Crushed stone: classification, density, fraction, specific weight. Specified rubble

Crushed stone is auxiliary building material, and is characterized by quite frequent use in various situations. The specific direction of application of rubble depends on its origin, fraction and some other parameters.

Granite rubble medium fraction

The most widespread crushed stone from the granite of the middle fraction with a particle size of 20-40 mm. Due to these by the following factors:

- The material of the origin of rubble (granite) is characterized by strength, resistant to negative environmental factors and high-load resistance.

- The 20-40 mm fraction successfully combines the advantages of rubble small fraction and large.

- The cost of this type of material is also quite medium.

The foregoing allows us to use this type of rubble in the production of concrete and reinforced concrete products, when preparing pillows for road construction or under the foundation.

Weight rubble

Since crushed stone refers to bulk materials, usually, its measurement is carried out in volume measures, that is, in cubic meters. In some cases, we need to better know the weight of rubble more or less.

- During transportation;

- When planning the outcome weight of the reinforced concrete product;

- When calculating the loads on the soil and other structures rendered by a cushion from rubble.

Weight rubble depends on various factors:

- Material of origin;

- Fraction size;

- Water absorption coefficient.

Since the granite crushed stone of the middle faction is the most popular, and consider it in more detail.

Determining weight factor is the material of origin. For example, a cubic meter of a tumped rubble (porous, lightweight material) will weigh about 800 kg, and the same cubic meter of sandstone rubble - 1.3 tons. If we consider the granite crushed stone of 20-40 interested in us, the weight of 1m3 will be about 1,400 - 1 500 kg.

In other words, the more denser the source material, the hardest it will be crushed stone.

The next important factor is the size of the fraction. What it is less, the less emptiness between the particles. Thus, rubble completely fills the volume, and the cubometer of small rubble will weigh more than the cubometer is larger, but to a certain limit. If the fraction refers to large, then the voids between the particles are compensated by the weight of the particles themselves, and the total weight of the rubble in the cubic meter is growing again.

The fraction of 20-40 mm considered by us is medium, and it is its weight in the cubic meter that will be minimal. For granite rubble It will be approximately 1,400 - 1,410 kg.

Secondary weight factors

The leachy of particles is less affected by weight, but still noticeable. The amount of emptiness in the crushed stone with high testicle will be greater than that of a low-rate crushed stone. Accordingly, it will be less than the average.

Similarly, the high coefficient of water absorption increases the weight of rubble due to the addition of the weight of absorber water.

Important clarification

Please note that the specified numbers are averaged. If you're important to know accurate weight The rubble used, it is necessary to resort to a special procedure for weighing bulk bodies, which allows you to determine the weight adjusted for all possible factors.

Granite rubble mining

Application of rubble fraction 5-20

Crushed stone Dolomite 5-20.

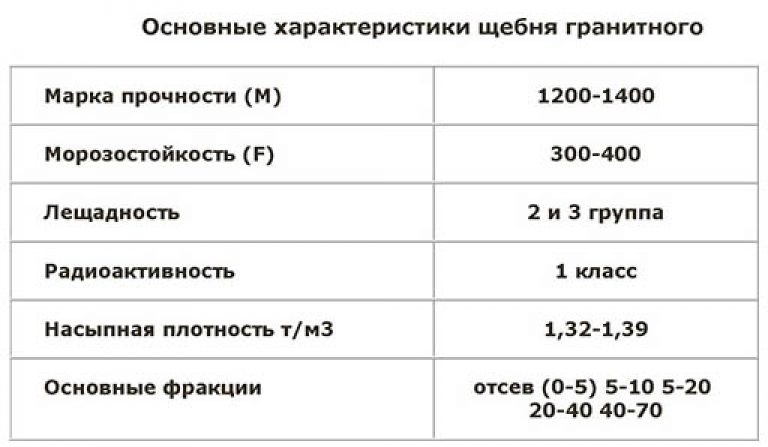

Today, granite crushed stone is the most sought-after building material. Such high popularity is associated with good performance characteristics that allow it to use it in almost all spheres of construction.

Get granite rubble by crushing solid natural stone Grain structure on special equipment. Initially, boulders are mined by an explosion of a rock, which consists of hardened magma. Next, these blocks are subjected to crushing and after that sifted by fractions (size). Thus, the granite crushed stone is completely natural materialwhich meets all the accepted environmental standards.

Depending on the final particle size, crushed stone is divided into various fractions. The most popular in construction is the granite rubble fraction 5-20. The crushed stone of this fraction is used in the production of concrete. It is also used for laying and repairing roads, coatings for runways of airfields, the construction of grounds for buildings, houses, other structures. The high quality of this building material allows to improve the final indicators of concrete, road surfaces and extend their life several times.

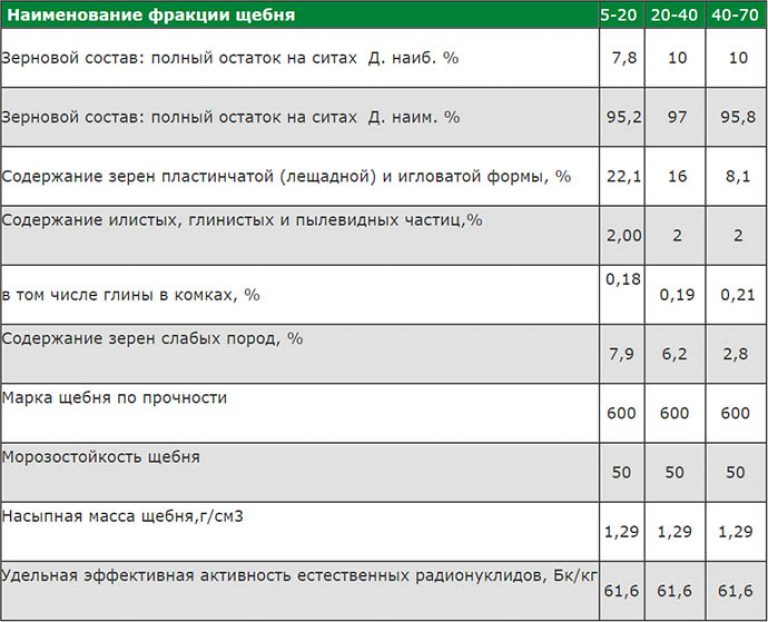

Characteristics, Properties of rubble fraction 5-20

One of the most sought-after factions of the granite rubble is 5-20. Its size and composition allow you to apply it in different areas Construction, as well as in the production of high-strength concrete.The main characteristics of the rubble fraction 5-20 are:

1. Density.Variable from 1.3 to 1.45 t / m3.

2. Radioactivity.Granite crushed stone refers to grade 1 in terms of radioactivity (less than 370 Kb / kg). That is, the content of harmful elements in it, impurities are within the permissible GOST norm. When using the rubble fraction 5-20 in the production of concrete, this indicator is significantly reduced.

3. Resistance to low temperatures. This building material is able to withstand up to 400 frost cycles. In this case, its internal characteristics do not change.

4. Beschy. Crushed stone fraction 5-20 belongs to the 1-2 bodybuilding group (low). The content in the composition of the needles and lamellar particles does not exceed 15-20%. This parameter is extremely important in the production of concrete. The lower the level of brees, the less costs for its production.

5. High level of adhesion.

6. Crushed stone 5-20 fraction perfectly interacts with other materials (for example, bitumen).

7. Low water absorption. Crushed stone 5-20 fraction can be used in the construction of buildings, structures with high humidity.

8. Grain composition. According to the content of weak particles, crushed stone does not exceed 4.9.

Granite rubble mining

Today, granite crushed stone is produced in the territory of many states. The main method of its production is a career way. Granite crushed stone is obtained from a solid rock (granite rocks), which is distinguished by the grainy structure. In its composition, such a breed contains quartz, mica, feldspar. For this reason, the granite crushed stone can be gray or pink with small splashes Dark color.To obtain granite blocks applied drill material. IN mountain breed A high depth hole is done and then the charge for undermining is laid into it. In this way, a small size of the boulder is obtained. If the first time it did not work out to get the blocks of the desired size, the cliff is undermined.

For crushing cliffs, crushers of different types are applied. The most economical option is the use of a cheek crusher, which simply crushes the granite rock between its carrier elements. The second most popular way is the use of a rotary crusher. When using such equipment, the breed is crushed under the influence of a rotary motor. To obtain as a result, the crushed stone of the smallest fractions use centrifugal-shock-type crushers.

In addition to crushing granite blocks, special devices are used by the usual option. sift breed directly in the career. In other words, the remnants from the main production (pieces, cobblestones) are sieved with subsequent sorting.

After the end of explosive works, all obtained granite blocks are transported by special technique to stationary crushing and sorting complexes in which they are under thorough grinding on various fractions (from 2 mm and up to 70 mm). Next, crushed stone is subject to sorting on various fractions. In some cases, mobile-type crushes are used, which allow you to sort the crushed stone to various fractions right on the place of its extraction in the career.

Application of rubble fraction 5-20

Due to its high performance characteristics, rubble shallow fraction (5-20) is widely used in various fields of construction, as well as decoration of premises and landscape design. The combination of small and small particles in the granite crushed stone allows you to give products from it (concrete, bitumen-asphalt coating, etc.) increased strength and makes it possible to use for coatings for which an increased load is projected.The main spheres of the use of granite rubble fraction 5-20 are:

1. Application in the construction of house foundations, including high-altitude;

2. Use in laying road surfaces, as well as repairs;

3. Production of concrete, asphalt;

4. Application in the construction of bridge designs;

5. Construction of coatings for the needs of airfields.

As practice shows, the use of granite rubble allows the extension of the service of concrete structures and asphalt coatings. on average in 2-4 times. Due to the use of granite rubble, the coefficient seals seals 1, which allows not only to extend the life of the coating, but to have a high level of its frost resistance. Also, when used by the Granite Rubble, the time costs of organizing a focal point (asphalting) are significantly reduced. Workers approximately 2 times will be able to faster all the necessary procedures.

When using the 5-20 fraction of the fraction 5-20 V construction workah significantly decreases capacity of the necessary binders, such as cement, bitumen. All their number decreases by 20 -25%.

Today, the granitstovebel is actively used in the production of concrete. It uses electricity costs 2 times, and as a result, the cost of concrete is reduced by 5-8%.

The modern situation of embedded is characterized by a constant increase in flow traffic on the roads, therefore, to ensure the safety requirements, the qualitative road covering. But one of the fundamental perpetrators of the rapid destruction of roads in our country serves the use of the community-based construction materials - rubble.

Crushed stone 5-20 How many tons in Cuba (rubble weight 5-20 fraction)

With any construction, it is important to pre-calculate the number of necessary building materials. In large construction organizations These calculations lead experienced professionals. But it is possible to calculate how much the rubble is needed for the needs of construction.Payment need quantity The rubble of the 5-20 fraction is carried out in tons or cubic meters. To calculate the calculation, it is necessary to know such a characteristic as the density of rubble. For the granite rubble fraction 5-20 given The indicator is from 1.3 to 1, 45 t / m3. To perform an accurate calculation, it is best to contact the supplier of granite rubble and clarify the data.

In order to find this value, it is necessary to divide the weight of rubble to the density. At the density of the rubble fraction 5-20 in 1300 kg / m3 (1.3 t / m3), 1000 kg is divided into density. Thus, we get result 0,769 m3 in a ton of the source material.

Fraction sealing coefficient 5-20 fraction

When carrying out construction work, it is necessary to clearly understand the number of materials that will be required. At the same time, the initial values \u200b\u200b(the amount of material purchased from the supplier) may differ from the final when delivered to a specific object. This is due to many factors, including the ability of bulk materials (sand, rubble, soil, etc.) to be seal during transportation.The seal coefficient is a numerical value that is determined based on the norms of the GOST and takes into account the degree of material sealing (in this case, rubble) during its transportation.

As for the granite rubble fraction 5-20 for it it is worth applied The value set by GOST 9757 - 90 in the amount of 1.10. That is, for the implementation of calculations when delivering a rubble, you need to measure the length and width of the machine's body, multiply these values \u200b\u200band multiply to multiply rubble seal coefficient 1.10.

If the crushed stone delivered in the car rolled over the surface of the side, another 2 m3 is usually added to the resulting volume value. This value is generally accepted.

Limestone crushed stone fraction 5-20

Limestone crushed stone is a building material that is obtained by crushing natural stone. The distinctive characteristic of this type of rubble is a unique shade of its stones. Depending on the presence and number of impurities limestone crusp Maybe white, yellow or red. All these shades are allowed in it.Limestone crushed stone is different fractions. The most demanded today is FR 5-20. Excellent performance characteristics of building material make it possible to be widely used in construction (industrial, housing, road) and national economy (in the glass and printing industry). The undoubted advantage of this type of rubble is its low cost.

The main characteristics of limestone rubble are:

1. Low level of brees (10-13%);

2. Density of 1.3 t / m3;

3. High levels of frost resistance;

4. Low water absorption (no more than 2.5%);

5. No harmful elements in the composition and various impurities.

In the construction of limestone crushed stone is actively used for the organization of the Motorog (not federal value), swelling of roads, congresses. Also, it is also applied in the sphere of landscaping of private territories (preparation of the base for asphalt, platforms, sidewalks and pedestrian-stage).

Crushed stone Dolomite 5-20.

Dolomite is a sedimentary breed, which consists of rowers, including dolomite. This natural mineral is distinguished by the level of strength. Crushed down of this type get through the end natural stone Special devices and equipment. The in the afternoon crushed stone is chemical processing. This crushed stone must contain at least 75% mineral dolomite in its composition.Grains rubble outwardly close to the shape of a cube. According to mine technical characteristics Dolomite crushed stone is similar to granite, but the price is significantly different. Not bad performance characteristics of dolomite rubble determine the wide range of its use in various fields of construction. It is used as the main material for the construction of roads with low transport loads, powder. Also, dolomite crushed stone is used in the production of cement, printing industry, metallurgy, as well as the glass industry and in the manufacture of mineral fertilizers.

Dolomite crushed stone differs from the granite number of essential characteristics. Firstly, He is less radioactive. Secondly, in its properties it can be called more connected compared to granite rubbleThat as a result, significantly increases the quality of final products, which is made using a dolomite rubble.

Among the features of the dolomite rubble can be allocated:

1. High degree of strength. According to many specialists, the dolomite crushed stone is not inferior to the granite.

2. High water resistance. In contrast to the limestone type of rubble, the dolomite crushed stone practically does not absorb water and does not hold moisture.

3. Low radioactivity. As practice shows, the degree of radioactivity of the dolomite rubble several times lower than the granite. At the same time, their strength and density are very close.

4. Frost resistance. Rubble Dolomite fraction 5-20 calmly withstands many frost cycles and thawing.

5. Low price.

The price for many people is a decisive factor when choosing a building material. In the case of a dolomite rubble, the cost of one ton 2 times lower than granite.

What crushed stone is better to use in the improvement of territories

The choice of building materials is the key to the successful work on the improvement of the territory around its home. After all, it is from their quality that the time of operation of the coating is largely dependent.To date, the preparation of the base for the coating (asphalt, paving slabs) implies the use of rubble. Here and the question arises, what crushed it is better to choose. What fraction to stop your attention.

Crushed stone is three species - limestone, dolomite and granite. They differ among themselves performance characteristics and price.

The most durable and durable is considered granite crusp. The service life is significantly different from the remaining types of rubble. The average cost of the granite rubble fraction 5-20 is from 1200 rubles per 1 ton. It is able to withstand up to 400 frost cycles. The level of its radioactivity is within acceptable limits (according to GOST - 1 class). The granite crushed stone of the fraction 5-20 practically does not absorb moisture and in the case of hitting it does not hold it. The high properties of granite rubble make it possible to use it during the construction of roads of federal significance, as well as covers of the runway at airports and airfields.

Limestone and dolomite crushed stone It is good to use under the base of the coating, which will not be paid for special pressure and load. It's nice to please their cost. The average price for 1 ton is 600-650 rubles. These types of rubble are not recommended to be used in places where it will be huge pressure on the surface, etc.

The second criterion for dividing rubble is its fraction (size). Currently, the most popular option is the fraction - 5-20. It is a mixture of cubic grains not exceeding a diameter of 20 mm. This size is ideal for the preparation of the base under the asphalt, laying paving tile And there is an almus of this fraction can only be dropped.

Thus, when choosing rubble the main thing to pay attention to the amount of loadwhich will be on the surface (asphalt, tile). If the load is big, it is better to take granite crushed stone. In other cases, you can choose limestone or dolomite. As for the faction, it is better to stop your choice by 5-20.

The answer to the question of how many brought the supplier you are very simple. It is enough to know the cubage of the car in which you brought crushed stone. The cube of any car is now not the problems find on the Internet.

Knowing the cube of the machine and the weight of 1m3 rubble will be easy to see if the supplier has a latter large amount of rubble. All this is easily determined using an ordinary roulette!

Weight rubble in fractions in the table.

| Fraction rubble | Weight rubble in t / m3 | Weight rubble in kg / m3 |

| 0-5 | 1,41 | 1410 |

| 5-10 | 1,38 | 1380 |

| 5-20 | 1,35 | 1350 |

| 5-25 | 1,38 | 1380 |

| 20-40 | 1,35 | 1350 |

| 25-60 | 1,37 | 1370 |

| 40-70 | 1,35 | 1350 |

| 0-70 | 1,52 | 1520 |

Opening Granite fraction 0-5 mm ~ 1.41 t / m3

Crusheden granite fraction 5-10 ~ 1.38 t / m3

Crushed stone granite fraction 5-20 ~ 1.35 t / m3

Crushed stone granite fraction 5-25 ~ 1.38 t / m3

Crushed stone granite fraction 20-40 ~ 1.35 t / m3

Crushed stone granite fraction 25-60 ~ 1.37 t / m3

Crushed stone granite fraction 40-70 ~ 1.35 tons / m3

Crushed stone mixture of fraction 0-70 ~ 1.52 t / m3

See the same way

- Sweet weight

- concrete share

The article specifies the approximate weight of the rubble of each fraction.

Become about the weight of rubble in 1 m3. How to determine how much will weigh the cube cube? What is the weight of 1m3 rubble. We hope the information pro volume weight Rubble will be very useful for you in further work.

Crushed stone 20-40 refers to the medium-complete, this brand is considered one of the most sought-after in private, road and industrial construction. When calculating quantity required material, volume of warehouse premises and carrying capacity of transport for its transportation by the main indicator of the bulk (bulk) weight, taking into account its mass in natural condition, including pores and emptiness. Its value is necessarily indicated in the supplied certificate along with the rest of the performance, if desired, it is experimental.

Specific and volumetric concept

At perfectly tight bodies, they coincide, in other cases the difference is to take into account the volume of the interior and emptiness. In practice, the volume (bulk) weight in most building materials is less specific to the magnitude of the porosity (for building rubble From dense and solid rocks, its value rarely exceeds 7%). Practically, it reflects the weight of the material that is combined from a height of 100 mm into a container equal to 1 l (at home the container is weighed before and after filling, its dimensions make it easy to find the exact volume). All calculations are carried out exclusively for rubble in a dry state.

In this way, specific gravity It is an absolute (ideal) value, volumetric - practical. In construction, the second term is often replaced by the concept. bulk density. For rubble with the size of fractions of 20-40 mm, the difference between it and the true (starting breed without pores and voids) reaches 50% and higher, this is due to the large amount of air involved between individual grains. Accordingly, the smaller the particle size, the higher the volumetric weight.

The indicator refers to auxiliary, but it plays an important role in calculating the number of building materials and selection of proportions. Knowing the size of a concrete structure, it is easy to find the required weight of solid large-scale filler. The desired value is determined by multiplying its volume on the proportion of the rubble and the coefficient of the seal (for bulk crushed rocks, its average value is taken equal to 1.3, the manufacturer is more accurate). Similarly, the lifting capacity of vehicles for transportation or required storage warehouses is carried out.

The value of the specific gravity is influenced:

- The true density of the initial breed. 1 m3 of a whole piece of cliff weighs almost 2 times the same material in a fragmented state. This indicator cannot be determined with high accuracy at home, oriented to the values \u200b\u200bspecified by the manufacturer. In practice, it differs even in the same rocks, with an equal grade of the strength of the crushed stone or gravel 20-40 mm (or another fraction) from different quarries will weigh differently.

- Fraction size - numerical differences in specific weight for different marks It's small, but the smaller the grain, the more dense they fit together and the better the concrete is better.

- The water absorption coefficient, which is dependent on many factors: from porosity and roughness to the form of particles (needle and incorrect is better absorbed and kept moisture on the surface even under the condition of a highly qualified internal structure).

- Beshechy - the higher the proportion of fractions with the right and cubic form, the less air is involved and the more he weighs.

The material quickly gains moisture, to change the bulk weight, a sufficiently light blotch under the rain. For this reason, all calculations and practical actions are carried out with a pre-prepared filler - maximum purified from foreign impurities and dry.

The weight of the fraction of 20-40 mm for different species rubble

| Variety of rubble | Value value,% | True material density, kg / m3 | Volumetric weight, kg in 1 m3 |

| Granitis | 19 | 2650 | 1350 |

| Gravine | 15 | 2600 | 1470 |

| Limestone | 20 | 2800 | 1300 |

| Secondary | 25 | 1800 | 1250 |

| Slag | 2950 | 1500 |

The figures presented are averaged, the specific gravity of 1 m3 of the granite rubble fraction 20-40 reaches 1400 kg / m3 (even higher at the gabbro-diabasic brands). They can be used under preliminary calculations, for private construction and small-sized structures, the error will be small. But when working with large volumes of crushed stone or gravel, repels exclusively from the value specified in the certificate.