Facade panels under the brick. Wall panel under the brick for the inner and outer decoration - beautiful and functionally.

The use of bricks in the interior is always original and stylish. But now, in modern apartments and country houses, such structures are not always comfortable. Combine classic European design and the latest technology Wall panels for bricks for interior decoration.

Use panels for walls under the brick

Using inside buildings finishing depicting brickwork facilitates the construction of partitions and reduces the investments on materials and work. For these purposes, various materials are used, and numerous technologies are used to install. But the leader is still plastic panels under the brick.

Select panels are quite difficult

Scope of application

Panels for walls, stylized under the brick, can be involved in the interior design in buildings with very diverse functions:

- In homes and private apartments it is possible to separate residential premises, the walls of the corridors and the ceilings.

- In addition, the decorative panel under the brick can help in creating a loggia and kitchen.

- In rooms having high humidity, such as bathrooms, shower cabins and bathrooms.

- In shopping centers, shops, hall hotels and other public areas. In this case, they can be decorated with walls, columns, arches, bar racks.

Installation options also differ. It can be covered at once all the walls. For small rooms, you can limit one or two walls. It will not create the illusion of the overload of the interior. In some cases, it is enough to close the panels only part of the wall.

Features and advantages

Such wide use of wall, including PVC panels under the brick, found due to their operational advantages:

- Comparatively low cost.

- They have a good imitation under natural bricks.

- Organically combined with other cladding materials. This contributes to their universal use.

- Easy installation. When installing, there is almost no waste and construction trash.

- Do not have a burden on building facilities.

- Wall panels under the brick maintainable. They can be quickly replaced by entirely or parts.

- Align the walls, hide defects and cover engineering communications.

- Provide increased soundproofing and heat protection.

- Have a long service life.

- Conventional detergents can be used to care for panels.

These benefits have become possible because the materials for creating panels for walls have the following physical parameters:

- moisture resistance;

- resistance to temperature changes;

- not susceptibility to the effects of solar radiation (non-burning);

- do not be corrosion;

- fabossability;

- flexibility, elasticity and strength.

Varieties of panels for wall decoration under brickwork

Serious difference in wall panels is their original billet. For decoration inside, it is advisable to use the MDF wall panels under the brick. They are made of wood chips with dry pressing. The binding material is the lignin, which appears under the influence of high temperature. Such products are almost no different from natural materials, but at the same time they are characterized by all the qualities of the latest technological products.

The naked brick wall in the interior looks stylish, but not always the masonry is performed carefully, and therefore the surface requires additional finishes. Inner cladding of enclosing structures decorative brick It takes a lot of time, considerable space room, lounge or hallway, and also has a lot of weight. It is for these reasons for the design of the premises, a panels under brick of various textures and colors are used, which is easier and cheaper. In the same way, concrete walls and gypsum partitions of entertainment establishments, residential and office space, giving them respectability or brutality, based on the situation and design plan.

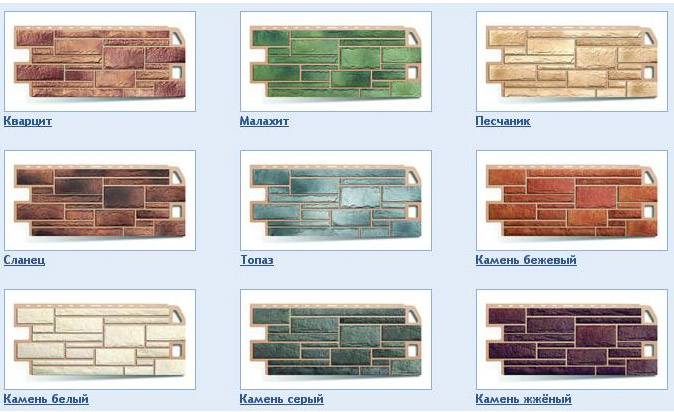

Panel varieties

Depending on the material of the manufacture, the panels, characterized by a characteristic brick texture, are divided into several types. The most popular among them are:- PVC - produced from polyvinyl chloride with the addition of special softeners;

- MDF - differ best properties and the presence as the main ingredient of natural wood chips.

"Brick" panels have different specifications, appearance, manufacturing technology and coloring. But their external similarity with brick and rectangular shape remain unchanged. Plate area can be from 3 to 8m2. Both materials are easily cut, which is convenient when docking angular surfaces. For cut, use the electric lobby or hacksaw for metal. Thin PVC plates are cut into scissors or stationery knife.

Panels that imitate brickwork are perfectly combined with almost any finishing materials, among which include wallpaper, ordinary or decorative plaster, wood, different kinds Colors, metal. They can be combined within one wall or on conjugated surfaces, which allows you to create unique interiors.

Decorative panels for the brick for interior decoration are successfully hidden irregularities on the walls, and with a frame of the fastening, engineering communications are hidden for lining and perform shallow decorative niches. Designers with the help of the skin create all sorts of decorative elements, starting with lining of podiums when the device of two-level floors and ending with the visual imitation of columns and the execution of "torn" surfaces. Often the panels are placed on the ceiling, which looks quite unusual.

The options for using the "brick" cladding are quite a lot, so creating an exclusive interior will be interesting and not difficult at all.

Advantages of decorative panels under the brick

The advantages of facing material include:

- simple installation with which even a novice home master will cope;

- undemanding to additional color, as it is already a finish;

- the unnecessaryness of the preparation of the perfectly level basis;

- versatility allowing to use PVC and MDF for outdoor and internal trim walls and ceilings, door and window slopes;

- the ability to replace individual panels in the event of significant defects, without the destruction of the main area of \u200b\u200bthe trim;

- ensuring additional heat and noise insulation.

PVC panels

The walls of the walls based on polyvinyl chloride are performed in residential buildings, public buildings and utility buildings. The panels are not afraid of moisture, so their use is allowed in the bathrooms, in kitchens, terraces and balconies. When choosing a material, pay attention to the fact that PVC under the brick:

- naturally imitates the texture of the stone;

- provides an opportunity to combine unusual colors;

- has a relatively low cost;

- serves a long time and does not require much care;

- not afraid of ultraviolet;

- copes with temperature drops;

- it has flexibility, elasticity and low weight;

- it is hardly ignited, although it starts to deform at high temperatures quickly.

PVC facing panels are produced in the form of sheets, rails or plates. Facial surface can resemble an artificial brick or a natural stone. The realistic volumetric form of masonry is created by means of special molds. In the process of manufacturing, resistant paints are applied to the surface with a certain way or a film with a pattern that creates visual volume is placed. In the latter case, the material is called laminated.

PVC panels are most often mounted directly on the walls with glue. Small irregularities do not become an obstacle in carrying out work, since the flexibility of the material allows minor deviations when lining surfaces. A small curvature, in fact, will be able to give fencing designs a special effect of naturalness than the designers widely use.

If there are essential defects on the walls that you want to hide, PVC panels under the brick are allowed to be installed on frame technology. But in this case, either a preliminary trimming of the frame of plywood will be required, or a decrease in the shade of the crate to ensure additional protection of facing. The fact is that the plastic panels are not as strong to resist the strong impact, so they require more reliable supplements.

It will rightly notify that the concrete surfaces are not always able to save PVC dents in the form of characteristic dents, and concrete surfaces due to the convex profile of panels, so any mechanical effects on decorative material should be avoided.

PVC panels are made of one or two-layered (with polystyrene foam from the back).

MDF panel

The material is obtained as a result of pressing wood chips with a dry method at high pressure. The binding element here is modified resins with the presence of minor formaldehyde content. This fact suggests that MDF does not have negative influenceWhat is important when choosing a material for interior decoration.

The most popular MDF panels were obtained when facing facades, arbors, balconies and street terraces, but they are used in internal works. The moisture resistance of the decorative material makes it possible to use it in rooms associated with high humidity - in the bathroom and kitchen. In the hallway and public corridors, it is necessary to ensure that the panels cannot scratch children or pets, as the anti-vandal coatings of the facing MDF surfaces are rarely treated, only in special cases.

The panels under the brick will harmoniously look at home and production rooms, they are combined with most building materials. Installation of elements is usually framed. The process takes a small time interval, and the work is made with a minimum amount of dust and dirt.

The pluses of MDF panels include:

- strength allowing the fixation of sheets to a rarely located crate;

- permissibility of hanging shelves and lockers;

- environmental friendliness;

- hygienicity;

- acceptable cost.

Other brick panels

For interior decoration, manufacturers produce brick panels from DVP, plywood, organity, gypsum, fiberglass and ndf. Each of the materials inherent in those or other restrictions in the application. Some have insufficient moisture resistance or unnatural imitation of brick textures, others - high price or low strength, and the third - large weight or certain inconvenience when installing. In this regard, the above materials have less demand, compared with PVC or MDF.

Variants "Brick" finish

The bare brick is characteristic of rural and some classic styles that include:

- country;

- gothic;

- english;

- romanesque;

- loft etc

Today it is not necessary to leave the erected walls without finishing, which plays not only a decorative role, but also functional - in the form of additional heat and sound insulation. Most recently, the market could suggest stylization brick masonry Only on the wallpaper, but their flat surface could not give the required realism. Modern manufacturers significantly expanded the range of facing materials that imitate the texture and texture of natural materials and bricks, and the designers thought out how to use the decorative panels in the interior in the best possible way.

We give some tips from specialists.

- A variant of the brick finish of all walls in the same room is suitable for a house in which there are several rooms for relaxing. The interior will remind the ancient masonry of the castle or Harchevni, but constantly it will be difficult here because of the emotional pressure and the lack of a certain coziness, to which the modern resident of the metropolis is used.

- Facing panels under the brick of one wall or partition will not overload the interior and is quite suitable for a one-room apartment, but the color should be chosen in soft shades, without the presence of aggressive tones.

- For part of the wall allowed to use bright color bricks. He will be able to add an interesting accent to the room or highlight a specific zone, but you should not apply the fireplace panels, since the open fire can deform the material.

- Red bricks suitable for restaurant or club. It is rare in residential rooms due to considerations of creating a calm emotional atmosphere in the house.

- White and light gray shades of bricks either to smell nor "put pressure" on those present will not. Such panels will harmoniously fit into the interiors of pastel tones, even in the bedroom, but will create a certain "chill", which should be taken into account when designing rooms.

Options for finishing internal space using decorative "brick" panels are very much. They depend on the room area, its lighting, the desires of the owner and its financial opportunities. But do not forget that for some style solutions, the facing of such material will be inappropriate.

One of the most trend directions in the world of interior design is the Loft. A distinctive feature of this style is the symbiosis of old and new items, such as trendy chandeliers and vintage tables, modern parquet and vintage windows. Brick walls are considered an essential attribute of the loft. Reaching the effect of aged wall will help finish under the brick.

- veneers

- gypsum,

- decorative plaster,

- clinker tile

- wallpaper,

- construction panels under the brick.

The main advantage of all these materials is a small weight, thanks to which the reedy wall does not create an additional load on the foundation. In addition, such a finish has a small volume, which allows you to maintain the useful space of the room.

Viniron

Viniron are separate planks stylized under brick spoons. This type of interior decoration is very similar to the usual tile. Unlike tile, which is made exclusively from clay, veneers can be made of glass, leather, wood or plastic.

Due to the high cost of veneers, it is rarely used to decorate the entire wall. Most often, with this decoration, the premises will produce zoning or focus on certain art objects. The veneers are attached along the same technique as the tile, so their installation does not require any special tools.

The advantages of veneers:

- high aesthetics,

- the possibility of replacing a separate veneer without disturbing the integrity of the whole masonry,

- wide color palette

- a variety of textures.

Disadvantage: High price.

Gypsum

Due to their advantage, plaster is widely used to create various decorative elements, such as bas-reliefs, stucco or bricks. There are two techniques for creating brick panels from plaster: the manufacture of piece slats and applying plaster directly on the wall with subsequent markup.

In the first case, a wooden form is assembled into which the gypsum mixture is poured. Pre-wall shapes are necessarily lubricated with vaseline to facilitate the process of seizure of a dried "brick".

In the second case, the gypsum is gradually distributed on the wall-processed wall. While the gypsum is wet with a spatula or wide knife creates bricks. To give the canvas of greater texture for the dried "masonry", you can walk with a dry rigid brush, and for smoothing - a soft and moistened with a tassel. Upon completion of the main works, plaster panels are covered with elastomeric paint, which fills existing pores and cracks, which provides wall protection against dirt.

The advantages of plaster:

- cheapness,

- the ability to show creativity

- easily digested to staining,

- suitable for finishing the walls of the wrong shape,

- fire resistant

- perfectly keeps warm

- environmental.

Lack: attracts dust.

Decorative plaster

Stucco is an affordable tool for interior wall decoration. The wealth of textures of this material allows you to get a variety of art objects, including stylized brickwork. Plastering is ideal for decorating curvilinear walls, to which it is impossible to lay a tile.

Benefits of plaster:

- durability,

- excellent thermal insulation characteristics,

- simplicity of application

- practicality,

- wide color palette.

Disadvantage: Dust accumulates in the slots of plastered surfaces.

Clinker tile

Clinker tile is an excellent alternative to real brickwork. Clinkers, like most bricks, are made of clay, but such briquettes are much thinner and easier than standard bricks. Due to a minor weight, clinker tiles can be used for the inner cladding of several walls of the room without the risk of creating unwanted load on the foundation.

The clinker tile is unlawed and glazed. The unglazed tile more than other clinkers is similar to the brick, but not suitable for decorating surfaces subject to regular contamination. The glazed tile is more practical, therefore is the ideal option For lining a bathroom or creating a kitchen apron.

Installation of clinkers is made by the same technology as the attachment of ordinary tiles. To give the finished panel of additional similarities with brick masonry, the seams between clinkers are wiping with a solution of cement mixture and large-phrase sand.

Advantages of clinker tiles:

- maximum similarity with bricks,

- not susceptible to fading

- non-toxic

- provides an extra heat and sound insulation,

- resistant to mechanical exposure.

Lack: Some types of clinkers absorb and hold moisture, creating conditions for the reproduction of pathogens of microorganisms, so you need to choose a tile, taking into account the characteristics of the room for which it is intended.

Wallpaper under brick

Wallpapers under the brick are the usual wallpapers for interior decoration of the walls. Unlike other decorative materials under the brick, the wallpaper provides air circulation, which allows you to maintain a microclimate indoor. In addition, after sticking wallpaper, there is practically no construction garbage, which is formed in large quantities when finishing the walls with tiles or.

Most wallpapers under the brick have a smooth surface, but there are also texture canvases, decorated with crumbs or textured folds. You can distinguish such wallpapers from real brickwork with close review.

The advantages of wallpaper:

- allow the wall to "breathe",

- do not reduce the useful space room,

- low cost.

Disadvantages of wallpaper:

- accumulate dust

- prone deformation under the influence of water, so they are not suitable for decoration of bathrooms or kitchen workers,

- it is difficult to clean from fat spots.

Construction panels for brick

The construction panels under the brick are made of plastic, so they are distinguished by increased wear resistance. Such panels are easily laundered from dust, rust and fat drops, so they are often used when decorating the kitchen.

Imitation panels can be mounted horizontally or vertically, varying the image direction. This decor on nails, self-tapping screws or screws is mounted. For high-quality consolidation of some building panels, it will take a doom.

The advantages of the panels under the brick:

- cheapness,

- durability,

- natural appearance,

- ease of installation,

- low weight

- easy to replace the damaged element,

- improve the thermal insulation of the wall.

Disadvantages:

- low-quality finishing panels can highlight toxins,

- when installing panels on the crate decreases the useful space of the room.

Important moments

Decorative wall decoration with imitation of brickwork is a relatively new trend in the decoration of the inner surfaces of the walls. Such a design has not yet had time to hate, so it looks very fresh and original.

Among the entire variety of finishes, you can find materials that will allow to implement almost any designer idea, taking into account the financed finances. However, when repairing repair, it is important not to overdo it with the decor under the brick, since the abundance of such elements can turn the living room into the basement.

The simplest way to finish the wall under the brick is facing with panels with an appropriate texture. Modern decorative materials From PVC, MDF, chipboard and fibrocement, they definitely imitate the brick surface and are suitable for internal and outer laying. The possibility of such a finish appeared relatively recently, but the demand for products is constantly growing. The technology is appreciated for simplicity and accessibility: large areas are quickly closed at a minimum of draft work and installation efforts.

Products are represented by durable plates or sheets standard sizes With the Schip-PAZ Connection System, intended for placing on walls or ceilings. Thickness and weight depend on the material of the manufacture, in PVC load of the load on the supporting structures can be neglected. A distinctive feature is the imitation of the texture and color surfaces for the brick, the remaining performance characteristics are determined by the properties of the base. Allocate:

- Decorative plates from PVC.

- Wall panels from MDF.

- Decorative imitation of bricks from fibrocement, fiberboard, organity, gypsum.

The first variety is considered universal: plastic is used in rooms with high humidity, not afraid of ultraviolet and external influences (with the exception of direct strikes) and little weighs. In addition to the interior, PVC is suitable for installation on loggias, terraces, in systems of ventilated facades. The material is cheap, elastic and unpretentious in care. Imitation of bricks is created at the expense of special molds, the decorativeness of products is practically not limited. The disadvantages include low impact strength and destruction (but not ignition) under the influence of high temperatures, although the usual working range decorative PVC Withstands without deformation or curvature.

MDF panels are made under high pressure chips with resin adding. Despite the wooden basis, they are not afraid of the intensive impact of moisture, mounted on open balconies and facades, arbors and terraces. In contrast to thin plastic, they withstand certain loads (shelves or kitchen cabinets), of course, provided a reliable crate. Fears at the expense of the content in the MFD plates of formaldehydes unreasonable: they are there, but in a slight proportion.

Considering products from other materials, it is worth noting:

- Fibro cement plates - spectacularly looking composite panels, the only substitution of which is high cost and weight. They are recommended to buy for facing facades or space over fireplaces.

- Warm plates made of compressed sawdust and chips are available and attractive, but mounted exclusively in rooms with normal humidity, the same can be said about plywood.

Products have many advantages, when proper care will last at least 10 years. Their installation allows strengthening the heat and sound insulation properties building structures And hide an unsightly surface. The finished wall panel under the brick for the inner and external finish does not need painting, the color of the coating will not fade and does not fade.

The only restriction of operation is low impact strength and poor resistance to high temperatures (However, as already noted, not all varieties). Unpretentious in care, if necessary, the element is enough just to replace.

Ideas for use in the interior

Facing, imitating stone and brick, is recommended by designers when placing rooms in classic English, Gothic, Romanesque and Country style. In addition to the external appeal, the finish allows you to hide communications and decorate small architectural forms: podiums, multi-level protrusions, niches, columns. Products on ceiling structures, arches look very original. There is no need for lining rooms completely, they are combined within the same plane with most other finishing materials.

Designers believe that brick imitation for interior decoration should not overload the interior, to achieve a decorative effect, there is enough facing of one wall or partition. When choosing a color scheme stick general rules: Aggressive colors do not apply in rest rooms, white, gray and pastel shades are not suitable for active zones. In the living rooms and premises with a large square advise to purchase products stylized under ancient or imitating naked unprocessed masonry. Wall panels for the kitchen under the brick used in a limited space should look bright and colorfully, the lacquered plates of MDF will be appropriate.

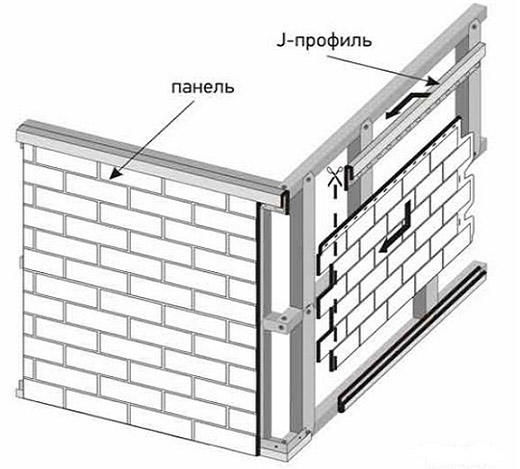

Nuances of Montaja

Fixed in two ways: glued to the surface on glue or placed on a wooden or metal-turning crate. Preliminary preparation Uncomplicated: The walls are cleaned of the old building materials and dry, the frame elements are processed by antiseptic or anti-corrosion compositions. In the kitchens, baths and other visits with intensive operation, it is desirable to cover their layer of waterproofing. Before the start of installation, plastic panels are kept in the installed room for a couple of days, it will exclude their curvature in the future.

Application on glue is selected with minor deviations in terms of level. The installation begins with the corners (for this purpose there is a special connection), glue composition Applied on the product and wall. The edges of the plate are made according to the Schip-Groove system, reaching the rotation or end, is easily clipped with a construction knife, after which the next corner fastener is fixed onto its free edge. To achieve the desired result, it is applied to the wall with effort and adheres to so a few seconds. The maximum allowable distance between adjacent sheets is 3 mm.

For curves of the walls, the interior decoration is complicated: the plates are fixed to the pre-placed clamp: to the tree - on the self-tapping screw, kleimer or with the help of a construction stapler, to the metal - exclusively on the press washer. The step of vertical guides should not exceed 40-50 cm, with the risk of flexing products they are set more often. The last condition is relevant for kitchens or when installing particularly thin PVC panels.

In rooms with high humidity there is a need for seams of seams. In this case, a small amount of transparent silicone glue is applied inside the groove compound, the rest of the installation runs along the same scheme - from the angle. The space between the wall and decorative facing is recommended to fit or insulate the foam. The finishing of external facades or outer surfaces occurs by the same scheme. The only difference is the weight, in addition to PVC siding on the street, heavier fibro-cement, SIP or thermopanels are recorded.

Cost decorative panels

| Brand Name, Short Description | Producing country | Material | Dimensions: d × sh × t, mm | Square in packing, m2 | Number of pieces | Price per pack, rubles |

| Crosaplast Unique, White Lacquer | Russia | PVC | 2700 × 250 × 8 | 8,1 | 12 | 3440 |

| VOX Motivo Parette Bianco, Smooth White Surface | Poland | 2,7 | 4 | 1400 | ||

| B-Plast, smooth matte, brown | Russia | 6,75 | 10 | 1430 | ||

| Facade composite Nichiha. | Japan | Fibro cement | 3030 × 455 × 14 | 1,4 | 1 | 2650 |

| Aquaton, structural texture, red-brown | Russia | MDF. | 2440 × 1220 × 6 | 2,97 | 1 | 1330 |

| Wall panel DPI with a structural surface stylized under white brick | USA | DVP | 1 | 3140 |