Properties of construction and finishing materials. Properties of building materials

Fire resistance

Heat capacity

Sound permeability

Fireproof

Elasticity

Sound conductivity

Relative density

Shock viscosity

Soundproofing

Open porosity

Chemical properties

Abrasion

Fire resistance limit

Physical properties

True density

Density

AlkhastyXt

Water resistance Building material -this is the ability of the material to maintain its design strength when saturated with water. The degree of reduction in the strength of the building material under the action of water is called the softening coefficient. Materials having a coefficient above 0.8 are considered waterproof and can be used in water or in places with high humidity. Water resistance building materials - A very important indicator for those materials that are used in water or in humid conditions. Some materials when saturated with water can increase their strength indicators, it is primarily due to the chemical interaction of components. For example, when saturated with water, cement can turn into a cement stone. The water resistance is characterized by the softening coefficient KP \u003d RB / RC, where RV is the strength of the material saturated with water, and Rc is the strength of the dry material. KP changes from 0 (reinforcing clay) to 1 (metals).

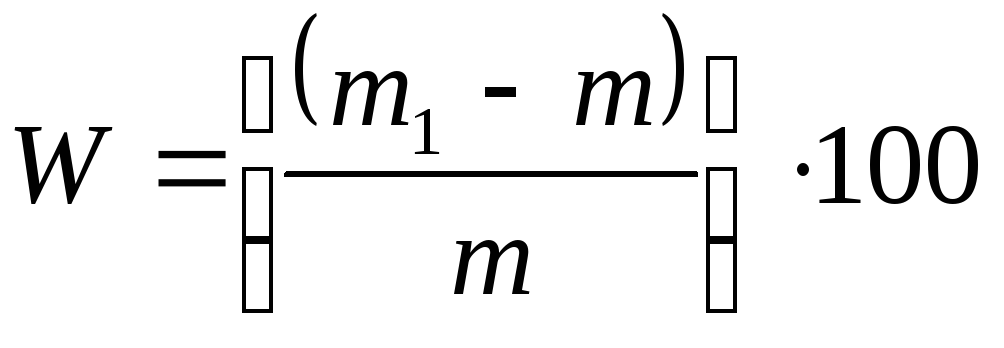

Water absorption of building material -this is the ability of the material to absorb and retain moisture. The water absorption is measured by the ratio of the volume or mass of the absorbent moisture to the volume or mass of the building material:

w M \u003d (M 2 -M 1) / M 1 * 100%,

w V \u003d M 2 -M 1 / V * 100%

Where

m 2 - mass of material in saturated water condition, kg;

M 1 - mass of material in a dry state, kg;

V - material volume in natural condition, m 3.

There are a lot of examples when moisture in the material is more than the material itself. This happens when specific gravity Material less water density.

Almost always excessive water absorption leads to excessive water in building materials, which leads to a change in very important qualities of building material, such as strength and thermal conductivity.

Moisture report Building material -this is the ability of the material to give moisture in the pores. For example, plaster solutions, giving an extra moisture, significantly change their indicators for strength, wall foam concrete blocks absorb moisture from solutions, and then give it to the atmosphere. The higher the humidity of the air and less temperature, the worse there is a moisture product. The moisture production is measured in the percentage of moisture given by the building material with the average air relative humidity of 60% and the temperature of +20 ° C.

Humidity Building material - The value characterized by the amount of water in the material. Almost always increased humidity of building materials adversely affects the quality. For example, an increase in the moisture content of some kinds of insulation is only a few percent, worsen their heat shielding properties. Wet foamclock or even brick significantly lose their performance by strength, etc. The humidity of building materials is measured by the ratio of the mass of water in the building material during the measurement period to the normative mass of the dry material.

Passenger Building material - This is the property of the material to pass water under pressure. The water permeability is measured by the amount of water in the course of one hour through the construction material of 1 square meter. m. and a thickness of 1 m at a constant pressure of 1MP. The water permeability of the building material is the greater, the more pores in its structure. Building materials that do not have pores, as well as materials that have closed pores, for example, special concrete belong to waterproof materials. The water permeability is characterized by the filtration coefficient of KF \u003d VV * A /, where Kf \u003d VV is the amount of water, m³ passing through the wall with an area of \u200b\u200bS \u003d 1 m², the thickness of A \u003d 1 m during T \u003d 1ch, with the difference in the hydrostatic pressure on the walls of the wall P1 - P2 \u003d 1 m of water. Art. Building materials in their waterproof are characterized by W2 brands; W4; W8; W10; W12. The lower the filtration coefficient of the KF, the higher the waterproof brand.

Air resistance of building materials -this is the ability of the material to withstand multiple saturation with water and drying out without significant changes in the physical condition of the building material. Different construction materials on different "transfer" multiple wetting and drying. Most often, this process causes deformation, loss of strength and as a result of a loss of bearing capacity building construction. To increase air resistance, building materials are coated with hydrophobic compositions or injected with hydrophobizers.

Gas Resistance of Building Materials -the property of the material to maintain its main characteristics in contact with the gases in the environment, such as, for example, hydrocarbon.

Gigroscopicity of building materials -the ability of materials to absorb water vapor from the air. There is a huge amount of building materials that are able to absorb a significant amount of water vapor. Such materials include: wood, foam concrete, heat insulation materials etc. Building materials with increased hygroscopicity in full saturation with water lose their properties, as well as can change geometric dimensions. Water-repellent protective compounds are used to protect building materials from saturation with water vapors.

Sound absorption of building materials -the ability of the material to absorb the sound or reduce its level when passing through the material. This ability of building materials primarily depends on the thickness, porosity of the material and the multi-layerness of the material. The more pores in the material, the higher its ability to absorb the sound. The sound absorption of building materials is made to evaluate the sound absorption coefficient. e. The ratio of energy absorbed by the material, to the total number of incident energy per unit of time. For the unit of sound absorption conditionally accept sound absorption of 1 m 2 open window. The sound absorption coefficient can vary in the range from 0 to 1. If sound absorption is 0, then the sound is completely reflected from the building material. If this coefficient is approaching 1, the sound is completely absorbed by the material. According to regulatory indicators, construction materials having a sound absorption coefficient of at least 0.4 at a frequency of 1000 Hz may relate to sound-absorbing materials. The coefficient of sound absorption is determined by the practical method in the acoustic pipe and is calculated by the formula: A (SV) \u003d E (LA) / E (PAD)

A (SV) - sound absorption coefficient;

E (weight) - absorbed sound wave;

E (Pad) - Falling sound wave;

Table. Comparative indicators of the coefficient of sound absorption of building materials

|

Name of building materials |

Sound absorption coefficient at 1000 Hz |

|

Wooden wall |

0,06-0,1 |

|

Brick wall |

0,032 |

|

Concrete wall |

0,015 |

|

Mineral wool |

0,45-0,95 |

Sound Permeability of Building Materials -the ability of materials to skip through its thickness of the sound wave. It is characterized by sound permeability of building materials by a sound permeability coefficient, which shows a relative reduction in the power of sound when it passes through the thickness of the building material. Sound permeability is practically a negative property of building materials. For example, the sound permeability coefficient of a wooden partition 2,5 cm thick is 0.65, and the concrete wall of the same thickness is 0.11.

Sound conductivity building materials - This is the ability of various materials to skip sounds and noises through their thickness. Good conductors Sound is considered building materials of high density and strength. Materials having a large amount of air pores are poorly transmitted sound and noise. The power of sound is measured in decibels (dB). And the sound conductivity of building materials is characterized by the sound conductivity coefficient (T \u003d IPR / IPAD) which is equal to the ratio of the sound of the sound to the incident.

Soundproofing of Building Materials -this is a magnitude and characterizes the process of reflecting the sound by any material. Due to the different nature of the occurrence of sound waves, there are soundproofing from air noise, this is when the source of noise is not connected to the enhancement structure physically and isolation from shock noise, when there is a contact between the source and the enclosing design, for example, a hammer knock on the wall. In SNIP, the normalized sound insulation indicator is the insulation index of the I B air noise, dB. It is determined by the formula as the weighted average of the sound insulation of the structure in the frequency range from 100 to 5000 Hz in the frequency-tailed bands. The value R W also defines the weighted average soundproofing of the structure in the same frequency range, but in a slightly different methodology. The difference between i B and R w is 2 dB, i.e. R w \u003d i in + 2 dB. Soundproofing of building materials and structures depends on the porosity of the material, its thickness, the presence in the material or structures of the holes and the adjoints to other structures.

Abrasability of building materials -property of materials resist abreasting effects. The abrasibility is determined by the laboratory on samples. The abrasion characteristic of the building materials indicates the resistance of the material to wear and is estimated by the loss of material mass relative to its density or decrease in the thickness of the material. The worse the abrasability of the building material, the more wearless. Facing building materials are divided into 5 groups on abrasion indicators: the first group - granite, quartzites;

the second group is marble, dense basalts;

the third group is loose basalts and marble;

fourth group - Colored marbles, herbers, limestone;

fifth group - loose limestone.

True density building materials - This is the mass of the unit volume of the material in an absolutely density state. ρ \u003d M / VA, where Va volume is in dense state. [ρ] \u003d g / cm³; kg / m³; T / m³. Methods of true density laboratory: the pre-dried sample is crushed into the powder, the volume is determined in the pycnometer (it is equal to the volume of the displaced fluid).

Building Materials - the property of the material is to resist simultaneously by the effects of abrasive and shock loads. Wear determine the laboratory in the drum with steel balls or without them.

Quality of building materials - This is a combination of material properties that determine its ability to meet certain requirements, including regulatory compliance with its purpose.

Coloring ability - These are the properties of Pigments of the LCM when mixing with other pigments to transmit its color. The relative coloring ability of the LCM is determined by a laboratory in accordance with GOST, or by visual method by comparing samples.

Acid resistance building materials -the ability of materials will retain their main qualities and characteristics under the influence of acids.

Corrosion resistance building materials - This is the property of the material to maintain its basic qualities under aggressive impact. external environment. Corrosion is biological, chemical and electrochemical. The most common corrosion manifestation is the aging of building materials under the action of the effect of ultraviolet radiation and temperature difference and air humidity.

Mechanical properties building materials -this hardness, plasticity, rigidity tensile strength, stretching and bending.

Frost resistance of building materials -this property of a building material that determines the ability to withstand multiple freezing and defrosting, without manifest explicit deviations from the quality rate. Good frost-resistant properties have construction materials that have low water indicators. To determine the brand of building materials for frost-growing cycles of alternate freezing, produced from minus 20 ° C to plus 20 ° C. An indicator of frost resistance of building materials is denoted by symbols F 100; F 25; F 50 .. F 500, where the numbers are shown the number of freezing and thawing cycles.

Tab. Frost resistance of building materials depending on water absorption and tensile strength

|

Material |

Water absolution,% |

Debris g / cm 3 |

R Range, MPa |

Frost resistance, number of cycles |

|

TO ceramic irpic |

8...15 |

1,6...1,9 |

0,9. .3,5 |

15...50 |

|

Concrete than boat |

40...60 |

0,5...1,2 |

0,078... 1 |

15...75 |

|

Concrete easy |

0,8...1,8 |

0,8..3,2 |

25.. .400 |

|

|

Concrete heavy |

3...10 |

2,2...2,5 |

0,8. .3,2 |

50...500 |

|

Asbestocent |

20...25 |

1,6...1,8 |

10..15 |

50...100 |

Bulk density of building materials - This is the mass of the unit of bulk rich grainy or fibrous materials.

Fire Resistance Building Materials -this is the ability of materials to maintain their main characteristics under the action of high temperatures. According to the degree of fire resistance, building materials are divided into: combustible (plastics, wood, roofing bitumen materials, etc.), challenges and non-aggravated.

Fireproof building materials -this material ability does not lose its basic qualities (not to deform, do not melt, not crack, etc.) with long-term exposure to high temperatures. For its refractoriness, building materials are divided into low-melting, refractory (up to 1580 ° C), refractory (above 1580 ° C).

Relative Density of Building Materials -this is the ratio of the total solid in the construction material to the entire volume of the material or the relation middle density Material to its true density.

Open porosity of building materials - This is the property of the structure of materials, when the pores communicate with the environment and among themselves. For example, when immersing the material with open pores into water, they must be filled with water. Open pores increase permeability and reduce frost resistance.

Fire Resistance Limit of Building Materials -this is the duration of the resistance of the building material or the construction structure (in hours) the effects of high temperatures before the exhaustion of its carrier or enclosing ability, as well as the loss of its basic qualities. The offensive limit of fire resistance is characterized as an increase in temperature at any point of the construction structure of more than 220 ° C from the initial temperature of the structure.

Density of building materials -one of the main characteristics of the material, which is defined as a ratio of the ratio of mass to the volume of the building material (kg / sq.m.).

p 0 \u003d M / V 1

where m is the mass of the material, kg;

V 1 - the volume of material in the natural state, m 3.

The true and average density of building materials is distinguished. The average density of the building material is the ratio of its mass to the entire volume, including the pores. The true density is the ratio of the mass of the material to the volume without the account of voids and pores.

Table. Examples of true and medium density of building materials

|

Material |

Density, kg / m 3 |

|

|

True density |

Average density |

|

|

Stool construction |

7850-7900 |

7800-7850 |

|

Granite |

2700-2800 |

2600-2700 |

|

Limestone |

2400-2600 |

1800-2400 |

|

Ceramic brick |

2600-2700 |

1600-1900 |

|

Heavy concrete |

2600-2900 |

1800-2500 |

|

Popoplasts |

1000-1200 |

20-100 |

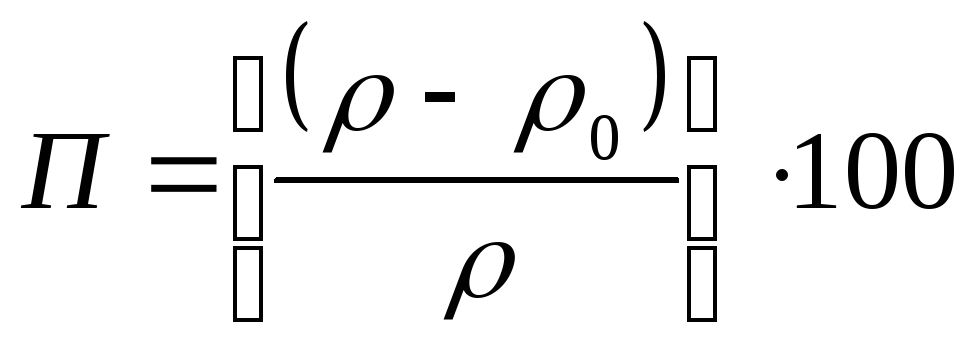

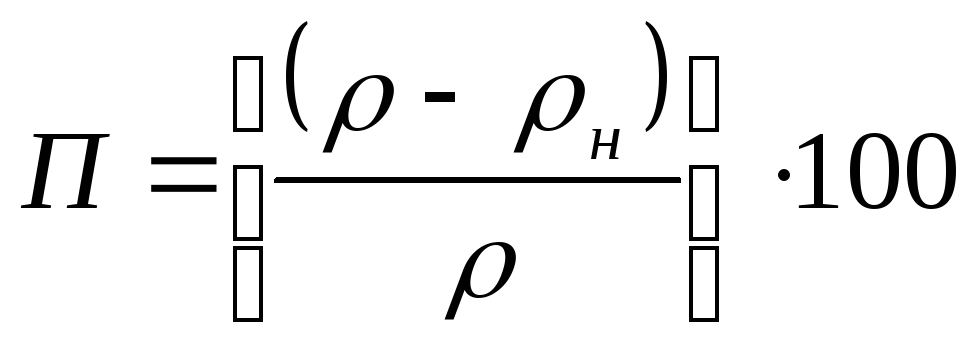

Porosity of building materials - This is an indicator of filling material pores (emptiness filled with air)

The porosity of the material is measured as a percentage and is calculated by the formula:

N \u003d (1-p 0 / p) * 100%,

where p 0 is a matter of material density, kg / m 3;

The rather density of the material, kg / m 3.

The more pores in the building material, the more exhibits its thermal insulation qualities.

Strength of building materials -the properties of the building material resist the destruction under the action of external and internal forces. Strength is assessed as an indicator as a strength limit. For fragile building materials, such as brick or concrete, the main strength characteristic is the tensile strength. For metal materials, the strength in bending and tension is more important.

Strength of building materials -the ratio of the destructive load P (H) to the cross-sectional area of \u200b\u200bthe sample F (cm2). The strength of building materials is established by the laboratory. Building materials depending on the strength limit are divided into brands and classes. Marks are recorded in kgf / cm², and classes - in MPa. The class characterizes guaranteed strength.

Relaxation of building material -the properties of the material spontaneously reduce the voltage, provided that its initial deformation is fixed with rigid bonds and remains unchanged. When the stress relaxation, the nature of the initial deformation may change, for example, from the elastic, gradually move into irreversible, while the size changes does not occur.

Technological properties of building materials- This is the speed of hardening, heat resistance, drying speed, workability.

Thermal conductivity of building materials - This is the ability of the material to transmit heat through the thickness of the building material or the construction multilayer design. The thermal conductivity of the building material depends on many indicators and primarily on the structure and presence of air pores and the presence of moisture in the material. The thermal conductivity of the building material is measured by the amount of heat transmitted through the material thickness in 1 m, with an area of \u200b\u200b1 sq.m. in 1 hour with temperature difference in 1 ° C.

The heat capacity of building materials - This is the amount of heat that must be reported to 1 kg of material in order to increase its temperature by 1 ° C. The heat capacity increases with the increase in humidity.

Elasticity of building materials -the property of materials after removing the load take its original shape and sizes.

Impact viscosity of building materials -the properties of the material resist shock loads. The shock viscosity of building materials is established experimentally in laboratory conditions.

Shelterness LKM.- The ability of the LKM to do a monochrome surface, reduce the contrast between the previous layer and subsequent. TO oliveness expressed in grams of paint needed to make an invisible color of the surface to the surface with an area of \u200b\u200bone square meter.

Hardness of building materials- The property of the material to resist the penetration of another material into it. Hardness indicators are derived experimentally. Hardness indicators received different ways (for example, "indulging" and "scratch") cannot be compared with each other.

Chemical Resistance of Building Materials -this is the ability of materials to resist the action of an aggressive medium and other effects at the chemical level, the ability to resist chemical reactions leading to the loss of basic material quality.

Physical properties of building materials -these are the generally accepted properties of materials: density, humidity, thermal conductivity, etc.

Scientifier building materials - property of materials to maintain their main qualities when exposed to alkalis. In the construction of the greatest alkaline aggressiveness, caustic sodes and solutions of caustic potassium are considered.

Currently, the nomenclature of building materials is very diverse. For the same structures or their elements, various materials can be applied. Choose the best and cheapest is not always easy. For wall materials, for example, belong: timber, brick, natural stone, concrete and reinforced concrete, saman, etc. However, for specific purposes, the material must be selected that most satisfying functional purpose Walls (residential premises, manufacturing workshop, warehouse, engineering structure, etc.), as well as economic requirements.

When choosing a material, it is necessary to take into account its ability to react to individual or combined factors - mechanical, external environment, temperature and its oscillations, chemical reagents, technological operations, etc. This material ability to respond to the specified factors is called its properties.

The rational use of building materials is possible only if the knowledge of its physical, mechanical, chemical, technological and artistic and decorative properties.

The physical state Building materials are quite fully characterized by medium and true density, as well as porosity. It is known that most building materials have a porous structure, an exception is glass, metals and some others. The ratio of body weight or substance in a natural state together with voids and pores to the entire volume occupied by them is customary to be called an average density, in contrast to the true density, representing the mass ratio to the volume when the volume is reduced to the point in which the density of the body or substance is determined without Accounting emptiness and pores available in them.

For bulk materials, there is a concept of "bulk density" - this is the ratio of mass of grainy and powdered materials to the entire volume occupied by them, including the space between particles. Units of these quantities: grams per cubic centimeter (g / cm 3), kilogram per liter (kg / l), ton on cubic meter (T / M 3), kilogram per cubic meter (kg / m 3). The technique mainly use a kilogram unit into a cubic meter (kg / m 3). Indicators of the density of building materials serve indirect estimates of porosity, water absorption, frost resistance, thermal conductivity and strength.

Usually, weight or volumetric water absorption is determined, which are the ratio of the difference between the weights of the water-saturated and dry samples by weight or volume of the dry sample, respectively.

The porosity of the material is estimated by the relative value showing what part of the material is occupied by internal pores. It fluctuates widely - from 0 to 98%.

Porosity can be open and closed. Open pores are most dangerous - they communicate with the environment and among themselves, which allows them to fill with water in saturation conditions. And this leads to an increase in water absorption and, as a result, to reduce the strength and frost resistance, an increase in thermal conductivity and water permeability. True, open porosity improves the sound-absorbing properties of the material.

Some building materials (brick, cement, concrete, timber, etc.) have hygroscopicity, i.e., the ability to absorb water vapor from air as a result of adsorption and capillary condensation. An increase in the hygroscopic humidity of the material leads to the deterioration of its main properties, as mentioned above.

Changing the strength of material as a result of water saturation is estimated coefficient softening - the ratio of the strength of the material saturated with water, to the strength of the dry material. This coefficient characterizes the water resistance of the material and it varies from 1 (metals, etc.) to 0 (splashing clay).

Power permeability is the property of the material to pass through itself under pressure. It is estimated filtering coefficient, equal to quantity Water, M 3, passing through a plate of material with an area of \u200b\u200b1 m 2, a thickness of 1 m in 1 hour with the difference in the hydrostatic pressure at the plate boundaries in 1 m water column. In order to reduce the water permeability, builders use more dense materials with closed, closed porosity or protect the structures with waterproofing materials.

The ability of the material to pass through its cracks and pores in the presence of a pressure difference of gas or steam is called gas or vapor permeability. Some materials are presented with full gas-tightness requirements, for example, to the materials of the gas storage. But wall materials, on the contrary, should have a certain permeability. The wall must "breathe", i.e. A natural ventilation should be carried out through it. However, to protect thermal insulation from moisturizing the wall and overlapping from wet rooms should be protected from steam penetration.

Many porous organic and inorganic building materials at moisture swell, i.e. Increase in size, and during drying - decrease. There is a so-called shrinkage or sleeping. Multiple moisturizing and drying often leads to destruction as a result of fatigue porous materials.

Very important physical characteristics of a number of building materials are their frost resistance. This is the ability of the material in a water-saturated state to withstand a certain amount of alternating freezing and thawing cycles.

The frost resistance of building materials largely depends on porosity, density and water resistance. Roofing, walls and other materials in the structures and finishes of buildings and structures under operating conditions are exposed to water saturation and freezing. When the water transition to the ice, its expansion occurs by about 9%, which leads to the destruction of the pores of the material. Multiple freezing and thawing is sometimes able to withdraw the structure in a short time. It is possible to increase the frost resistance by improving the structure of the material, a decrease in porosity, exclusion of water saturation, etc.

The heat engineering properties of building materials include: thermal conductivity, heat capacity, refractory, fire resistance, linear temperature expansion coefficient.

Thermal conductivity is the property of the material to pass through its thickness heat flux from one surface to another. For materials such as thermal insulation, walls and some other thermal conductivity is one of the main indicators of their quality. The thermal conductivity of porous materials depends primarily on the index of porosity and its character - open, closed, through, reporting. The temperature, temperature and, of course, the nature of the material itself, affect the magnitude of thermal conductivity, is influenced by the thermal conductivity. his substore composition. The thermal conductivity is estimated by the thermal conductivity coefficient - W / (m 0 s). Here are some examples, the coefficient of thermal conductivity of copper is 403 W / (m 0 s), and the steel has only 58, in heavy concrete -!, 5, light concrete - 0.5, mineral Wat - 0.08, etc. The lowest thermal conductivity in the air is 0.023.

The heat capacity is the ability of the material to absorb heat. It is estimated by the specific heat capacity - the amount of heat required for heating 1 kg of material 1 0 C.

Refractory - the property of the material is to resist, not melting and not deformed, long-term exposure to high temperatures (from 1580 0 s and above). Fireproof materials Apply for inner lining industrial furnaces. The refractory materials are softened at temperatures above 1350 0 S.

Fire resistance - the ability of the material to maintain physicomechanical properties in a fire for a certain time. It depends on the ability of materials to burn. According to this performance, building materials are divided into: non-aggravated (brick, concrete, metals, etc.), challenges (fibergolite; Some fiberglass; wood, impregnated with flame retardant compositions, etc.), burned (wood, bitumen, plastics, etc.).

The linear temperature expansion coefficient characterizes the body's ability to deform when the temperature changes. The various coefficients of linear expansion of the components of the conglomerate or composite materials can lead to their destruction. In order to avoid cracking of the buildings of a large length, they are cut into temperature seams.

TO mechanical propertiesbuilding materials include their strength and deformative characteristics, hardness and abrasibility.

Strength - The ability of the material to resist by external or internal loads without destruction. It is assessed by the strength of the strength in a specific form of deformation (compression, stretching, bending, tapping, etc.) and is equal to the ratio of the destructive force to the initial area cross section (Unit of measurement of PA or MPa). The strength of the material depends on numerous factors: density, porosity, structure, humidity, shape, and sample sizes, loading rates, etc.

DeformativenessmATERIALS This property change its dimensions and shape under the action of external load or internal stresses.

Deformation can be elastic (reversible) and plastic (irreversible, residual). Elasticity This feature of the material is to restore the original shape and dimensions after the termination of the load. The plasticity of the solid is called its ability to change the shape and dimensions under the action of the load and maintain the resulting shape and dimensions after removing the load.

Hardnesscalled the ability of the material to resist the penetration of another more solid body into it. It is determined by the structure of the material. When choosing floors for floors, road coatings And in a number of other cases it is necessary to know their hardness. From hardness depends abrasion Materials.

08/19/2009 | LLC "STROY-CITY" | 39274 views

Today on the roar construction mixes Both materials are presented a large number of different products of both domestic and foreign manufacturers. Usually all manufacturers for description technical characteristics It is used by terminology, which is sometimes not always clear for ordinary citizens. In the description of its products, manufacturers usually advertise those properties of building materials that are beneficial to them are distinguished before the rest, or use characteristics that provide advantages in their use. In order for you to more freely navigate the terminology of the properties of building materials, we decided to disclose the description of the main characteristics that use manufacturers for their products.

The main properties of building mixtures and materials are their physical, chemical, technological and mechanical properties.

The properties of any building material on direct depend on its composition, therefore the composition is listed at the beginning and the terms are used about its structure. For the correct understanding of the properties of building materials, their chemical, mineral and phase formulations need to know.

Chemical composition

Shows, characterizes the percentage in material Chemical elements or oxides, makes it possible to judge some of the properties of materials - mechanical strength, fire resistance, bioscistance, etc.

Mineral composition

Shows which minerals and in what quantities are contained in stone material or in binder. For example, an artificial mineral three-killy silicate (3SIO2) is contained in Portland cement in an amount of 45 ... ..60%, and with greater content of it, the cement stone strength is accelerated and the strength of cement stone is accelerated.

Phase composition

Indicates the content in the phase material, i.e. parts, homogeneous chemical composition and physical properties And separated from each other surfaces of the section. For example, the main phases of the portland cement clinker is Alite, Belith, celite and aluminum phase. In porospo material Solids form solids forming pore walls, and the pores themselves filled with air, water. If the water freezes, the ice-forming ice changes the heat engineering, mechanical and other material properties, causes large internal voltage in it to increase the volume of freezing in the pores of water. The phase composition of the material and phase transitions of water in it affect all properties and behavior of the material during operation. The materials represented by one phase are called homogeneous, and two or more - heterogeneous.

Structure of material characterizes its structure and texture.

Structure - the inner structure of the material caused by the form, dimensions, mutual arrangements of the components of its particles, pores, capillaries, the mutual arrangement of the components of its particles, pores, capillaries, surfaces of the phase, microcracks and other structural elements. Depending on the structure distinguished materials isotropic -possessing the same properties in all directions (solidified concrete and mortars, ceramic materials), or anisotropicwhose properties are different in different directions (reinforced concrete, wood, fibrous materials).

Texture- The structure due to the relative location and distribution of the components of the material in the space occupied by them. The texture is layered, massive, haired, porous, etc.

Largely construction Materials Have a porous texture. They are divided into fine-pore, pore sizes, which are determined by hundredths and thousands of millimeters to 1 ... 2 mm. Melchoporous materials are hardened building solutions and concrete, ceramics, row of stones, and large foam and aerated concrete, gas-pores, popoples, etc. Large pores (to centimeter) are called voids, they include spaces between pieces and grains of loose materials.

The macro and microstructure of the material are distinguished. Macrotructure - structure visible to the naked eye or with a slight increase; It is a conglomerate (characteristic of concrete), cellular (gas and foam concrete, cellular plastics), fibrous (wood, fiberglass), small-faceted (a number of ceramic materials), layered (textolite, boomoplastic), loose (powdered and grainy materials).

The microstructure is a structure visible to an optical or electron microscope. In relation, for example, to the construction cementthe solution on the microstructure can be judged on the mineral composition, the number of location of the main phases in the cement stone, the pore structure, the size, arrangement, and the number of micropores, the features of the contact layer between the cement stone aggregate.

In physical state, all substances are divided into solid, liquid, gaseous and plasma. In plaster and painting work, materials that are in solid or liquid state are used.

A solid body is called every body that has a certain form. So, the solid bodies include metals, stones, ice, wax, bitumen, glass, etc. Solid bodies May be in crystalline (granite, metals, ice) and amorphous (wax, glass, ebonite) states.

Crystal bodies have an ordered mutual arrangement of their particles that form them - atoms and molecules, and their amorphous chaotic location. Crystalline substances have characteristic properties to move from a solid state into a liquid with a certain, constant for a given substance, temperature. This temperature is called the melting point is equal to the rejection temperature (each molten substance has rehabilitated when cooled). Amorphous substances do not have a well-pronounced melting point and hardening, when heated, they gradually soften and go into a liquid state.

Solid materialsUsed in plastering and molar works are bulk and coum.

Liquid state of aggregation Substances that combine the features of a solid state (maintaining the volume, a certain tensile strength) and gaseous (form variability).

In the process of working plasterers and painters, it is dealt not only with solid and liquid substances, but also with so-called colloid-dispersed systems and solutions, various mixtures.

Dispersed systems - formations of two or more phases (tel) with a highly developed surface of the section between them. In dispersed systems, one of the phases - the dispersed phase is distributed as small particles (crystals, droplets, bubbles) in another phase - a dispersion medium - gas, liquid or solid. Dispersion - characteristic of the size of solid particles and droplets of the liquid (the smaller the particle, the greater the dispersion). In practice, as dispersed systems, the particle size of which is more than 0.1 μm, use suspensions, emulsions, colloids. Coarse systems (suspensions, emulsions, powders, foam) are unstable; Excessive grinding of powders leads to their sticking (coagulation).

Suspension is a system in which particles of solid dispersed phase are weighted in a liquid dispersion medium. Such systems include paints ready to use, which are suspensions of pigments and fillers in binders and solvents, putty, sealing pastes.

Suspension is a system in which particles of solid dispersed phase are weighted in a liquid dispersion medium. Such systems include paints ready to use suspensions of pigments and fillers in binders and solvents, putty.

Emulsions - a system consisting of two non-soluble fluids in each other, one of which (dispersed phase) is distributed in another (dispersed medium).

In suspensions and emulsions, the particles of the dispersed phase are striving for sedimentation, i.e. To precipitation. In addition to this, they can coagulate, clutch under the action of molecular forces.

Colloids - intermediate systems between true solutions and coarse systems. Liquid colloids - evil, solid chatteries - gels. Gele formation is one of the most important properties of colloid systems. The gels are formed as a result of the action of molecular clutch forces between colloid particles. The formation of gels is important to explain the process of hardening and properties of cement stone and polymeric materials. The mesh gel structure holds a significant amount of dispersion medium fluids. Under the action of mechanical effort, many gels are able to move into evil, i.e. Dissoliated, this phenomenon is called ticcopropy and it is manifested when breeding concrete, mortar and other mixtures.

Colloids are capable of swelling, while they increase in volume. Animals adhesives, protein, starch, soap - colloids, which, with long-term contact with water, form colloidal solutions (eval). In contrast to the cooler systems, colloidal solutions of the rack for sedimentation, have a glow in the transmitted light and movement of particles to the electrodes when passing the electric flow.

True solution - molecular - dispersed homogeneous (homogeneous) system of variable composition of two or more components. The solution is called true because the substances are indeed and spontaneously dissolved in a suitable solvent with the formation of a homogeneous system. True solutions are resistant for a long time. With a true solution, the paintery is dealt with whenever it dissolves in water the crystals of copper sulfate, alum, caustic soda, acid, alcohol.

The most important practical importance is the phenomena occurring on the surface of the phase separation for all dispersed and especially colloid systems. By such, the phenomena refers adsorption - the absorption and concentration of the substance on the surface of the phase raded. Adsorbing substances are called superficially active (surfactant), they reduce surface tension, are of great importance in building materials technology. Pav helps to obtain stable emulsions and suspensions (the adsorption layer envelops the particles of the dispersed phase and does not allow them to stick together); Due to the effect of adsorption reduction of strength, the grinding of powders is accelerated, plate dissolves and concrete mixes, hydraulic surfaces, etc.

Physical properties

Construction Materials Possess a complex of physical properties, numerical indicators of which are determined in the laboratory using special devices and standard methods.

Physical include properties expressing the ability of materials to react to the effects of physical factors - gravity, heat, water, sound, electric current, radiation, etc. Construction Materials There are solid and liquid. Everyone material It has a volume and has a certain mass.

The mass is a combination of material particles (molecules, atoms, ions) contained in this body or substance. The body weight occupies part of the space, i.e. has a certain amount; It is constant for this substance and does not depend on the acceleration of free fall, from the speed of its movement and position in space. Different bodies of the same volume have an unequal mass, i.e. Possess different density.

The most important parameters of the physical condition of the materials are density and porosity, and for dispersants, for example, powdered materials - a scented surface, i.e. Surface related to a unit of volume or mass material. The density is characterized by the ratio of the mass of the material to its volume, length, area.

Density. True density R -mass of a unit of homogeneous material in absolutely dense state, i.e. without accounting for pores and emptiness. Determined by the ratio of mass M (kg) of material to its volume VA (m3) in absolutely dense state P \u003d. M / VA (kg / m3). The true density of each substance is a constant physical characteristic that cannot be changed without changing it chemical composition or molecular structure. The density close to theoretical, possess metals, liquids, glass, polymers.

The density of solid and liquid materials is compared with water density. The greatest density of water at a temperature of 4 s is 1 g / cm3, since the mass of 1 cm3 of water is 1 g. Basically the true density of the substance depends on its chemical composition. So, not organic Materials (natural and artificial stones) consisting mainly of silicon, aluminum and calcium oxide, the true density is in the range of 2.4 ....3.1 g / cm3, in organic materials consisting mainly of carbon, oxygen and hydrogen, is 0.8 ....1.4 g / cm3, in wood 1.55 g / cm3. The true metal density is quite different (g / cm3): aluminum - 2.7, steel - 7.85, lead - 11.3.

Average density rm. - the mass of the volume of material in the natural state, i.e. with pores and voids. Determined by the ratio of mass M (kg) of the material to its volume V (m3) in the natural state: rm \u003d. M / V (kg / m3).

The average density (hereinafter, we will call it simply density) - an important physical characteristics of the material varying depending on its structure and humidity. So, by changing the structure, it is possible to obtain a heavy concrete with a density of 2400 kg / m3 and a particularly lightweight density of less than 500 kg / m3. The average density has a significant impact on mechanical strength, water absorption, thermal conductivity and other properties materials. In dense materials, the number of true and medium density is the same, other materials have an average density less than the true one. The density of building materials fluctuates in very wide limits: 15 (porous plastic) to 7850 kg / m3 (steel).

For bulk materials determine bulk density. Bulk density rn -mass of units of bulk of bulk grain materials (sand, cement, gravel, rubble): rn \u003d.m |V.For example, the true density of granite is 2700 kg / m3, its average density is 2670 kg / m3, and bulk density granite rubble - 1300 kg / m3.

Porosity - the degree of filling the volume of the material by pores. Most materials contain pores - small cells filled with air or water. Porosity is calculated by the formula (%): n \u003d (( R- R.m.) / R) * 100 and expressed in the fractions of the volume of material taken in 1, or as a percentage of the volume. The porosity of building materials varies widely: from 0 (steel, glass) to 98% (Mijor).

Align open and closed porosity. By changing the ratio of open and closed pore volumes, their size, in the technology of materials reaches obtaining materials with specified properties. For example, with a decrease in porosity, an increase in the strength of materials is achieved.

When producing thermal insulation materials, they seek to increase the porosity and create a small-pouring structure. If in the total volume increases the share of closed pores, then it will be favorably affected by frost resistance materials. To improve sound-absorbing properties, seek to create a system of branched and communicating pores in the material. Consequently, their average density, strength, water saturation, thermal conductivity, frost resistance, sound absorption, and other properties depends on the porosity of materials.

Bulk and loose materials (sand, ground chalk, pigments, slag) besides pores have voids - air cavities between individual particles of material.

Emptiness The ratio of the total volume of emptiness in loose material to the entire volume occupied by this volume. For numerical expression of emptiness, it is necessary to know the density and bulk density of the material. The voidness of Ppaust is calculated by the same formula as porosity, and expressed in percent.

The coefficient of density of the CLV is the degree of filling material of the material with a solid substance; Calculate it according to the formula of the CPL \u003d PM / R. In the amount of CLV + P \u003d 1 (or 100%), i.e. Dry material consists of a solid frame and air pore.

When transporting, stored and in designs, materials can be exposed to water. Wet materials are less durable, more severe and thermal conducting than dry. Cement, gypsum binders, pigments, glue, and other materials will be spoiled from the atmospheric moisture, and the wet wood is easy to rot. Properties associated with exposure to water material are called hydrophysical.

Gigroscopicity - Property of Property-Capillary materialabsorb moisture from the air. The degree of absorption depends on temperature and relative humidity. With an increase in the relative humidity of the air and a decrease in air temperature, hygroscopicity increases. Hygroscopicity is characterized by the ratio of the mass absorbed by moisture with a relative humidity of 100% air and a temperature of +20 C to the mass of dry material.

Hygroscopicity adversely affects quality building materials. Thus, when stored under the influence of moisture, the air comes and reduces its strength. Extremely hygroscopic wood, it will scatter from the moisture of the air. To reduce the hygroscopicity of wooden structures and protect them from swelling, wood is covered with oil paints and varnishes, soaked with polymers that prevent moisture penetration into the material.

Capillary absorption - the property of the porous capillary materials lift water in capillars. It is caused by the forces of surface tension arising on the boundary of the partition of solid and liquid phases. Capillary absorption is characterized by the height of raising the water level in capillary materials and the amount of absorbed water and the intensity of suction. When the foundation is in a wet soil, groundwater can rise in capillars and moisturize the bottom walls of the building. In order to avoid dampness in the room, a layer of waterproofing is arranged separating the foundation from the wall. With an increase in capillary suction, the strength, resistance to chemical corrosion and frost resistance of building materials decreases.

Water absorption - the property of the material with direct contact with water to absorb and hold it in their pores. Water absorption expresses the degree of filling material with water (water absorption in volume Wo) or the ratio of the amount of absorbed water to the mass of dry material (water absorption by weight of WM). Calculate water absorption by the formula (%):

WM \u003d ((M2-M1) | M1) * 100; WO \u003d ((M2-M1) | V) * 100,

Where M1 and M2 are the mass of the material, respectively, in a dry and saturated water, r; V- volume of material in a dry state, cm3. Dividing WO on WM, we will gain dependency:

The water absorption of various materials is in wide ranges (% by weight): granite 0.02 ... 1; The density of heavy concrete 2 ... .5; ceramic brick 8 ... .25; asbestos-cement pressed flat sheets - no more than 18; Thermal insulation materials are 100 or more.

In high-faceted materials, water absorption can exceed the porosity, but water absorption in volume is always less porosity, since the water does not penetrate into very small pores, and it is not restrained in very large. Water absorption of dense materials is zero (glass, steel, bitumen) water absorption negatively affects other properties of materials: the strength and frost resistance decreases, the material swells, its thermal conductivity increases and the density increases.

Humidity is the ratio of the mass of water currently in the material, to the mass (less often to volume) of the material in a dry state. It is calculated according to the same formulas as water absorption, and is expressed as a percentage. In this case, the mass of the material is taken in a natural wet, and not in saturated water.

During transportation, storage and application of materials, it is not dealt with water absorption, but with their humidity. Humidity varies from 0% (for absolutely dry materials) to the value of complete water absorption and depends on porosity, hygroscopicity and other material properties, as well as ambient - relative humidity and air temperature, contact material with water, etc. For many building materials, humidity is normalized. For example, the mooler of the ground chalk - 2%, comob - 12%, wall materials - 5 ....7, air-dry wood 12 ....18%.

Since the properties of dry and wet materials Very different, it is necessary to take into account both the humidity of the material and its ability to absorb water. In all cases - during transportation, storage and application - building materials are protected from moisture.

Water resistance - the property of the material to maintain strength when it is saturated with water. The criterion of water resistance of building materials is the softening coefficient of KR \u003d RB / RC - the ratio of strength in compressing material saturated with water RB, to the strength of dry material RC. It changes from 0 (for clay) to 1 (glass, metals). Materials in which the softening coefficient more than 0.75 is called waterproof.

Moisture studio - the properties of the material to lose water in its pores. The numerical characteristic of moisture ratings is the amount of water (in%), evaporated from the sample for 1 day at a temperature of 20 s and relative humidity of 60%. The moisture date is taken into account, for example, when leaving for hardening concrete, when drying the wall and partitions plastered with lime mortar. In the first case, the slow motion is desirable, and in the second - fast moisture product.

Power Permeability - the property of the material to pass through itself under pressure. The degree of water permeability mainly depends on the structure of the porosity of the material. The larger in the material of open pores and emptiness, the greater its water permeability. The water permeability is characterized by a filtration coefficient (m / h) - the amount of water (in m3) passing through the material with an area of \u200b\u200b1 m2, 1M thickness per 1 hour with the difference in hydrostatic pressure on the boundaries of the wall of 9.81 pa. The lower the filtration coefficient, the higher the material brand of waterproof. Waterproof are dense materials (granite, metals, glass) and materials with small closed pores (foams, extruded polystyrene).

For waterproofing materials, an assessment of non-water permeability is important, and their waterproof, which is characterized by either time, after which the water seepage appears under certain pressure through the sample of the material (mastic, waterproof), or the maximum water pressure at which it does not pass through the material sample Time Test (Special Construction Solutions).

Air-, gas and vapor permeability - the properties of the material pass through their thickness, respectively, air, gas and steam. They depend mainly on the structure of materials, the defects of its structure and humidity. Quantitatively air - and gas permeability are characterized by a coefficient of air - and gas permeability, which are equal to the amount of air (gas) (M3), passing for 1 hour after 1 m2 of a thickness of 1 m with a pressure difference at 9.81 Pa. Air - and gas permeability is higher if there are more reporting pores in the material; The presence of water in the pores lowers these properties of the material.

Parry permeability occurs with different content and elasticity of steam on both sides of the surface, which depends on the temperature of water vapor and is characterized by a vapor permeability coefficient, which equal to quantity Water vapor (in g) penetrating for 1 hour after 1 m2 of material with a thickness of 1M with a vapor pressure difference on the surfaces of 133.3 pa.

Benches and finishing materials must have a certain permeability, must "breathe".Sufficient air - gas and vapor permeability of wall materials support the optimal air-humid mode in the rooms and prevent the walls of the walls under the action of frost and subsequent thawing. In wet rooms, the walls and coatings are protected from the inside of the penetration of water vapor. Playproof materials are located on the side of the fence with which the pair content in the air is greater. Materials, saturated with water, practically gasproof.

Paint and varnish coatings are either reduced or retain the vapor permeability of building materials. The smaller the vapor permeability of the paint film, the higher its anti-corrosion properties.

Frost resistance - the property of materials in saturated water condition to withstand a multiple number of cycles of alternate freezing and thawing without visible signs of destruction and without a significant reduction in strength and mass. Frost resistance is one of the main properties characterizing the durability of building materials in structures and structures. When changing the seasons, some materials are subjected to periodic freezing and thawing in conventional atmospheric conditions, destroyed. This is explained by the fact that the water in the pores of the material, during freezing, increases in the amount of about 9 ... 10%; Only very durable materials are able to withstand this ice pressure (200 MPa) on the pore walls.

High frost resistance has dense materials that have low porosity and closed pores. Materials porous with open pores and, accordingly, with large waterworks often turn out to be not frost-resistant. Materials in which, after established for them, standard tests consisting of alkalized multiple freezing (at a temperature not higher than -17c) and thawing (in water), cracks do not appear, decrease, chipping and which lose no more than 25% of the strength and 5% of the mass are considered frost-resistant.

According to frost resistance, that is, according to the number of compressed cycles of freezing and thawing, the materials are divided into brands: MPZ10; 15; 25; 300; 50; 100 and 500. So, the brand of frost resistance of a plastering solution MRC 50 It means that the solution withstands at least 50 cycles of alternate freezing and thawing without loss of strength and mass.

It is important to understand that for porous materials, the joint action of water and alternate temperatures is particularly dangerous. Frost resistance depends on the composition and structure of the material, it decreases with a decrease in the softening coefficient and an increase in open strength.

The criterion of frost resistance of the material is the coefficient of frost resistance of CMRZ \u003d RMPs / RNAs - the ratio of the strength of the material when the material is compressed after the test to the strength of the strength in the compression of water-saturated samples that are not subjected to the test, at an equivalent age. For frost-resistant Materials, CMRs should be more than 0.75. It is also assumed that if the coefficient of softening to the crash of the stone is not lower than, 95 stone Material Frost.

The properties of materials are associated with a change in temperature, refer to the thermophysical. They are important for thermal insulation and heat-resistant materials, for materials of enclosing structures and products hardening during thermal processing.

The heat capacity is the properties of the material to absorb during heating and give a certain amount of heat during cooling. The heat capacity is the measure of the energy required to increase the temperature of the material.

The heat capacity attributed to the unit of mass is called specific heat C (J / (kg * c)). Specific heat equal to the amount of heat required for heating 1 kg of material on 1 C. In organic materials, it is usually higher than that of inorganic (KJ / (kg * c)): Wood - 2.38 ....2.72; Steel - 0.46, water - 4,187. Water has the greatest heat capacity, therefore, with an increase in the humidity of materials, their heat capacity increases.

Heat conductivity - the property of the material to transmit through its thickness of the heat flux resulting from the temperature difference on opposite surfaces. This property is essential for building materialsused in the device of enclosing structures (walls, overlaps, coatings) and materials intended for thermal insulation. The thermal conductivity depends on its structure, chemical composition, porosity and the nature of pores, from humidity and temperature at which heat is transmitted.

The thermal conductivity is characterized by a thermal conductivity coefficient, showing how much heat (J) is able to skip the material after 1 m2 of the surface at the thickness of the material 1 m and the temperature difference on opposite surfaces 1 s for 1 hour. The thermal conductivity coefficient (W / m * C): air - 0.023, Woods along the fibers - 0.35 and across the fibers - 0.175, water - 0.59, ceramic brick -0.82, ice - 2.3. Consequently, air pores in the material sharply reduce its thermal conductivity, and moisturizing - strongly increases, since the thermal conductivity coefficient of water is 25 times higher than that of the air.

When water freezing in the pores of the material, thermal conductivity increases, as the ice is approximately 4 times with thermal conductory water and a hundred times thermal conductor. The less pore, i.e. The more dense material, the thermal conductory. With an increase in temperature, the thermal conductivity of most materials increases and only a few (especially from metals) decreases.

Heat Extension - Property materials Expands when heated and compressed when cooled, it is characterized by a linear dimension change, and the volume volume of the material is important, the temperature coefficient of linear extension (TCCR), showing how the value of the initial length is expanding with an increase in temperature by 1 C. So, for TCC steel is (11 ... 11.9) * 10-6, for concrete - (10 ... 14) * 10-6, for wood along the fibers - (3..5) * 10-6. In the structures that combine several materials, it is necessary to take into account the TCCR each; For example, in reinforced concrete, so and concrete are well combined, since the TCRR of these materials is almost the same. As a result of a significant difference in TCCR in composite materials, voltages occur, which can lead not only to the appearance of microcracks and warping, but also to the destruction of materials.

Fire resistance - the property of materials to withstand without destruction exposure to high temperatures, flames and water in a fire conditions. The materials under these conditions are either burned or crackdown, they are strongly deformed, or destroy from loss of strength. Fire resistance is distinguished by non-government, challenges and combustible.

Failed materials under the action of fire or high temperatures are not lit and are not charred. It is, concrete and others. Meanwhile, some non-aggravated materials - marble, glass, asbestos cement - with sharp heating are destroyed, and steel structures are strongly deformed and lose strength.

Ground materials under the action of fire or high temperature are burning and continue to burn after removing the source of fire. It is wood, wallpaper, bitumens, polymers, paper, etc.

To increase fire resistance, materials are impregnated or treated with flame retardant compositions - antipyrenes. When heated, they identify gases that do not support burning, or form a porous layer with a porous layer, slowing it with heating.

Fire resistant materials cannot be identified with the fire resistance of the building of the building and structures, since the structures made, for example, from the combustible materials, but processed by flame retardant or protected from fire with plaster or facing from non-aggravated materials, respectively refer to the challenges.

To increase fire resistance of materials, various fire is used protective coatings, including paint. Binders in such paints serve liquid glass, lime, perchlorvinyl and carbamide resins, phosphorumorganic polymers. Silicate and other fire retardant colors simultaneously protect the materials from the fire and perform the finishing coating features.

Fireproof - the property of the material to withstand a long exposure to high temperature (from 1580 s and above), not deformed and softening. Fireproof materials used for the inner lining of industrial furnaces - Dynas, Shamot, Romomagnezit, Corundum - are not deformed and not softened at a temperature of 1580 s and above. Holding materials (refractory chimney) withstand no melting temperature 1350 ... 1580 s, and low-melting (ceramic construction) - up to 1350 C.

Acoustic properties of materials are associated with the interaction of materials and sound; First of all, it is sound conductivity and sound absorption.

Sound conductivity - the property of the material through its thickness sound; It depends on the structure and mass of the material. Heavy materials (), as well as porous and fibrous, poorly conduct sound. Sound permeability is a negative property, since in most cases building materials presented the requirements of insulation of rooms from external noise. Soundproofing - the weakening of the sound when it penetrates through the enclosing structures is the property of the material, inverse sound permeability.

Sound absorption - the property of the material to absorb and reflect the sound falling on it. It depends on the porosity of the material of its thickness, the state of the surface, as well as on the frequency of the soundtone, measured by the amount of oscillation per second. Per unit of sound absorption take the absorption of the sound of 1 m2 of the open window; With open fire, the sound is completely absorbed. The sound absorption of all building materials is less than one. The sound absorption of the material is estimated by the sound absorption coefficient, i.e. The ratio of energy absorbed by the material to the total amount of energy per unit of time.

Sound absorption depends on the nature of the material surface. Materials with a smooth surface well reflect the sound falling on them, so indoors in rooms with smooth walls A constant noise is created. Materials with developed open porosity are well absorbed and do not reflect the sound falling on them. Special acoustic stucco with small open pores well absorbs sound and drowshes it. It is known that carpets, paths, upholstered furniture drown out sound. In principle, those building materials that poorly pass through themselves, it is well absorbed and do not reflect, are acoustic materials. Reducing noise as a result of using such materials retains human health, creates certain convenience for them and promotes labor productivity.

Electrical conductivity - the property of materials to carry out an electric current. Electrically conductive are metals, materials in a wet state - concrete, cementa rock, building mixture, Wood.

Radiation resistance - the property of the material to maintain its structure and physico-mechanical characteristics after exposure to ionizing radiation. Radiation in its level may be so high that can cause deep changes in the material structure. For example, minerals of the crystal structure become amorphous, which is accompanied by volumetric changes and the occurrence of internal stresses. All this ends with the destruction of the material and the pector of its protective properties. To protect against radioactive emissions, particularly heavy (pm \u003d 3000 ....5000 kg / m3) and hydrate concrete, having an increased content of chemically bound water creating good defense from neutron flux.

Chemical and physical chemical properties

For the correct and complete assessment of materials in their manufacture, choosing and operating in structures you need to know and take into account their chemical and physicochemical properties.

Chemical properties express the degree of material activity to chemical reaction with the reagents of the external environment and the ability to maintain the constant composition and structure of the material in the conditions of an inert environment. Some materials are prone to spontaneous internal chemical changes in the usual environment. A number of materials exhibit activity when interacting with acids, water, alkalis, solutions, aggressive gases, etc. Chemical transformations also occur in the technological processes of production and application of materials.

|

Construction Materials. Lectures. 31

General information about building materials.

In the process of construction, operation and repair of buildings and structures, construction products and structures of which they erected are subjected to various physical and mechanical, physical and technological impacts. From the engineer-hydraulic engineering required with knowledge of the right to choose the material, products or design that has sufficient resistance, reliability and durability for specific conditions.

Lecture №1 General About building materials and their basic properties.

Building materials and products used in the construction, reconstruction and repair of various buildings and structures are divided into natural and artificial, which in turn are divided into two main categories: the first category includes: brick, concrete, cement, timber, etc. When erecting various elements of buildings (walls, overlaps, coatings, floors). To the second category - special purpose: waterproofing, thermal insulation, acoustic, etc.

The main types of building materials and products are: Stone Natural Building Materials of them; Binding materials are inorganic and organic; forest materials and products of them; hardware. Depending on the purpose, the conditions for the construction and operation of buildings and structures, appropriate building materials are selected, which have certain qualities and protective properties from the impact on them of a different external environment. Given these features, any building material must have certain construction and technical properties. For example, the material for the outer walls of the buildings should have the smallest thermal conductivity with sufficient strength to protect the room from the outer cold; Material of the structure of hydrochromelic purposes - waterproof and resistance to alternate humidification and drying; The material for the coating is expensive (asphalt, concrete) should have sufficient strength and low abrasibility to withstand the load from transport.

Classifying materials and products, it must be remembered that they must have good propertiesand qualities.

Property- The characteristic of the material manifested in the process of its processing, application or operation.

Quality- A set of material properties that determine its ability to meet certain requirements in accordance with its appointment.

The properties of building materials and products are classified by three main groups: physical, mechanical, chemical, technologicaland etc .

TO chemicalthe ability of materials to resist the action of a chemically aggressive medium, which causes metabolic reactions leading to the destruction of materials, changes in its initial properties: solubility, corrosion resistance, resistance to rotting, hardening.

Physical properties: medium, bulk, true and relative density; Porosity, humidity, moisture production, thermal conductivity.

Mechanical properties: limits of strength in compression, stretching, bending, shift, elasticity, plasticity, rigidity, hardness.

Technological properties: Convertibility, heat resistance, melting, hardening and drying rate.

Physical and chemical properties of materials.

Average densityρ 0 Mass medals volume V. 1 absolutely dry material in a natural state; It is expressed in g / cm 3, kg / l, kg / m 3.

Bulk density of bulk materialsρ n. Mass medals volume V. n. dried freely fused material; It is expressed in g / cm 3, kg / l, kg / m 3.

True densityρ mass medals volume V.material in absolutely dense state; It is expressed in g / cm 3, kg / l, kg / m 3.

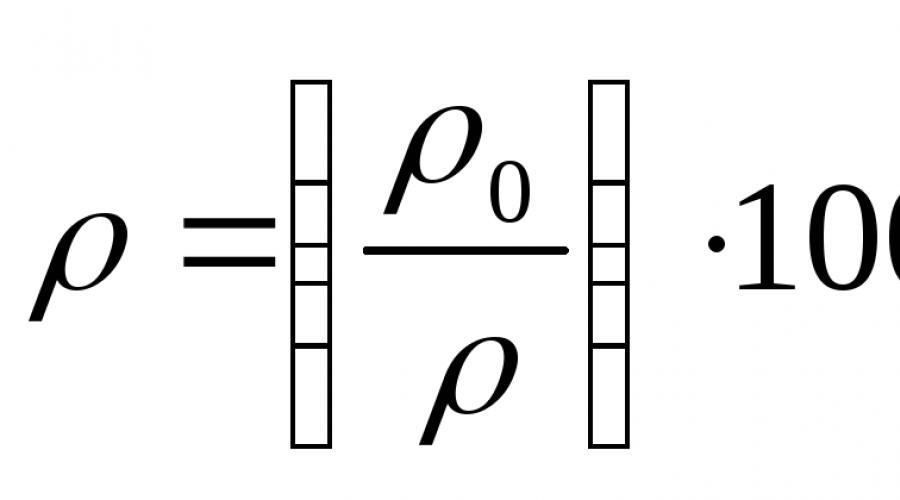

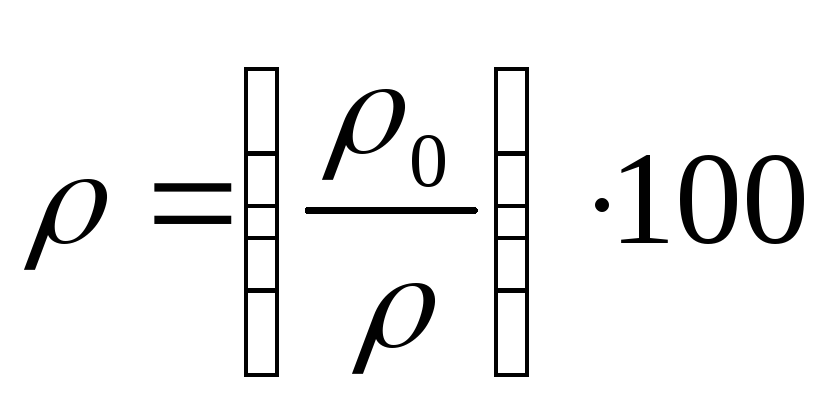

Relative densityρ(%)

- degree of filling material of the material of the solid substance; It is characterized by the ratio of the total volume of solid V. In the material to the entire volume of the material V. 1

or ratio of medium density of material ρ

0

to its true density ρ:, or  .

.

PorosityP - The degree of filling the volume of the material by pores, voids, gas-air inclusions:

for solid materials:  For bulk:

For bulk:

Gigroscopic - The ability of the material to absorb moisture from the environment and thicken it in the mass of the material.

HumidityW.

(%)

- the ratio of the mass of water in the material m. in =

m. 1

-

m.

to the mass of it in absolutely dry condition m.:

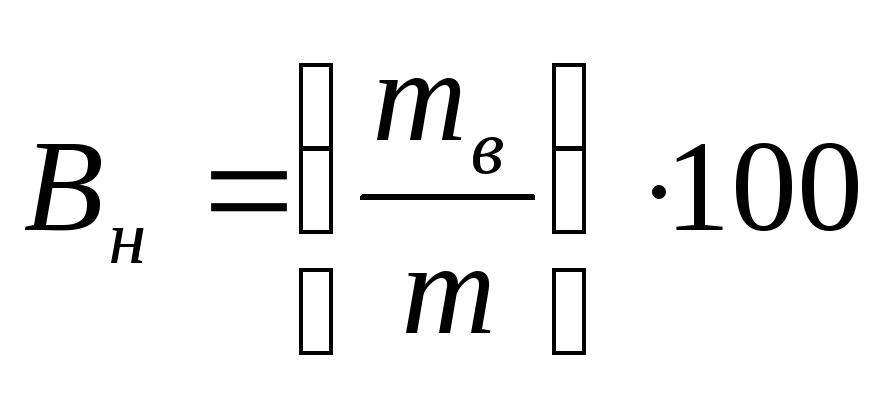

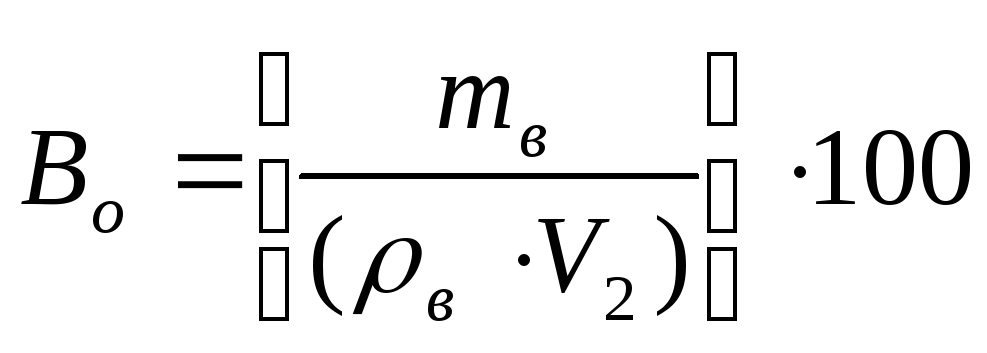

Water absorptionIN - characterizes the ability of the material when contacting with water to absorb and hold it in its mass. Distinguish between mass IN m. and volume IN about Water absorption.

Mass water absorption(%)

- the ratio of mass absorbed water material m. in to the mass of the material in a completely dry condition m.:

Volume water absorption(%)

- The ratio of volume by absorbed water material m. in /

ρ

in

to his volume in a water-saturated state V. 2

:

Moisture report - The ability of the material to give moisture.

|| Brick masonry || But and boot concrete masonry || Facial laying and lining of walls || Waterproofing of stone structures || Winter conditions || ChimneyThe physical properties of the material include density, porosity, water absorption, moisture ratification, hygroscopicity, water permeability, frost resistance, thermal conductivity, sound absorption, fire resistance, refractory and some others.

Density. The material density is medium and true. The average density is determined by the ratio of body weight (brick, stone, etc.) to the entire volume occupied by them, including the pores and emptiness available in it. And it is expressed in the ratio of kg / m 3. The true density is the limit of the mass ratio to the volume without taking into account emptiness and pores. In dense materials, such as steel and granite, the average density is almost equal to true, in porous (brick, etc.) - less than the true one.

Table 1. The true and average density of some building materials.

| Material | Density, kg / m 3 | |

| true | average | |

| Steel | 7850-7900 | 7800-7850 |

| Granite | 2700-2800 | 2600-2700 |

| Limestone (dense) | 2400-2600 | 1800-2400 |

| Ceramic brick | 2600-2700 | 1600-1900 |

| Heavy concrete | 2600-2900 | 1800-2500 |

| Popoplasts | 1000-1200 | 20-100 |

Porosity. This characteristic is determined by the degree of filling the volume of the material by pores, which is calculated as a percentage. Porosity affects such properties of materials, as durability, water absorption, thermal conductivity, frost resistance, etc., the materials are separated into fine-porous, in which the pore sizes are measured in hundredths and thousands of millimeters, and large-perch (sizes of pores - from tenths of a millimeter up to 1-2 mm). The porosity of building materials varies in a wide range. So, for example, glass and metal it is zero, it has a brick - 25-35%, from MIPRA - 98%.

Water absorption - The ability of the material to absorb and keep in their pores moisture. In terms of volume, water absorption is always less than 100%, and by weight there may be more than 100%, for example in thermal insulation materials. The saturation of the material with water impair its basic properties, increases thermal conductivity and average density, reduces strength. The degree of reduction in the strength of the material under its limitization is called water resistance and is characterized by the softening coefficient. Materials with a coefficient of softening of at least 0.8 are apparent. They are used in the structures in water, and in places with high humidity.

Moisture report - This property of the material to lose moisture in its pores. The moisture studio is characterized by the percentage of water, which material loses per day (with the relative humidity of the ambient air 60% and the temperature of +20 ° C). Moisture studio is of great importance for many materials and products, for example wall panels and blocks that in the construction process usually have increased humidity, and under normal conditions, due to water, water is dry - water evaporates until the balance between the moisture content of the wall material and the humidity of the ambient air is established, i.e. until the material reaches air -Suh state.

Gigroscopic - Property of porous materials absorb moisture from the air. Hygroscopic materials (wood, thermal insulation materials, semi-dry pressing bricks, etc.) can absorb a large amount of water. In this case, their mass increases, the strength is reduced, dimensions change. For some materials in conditions of increased and even normal humidity, protective coatings have to use. And such materials as dry pressing brick can only be used in buildings and rooms with reduced air humidity.

POWER PERFORMANCE Call the body's ability to pass water under pressure. This characteristic is determined by the amount of water under constant pressure for 1 hour through the material of 1 m 2 and 1 m thick. The waterproof includes particularly dense materials (steel, glass, bitumen) and dense materials with closed pores (for example, concrete specially selected composition).

Frost resistance - This is the ability of the material in a saturated water condition to withstand multiple alternate freezing and thawing without reducing strength and mass, as well as without cracking, separation, crumbling. For the construction of the foundations, walls, roofs and other parts of the building subjected to alternate freezing and thawing, it is necessary to use materials of increased frost resistance. Dense materials that do not have pores or materials with a slight open porosity, with water absorption not more than 0.5%, have high frost resistance.

Thermal conductivity - The property of the material to transmit heat in the presence of temperature difference outside and inside the structure. This characteristic depends on a number of factors: the nature and structure of the material, porosity, humidity, as well as from the average temperature at which heat is transmitted. Crystalline and coarse materials are usually larger than the materials of an amorphous and small-handed structure. Materials having closed pores have less thermal conductivity than materials with informative pores. The thermal conductivity of a homogeneous material depends on the average density - the smaller the density, the less thermal conductivity, and vice versa. Wet materials are larger than dry, as the thermal conductivity of water is 25 times higher than thermal conductivity of air. The thickness of the walls and overlaps of heated buildings depends on the thermal conductivity.

Sound absorption It is called the ability of the material to weaken the intensity of the sound when it passes through the material. Sound absorption depends on the structure of the material: the reporting open pores absorb the sound better than closed. Lilated walls and partitions with alternating layers of porous and dense materials have better soundproofing indicators.

Fire resistance - This property of materials is to withstand the action of high temperatures. According to the degree of fire resistance, materials are divided into non-aggravated, difficult-combustible and combustible. Failure materials (brick, concrete, steel) under the action of fire or high temperatures are not ignited, not smoldering and not charred, but can be very deformed. Empty-facilible materials (fibrololite, asphalt concrete, etc.) are smoldering and harbor, but after removal of the source of fire, these processes are terminated. The combustible materials (wood, rubberoid, plastics, etc.) flamm or smoldering and continue to burn or smoldering and after removal of the source of fire.

© 2000 - 2002 Oleg V. Site ™