Aerated concrete all about him. What advantages and disadvantages are noted at a gas-concrete house. Mechanical strength and bearing power of aerated concrete

They have aerated concrete blocks limitations? Recently, this question interests many. The material is becoming increasingly popular, and the demand for it grows in geometric progression. On the modern building market, the product from aerated concrete is more confidently occupied by leading positions. What kind of pluses and minuses have the properties of aerated concrete blocks, in what specific technological processes By construction, their use is optimal, and in which there is an alternative. How not to overpay for the material and work, and not repent of the deed late.

What is autoclave aerated concrete?

Building material that adds value for projects

Most of the heat loss taking place in the buildings takes place on the external walls. Construction of the house - the task. With good planning and preparing your project succeeds. What is the difference between compact homes and innovative houses. A special qualitative feature is a solid design - from the basement to the roof. Smart builders require cost-effective solutions with high cost.A comprehensive system helps to control the cost of construction, without sacrificing quality. Each house is constantly adapted to your needs and is equipped with modern home and heating technologies. Spacious single-family houses, well-thought-out two-quarters, practical compact homes, innovative houses that create a tendency, silent bungalows or gorgeous townhouses - Our series of houses offers correct solution For all needs. Our special power is to plan your dream home planning.

Easy and size

Block D500 with dimensions of 30x25x60 cm Weigh about 30 kg, for masonry the same volume will require 22 bricks, the weight of which is twice as much, about 80 kg. Thanks to large dimensions and light weight, construction steps are carried out faster than from other materials. Such assembly works can even perform one person. These characteristics reduce the cost of transportation and costs of the foundation. High accuracy and large block sizes allow you to erect walls with minimal deviations and high speed. Accordingly, the costs of external decoration are reduced.

Are there any cost of free planning?

You decide whether we will develop your ideas and wishes together on a clean sheet of paper or we will focus on the template. At this stage of searching, you will be accompanied professionally. Your project of your dream home is fully adapted according to your wishes and ideas. With all architectural issues you will be competently advised: what style do you prefer? Rather, regional and traditional or deliberately different?

For all of the freedom, we always maintain expediency, such as building rates, technically simple implementation or economic efficiency and energy efficiency. Together with you, we will develop a plan of how your personal project will develop and where you make a great contribution. In the end, your individual house will become yours - a reliable basis for your future. First we perform the definition of 360 ° demand. At the same time, we bring your wishes to such an extent and consider what skills and resources you can or want to enter your dream project.

Thermal conductivity

The cellular structure creates a thermal insulation effect. Also, this material is able to maintain heat, and in the summer season - a pleasant coolness. It should be noted here that the thermal conductivity of the gas-concrete block with a thickness of 375 mm is equivalent to a brick laying with more than half the meter. Due to the presence of gas (air) products, products have high specific thermal resistance, which provides good heat insulating properties Foot concrete blocks. This statement is true when the cavities are really filled with gas or air, i.e. When the material is well dried. The picture changes dramatically with high humidity.

How long is it required of planning before starting construction?

We distinguish between construction and direct construction costs. As part of our planning for your dream home, we will provide you with relevant costs about expenses. After discussing the rough planning with you and the conclusion of the contract, your dream house is included in detailed planning. Your home will be architectural and static planning, counting and fill everything required documents for construction. Here you can also contact our architect who implements your wishes in the plans.

Based on the size of the specific thermal resistance of the aerated concrete, to ensure the desired thermal insulation, the normalized (recommended) wall thickness of the fuel-concrete blocks is 375-380 mm, which is considered the advantage of this material compared to others.

What does detailed planning look like?

This time may change and depends on your wishes. He has a well-proven network of regional experts who work quickly, practically and economically efficiently, including, for example, engineers-designers and engineering specialists.

What is part of the price of the house?

Our architect prepares all formalities for the authorities, in particular, for use in construction. Sound financing is the basis of your construction project. Thus, you have the full cost of your home. The price of the house includes all the costs of building your home - including a basement, if such is provided. To calculate the price of the house, we begin with a clearly defined and specified design description design.

However, in reality, even under the influence of moisture with the normalized construction standards The magnitude of moisture absorption (12%) thermal resistance is reduced by 30-32%.

In addition, when laying walls from blocks is usually common cement mortarIt reduces thermal resistance by another 25% (with the use of special expensive adhesive compositions - up to 10%). Thus, to ensure equal conditions of thermal protection in real conditions, it is necessary to increase the thickness of the wall by 55-57%. In areas with high humidity, water absorption can exceed 30%, which further increases the required wall thickness. These circumstances make dubious advantages of aerated concrete in terms of thermal protection.

In periods of low interest rates, there are numerous opaque proposals, but not only favorable interest rates are important, but also the concept of agreed repayment. If necessary, he gladly establishes contact and takes care of the verification of subsidies. Directly with us, your regional partner for configuration. After we find out all your questions, we will conclude a sale agreement. This sale and purchase agreement also contains full description Deliveries and maintenance.

Our houses are planned from the top edge of the slab overlap. Similarly, the cost of earthworks is not included in the purchase price. Do you have recommendations as to which professions can be provided within the company, and which are not. It depends on your technical skills and resources. How much do you want and you can contribute to your work, you must decide yourself. We are pleased to provide you with recommendations. Our system is designed in such a way that almost everyone can easily create their own shell independently with professional control.

With the arrival of winter, it turns out that the walls from aerated concrete are blown quite strongly. Disadvantages can be eliminated using a special thin-layer adhesive solution (3-5 mm) for foam concrete. But in practice, it is rarely used, since working with it requires certain mason skills and costs more.

Gasilicate blocks are not much cheaper than ordinary bricks, and attracting highly qualified specialists to the construction makes doubt on the appropriateness of the application of this material. In addition, the environmental purity of this glue still remains in question. Gasilicate blocks, laid using cement-sandy solution, worsen the heat resistance of masonry by 25%.

To do this, we optimized the concept of organized self-employment over the years. Nowadays, builders can see how easy it is. Thanks to the payment system associated with the relevant transactions, you are paying in stages. The first contribution when signing the contract. Subsequently, gradually in accordance with the construction of construction and material requirements is paid.

Do you also support support in the construction of the slab overlapping and during excavations?

Excavations and the creation of the bottom plate are not part of the package of the kit. Thus, you are responsible for the excavation and the creation of the bottom plate. However, here we have a competent network with many contacts and recommendations that we will gladly give you.

The properties of aerated concrete blocks associated with a small inertia of heating are not always positively. In part, the problem can be compensated by the use of internal partitions, using panel or monolithic overlaps from concrete. But because of the large wall area, the difference between the brick or concrete house (with effective insulation) It will still be essential.

We will gladly support you in the choice of possible companies. Detailed description Delivery and maintenance you get in the context of our sale contract. Providing all planning services: the concept of architecture, space and energy, detailed planning, the use of buildings, calculation of the cost of construction, construction schedule. Supervision at the construction site: the creation of the first stone series, help with questions, assistance in the installation of roofing and ceiling panels, etc. There are close cooperation with masters from the region, which ensure that your dream house will be completed.

Houses from aerated concrete have a small thermal inertia (stone in it is 5-15%). The structure of frosty weather warms up quickly quickly - in 1.5-2 hours the air temperature can be raised from 0 to + 20 ° C. Of course, this characterizes aerated concrete on the positive side, but the problem is that the house is also quick and cooled.

Using a special adhesive composition instead of the usual cement mix Minimizes the effect of cold bridges. This reduces heat loss from 25% to 8-10%. The amount of glue used is significantly less, up to 5 times, compared with cement mortar.

Frost resistance

When compliance with technology at all stages of construction, this material is able to withstand more than 25 frosting / thawing cycles.

High frost resistance of aerated concrete blocks in facade walls is not confirmed in practice. This is largely due to water absorption and accumulation of water in the pores of the material. At the same time, the water at low temperatures in the cavities freezes, and, expanding, creates an internal voltage in blocks. The frost resistance of the structural-thermal insulating aerated concrete Mark D500 is only 25 cycles (no less than 50 cycles). This limits the use of aerated concrete for facade walls or requires additional protection. This variety is recommended for use in construction in climatic conditions, not exceeding -18 ° C.

The characteristic of the frost resistance indicates how many times the design of aerated concrete blocks can withstand freezing-thawing without significant damage and deformations. When the indicator is reached in 25 cycles, the D500, the D500 is starting to lose in the strength and other characteristics. Significant frost resistance can be achieved when using more dense blocks. But it should be remembered that they are no longer insulating, but structural, and, therefore, increase the thickness of the walls.

Parry permeability and gas permeability

The advantage of the material is considered high vapor and gas permeability, which makes it possible to breathe walls. But these properties of aerated concrete blocks have a negative side. High air permeability is good with warm and normal temperatureBut when cold, and especially with windy, weather penetration into the cold air is noticeably reduced the heat protection of aerated concrete. Cold "draft" runs right through the facade wall.

The negative side of vapor permeability affects the use of aerated concrete in the construction of baths, saunas. In this case, there is a moistened couple, which passing through porous materialcauses water absorption in the pores. To prevent the accumulation of water in the thickness of the aerated concrete, a pair-protective barrier should be made in the form of primer, plaster or cladding. This, firstly, leads to the rise in the cost of construction; Secondly, eliminates the implementation of one of the most important advantages of aerated concrete - "weathered" pair of rooms.

Soundproofing

The well-known property of materials is at a lesser density and large volume, possess high sound insulation qualities. Aerated concrete has exactly such a structure. Received as a result of a chemical reaction between powder aluminum and lime, the lightweight cell of the aerated concrete is filled with air bubbles. Such a composition of the material will be a good obstacle to the sound wave.

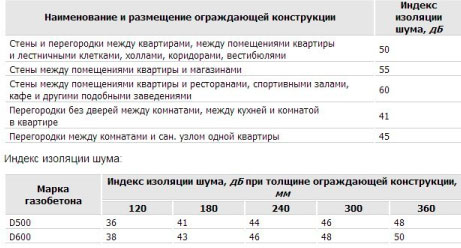

Sound insulation properties of aerated concrete blocks

Noise absorption index for aerated concrete blocks Average 43-4 dB. The rate for residential premises, derived from the properties of building materials, is equal to 41 dB.

You can increase sound insulation properties if you increase the gap between the layers of blocks. This goal can be achieved by applying the appropriate finishing materials. The walls plastered on both sides are able to provide sound insulation up to 50 dB! Eliminate foreign sounds will help a combination of this building material with a foam finish and other foamed materials.

Moisture permeability and water absorption of aerated concrete

Disadvantages of the blocks of aerated concrete are especially manifested in the cold season with high humidity; And that is, their reasons.

One of the main flaws of aerated concrete is increased moisture permeability and water absorption. This disadvantage is determined by the presence of pores in the thickness of the material. Water, penetrating the inside of aerated concrete, is absorbed in the cavities and accumulates. Even the established building standards allow moisture accumulation to 12% of the mass of the material. Drying due to the insulance of pores is slow. High water absorption affects all the basic properties of aerated concrete blocks, significantly worsening them.

Aerated concrete absorbs water perfectly

Aerated concrete is a strong moisture absorbent and absorb it from the surrounding space. Therefore, a professionally made and high-quality steam barrier is simply obligatory. For this wall need to be treated with primer deep penetration And only after that proceeding to the putty of the inner surfaces.

If the project of the house does not provide for the decoration of external walls with decorative finishing materialsThe facade surface must be hydrophized. Moreover, repeating this manipulation is necessary once in 2-3 years. For these purposes, manufacturers recommend using only gypsum plaster, since cement-sand solutions They have the property crack and peel.

Mechanical strength and bearing power of aerated concrete

When using aerated concrete blocks, builders are faced with a dilemma. To ensure high mechanical strength, it is necessary to choose a high-tech material; At the same time in aerated concrete elevated density The thermal insulation properties are noticeably reduced. Such an alternative leads to the fact that a density of 400-500 kg / m³ is usually used, which cannot provide high mechanical strength.

Mechanical strength of the gas-concrete block

When building walls from aerated concrete blocks, a number of disadvantages of the material in terms of ensuring mechanical strength are manifested. So, when erecting overlaps, their slabs or beams are cut and crumble aerated concrete, which requires additional elements: a special reinforced concrete reinforcing belt or support pillow. This leads to the emergence of "cold bridges" and significantly reduces thermal protection. In addition, the need for complex additional elements leads to the rise in the cost of construction.

The use of a density density of less than 500 kg / m³ cannot provide the necessary mechanical resistance to compression.

The fuel-concrete blocks of such strength have brittleness, besides, you should add low resistance to bending. This practically limits the construction of up - the construction of structures above one-story unwanted.

Negative mechanical properties Aerated concrete blocks: insufficient bending resistance, i.e. Low elasticity. During operation, the foundation of any building is subjected to small shrinkages that calmly carry brick or wooden walls. Another thing is aerated concrete. After 1-2 years, microcracks appear on the blocks. After 3 years, such cracks are subjected to 25% of all aerated concrete blocks.

The appearance of microcracks does not lead to rapid destruction of the walls, but noticeably reduces their mechanical strength and can manifest itself in the future. It is especially dangerous to the fact that over time these cracks are expanding, and their number is growing. The increase in the foundation shrinkage leads to a serious crackling of aerated concrete.

All this leads to the need for the foundation to build massive basement semi-estates from ordinary concrete. For small residential buildings, such a foundation is simply not profitable economically.

Dangerous behavior and seams in the walls of aerated concrete blocks. Over time, the suture solution is noticeably cracking and departs from the surface of the blocks, even without shrinkage of the foundation. After 7-10 years, the blocks almost simply lie on each other under their weight. Significant cracking of the aerated concrete is noticed in places of passage of metallic reinforcement or column of the carrier frame without the impact of the deformations of the foundation.

The behavior of plasters made by aerated concrete blocks should also be attributed to the lack of aerated concrete application. On the plaster, cracks appear in a short time, as a rule, on the seams between the blocks. Such cracks occur both on cement and on gypsum plaster. Especially actively they arise when exposed to low temperatures outside the wall. It should be noted that the greater the frost on the street, the cracks are more indoors. Manufacturers recommend using plaster on a plaster basis, and it really has a high level of adhesion with a delicate surface. But with sharp thermal drops, such a wall immediately formed cracks, repeating masonry contours. These places need to strengthen the mounting grid, which additionally increases the cost of finishing works.

The design and heat-insulating brand D500 is designed for the construction of houses height up to the 3rd floor. Its bearing ability is enough to maintain the load of the entire design of the house and the slabs of the overlap. At this moment overlap one "But!". At the same time, in places of support plates of overlapping and other loaded elements, there is a need to build reinforced concrete armojois or ordinary brick masonrywhich are the bridges of the cold. Houses of greater floors from the gas silicate are not elevated, as the high density aerated concrete (D900-D1200) does not differ in good thermal insulation and increases the cost of construction.

Ease of processing and manufacturability of aerated concrete

You can give it any form using hand-made means, for example, hacksaws or saws. The block is easily cut, dried. Run the sticking, score a nail or to do the working hole under the outlet will not be difficult. But at the same time, the advantage of aerated concrete is strongly limited as manufacturability. Dowels and nails are really easily driven into the blocks, but due to the fragility of the material, they are also easily flying after clogging. This lack of aerated concrete manifests itself especially noticeable when using anchors or screws. Such fasteners are bad in blocks, which significantly complicates facing or strengthening masonry. This problem is solved only by the use of special fastening dowels and anchors with plastic capsules, which also leads to the rise in price.

Aerated concrete is easy to cut, stroke and drill

Ecology, biological resistance and fire safety

New technologies make it possible to produce this material from raw materials that do not excrete toxic substances. The indicator of the radioactive background 54 BK / g with a permissible in the housing construction of the norm in 370 BK / g. According to GOST 30108-94 * "Construction materials and products. Determination of the specific activity of natural radionuclides ":

It is not susceptible to burning, rotting, influence of insects. The raw material used in production has a mineral origin, in its properties - not fuel. Therefore, blocks are able to withstand the effect of open flame for 3 hours.

Environmental, biological and fireproof properties of aerated concrete blocks

Aerated concrete blocks are resistant to damage to various microorganisms, rodents and insects. Although a small green raid on it can still form, but only in case of constant moisturizing.

Let's summarize: parsing the minuses of aerated concrete

The main disadvantages of aerated concrete are susceptible to moisture and overestimated frost resistance. The hygroscopicity of concrete reduces the heat engineering properties of the aerated concrete blocks and leads to deformations that contribute to the appearance of finishing defects. It limits its use in areas with high humidity, in raw rooms, as well as in the construction of facades. To avoid this before finishing, the use of an expensive complex of measures to protect building materials from condensate is necessary.

The actual frost resistance of the material is significantly lower than the inventive values, which makes it impracticable to use aerated concrete for residential buildings in areas with a cold climate. A strong decrease in thermal resistance at moisture causes to increase the thickness of the walls, which reduces the benefits of aerated concrete compared to other building materials.

The flaws in the mechanical strength of the aerated concrete require the construction of expensive types of foundation and the use of special fasteners. Construction of houses with several floors is not allowed or requires special reinforcing operations. Overlay protective or decorative plaster Causes complication due to cracking.

Disadvantages of aerated concrete significantly limit its application during the construction of residential buildings and baths. At the same time, advantages allow it to be widely used when erecting household buildings, fences and other buildings.

With close consideration of the question of the stated low cost of aerated concrete and guaranteed durability, it turns out that these characteristics are significantly overestimated manufacturers.

When complying with the norms regarding the heating indicators, the laying of a thickness of 380 mm is insufficient. Ignoring standards leads to elevated energy consumption for heating and air conditioning. In order for the building to comply with all standards, the masonry thickness must be increased at least to 640 mm. In this case, the maximum thickness of the gasoblock is 500 mm.

Another disadvantage of aerated concrete masonry is the need to build a monolithic belt Fundamentwhose use leads to a significant increase construction work. Without such a foundation, the risk of shrinking deformations and the occurrence of massive cracks in the masonry increases significantly.

In the study of the facts described above, the conclusion suggests that such advantages of the properties of aerated concrete blocks, as high thermal insulation indicators and the carrying ability of flooring from aerated concrete, are significantly exaggerated and are exceptionally obsessive advertising. In defense of the gasilicate, I would like to say that at the moment there are no ideal building materials, and each of them has both its disadvantages and indisputable advantages. Although, for example, if you compare the properties of aerated concrete blocks of CO, then the last explicit advantage!

You can build your house from different wall materials: bricks, aerated concrete, wood. However, decide on right choices You can, only knowing the benefits of each building material. In this material, we will stop at the strengths and weaknesses of the aerated concrete, so that it is easier to weigh everything for and against.

Aerated concrete made from cement, lime and sand, simply process. And in order to build a house from gas blocks, it is not necessary to have jewelry skill at all. Houses from aerated concrete blocks are easy to separate, repair and rebuild, so the use of this building material is actively gaining popularity.

Where did the aerated concrete, or the variety of cellular concrete

Aerated concrete belongs to one of the varieties of cellular concrete, an artificial building material with a porous structure in the form of uniform pores, by 85% air filled with air or gas. Such a porous structure provides for cellular concrete several important features: low thermal conductivity, low weight and ease of processing. In the manufacture of aerated concrete, gas is distinguished during the chemical mutualization of the gas inverter used, which can act as an aluminum powder or pasta, with a solution from sand, water and a binder. In the process of producing foam concrete, poring occurs as a result of mixing the solution with a predetermined foam or with intense foaming of the mortar mixture containing the foaming agent.

In the store you can meet other types of cellular concrete. Depending on the use of the binder, such varieties of cellular concrete are distinguished: aerated concrete and foam concrete - on Portland cement, on SlagoporTland cement, on a mixture of cement and lime; Gasoslakobeton, Paintsylakobeton - on slag binder; Gasilicat, Penosilikat - on lime. By functional purpose Cellic concrete (according to DSTU B.2.7-45-96) are divided into thermal insulation density of 200-500 kg / m³, structural-heat insulating density 500-900 kg / m³ and structural density 1000-1200 kg / m³.

Advantages of aerated concrete:

low cost: aerated concrete is one of the cheapest building materials;

good thermal insulation: aerated concrete is well kept warm, which will reduce the cost of heating the premises, and in the summer to keep a pleasant chill in the house;

convenient in operation: with a depletion easy to work and hard to make mistakes. Large sizes, grippers, ridges, grooves and light weight blocks make it easy to mount, transport, cut and grind gas blocks;

parry permeability: the porous structure of cellular concrete provides a water vapor output from a heated home outward;

allows you to build single-layer outer walls without insulation;

it will quickly dry, thanks to vapor permeability. The main thing is not to cover the paint plaster, which does not let water;

safe for health, because it is made of natural raw materials.

Disadvantages of aerated concrete:

Despite a large list of strong qualities, aerated concrete has some weak parties, such as: fragility (with a small density), thermal conductivity, high absorption of moisture, has a low compressive strength (blocks with a low thermal conductivity coefficient). However, if you choose blocks with correct parameters For your home, you can build all kinds of walls from aerated concrete, including basements.

What can be built from aerated concrete blocks:

1) Partitions and fences. Blocks with such an appointment are easier by weight than blocks for bearing walls, have a width of 5-24 centimeters. Side faces can traditionally have a puzzle form, but the blocks are wider than 24 cm not equipped with grips, so it will be more difficult to transfer them.

2) external single-layer walls. This uses full-scale blocks wide from 30 to 48 cm, with a D350 density brand; D400; D500. The block length is 59.9 cm, 60 cm and 62.5 cm, height - 20 cm, 25 cm. The weight of such blocks is from 19.9 to 21.9 kg. Such blocks often have a puzzle structure of narrower vertical end sides. This allows them to be easy to dock during masonry on adhesive solution Without vertical seams. Blocks with such characteristics make it possible to build walls with heat transfer resistance of 2.67-3.31 m2.k / W corresponding to regulatory requirements.

3) Two-layer and three-layer outer walls, the internal bearing walls are put out of blocks with a thickness of 20 - 36.5 cm. There are blocks with puzzle ends, which are placed without vertical seams, and there are no blocks without a puzzle profile, so the masonry is performed with vertical seams. Such walls usually be insulated with polystyrene foam or mineral wool.

4) Tray blocks for jumpers have a U-shaped section. Their height - 19.9 - 24.9 cm, width - from 17.5 cm to 40 cm, length - from 49.9 to 59.9 cm; Density class - D400-500. These blocks are ready for reinforcing and filling with concrete, therefore, they perform the function of the formwork and the plating of the jumpers. Thanks to them, the walls will become homogeneous, which will make it easier for plaster and reduce the risk of cracking in the jumper area. When using these blocks in single-layer walls, it is necessary to lay a layer in the installation places heat insulating material Thick about 4 cm. Before filling out the blocks of concrete, be sure to install them on the board of the board - the depth of the blocks on the wall will be 20-25 cm. In addition, the U-blocks can be used as a formwork for pillars, including those that are used for Strengthening attic attic walls.

Aerated concrete: Choose gas blocks correctly

Correctly choose aerated concrete will allow knowledge of the basic parameters of this building material, such as: thermal conductivity, density, strength, sound insulation, fire resistance and vapor permeability. When buying, compare these indicators of the aerated concrete of different manufacturers - this will allow you to choose the most suitable aerated concrete for your home (Solbet, Ytong, H + H, Aeroc).

1) Thermal conductivity of aerated concrete is provided by air in the pores - it perfectly keeps heat inside the house. The coefficient of thermal conductivity (λ) of the cellular concrete is from 0.075 W / (mK) for a block with a density brand D350 and 0.25 W / (MK) - for the block of the D700 brand. The lower the coefficient of thermal conductivity, the warmer it will be in the house. However, it should be borne in mind that the manufacturers of aerated concrete determine the coefficients of the thermal conductivity of their products in different conditions. The most often practiced laboratory conditions, but the calculated coefficient is most close to the reality, typical of blocks in conditions of constant humidity.

2) the density of aerated concrete (the mass ratio to volume) is determined by such density marks: D300; D350; D400; D500; D600; D700; D800; D900; D1000; D1100; D1200 kg / m³. The higher this value, the more dense aerated concrete, and therefore, more durable, with good sound insulation and low thermal conductivity. The minimum density of concrete makes it less resistant to damage, but they are much easier by weight and easy to trim.

3) The strength of the aerated concrete depends on the density. How durable blocks from cellular concrete, indicates the compression storage stamp M with a digit indicating the average compression strength in kgf / cm2. As far as the quality of the material can fluctuate, shows the strength class (letter B with a digit denoting guaranteed strength in MPa). Standard DSTU b B.2.7? 45? 96 "Cellic concretes" sets such classes (stamps): B0.35 (M5); B0.5 (M7.5); B0.75 (M10); B1 (M15); B1.5 (M25); B2 (M25); B2.5 (M35); B3.5 (M50); B5 (M75); B7.5 (M100); B10 (M150); B12.5 (M150); B15 (M200). These are quite outdated characteristics, because in the range of leading manufacturers you can already meet gas blocks with higher indicators, for example, a density of 350-400 kg / m³.

4) Fire resistance. Mesh concrete is classified as non-combustible material. It was determined that the plaster partition from cellular concrete could withstand the fire for two hours.

5) Parry permeability is the property of concrete to quickly weathelate the accumulated moisture and remove water vapor from heated room.

6) Soundproofing aerated concrete can be checked according to the air noise insulation index, expressed in dB: the higher the index, the best sound insulation properties has a power concrete. And, of course, the thickness of the wall and more dense construction materialThe smaller the sound will penetrate through the walls of your home.

7) Dimensions of gas blocks. New aerated concrete blocks are made with a puzzle form of end faces. This allows you to make a masonry without filling vertical seams. And recently, manufacturers are increasingly making special captures in blocks, thanks to which the blocks are easier to carry.

according to Domodel.net