Varieties of decorative plaster for internal work. What better to choose the facade plaster for outdoor work? Useful video: how to choose decorative plaster

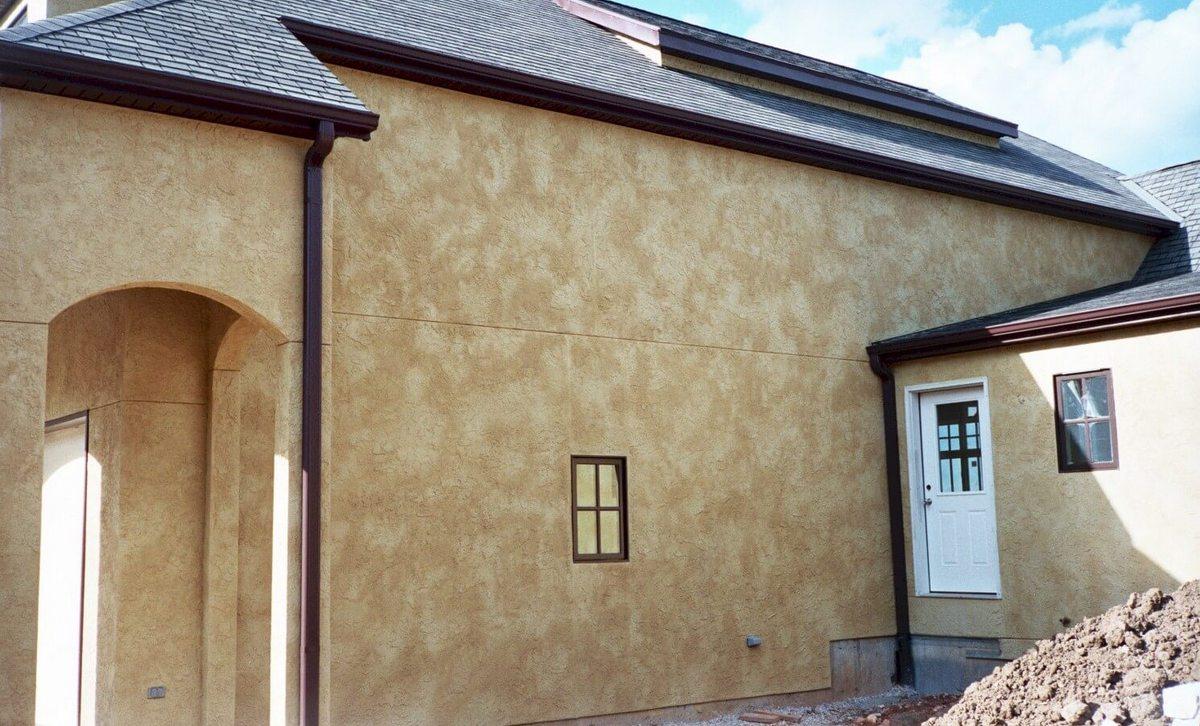

Facade finish has its own characteristics regardless of the material selected. Often, such works choose the most affordable products with more or less suitable properties. Decorative plaster for external finishing of the house is not often used, because such a material is more expensive than other solutions for facade finish. Not every decorative is able to withstand precipitation, ultraviolet and temperature differences. However, such an finishing coating (if it has the necessary properties) can decorate the facade of any building.

The substrate for precious plasters may be cement-lime plaster or heat-resistant plaster. Plaster gypsum plaster - special plaster. These are materials with wide placement capabilities. Their preparation is quite complicated. They are created by repeated overlapping layers and create some decorative fragments with scrapers.

Fig. 2 Plastecration, Damn Palace in Torun. The top layer smoothes a wet metal float. Plaster - they are made of plaster, limestone or lime and impurities from marble dust or fine sand. The stucco surface is very smooth and glossy. They apply to a raw, smooth surface. Stucco can imitate marble or raw concrete. They are used to finish columns, ceilings and other architectural parts.

What should be the facade decorative plaster

With an external decoration to decorative material, much more requirements are put forward than internal workoh. After finishing in the interior, we are primarily interested in decorative properties, and only then we think about wear resistance, vapor permeability, adhesion and other things. In the case when decorative plaster is used for external work, you must first pay attention to completely different factors.

It is difficult to say which feature first of all the facade decorative plaster should be possessed, so we will list them in an arbitrary order:

- Resistance to atmospheric influences. It is in mind not only resistance to periodic rain with snow, but also the ability of the material to stop years, despite the constant temperature changes and ultraviolet effect.

- Waterproof is required not only due to rain, but also in view of the drop-down dew, fog and just high humidity.

- Strength. Decorative coating will remain unchanged even due to mechanical loads that are often suspended with a building facade.

- Parry permeability. It is difficult to overestimate the ability of the "breathe" surface.

All these items are suitable for conventional plasterBut in our case, another moment is important - this is the possibility of creating a variety of textured surfaces of the desired color. Only with decorative plaster you can choose any colors and pictures that the facade is more beautiful. What kind of texture and patterns will be on the facade, it depends, both from the technique of applying and from the variety of the most decorative plaster.

Acrylic plaster - unique material for the facade

Acrylic decorative plaster for the facade is characterized by its composition in which it includes water solution acrylic. This solution is the characteristic difference of acrylic decorative from the usual cement mortarwhich often separate buildings outside.

The advantages of this material include:

- Elasticity that allows you to work with a solution, as it will want.

- Large selection of possible textures.

- Sold in ready-to-use form.

- Parry permeability allows the walls to "breathe", giving out an excess of moisture.

Not everyone wants to choose this material for outdoor decoration, because it attracts dust, and with her and dirt. However, after the rain the walls remain clean. Also, decorative products from acrylic are known for the speed of its drying. Therefore, it is better to work in a pair. If you spend all the work itself, that is, the risk of joint formation due to the fact that the material will dry quickly, and the working area is very large.

Acrylic decorative plaster for external work should be applied all and immediately. You can relax only when one wall is ready. It is not necessary to work in small areas, because if you manage to get rid of visible joints, the color difference will be visible and will have to do additional staining.

Giving the color acrylic plaster with an outer finish should not be manual. We need a lot of material for such work, so add toner will have to several buckets with decorative. It will not be done in the same proportions, which means that the solution will differ by tone. Therefore, you should immediately order a machine tinting. With the help of computer equipment, the shade in all buckets with solutions will be the same.

Decorative plaster with mineral filler

The solution, which contains mineral fillers, is considered the most fiscal option for the facade finish. The basis of this material contains a cheap cement, which causes its popularity. Such a solution will have to be prepared independently, and there is also no rich selection of colors. You can attribute this material to decorative mixtures with a large stretch, but it is still possible to create beautiful patterns with it.

Outdoor decorative plaster on mineral base has bad adhesion properties in comparison with other decorative materials. Also, the elasticity of the material is at a very low level. However, none of the plasters are applied as simple as mineral. In this case, the mixture is sold in a dry form, and it will need to be independently kneaded to the desired state. The most popular mineral mixtures are "Coroed" and "Kameshkovaya".

Silicate and silicone materials

Decorative plaster for facade works can also be silicone or silicate. Though silicate material It consists of mineral components, but its difference is liquid adhesive glass, which acts as a binder element. Bad elasticity and high moisture absorption are the defining qualities of silicate decorative plasters during the outer decoration. Therefore, this material is traditionally used in the case when it is necessary to work with concrete surfaces.

Silicate solution can be treated to taste, and it is sold in ready for applying. At the same time, after applying, the finished coating does not need additional care.

Silicone decorative plasterings are extremely rare when finishing the facades. The reason lies in their big value. Silicone base allows the use of a wide variety of fillers in solution, with which a variety of decorative effects are achieved.

The same effect natural stone It is achieved through the use of quartz sand as the main filler. The solution for the facade is very beautiful, but also expensive.

The facade of the house with decorative plaster on silicone base will create a vapor-permeable coating that does not require additional care. It is also worth noting the high elasticity of these mixtures. According to this indicator, they are even ahead of acrylic solutions.

Features of external work with decorative plaster

There are several features that distinguish an outdoor finish from the inner.

- The working area is always big, so you need to choose the materials with which you can work for a long time without fear that they are dry and leave visible joints.

- It is necessary to work in warm, dry and weak weather so that the coating came high quality. Walls should be dry, and air humidity is less than 80%. In severe heat (from +35 0 c), the solution will quickly dry out that it will complicate work with it.

- In winter, it will not work out, as in most cases decorative materials The temperature is required not lower than 5 degrees. There are mixtures that work under negative temperatures, but their value is an order of magnitude higher.

- Decorative plaster for external work will dry after applying, and must be provided good conditions for this. The weather during the drying period should be the same as during application. If the work is carried out with the Facade of the Big House, then you need to make sure that this weather will be several days in a row. Most decorative plasters dry very quickly (per day), but often the maximum strength is dialing only one week.

The procedure for performing all works

Regardless of the selected material, the working equipment and the desired pattern, the order of work will always be the same.

First of all should be held preparatory work. Their essence comes down to the preparation of the wall. It must be aligned and clean from the old coating, if any. Special leveling mixtures we achieve the wall to reach the most smooth, without a height drop. After that, primer is used for better adhesion. It will perform a function of a kind of glue, which will allow the decorative plaster firmly to hold onto the wall.

When the primer is driving, it will be necessary to prepare a solution. If decorative plaster for outdoor work is sold in finished video, It should be simply mixed before use. Mineral compounds will have to be mounted manually, and then immediately apply. The solution always requires periodic mixing if the work is carried out for a very long time.

The applying of the solution can be carried out manually or with a hopper. It all depends on the selected material and the desired texture. If you want to apply more than one layer, there is a pause between the application for a complete drying of fresh coating.

The final will form the desired texture and patterns. Or you can just sweep everything. It all depends on the design preferences and skills.

When a person passes by any structure, he first turns attention to the appearance, and more specifically, on its front part, which is called the facade. By how qualitatively, the decoration of the building is made, you can get a general idea of \u200b\u200bits owner, about its financial capabilities and even the character. This is perhaps one of the main reasons, because of which the facades are attached great importance. The modern and beautiful facade of the structure can be decorated with various methods, including marble tiles, and all sorts of lining panels such as siding or aluCobonda and even simple plaster or effect "fur coats" on the facade. But the most extravagant and exotic way for facing the facade is currently facade decorative plaster, whose features will be discussed later in this article.

Decorative facade plaster is not simply responsible for the beautiful appearance of the building, but also serves as an additional protection of the walls from various atmospheric manifestations, for example, from wind, water and ultraviolet radiation. Today, many options for mixtures for various surfaces and conditions of application are produced. Types of facade plaster differ from each other not only by their composition, but also characteristics and features of their use.

Properties of decorative facade plaster

The basis of the material function is that it forms an attractive design of the facade, and also protects against various external influences leading to destruction. These all requirements are achieved due to the fact that outdoor plaster There are the following properties:

- Waterproof, since the plaster under the action of moisture is not modified and is a kind of layer for protection, which prevents the effects of destruction from moisture.

- High resistance to climatic changes and temperature drops, which is especially valuable for regions with a significantly different seasonal difference in temperature. High-quality facade plaster has sufficient resistance to the effects of sunlight and precipitation, and some of its species also have to radiation compounds.

- High strength, and although the facade of the building is not so often subjected to mechanical loads, but even if such a place, the plaster will be able to withstand them.

- Parry permeability, that is, the ability of air flow or vapor outside, which makes it possible to maintain the primary structure of the structure of the structure.

- Enhancing sound insulation I. thermal insulation quality at home. Using facade plaster, you can save on heating, since this material increases the thermal insulation parameters of the house. In addition, due to such a finish, the level of noise coming from the street is reduced.

- The ability to create various textures and the presence of a wide selection of color shades. Thanks to the decorative facade plaster, you can realize almost any ideas of design. Coatings are a variety of colors that can be obtained by adding killers. You can also improvise with patterns and textures, while the main thing is to correctly apply the layer of plaster and use stencil if there is a need. For example, if the facade plaster of the type of "cored" is used, then the impression is visually created that the surface of the walls is made by insects. At the same time, this design of design attaches general image Construction originality. The choice of color solutions and ornaments depend only on the technology of coverage and fantasy customers.

- The comparative ease of application of the plaster mortar, as the plaster of the outer walls can be carried out even with their own hands, if there is a certain experience in construction business.

- Cost of material. When comparing the average price of other finishing materials, plastering will be quite profitable. At the same time, each variety of the mixture has its own price, depending on the final structure of the wall coating, which is available in the composition of ingredients and properties.

The listed qualities are characteristic of almost all types of facade plaster, but, one way or another, the degree of manifestation of certain basic properties may differ depending on the type of mixture used and its composition.

Varieties of facade ornamental plasters and recommendations for their choice

The facade plaster for external work may have various binders, however, the role of a filler will always perform fragmented stone with different fraction From large grains of 5 millimeters to small sand.

Cement plaster for finishing facade

Cement plaster is made on the basis of portland cement and fractional sand with water-retaining and other additives that improve their operational qualities. Also, decorative plaster for external work include elements that are responsible for the texture of the resulting surface. For example, the facade mixture of the type "cored" contains grains of crushed granite with a fraction of 0.5-3 millimeters.

Distinctive features of facade decorative plasters on cement based The following are:

- High degree of strength of the finished coating.

- Such plaster does not have a negative effect on vapor permeability, since such a coating is "breathing."

- The material is not smoldering and does not burn, does not release toxic gas when heated.

- It has an affordable cost relatively to the rest of the facade finishing materials for external work.

- Good and high qualityly paint with mineral paints.

- Qualitatively falls on most varieties of facade surfaces. To apply plaster on the insulation, the plaster grid is mounted in advance.

The lack of material is not too rich in the palette of colors for the outer finish, and if the existing range does not suit the Customer, it will have to be included in the budget also costs for the appropriate paint.

It should be paid to the fact that the degree of strength of the obtained outer coating depends directly from the exact compliance with the proportions of the ingredients. It is advisable to buy at once the finished front dry mixture, rather than make it with your own hands. Accidental attention is also required for the preparation process for use.

Silicate plaster for decorative facade cladding, as well as cement, is mineral. Here, potassium liquid glass is applied as a binder. The filling composition of approximately the same sand and / or stone crumb, water, mineral pigments and improving additives in small quantities.

Aesthetic and operational characteristics are specified by liquid glass:

- high exterior windproof and moisture resistance of the facade

- long service life and high decorative properties;

- good adhesiveness with concrete, lime-concrete and silicate exterior compositions;

- fireproof material quality;

- a fairly high degree of vapor permeability of the facade coating;

- the variety of color palette;

- the possibility of staining with silicate paints.

The lack of such decorative plaster based on liquid glass consists in high cost.

It should be noted that the facade decorative silicate-based plaster can be applied on all types of insulation and the outer draft finish. For example, such works are not acceptable polymer insulation and surfaces that are covered with varnish or oil paints. Gypsum and other external gypsum-containing bases are considered conditionally suitable and need a trial application.

The material base is a stone crumb, coloring pigment, sand and hydrophobic additives. Acrylic resins serve as a binder, and more specifically their water dispersion. They are produced in the form of decorative prepared mixtures for external work.

Decorative facade plaster on acrylic basis For external work there are the following characteristics:

- Good wind protection and moisture resistance;

- High degree of elasticity of decorative finished facade coating. Due to this, the probability of cracking of the coating is practically eliminated.

- Resistance to abrasion and shocks.

- Wide color assortment.

- The ability to color the facade after cladding.

- Good prilence of material with many outer coatings.

The disadvantages of the outer composition on an acrylic basis consist in low stability of the pigment to ultraviolet radiation.

It should be known that acrylic outer coatings are not intended for work with them over the plates of mineral wool. Conditionally suitable can be called cellular concrete in this case.

Facade plaster for external work with facades produce from a combination of coloring pigments, mineral fillers and silicone resins. The material forms a thin layer decorative coating. It is impossible to call such an outdoor plaster cheap, however, such a cost is justified by its aesthetic and operational qualities:

- The material is suitable for the behavior of the work in difficult weather conditions.

- Performs good defense From atmospheric impact, including moisture.

- Released more than 200 shades.

- Color decorative pigment has resistance to sunlight and, therefore, does not fade.

- The service life of the coating is more than 10 years.

Minus silicone facade plaster is that it cannot be applied to the outer insulation. The problem is solved by creating a basic layer under decorative on the reinforcing grid.

Another species should also be noted - decorative silicate-silicone outer plaster. The connected substance here serves composite from the dispersion of potassium silicates and silicone copolymers. Such a cladding for external work on the operational qualities is quite close to Silicon.

It should also be said about the varieties of external plaster textures. There are several types of textures:

- The effect of "cored", for which the working mass includes stone grains with a certain fraction. It depends on their size, how intense will be the relief on the surface of the walls. The textured surface is created precisely at the expense of these grains. The texture is obtained like a drawing on wood, trained by the beetle-tree.

- The effect of "lamb", where filler contains stone grains different sizes, making a decorative surface soft blades.

- The effect of "fur coat", in which the relief depends on the features of the filler directly in the working mass, and not from the application technology.

- Crupes or pebble plaster, which contains in its composition a lot of stone large grains of the same size. Such plaster gives a small-baked surface.

- Mosaic decorative plaster with decorative stone. Such a material, in contrast to the rest of the above, there is only in silicone and acrylic compositions. The binder is transparent, and the surface has the form of a tightly laid stone crumb.

- Color decorative plaster based on a solution of sand and limestone with the addition of coloring pigments. It is used to treat brick surfaces, as well as tuff, light concrete and porous blocks. Such a plaster is applied by creating combined or set textures. In a plastic or hardened form, it gives a specific form by applying special tools and shapes.

- Stone texture of decorative plaster - cement decorative plaster, which contains granules and grains of natural stone, which makes it possible to obtain a mosaic facade or imitation of granite, marble or limestone. It is used to finish brick and concrete surfaces. According to the technology of applying facade plaster, it is additionally treated with mechanical pathways or etching hydrochloric acidand then washed with water. As a result, the cement layer is destroyed, leaving a relief surface with a stone crumb. This method is considered one of the most complex options For finishing the facade of the building.

- Terrazite decorative plaster, which is obtained from terrazite mixtures, which includes lime, cement, mica, stone crumbling and quartz sand. It can be used for any part of the building. Such plaster in the almost hardened state is treated with a nail brush or sandblasting machine. The resulting surface appearance is similar to sandstone or tuff.

- Fewer graphite, allowing to create unusual embossed images and a colorful surface. It is made, combining several colored solutions. This plaster is used to decorate the design and restoration of buildings. First of all, the preparatory layer is applied, and after 2-3 additional layers. After six o'clock on the top, a cut off has not yet solidized layer, allowing you to expose the bottom layer. The result is an unusual embossed pattern.

Choosing a suitable mixture of facade decorative plaster for outdoor work

There are numerous features of the facade plaster for external work. To select the most optimal of them, taking into account the parameters of resistance to aggressive external factors, the compatibility of any type of facade plaster with the surface is to be applied. It is from these parameters that the exterior decoration will be. For example, cement formulations are good at the walls of any quality, while the only condition is that if the works are on top of the insulation, it is required to pre-mount the plaster grid.

Stability depends on various factors. Each decorative mixture is good, but something loses the rest of the species. For example, acrylic plaster is able to withstand a mechanical impact, and the service life reaches 15-25 years, but it has a tendency to burn out the color. But if you plan to paint the facade for a couple of years, then such a moment will be insignificant. Thus, it is necessary not only to compare the facade plasters, but also evaluating its priority for itself. The least durable of all is considered cement plaster With a service life of 10 years before the next cosmetic repair. The greatest resistance to atmospheric precipitates is observed in external facing materials on acrylic and silicone basis, and the smallest - in silicate and minerals.

To prevent the formation of mold and fungus into silicate and mineral mixtures, antifungal and antiseptic reagents are added, and the types of outdoor decoration with greater water resistance do not need it.

Direct influence on the durability of decorative outdoor facing It has the texture of plaster for the facade. Internal stresses are worse than the smooth surfaces that are easy to crack. Coatings with roughness and more persistent and can also mask cracks due to relief on the outer surface.

The durability of color coating depends on several conditions. First, whether painting the outer surface was made with paint and varnishes or pigment was evenly distributed in the total mass. Secondly, the antistatic quality of the material, which prevent the deposition of dust to the surface. Third, the factor of the resistance of the pigment to fading, that is, resistance to ultraviolet rays. In all parameters, the highest performance has silicone plaster For outdoor work.

Choosing the material, it is also necessary to take into account the coverage of the working mass. In the work, plastering mixes are divided into thin layer and thick layers. Tolsti-layer include silicate and cement decorative compounds, and to thin-layer - silicone and acrylic. The thin layer type of plaster is more demanding a reason for which it is applied.

Among the popular manufacturers can be allocated as follows:

- Knauf (Knauf), Ceresit (Ceresit), Caparol (Kaparol) - the most famous and at the same time worthy trading companies that are founded in Germany. Their products are distinguished by high quality and the same high cost. This brand is produced in many countries of the CIS countries and Eastern Europe, but this does not reduce product quality.

- POLIMIN (Ukraine), Baumit (Austria), Kreisel (Germany), Atlas (Poland) are located on the next step in popularity. Produce reliable and high-quality finished and dry construction mixes For external and internal works.

- Synerges (Kazakhstan), items (Russia), Bolaris, VOLMA - Dry plaster for external work with sufficiently mediocre performance. Their advantage of their advantage is in the low cost of products relatively with branded expensive brands.

Preparation of the necessary tools

What to produce plastering No specialized tools need, and everything you need can be found at any economic store:

- spatula - It is advisable to use several options;

- capacity for the manufacture of the solution;

- roller and brush, and if there is an opportunity, you can use a sprayer, which will make the procedure for applying plastering the plaster even faster;

- sandpaper.

To ensure your own safety, work is better to take the mask and gloves with glasses, since there were cases when the solution got into the eyes or irritated when the skin came into contact. You must also try to wash the instrument after each working stage so that dried plaster does not damage the next time the surface.

Technique of applying decorative facade plaster for outdoor work on various surfaces

Flow consumption

Foreign decoration In most cases, they are equally applied to the walls equally, with the exception of the so-called "complex" surfaces, for example, insulated with foam surfaces, bruschers, chipboard and OSB.

Facade finishing from aerated concrete and surface with a layer of reinforced leveling coating

The easiest way to apply a plaster mixture on bricks and on aerated concrete blocks. In addition to standard actions for leveling and applying adhesive soil, there are no preparation of walls. Additional work will be necessary when using thin layer material. In this case, it is necessary to treat the walls with a roller with a staining color of the future facade plaster.

Step-by-step process manual application It is as follows:

- Dry stucco for outdoor work is diluted with water in required proportions And as it should be stirred. The mixture is completely ready 10-15 minutes after stagnation.

- If necessary, the prepared amount is applied.

- The spatula is buried by mass and laid out on the lower edge of a wide cell.

- Kelma with a solution is applied to the wall almost perpendicularly, during the movement, reducing the angle to the tool almost to the parallel position.

- Kelma is almost without pressure on the wall, stretching the plaster mixture until the layer of the desired thickness is obtained.

- After performing a plot of approximately 1.5 square meters, a plastic grater is taken and the surface is maintained until the desired texture is obtained.

The actions of paragraphs 3.4, 5 and 6 are repeated until the building facade complete finishes. At the same time, it is better to work at once with squares, and not square meters. Thus, the coating will have a homogeneous texture. If it is not possible to separate the planned areas, the connecting seams need to be issued using painting tape.

Outdoor activation technique for mineral wool, polystyrene foam or penplex

These two material have a surface, difficult to finish, so in this case it is necessary to perform the preliminary installation of the facade mesh under the plaster. An error that is usually allowed during the reinforcement of insulation is to apply adhesive composition only on the membrane. The special composition of the glue with an area of \u200b\u200b1.5-2 square meters is correctly applied to the surface. The grid segment is taken into the hands and fixes in the corners with small thin sticks.

The process of plastering of outdoor frame walls on wood - OSB, chipboard and bruus, implies two types of work:

- The technology is identical to the above for finishing wall foam.

- The outer surface of the facades is closed with construction paper, reinforcing the protection of the base from various atmospheric manifestations. Such paper can be attached using a construction stapler.

It is important to consider that the woods are very hygroscopic, and the facade can "lead" from moisture, which is contained in the working mass. In order to avoid such consequences, it is necessary to apply a special hydrophobic soil and the impregnation of a tree to perform external work.

On top of the construction paper, a metal largest facade mesh for plastering is mounted. The grid can be fixed with the same stapler. The degree of adjustment of the web and its slope in relation to the outside of the facade depends on its evenness. In this case, the plaster layer is made quite thick, so the profile limiter from aluminum is fastened to the lower edge of the grid. The first layer of the outer reinforcing grid should almost hide the grid under his way. After drying, the second leveling layer is applied to the facade. Works for finishing finishes are performed according to the method described for gas-silicate concrete.

Calculation of the flow rate of the mixture for decorative plastering of facades

External plaster consumption for one square meter Calculated with several factors: the fatality and type of base, the nature of the binder and the filler. On the packaging of working materials, the indicators are provided with the above parameters. On average, the figures of the material look like this:

- mineral plaster - 2.5-4 kilograms per square meter;

- silicone plaster - 2.53.9 kilograms per square meter;

- acrylic plaster - 1.5-3 kilograms per square meter.

It should be noted that to calculate the necessary working material it is required to add 5 percent of the result obtained on working loss. Thus, it does not have to reach the plaster mix, delaying the work, and the parties of the material will not differ in color.

A wide cell is taken in the hands of 30 centimeters long and it is carried out on the grid with a small pressure in different directions. In this case, the adhesive composition appears outside, practically hiding the reinforcing membrane under him. The edges of the plaster mesh of the facade hanging down on the basement is flexing down and is lined with the same composition. To handle the bend, it is better to apply a spatula, which has a surface complex in a triangle. Thus pass on all the walls of the building. When the glue dries, it is applied again, but on top of the grid.

In addition to the above-described method, for calculating the volume of consumable material, you can find a lot of special calculators on the Internet, allowing more accurate calculation of the amount of bag for any type of decorative facade plaster.

Various technologies for applying facade decorative plaster

Textual varieties for the external use of decorative plaster are quite limited, which is associated with the peculiarities of their operation, namely the exposure to aggressive ambient. One way or another, by combining various textures and colors, you can find out which texture will be most common with the common style of the house.

To fulfill work, medium and large spatulas will be required, as well as the average and large celma. Works are performed in the following sequence:

- Small spattela material impose on a large and applied to the wall. Movements are made from bottom to top from the angle.

- The mixture after applying is smoothed.

- When it grab, namely, 5-10 minutes later, depending on the humidity and temperature, the formation of the image with plastic cells is performed. The drawing can have vertical and horizontal lines or at an angle in the form of "rain".

- After 40-50 minutes, when the processed area is completely dry, it is possible to walk along the outer layer of a shallow grater or a pure plastic cell.

Plaster with the effect of "fur coat" is the most technological type of facade plaster. There are several methods for mechanized applying a facing mixture. On a pre-prepared surface of the walls, a mixture can be applied using a special mechanical device "Charmanka" or a pneumochloric device. The easiest way to apply "fur coats" is the use of already ready-made outer mixtures, which are designed to apply a roller. One of the varieties of "fur coats" is the texture of "lamb", which refers to the outer peasor facade plaster. It characterizes a more rounded surface relief. It is also released in the ready-to-work mixtures and apply a spatula. Another embodiment is the "crocodile" or "rubbing fur coat", which is a conventional mixture of "fur coats" with the presence of fine-forming quartz sand up to 1 millimeter, which is peers outdoor surface.

Mosaic facade plaster is an acrylic knitting and multicolored marble crumb with a shallow fraction to 1 millimeter. Such an outdoor decorative plaster For the facades, they are applied to the surface prepared in advance with a cell or a wide spatula from the bottom up. The advantage of such a finish is that it does not require subsequent processing. High resistance to humidity and mechanical damage make it ideal in order to cover the grounds for the facades.

Conclusion

After the surface of the surface is ready, it is desirable to stock up with a small number of plaster for the future on the event that it is necessary to cut the sections on which defects from physical contact with any objects will appear. Caring for the facade of the house, finished decorative plaster, simple, you just need to periodically wipe it with a dry cloth from dirt and dust. You can also use compressed air and blew the surface. This cleaning will be much more efficient. This is probably all that is worth considering during the operation of decorative facade plaster.

Decorative plaster for facing the facade will give the possibility of transformation external view building. Such a coating does not have drawbacks as in the coatings of a spike view, as it is moisture-resistant, durable and durable finishing material. It is possible to qualitatively to apply facade plaster with their own hands, without even having a lot of facing work. At the same time, the main thing is to clearly observe the order of the process and the technology of forming a decorative plastering layer.