What does the decorative plaster look like? Overview of the coating

Perhaps it is difficult to find a better known decorative plaster than a croroede. This method of finishing and the products of the same name are the most sought-after in our time when choosing a facade design option. Finishing trim called Decorative Coroede Stucco Most often used for outdoor decorationBut you can also meet it in the interior.

The composition and features of the core

The textured plaster of the coroede received its name thanks to special furrocks, which appear after it is applied. These grooves copy special patterns, which are similar to the trail of the cored beetles, which they leave in the wood. Achieving such an effect was possible due to the use of various mineral fillers in the composition of decorative plaster. The smaller such a filler, the smallest drawing it turns out, and vice versa - the larger the size of the granules, the more the furrows come out.

Standard is considered the size of the granules is 2.5 mm. In this case, the most beautiful texture is obtained, which is suitable for facades. Very often there are 2 mm granules, but grains of 1.5 mm and 3 mm are rare. In some cases, to stand out among competitors, a mixture with a mineral crumb is produced, the size of which is 0.1 mm or 4 mm. It is believed that the smaller the granules, the more material is suitable for decorating walls in the interior.

Varieties of decorative plaster Coroed:

- Gypsum. This material is sold in a dry form, and it must be diluted with water to create a solution.

- Acrylic. Material Sold By finished video And before applying it will only be mixed.

Regardless of the variety of a kororad will have to choose among manufacturers. All of them create decorative plaster for approximately one technology, but always add something to the composition. Various formulations Cororad from different manufacturers leads to small differences and features.

A number of manufacturers use polymer components and mineral fillers in their products instead of sand. This reduces the weight of the finished material at the same volume, and this in turn reduces the load on the walls and other elements of the building, which is coated with solution.

Positive characteristics

- Low cost of decorative plaster Coroed is one of its main advantages.

- Simplicity of application in comparison with other decorative materials causes an increased interest in the core from those who have never been engaged in plaster walls.

- It is easily measured and stained after applying, which allows you to get any desirable color.

- The absence of harmful substances makes the material is environmentally friendly.

- Resistance to mechanical exposure makes it possible to vacuum the finished coating and wash it with a sponge.

- The ability to use when finishing facades is not afraid of strong frost and bright sun. Facade decorative plaster Coroede does not spoil at low temperatures and does not fade from ultraviolet.

- Parry permeability of material excludes the possibility of fungus.

Scope of application and subtleties

Knowing what kind of coroede is what its main features and dignity, it's time to think about where it can be used as well as how to choose the material. In fact, the scope of application of decorative plaster cores is very large, because this material can be used to level the slight difference in the walls.

Knowing what kind of coroede is what its main features and dignity, it's time to think about where it can be used as well as how to choose the material. In fact, the scope of application of decorative plaster cores is very large, because this material can be used to level the slight difference in the walls.

Bedroom, corridor, hallway, facade country house, internal and outer walls of the garage, kitchen, etc., - There are many places where the cored can be used. Simply, when interior finished, it will have to more neatly approach the choice of material and the method of applying it, because in this case it is decorative properties that will stand in the first place.

Created grooves may have different orientation (on top below, from left to right or from angle to corner), which will allow you to visually change some shortcomings in the interior.

An important role is played by the choice of material. Most preferred proven brands, so mineral decorative plaster Coroede Cresit for them is an obvious choice. However, even in this case will need to choose the brand of material, so it is not enough to know the brand.

But it is worth starting from choosing a dry solution or ready to use the material. The finished material is more expensive, since you do not need to look for a mixer, add water and carry out a sinus. Finished mixtures are created at the factory, which means they will have a homogeneous structure without lumps. If the dry decorative plaster core is properly involved, it will also be high quality.

Also pay attention to the graininess mentioned earlier. It is better to see examples of the texture of the core with the granules of different diameters. Only seeing how different the effects of the grooves are, it is possible to understand which granules will be suitable personally. Do not forget that the larger the fraction of the filler, the greater the consumption of the material.

For facade finish Ideal solution with granules from 2 mm. But for decorative finish In the interior it is best to use a small fraction. The smaller it is, the more beautiful the coating will look. It is best to take grain 1-1.5 mm. Larger to look rudely, and for smaller, certain skills and skills are required.

Preparatory work and selection of tools

Before applying the decorative plaster, the croroede needs to prepare a working surface. The wall should be prepared as the most common and standard way. It should be cleaned from old coatings, dust, dirt, fat, rust and mold. Next, the wall is processed with putty to make it as smooth as possible and remove all defects (cracks, chips, deepening). Ideally, a smooth and smooth surface is not required, because the decorative plaster of the coroede creates an uneven texture.

Before applying the decorative plaster, the croroede needs to prepare a working surface. The wall should be prepared as the most common and standard way. It should be cleaned from old coatings, dust, dirt, fat, rust and mold. Next, the wall is processed with putty to make it as smooth as possible and remove all defects (cracks, chips, deepening). Ideally, a smooth and smooth surface is not required, because the decorative plaster of the coroede creates an uneven texture.

If work is carried out with fine-grained materials (granules up to 1 mm), the walls must be aligned to the maximum, because the solution will be applied with a thin layer, and will not be able to hide such a defect.

Additional protection in the form of antifungal agents is required only if the work is carried out in a high level of humidity. Framed after shtlocking wall is processed by a soil layer, which implants the adhesive properties of the solution. The color of the primer must be identical to the color of the future coating. Depending on the selected material and factors ambient Drying will take from 4 to 12 hours.

The following tools will be required to work:

- roller (for primer and painting);

- putty knife;

- half-sash;

- trowel;

- plastic grater;

- bucket;

- drill with a nozzle mixer;

The last two points are needed to knead the solution. Of course, if it was purchased dry mixture, and not a ready solution. Decorative coastal plaster is done with her own hands very simple. To do this, you need to pour the acquired dry mixture into a bucket with water and stir. The required volume of water always indicates the manufacturer.

Tying required amount Indoor temperature, dry mixture is added to it. Constantly adding a dry solution in a bucket, it is stirred with a drill with a mixer nozzle. Then the resulting mixture defended 10-15 minutes and mixed again.

Periodic mixing of the mixture will be required during operation. This will prevent the formation of lumps and drying the solution. It is believed that one is suitable for work 1-3 hours from the moment of preparation, depending on the manufacturer and material brand.

The most optimal is the applied solution on cement-sand plaster. However, you can also work with the following surfaces:

- Concrete

- Brick

- A rock

- Plasterboard

Simple and understandable application technology

Decorative plaster The core must be applied to the dry and prepared surface. For applying, metal seater is used. The spatula is recruited on the half-sash, and then uniformly smeared along the wall. At the same time, the instrument is kept with two hands at an angle to the wall and spend upwards. This manages very quickly cover with large areas.

The thickness of the applied layer must correspond to the size of the grain of the filler. If you try to make a layer thinner, then all the granules will be visible on the surface, and in the end the rough structure will be released. If the layer turns out to be too thick, then the decorative plaster Coroed will not be able to show itself. The fact is that the notorious grooves are created just that due to the fact that the grater affects the filler granules, forcing them to move from the place. In the process of movement, they create grooves. If the layer of the solution is too thick, then all the granules are lost in it, and the grater will not be able to "stir".

It is advisable to have to cover the whole wall at a time until it dried. After applying the solution passes half an hour before it gets free. It is at the expiration of this time that the most favorable moment comes to the manifestation of decorative plaster cores on the surface. The solution is not yet dry and you can work with it, but it is already not raw, so it will not be broken.

If you do not have time to handle the entire planned area, then you should stick the strip of painting tape to the place that you have time to walk. Next, apply the solution to the scotch and on it. Then this tape will be divorced together with the solution on it, and it can be continued to work from the smooth edge.

Immediately after applying the solution and before forming patterns, you should perform another procedure. It's about grouting using Colel. It is necessary to simply carry on the wall of the culma under pressure, removing the surplus of the decorative plaster core. And the solution is removed without granules and it is essentially not needed, since it does not help to form patterns. This solution is removed with a spatula from the cell and is removed separately from the bulk of the material. You should walk throughout the surface and collect all excess solutions with it. More information about this technique and many other things can be found from the video below.

After the application of the decorative plaster, the cored is completed, it's time to proceed to the formation of patterns. If you doubt, it's not too early, then just spend your hand on the wall, it should not stick.

Options for possible patterns

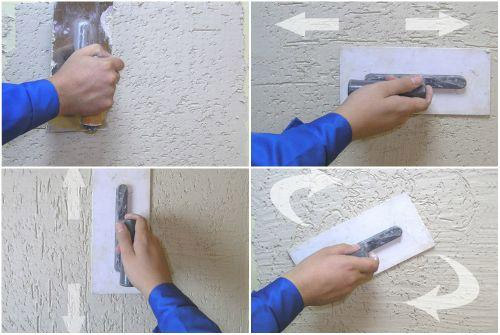

When making a coating of texture, a plastic grater is used. It shares the granules in the solution, forcing them to move and create various patterns. For this you only need to move the grater along the wall and that's it. However, despite the seeming simplicity, this is a decisive stage, because it should create beauty on the wall.

- "Rain" is the most popular option from all. For this plastic grater you need to make vertical wiring, but sometimes make diagonal. In the second case, it will be necessary to post the wall so that the pattern is beautiful.

- To create a "lamb" effect, circular motions with a small amplitude are used. Chaotic grooves, which appear due to this method, resemble the wool lamb. By the way, the decorative plaster of the cored in some regions is called lamb.

- The "carpet" effect is manifested due to alternate vertical and horizontal rubbing. The resulting cruciform texture, if it is not very large, resembles a carpet.

- "Crosses" are a kind of "carpet". Their difference from the previous method lies in the fact that the grout is carried out diagonally in two perpendicular directions.

With the presence of a rich imagination, you can always come up with your method and create a unique texture.

Finish painting

Although the decorative plaster, the coroede can be cooled in mass, but much more preferable to paint the finished coating to obtain the desired color. Painting has a number of advantages over the tip of mass:

- No need to immediately choose a color and spend money on it. Painting can be postponed for a week and to think slowly above the color scheme.

- You always know what color you get. If you use toners, then with a shade, you can guess due to the large mass of the solution. The paint is visible immediately, like its shade. It will not change after applying.

- You can align the coverage of sandpaper, and then spend painting. In this case, traces of such a procedure will be invisible.

- The grooves themselves and the protruding part of the coating can have different shades due to the use of two different colors during painting.

Painting of decorative plaster Coroede is carried out in a day after the end of all works. During this time, the solution will completely dry, and it will be possible to paint the wall without fears. Some experts recommend to wait 3 days. However, it is recommended to walk on the wall of sandpaper to remove all the small protrusions that appeared after working as a plastic grater. After such an opening, dust will be asced to the walls, which should be removed with a damp cloth, and only then the wall can be painted. Make it more convenient and faster with roller.

Experienced masters prefer to paint the whole wall, and through time to do another color to another tint. The second layer is applied carefully so that it does not enter the groove, and remained on the surface. In this case, the coating will be two-color. Sometimes at the very end of the wall additionally covered with a matte varnish to emphasize the decorative characteristics of the coating and make the decorative plaster of the croroede more wear-resistant.

Coroed composite plaster is valued for the original appearance and resistance to external influences. The thin layer is enough to create full-fledged protection against atmospheric precipitation, wind, heat loss, mechanical damage, fungus and mold. The plaster received its name for the effect of the scorded core - walls and facades, processed in this way, fit into any style. At the same time, the installation of the material does not represent a special complexity and quite performed independently. It is important only to comply with the main nuances of the application technology: to level the surface and preparation of the surface, to withstand the necessary time intervals and proportions during the knead and the use of the solution, give it completely frozen.

Coroede is a composite plaster with small stone granules, a diameter of 0.1 to 4 mm. Most often it is minerals, marble or stone crumb, such components enhance water-repellent and thermal insulation properties. TO useful qualities This decorative plaster includes:

- Resistance to ultraviolet, heating, rotting, mechanical and atmospheric influences.

- Ecological I. fire safety, Coroede mixtures do not emit toxic substances.

- Hiding small defects and irregularities.

- Light weight, load on the design and the foundation is minimal.

- Resistance to temperature effects: a thin layer of coroede coating withstands the differences from -55 to +60 ° C.

- Long service life: up to 7 years old on exterior facades, up to 15 on internal surfaces.

- Available cost, an average of 1 m2 costs 150 rubles (excluding painting costs).

When buying pay attention to such characteristics as:

- The diameter of the granules (the brand is most in demand, 2.0 and 2.5 mm grain).

- Strength: to compress up to 7.5 MPa, clutch - 0.5.

- Frost resistance: from 50 to 100 cycles.

- The viability of the solution: depending on the composition - 1-3 hours.

- Throwing time (up to 3 days) and achieving final hardness (up to month).

Varieties

Based on the operation of the operation, the plaster is highlighted for external and internal workThe universal mixtures are also common. Another distinction relates to the size of the granules: the fine-grained compositions with a diameter of up to 2 mm, mean - up to 3, coarse-grained - from 3 mm. Depending on the basis, you can buy dry mineral mixes or ready-to-use polymer: acrylic, silicone and silicate brands of plaster croroede. Powder varieties are valued for accessibility and vapor permeability, but require mandatory painting. Polymeric are considered more resistant to external influences and pollution, have less consumption, but also cost more.

The desired factor of the coroede is obtained thanks to the part of solid granules: the mineral crumb after alignment creates furrows and cracks that imitate the bark of the tree. Depending on the diameter of the granules, there is a different effect, the inhomogeneity of the size plays its role. Much is determined by the direction and ordering of smears: movements can be horizontal, vertical, angular, with a certain step or chaotic. To enhance the effect of the korea, painting and treatment with wax and lesing compositions that give shine are used.

Recommended surface types for decorative material: concrete, brick, plasterboard, plastered previous walls. That is any solid building construction With suitable adhesion, the glass or gland plaster will not hold on. This type of finish belongs to the finishing, use the mixtures of the cored for seelings of cracks or as an aligning layer is unprofitable both due to high cost and due to the inappropriate structure. Plaster is completely unsuitable for restoration purposes. Another limitation concerns the surface tilt: it must be vertical, only some brands are suitable for applying to the ceilings. To finish complex curly and horizontal structures, it is better to invite specialists, in the absence of experience, it is difficult to perform such work with your own hands.

Calculation of the required number

Recommended layer thickness and average flow On 1 m2 are usually indicated on the package, it is enough to multiply the last on the processed area. Sophisticated architectural designs are divided into simple sections, which are separately calculated and further are summarized. Apply decorative mixtures without prior equalization of the surface is impractical due to the high cost of the material, although this is allowed by technology.

Another way to save the solution is the knees of small portions: most often these are quick-taking plasters that are not reused. There is another important factor associated with the dimensions of the granules, in particular, the flow rate of the cores directly depends on their diameter. Example: To apply a thin layer with grains to 2 mm, it will take about 2.5 kg to 2.5 - not less than 3, for coarse-grained compositions - from 4. Accordingly, it will take more material to perform external work than for the same area Internal surfaces, as there are more often used mixtures with granules from 2.5 mm.

Technology application and creating texture

Much attention is paid to the preparation of the plane: it is not only cleaned from dirt, but also thoroughly aligns, the magnitude of the deviations in the level should not exceed the grain size. It is advisable to handle the walls with paint-ground, with a shade close to the metering of plaster, for these purposes it is better to buy materials from one manufacturer. Dry mixes require accuracy when stirring: a drill or mixer is not turned on at full power. They suck in warm water (up to 20 ° C), and not vice versa. Unnecessary additives and the use of old plaster residues are unacceptable.

The solution is applied to an absolutely dry wall with a wide spatula or grater, it is applied to the surface at an angle of 50-60 °, the layer thickness does not exceed 5-6 mm. After that, the gaps indicated in the instructions are waited, usually from 5 to 25 minutes, followed by the formation of the invoice. The required point in time is easy to determine independently to the touch or visually: the plaster ceases to glisten and stick to the fingers and tools. Rubbing is carried out with plastic cells, the tool is applied in parallel with the wall and moves in the desired direction.

The work is performed without delays, it is impossible to leave a part of the wall unfinished, as a last resort, the solution is applied to the edges of the building tape (otherwise the joints will be seen), all excess are removed immediately, the frozen components are cleaned only by mechanical manner. Bringing into painting plaster for the walls of the cores is allowed after 72 hours (the exact time is indicated in the instructions, for acrylic compositions it is better to wait 2 weeks).

- Rain. A simple processing method, plastic culma moves into a strictly specified direction. The original decorative effect is achieved with diagonal strokes, to comply with the step, it is necessary to pre-mark the walls or use the tape to indicate the clear boundaries of the pattern.

- Carpet. The effect is due to the cross-like rubbing, chaotic or corresponding to a specific geometric pattern.

- Lamb or spiral. It turns out when there is a circular grout, it is important that the sections do not have strong abnormal deviations.

Cost

| The name of the brand of plaster with the texture of a coroede | Features of the mixture | Grain size, mm | Average consumption per 1 m2, kg | Weight, kg | Price per bag / pack, rubles |

| Ceresit Art 175. | On silicate-silicone basis. It is a ready-to-use composition for walls and facades, resistant to UV, frost, moisture and pollution | 2 | 2,7 | 25 | 2440 |

| Ceresit st 64. | For decorative thin layer outer and internal coatings. Acrylic mixture is characterized by high weather resistance, elasticity and deformation resistance | 2160 | |||

| Ceresit CT 35. | Mineral-based plaster, recommended for internal work. Differs on shockproof and high vapor permeability | 2,5 | 2,4–3,4 | 850 | |

| Bests Exterwall OS-2.0 GK | Universal decorative plaster with thermal insulation properties. Has significant abrasion resistance and mechanical loads | 2 | 2,4–2,6 | 370 | |

| Knauf diamond light emerald | Dry cement mix For facades and premises with high humidity | 3 | 3,8 | 350 | |

| Bergauf Winter DeKor | Frost-resistant plaster based on white cement, marble flour and modifying additives. Mounting at low temperatures | 2,5–3 | 2,5–3 | 600 | |

| Bergauf dekor | Textured plaster for outdoor and internal works. Valued for vapor permeability, high adhesion and strength | 2,5 | 580 |

Plaster Coroede decorative not so long ago appeared in the sales market. But already has its admirers. Today we will look at what plaster decorative cores, where they are used and how they need to be preparing correctly. Also you look at the plaster decorative koroed Video lessons that will help make preparation and applying correct.

From the video Decorative Plaster Coroede, you can find out that this material can be two species, it is acrylic and gypsum.

- It is realized in the form of dry mixtures and packaged in bags.

- Acrylic plaster is implemented in buckets and ready to use, while the gypsum still needs to miss.

- Each manufacturer owns its preparation recipe construction mixesBut all of them have almost the same, the addition, in the form of small mineral or marble granules.

Attention: decorative plaster Coroed video lessons will show the difference in material on the fraction. In the market putty and plastering mixes You can find materials having granules, sizes from 0.1 to 3.5 mm. The grain of such plaster and determines its area of \u200b\u200buse.

The advantages and characteristics of the material

Coroede decorative plaster video will talk about the merits and disadvantages of the material and will affect the question of its characteristics for use.

Main settings:

- The possibility of using polymer and mineral additiveswhich makes the material easier, which reduces the burden on the main structure.

- Its composition does not contain poisonous substancesWhat makes this decorative plaster environmentally friendly.

- Temperature modes of such a putty lie ranging from -55 ° C to + 60 ° C. At the same time it is fire resistant and does not fade in the sun, and when exposed high temperatures Does not highlight harmful substances.

- Applied to the surface without violations of the technology is capable of serving for a long time, without exposing the actions of atmospheric precipitation and the appearance of mold and fungi.

- It is resistant to mechanical effects: can be brushed with sponge and vacuuming. At the same time, it can withstand not strong blows.

- The basic color of such plaster is white, but you can get any color of the "Coroed" by adding a dye to the finished mixture, and it is very well stained (see).

- Prices for such plaster are not high, which makes it available to all segments of the population.

Ability to use

Plaster Decorative Coroede Consumption depends on the area and drop plane drops. Based on its main characteristics, the scope of such a putty is very large.

You can decorate the building "Coroed" plaster, both outside and from the inside. In the course of the article, some options for applying such a finish will be considered.

So:

- You can get a different surface texture due to the direction of movements. The drawing is obtained depending on the direction of movement: if the movement is carried out along, then one drawing, and if it is different. Real masters "Koroeda" are able to portray unique ornaments on the walls of buildings.

- The decorative plaster "Coroed" makes it possible to express this skill and fantasy, and therefore its use is not limited to the examples below.

Selection of material

Before starting to finish at home, you need to choose the appropriate material. There are many producers, but attention should be paid to the graininess, since the texture of the "Coroed" will depend on it.

ATTENTION: It is necessary to know that, the more graininess, the more the material goes to finish the housing.

- Next, it is necessary to determine the type of plaster: it can be a finished mixture or a dry plaster, which will have to be prepared independently.

- The finished mixtures are more comfortable and better, as they are stirred in the factory and have the same consistency. But, such mixes are much more expensive, and if, to make it possible to make a dry plaster, it will give a little, ready.

- In this case, it all depends on financial capabilities, which determine the factor, and whether to knead the putty at home: I bought and cover the surface.

ATTENTION: The packed material will always be more expensive. Therefore, the price of the finish increases. With a large amount of work, it is much more profitable to make it with your own hands.

Completing of the work

Such plaster is designed to be applied to building structures that have good adhesion in relation to the Coroede.

- As a rule, it is plasterboard, brick, concrete, stone, etc. The plaster has a decorative purpose, and therefore it is not recommended to use it for sealing shells and cracks. At the same time, it can be applied to the ceilings (see), which can be seen on the photo provided.

- The technology of applying "Coroed" is simple, and it can be mastered by anyone. The main thing is to comply with technology and not retreat from the instruction that is available on each packaging of the Coroed plaster.

To separate the accommodation with such plaster, you need to stock:

- Spatulas;

- Plastic grater;

- Bucket;

- Electric drill with a nozzle;

- Stucco "Coroed".

To begin with, the plaster must be seen (if it is a dry mixture) and only then you can begin to apply it to the prepared surface:

- To do this, it should be prepared to prepare the surface: clean from dust, fatty spots or dirt. If the surface is not flat, it must be aligned with sand-cement mixture or . While, surface irregularities should not exceed the size of the seeds of the plaster mix.

- Before applying to the surface, the latter must be projected or a layer of paint-soil should be applied to it, as well as plaster. After complete drying of the primer layer, you can proceed to the application of the "Corad".

- It should be noted that the result will be excellent if the materials of one firm will be applied. Instructions for the use of plaster "Coroed" indicates which brand of certain materials should be used in intermediate operations. So, for example, the "Coroed" brand "Cerezit" involves the use of primer St16.

Preparation of mixes

Now let's look at how to do the decorative plaster cored. As a rule, dry mixes are used, which cost much cheaper ready. In order for the mixture to use, you need to add a certain amount of water and stir.

It may look like this:

- In the bucket you need to pour water and add plaster;

- The water temperature should be room (15 ° C-20 ° C);

- Stir the composition using the mixer;

- After receiving the desired density, the mixture is left for several minutes and is mixed again.

Decorative plaster Coroede after cooking should have a structure of thick sour cream. It should not run on the surface and spoil the drawing.

Attention: ate during the work the mixture began to thicken, then it is harvested more than necessary. To bring it to the desired consistency by the addition of water is not recommended. It is necessary to breed it as much as it will be possible to work out before it starts to grab. It is better to mix it less, then there will be a guarantee that the surface of the "Coroed" will be reliable.

Application technique

Plaster Decorative Coroede video will show and correctly applying material. Moreover, decorative plaster for the walls of the core is the same to apply for exterior and external surfaces. Material is applied to the surface with a spatula or grater.

- The tool is located at an angle of 60 degrees to the applied surface and the wide movement of the plaster is smeared along the wall. From what graininess has a "croroede", the thickness of the applied layer will be formed. After the plaster stops being taken for the tool, you can proceed to the formation of the pattern.

- The drawing is produced depending on the selected pattern and is obtained as a consequence of horizontal, vertical, cross, circular motions of the working tool. On the provided photos, it can be seen how the "Coroed" drawing is produced depending on the direction of movement of the hand of the plaster.

- To learn more about the method of applying this decorative plaster, viewing the appropriate video in this article.

- The method of application of the "Coroed" requires the continuity of the process, so the selected surface is preferably covered in one occasion without any smoke and dinner. After that, the plaster makes it possible to dry. It can take it from the 1st to 3 days, depending on the ambient temperature. With high-quality applying plaster, the surface should not have joints and visible transitions, but to have a smooth and monophonic surface.

In conclusion, the disadvantages of such a surface should be noted, since without them, the conversation about the "cored" will not be complete.

ATTENTION: The most important lack of textured surfaces is that they are actively collecting dust. Then, under the action of the wind strength, it actively begins to spread in the air in the immediate vicinity of housing.

This is such a dust sponge, but unlike a sponge, "Coroed" not only collects, but gradually spreads this dust around him. Of course, collects dust not only "Coroed", but also other surfaces, but if we consider that the price of plaster is not cheap, then you can think about whether it is worth decorating your housing such a plaster, although the choice always remains for those who decided Make your accommodation more modern and attractive.

The decorative plaster of the croroede is simply applied sufficiently. Therefore, look at its characteristics and the possibility of use and with a positive solution you can start work. With the right work, the decorative plaster 'the koroede will last for a long time.

Video lessons of application of which are presented on the site. It received the name due to the furochy surface texture. This type of plaster reproduces the intricate drawing under the crust of trees that travelers are doing a beetle. It has high quality and is designed for the inner and outer surfaces of the walls, building bases, as well as surfaces that are subjected to high operational load, ornamental coatings.

Decorative Coroed Stucco - Composition

The plastering mixture is made by different manufacturers using an acrylic copolymer, white cement and natural marble crumb. The composition includes fibers that strengthen the coating structure. The mixture does not contain plasticizers and solvents. In different manufacturers, the composition of polymer fillers may be different, which affects the technology of plastering. These differences, as a rule, relate to temporary regulations and the method of kneading. All stacking brands in their composition contain grains of marble chips with a diameter of 0.1 - 3.6 millimeters, the size of which and determines the consumption of plaster - the greater the graininess, the consumption is higher.

The plaster is usually white, however, at any time it is possible using special paints to spend its tinting or subsequent coloring of decorative plaster over a dry layer, which allows you to create an original interior or facade of the house. The color of the plaster in the sun does not fade, it can be washed. It is characterized by high strength and resistance to frozen, resistant to atmospheric precipitation. When applying plaster on the building base, even with high humidity of the foundation, it retains its appearance for a long time. Such plaster in the process of hardening does not give a shrinkage, does not succumb to the destructive effect of mold, is not washed away with precipitation.

![]()

Preparatory work and solutions

Preparatory work includes the preparation of the surface and the preparation of the solution. Preparatory work Start with the removal of old paint and plaster. To remove the layer of previously applied plaster, we use a sufficiently acute spatula. In the process of work, it must sometimes be sharpened. If the ceiling is covered with lime, it must be made with water from the water pipeline. To facilitate removal water-emulsion paint It is recommended to add iodine in the water. Also, special fluids are used to wash off water-dispersion paints. They are applied with a roller, and about 30 minutes of exposure to the old paint is removed by a spatula without much difficulty. It is necessary, except for paint, remove all pieces of plaster, which are badly held and other protruding on the surface of irregularities. Old stucco (if any) is preferably completely removed, because there is a chance of detachment from the base of the new coating simultaneously with the old one. Also close attention should be paid to the place of the combination of overlaps and outer walls. Usually in these seams are empty and only on top of the stucco. These places before plastering is best made by mounting foam. The state of the removed plaster coating can be checked with the climbing of the hammer. Plastering in unreliable locations will ring, and where it keeps well, the sound will be deaf.

Important! Before shooting down the plaster at mandatory, using the wiring detector or the tester, determine the location of the wiring.

It is necessary to check the surface to check for the presence of a fungus, which is especially developing in a room with a periodic increase in humidity with insufficient ventilation. In small areas affected by fungi, we carry out treatment with a solution of copper sulphate. When defeated on a large area, we rock the outer layer of the surface, after which the infected area is processed by the flame of the burner. If you do not withdraw the fungus before applying the plaster layer, it will "germinate" again and spoil the coating.

Sollar cooking technology Usually described on bags with a dry mixture, which is mixed with warm water (15-20 ° C) in the desired proportion. Water consumption depends on the type of mixture, grain size, manufacturer. With the help of a special nozzle for the electrically small portions of the dry mixture are stirred with water to a homogeneous consistency, the resulting solution retars for 5 minutes, is again stirred and used within an hour.

Important! It is impossible to add water to the finished solution.

Decorative Plaster Coroede - Application Technology

The process of plastering includes the following types of work:

- applying plaster

- formation of drawing,

- coloring plastered surface.

Application of decorative plaster Coroede (Video can be viewed on the site in the appropriate section) is made in one layer with a spatula or stainless steel grater, which is kept at an angle of 60º. The thickness of the layer should not exceed the diameter of the grain. Stack decorative plasternecessary Continuously. The surface on which the mixture is applied at a time should not exceed 1.5 m², because the life of the solution, depending on the manufacturer, fluctuates from half an hour to one hour. Conducting on the surface of the plaster with a spatula at an angle, evenly distribute it over the surface and remove the excess.

After 20 minutes, when the plaster ceases to stick to the tool, we begin to process the surface using a plastic or wooden grater - apply the drawing. The grater should move easily and smoothly, without an excess pressure, parallel to the plane. The direction of the grooves and their appearance on the plaster layer depends on the direction of movement of the grater (circular, cross, vertical or horizontal) and the diameter of the grains of the filler. Conducted acrylic or silicate paints. Acrylic paints are applied after three days since the decorative plaster, and silicate - in two weeks.