a greater working clamping area and low height cap. Purpose - attaching low-density sheet details. |

|

Hexagonal |

The configuration of the cap, allows you to twist the screws with smaller effort, reaching a strong pressing of fastened items. |

|

Fluor-like secret with thickening on the body of the rod |

Allows you to disguise the connection. Makes it possible to close the hat with a decorative plastic lid. Muffins a specific key (4 mm). |

The fact that there is a lot of effort to screwing out does not speak of titanic flour, which will have to go through if the need to unscrew the screws. Therefore, every time you advise the "disy" method, it is worth thinking about feasibility. Manufacturers offer a variety of self-tapping screws that differ from which they are made. The cost also varies. In order not to overpay, you need to give an objective assessment of the load that the fastener will be exposed. If we are talking about "carnation" for a picture on a wooden wall, it makes no sense to spend money on expensive screws.

Screwing tool is used both manual and electric. Often enough screwdriver. This method will not allow to achieve high labor productivity, if it comes to professional work and large fasteners. For work is optimal for all familiar screwdriver.

Slot - Smile :) Incredible, but the fact

The Japanese plant Komuro Seisakusho released a batch of fasteners with a non-standard slot in the form of a smile. The author of the funny idea is designer Yuma Kano. Unfortunately, in the domestic market, the novelty has not yet been represented.

We hope that now you and forever dealt with the question of destination and the size of the fasteners. We will be grateful for recommendations, criticism and detected inaccuracies.