How to glue the cellophan to concrete on the street. How and how to glue a foam to concrete to increase its thermal insulation qualities. Properties and methods for using different types of glue.

If concrete buildings have long been famous for their fortress and durability, then thermal insulation properties of them, unfortunately, low. The lists of foam solid and industrial designs are solved easily and efficiently this problem. But what kind of difficulty - you need to know exactly what can be glued to the foam to concrete, because this material is afraid of solvents, gasoline or acetone. Here we will look at the best adhesives that are used in assembly work with this excellent material.

Competent internal contacts have correct solution And they are responsible for each issue in engineering engineering. Intensive training seminars for fasteners and glue help users in each industry learn about fixing systems and develop individual solutions for many problems arising in everyday practical work.

Users will also find help and convincing examples on the Internet. Fisher offers practically "all of one source"! And if the Internet or advice on site will not be available at any time, the challenge of the technical hotline will perform this work. Our hotline users have an open ear for each customer request and always have a solution at hand.

How to glue foam to concrete?

- Cleaning mixture of dry powder. There are special adhesives for polystyrene foam slabs (PPS moment, DOBS therm Fix, adhesive for the foam of AnsergLob BCX 39 and others). Also suitable for foam plastic The facade glue and adhesive tiles from ceramics. You will need an additional tool - drill, nozzle, spatulas, buckets. The operating time here is somewhat limited, it does not exceed 2 hours, after which the solution becomes viscous. It is not recommended to dilute it with liquid.

- Silicone sealants or liquid nails. These adhesives are supplied in tubes, for working with mounting guns. They strongly quickly (about 30 minutes), have a good heat resistance and moisture resistance. Due to the fact that the sealant includes harmful components, you will have to work in gloves. Suitable this method For exceptionally smooth surfaces.

- Glue-foam in cylinders. You can use Ceresit CT 84, Insta Stik adhesive for foam.

- Montagefix-St. other. Additional tools with this method - a mounting gun and a special flushing-cleaner. Considering all the ways how to glue the foam to the ceiling, one can state that this method is almost perfect. The cylinder of high-quality foam will replace the bag of glue, and it is easier to work with it. In addition, it will exceed all the gaps and joints, ensuring better thermal insulation. One disadvantage of foam - the value of the material is higher than in powder compositions.

Almost all listed methods than to glue the foam to concrete to the ceiling can be used in our business. The difference is here in the cost and convenience of work. The only condition is fixed for the reliability of the lips of the umbrellas with dowels, and the gaps and joints arising with adhesive compositions. The reinforcing grid is applied, which is attached to a special solution, and only then the finish

Properties and methods of applying different types of glue

Wide applications for adhesives. This electronic applications adviser lists suitable products for each material - quickly and securely. There are fastening adhesives that are suitable for various materials and scenarios, but no one can do anything. The glue is placed on the floor, on the wall, on the ceiling or simply on another object, depending on whether it is glued, for example, in raw rooms or depending on the substrate, texture or weight of the riveted part other problems. Therefore, you should always think well before buying fasteners that it should do.

Polyfoam is used as a heater, since its thermal insulation properties are higher than that natural materialsand cold buildings in which it is used mainly from concrete. Often, polystyrene foam is required to attach to surfaces where it is impractical to collect a tough crate (walls, ceiling, facades). In such situations, the attachment of sheets of material is carried out in various ways and adhesive compositions. Right technological solutions facilitate work. So, what to glue a foam to concrete?

Below are the most important adhesive properties and are explained in brief. Materials and substrates currently exist mounting adhesives for almost all materials. For subsoil, they are stable, dry and do not contain dust and fat. If you know before purchasing, for example, that the content in the room intended for you indoors on the table at the table will not be completely absorbed, and you must put something in a wet room, for example, in the bathroom or near the garage, you must make sure that glue "is suitable for inside and outside."

Adhesives that can be used in the room should be odorless and without solvents. If you use pure inner adhesives in the outer zone or in the bathroom, where they are subject to strong temperature fluctuations, weather effects, or just moisture, can no longer be guaranteed forever good grip.

Optimally use with foam special adhesive in powder form. You can also use adhesive compositions for ceramic tileFacades (frost-resistant). Their base is cement with the addition of binding polymers. Glue before use is subject to dilution warm water. Such compositions are securely connected with concrete, moisture-resistant, do not react to temperature differences, serve for a long time.

The power and force of the clutch. If the engaging item has a high weight, high instantaneous adhesion or immediate force is necessary. If it is too little to be glueding the object must be maintained or secured to prevent its slipping or drop. Often you can find information about the direct strength of more than 50 or 100 kilograms on square meter. Some strong fastening adhesives even have a direct clutch force of 200 kg per square meter, and only after that support is required.

The term "hand force" is often used, which describes the time required for the use of shift force 0, 1 Newton per square millimeter of glue surface in minutes to separate the adhesion bond. If the strength of the hand should be achieved after 30 minutes, at least one of the adhesive surfaces should also be absorbent or porous. Of course, the high target force is also desirable. This does not mean, however, that the glue itself becomes solid, since some remain elastic even after reaching their final strength.

Restriction - adhesive compositions are used at positive air temperatures. The kneading is better to carry out a drill with a nozzle so that no compelling occurred. After sludge within 5 hours, the mixture is re-stirred. Then for 2 hours the glue must be used. The fastening mixture is applied to the insulation material. The slab should be glued by clamping to the surface and hold in this position for several minutes.

They can also be waterproof, resistant to weathering, aging and chemical impact. For example, if you want to stick to the substrate, which becomes very warm, the temperature resistance is especially important. Most assembly adhesives can be adjusted, which means that after applying and gluing, the correction of the position of the workpiece is still possible within a few minutes. Some mounting adhesives can also be used as sealants to insert into connections.

This is usually constantly elastic and non-subsidizing adhesives. Cement glue for laying ceramic tiles, stone, marble, granite, slate, artificial stone, placing various coatings on difficult to binder surfaces. It significantly surpasses the properties of adhesive cements, dries faster, has a greater mechanical strengthIt has waterproof properties, its use reduces the risk of spots due to humidity and risk of fading. Its use allows you to apply on ceramic surfaces both on the walls and on the floors for the subsequent use of cracks that align the pastes, cement glue, etc. It is very suitable as a connecting bridge in sidewalks, because it does not have a clutch. Adhesive white powder, which is mixed with water, is very effective for laying grilles and balustrades from cement and ceramics. Apply a spatula with a thickness of 2 to 5 mm. The surface of the laying should be clean, without dust, fats, oils, and coarse. Prices in accordance with the amount of order and term. Prices in accordance with the amount of order. It is not suitable for areas where water can be constantly or for a long period. Fuzzy use in the interiors and exterior. The color is super white, to relieve grout. For internal and outdoor use. Heated floors. It has high adhesion, the ability to deformation is suitable for facades, large surface coatings, marble, ceramics, stone, granite, small and large format, absorbent and not absorbing, drywall panels, outdoor heating, indoors or outdoors. Apply the brush on both sides of the elements glued. This glue suitable for the manufacture of anchors, connections between materials of the same or other type, etc. In this case, no mold is required, since the mixture is thixotropic. It is also ideal for gluing concrete bodies, cured to each other or to metal surfaces. To glue the tiles on balconies and terraces, patio, kitchens, bathrooms and other surfaces subject to water. Also as an elastic glue for placing parquet and all types of wooden surfaces. It has impenetrable properties, breathable and together with insulation forms a non-combustible system. It is used on brick supports or concrete blocks acting as plaster and glue.

- Adhesive powder for placing stone plates, floors, walls, facades.

- The colors of the white and gray binder bridge for applying complex adhesion to support.

To eliminate the formation of the air traffic under it. After installing the stove in the interval 2 - 3 minutes there is an opportunity to adjust its position on the surface. The period of final frost is the 3rd day. The method of applying adhesive depends on the height of the irregularity drops on the surface. When they are within 50 mm, the composition is applied by wide barbars (passes for air output).

Metal may be difficult to attach to other surfaces. It has a soft texture that can resist attempts to glue it to the walls. With heat, it easily expands and shrinks, which makes fasteners and clamps less useful than wooden or other materials. However, if you want to fix the metal on one of your walls, you still have viable options.

Most adhesives have problems with metal: either adhesive relationship is not durable enough, or the conducting properties of the metal prevent glue strength. However, cyanoacrylate adhesives can be useful for binding small amounts of metal with walls. Due to its high-speed properties, they are often referred to as instant glue or super glue. Keep your metal items small, and cyanoacrylate glue can cope with this task.

If the deformation drops are up to 15 mm, the substance is placed in intermittent stripes with a protective indentation of 20 mm from the edges of the plate. Some glue is applied to the middle of the square. When the concrete surface is almost smooth (the difference of heights of about 3 mm), uses a toothed spatula for laying glue on it, so as to cover it all. Surplus squeezed from under the plates are removed by a moistened napkin. Adhesive compositions May be ready to use.

Application of mounting foam

When it comes to metal structures, metal parts must often be attached to another metal design, such as metal window sills around the window or metal frame around the door. For these projects in the metal construction, finishing nails are used, nails, which are intended for accurate installation in pre-made grooves in a metal material. Workers sometimes fix the wooden frame to with the proper clutch with the nails.

Magnets and screws are options if you want to hang a metal object of art, metal shelves or similar objects. In some cases, you can install a bolt or block on a wall that is placed for storing a small, but powerful magnet to which you can apply metallic design. Fastening bolts or bolts can also be used with bolts, dried directly in racks.

Bituminous glue has hydrophobic properties, frost-resistant, combustible. It needs heating to 20 degrees at a temperature of about 0 degrees. It is applied with a toothed spatula, provides a clutch after 20 minutes. Bitumen-latex emulsion mastic before applying does not heal, resistant to low temperatures, can be laid on a wet concrete surface. From 3 hours until one day.

Powerful fasteners and tips may be required if you are creating metal to solids such as concrete. Concrete blocks are designed to expand outside in concrete, blocking and preventing the fastener movement. This is necessary when metal objects are screwed to concrete walls, as they can wear out and collapse over time.

What resistance? What is the answer of the system for possible earthquakes? Before building it is important that there is a constructive design that guarantees the security of buildings in the case of a seismic event. What is the size of the film: width-thickness? The weight of the 22-mm blade is 75 kg. For 25 mm, weight is 88 kg.

Another alternative is the adhesive dense rubber-based liquid (dimethylpolyasiloxane), vulcanized in air per day with the formation of strong compounds. The temperature range of its vulcanization is from minus 60 to plus 300 degrees.

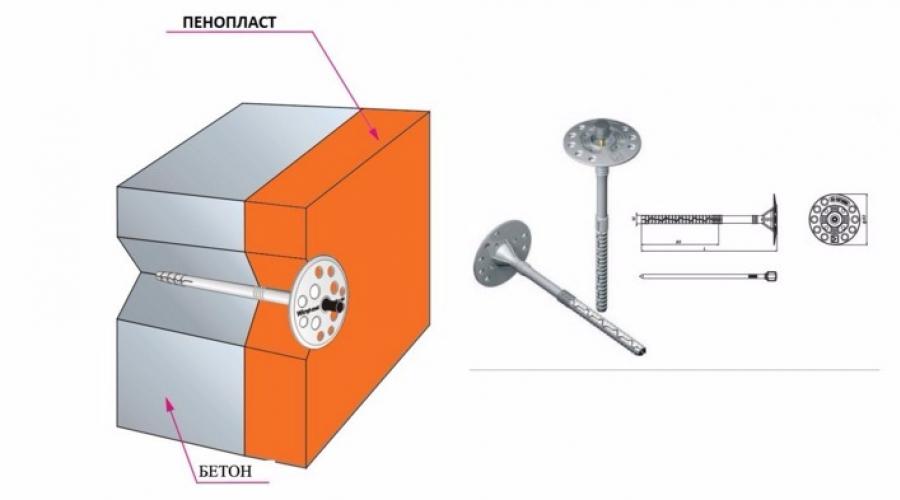

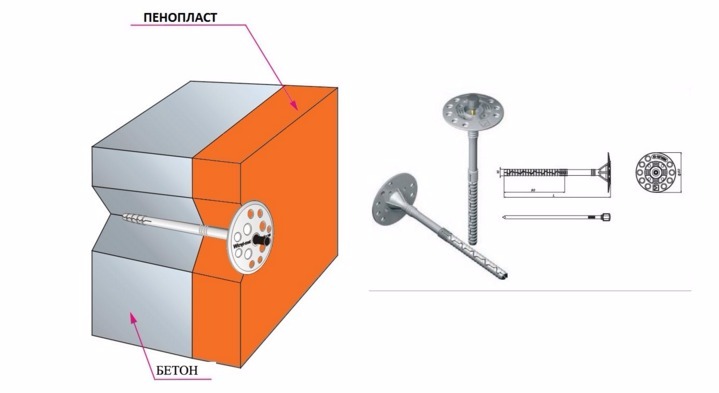

Using dowels

Foam fasteners with dowels.

Foam fasteners with dowels. Simple, inexpensive, operational and durable delicious method of fastening polystyrene, but requiring the use of perforator and need quantity umbrella dowels. Their length is selected sufficient for reliable mounting plates to a concrete basis (taking into account the thickness of the sheets). On the purified level surface, the lower start level is set, from which the installation begins.

Is the mezzanine leaf fire-resistant? What is the machine block? Is there a sheet of prystone reveal and is reduced? The main component of the flasp sheet is the cement in which it exhibits constructive movements on temperature and moisture changes.

In addition to non-angry against wood and deterioration to the beginning. What is the guarantee for the product and what does it cover? Can the reference design be welded? Metallic structure of mezzanine can be welded. Maximum distance between supports? Minimum amount of supports?

Always make sure that the mezzanine sheet is set at least 3 supports to ensure the strength of the sheet. How is the structure of the mezzanine tied to the walls? If concrete walls or walls on which mezzanine is installed, should ensure that levels are installed steel or angular plates on existing wall For mounting on structures from steel or wooden mezzanine. Threaded anchors or welding elements, such as pins and steel plates, can be used.

Each sheet is fastened with three dowels: one - in the middle and two - in the corners, so that their "umbrellas" pressed the angles of adjacent plates. Between the sheets, a gap of 3 mm is a deformation-temperature seam, eliminating the mutual deformation of the plates at daily and seasonal change of temperature and humidity. Sealant fit in the seam.

Another alternative way to glue polystyrene sheets. Suitable exclusively for smooth concrete surfaces. The proposal of liquid nails is extensive, therefore it is advisable to familiarize themselves with their purpose, the conditions for use and operation specified on the package. The compositions are created for various pairs of glued materials, including for a pair of polystyrene foam - concrete. This product is a polymeric pasta composition, which added components that improve adhesive properties.

Fastening with liquid nails.

Fastening with liquid nails. Due to this, liquid nails are stronger powder adhesives, they are frozen even with high humidity. However, there is a significant minus - the compositions of poisonous, so you should work in gloves. Such adhesives are fushed into oblong tubes that are inserted into. The advantages of their use include:

- the highest strength of the compound of materials;

- heat resistance;

- small technological flow;

- full dumping junction during the day;

- frost resistance;

- efficiency and ease of installation;

- lack of smells I. a short time Grapping (from 20 to 40 minutes).

The latter increases the labor-intensity of the work when the plates have to be attached to the ceiling (equipped, patience and skills). The composition will firmly glue polystyrene foam, when the surface of the concrete is aligned, cleaned and sucked. The substance, extruded from the tube, is located on the foam in a small volume at several points, and not on the entire area of \u200b\u200bthe sheet, as, for example, in the case of applying a mounting foam. It is necessary to glue the plate, providing clamp over the entire surface for a long time for a long time so that there is a grasp of liquid nails. Then the seams between the sheets are processed by mounting foam (sealant).

Blind with foam

Foam-adhesive for foam.

Foam-adhesive for foam. Print polystyrene foam on a flat concrete surface can be special glue-foam. This requires a little time. This method is relatively inexpensive. At the same time, the material can be glued to the usual mounting foam. However, this will increase the work time, since it will have to press the plates to the surface for a long time.

If this is not done, due to an increase in the volume of foam, the sheets swell and rise above the surface, and the seams will disperse. Before using glue-foam, make sure that the contents of the tube are intended for foam (and not for foam concrete) and find out the conditions of use. The use of special is possible even without priming, it suffices to clean the concrete surface from pollution and moisten it for better clutch.

The advantages of this composition are:

- acceptable adhesion;

- the ability to glue the slabs at low temperatures inside and outside buildings;

- no smells;

- moisture resistance;

- the ability to make long interruptions in the installation;

- frost resistance;

- lack of shrinkage;

- biological resistance;

- safety (fire, chemical);

- ease of use.

The minuses of this substance are that the foam needs protection against UV rays, a washing of the mounting "gun" is required during long breaks in operation, as well as the clutch force (holding ability) with smooth concrete surfaces weakened.

Care should also be taken to make the composition of the mucous eye. Special foam is refilled in standard cylinders filled with polyurethane composition. Before use, it is installed in the mounting "gun", which adjusts the output of the substance. The spray can shake the spray, it can be heated in warm water. The temperature of the application of the cylinder is approximately plus 20 degrees.

Foam can be placed on concrete or foam, shelting at least 40% of the area under the sheet. The drawings of its application are stripes around the perimeter of the plates or in a checker order (with increments from the edges), the center is extruded zigzag (it is necessary when the surface is not smooth). It is then given a little time to absorb the mixture into the surface to improve the clutch. Speaking foam is cleaned. This composition propumes the seams between the sheets of the material.

The polystyrene foam is not hygroscopic, so free water should not be a component of glue, otherwise the plates will stop the carrier surface. You should also exclude their contact with adhesives containing solvents (gasoline, acetone), which destroy the structure of the material. Appointment of adhesive compositions and conditions for their application should be found out from the manufacturer's recommendations on the package.

Works begin with a high adhesion of concrete surfaces (purification from dust, building materials, fatty spots, priming) with adhesive composition applied to the insulation plates. Before their onset of deep defects, the cracks are expanded and closed sand-cement mortar, then the surface is rejected again.

The sheets of polystyrene are glued from the bottom up from the level line. Adhesive compositions are applied in such a way as to avoid the formation of air plugs under the surface of the sheets. The joints between the plates are not specifically skled, as they are subsequently filled with sealant.

In some cases (due to a long time of setting mixtures), it is necessary to force the plates with pressed on the entire plane to the surface of the concrete while the mixture is grabbed. All heat-stitch after soaring glue, foam or liquid nails can be additionally inspired by dowels. Their amount on the sheet may be greater than five (center and 4 corners), if it has a significant area.

conclusions

Polystyrene foam plates - efficient light heat insulation materialnot requiring clamps to install outside and indoors.

The durability of attachment to concrete is provided right choices and appointment adhesive mixes and dowels.