What does cement brand mean. Marking of different types of cement. Cement production technology

Today on the counters of construction stores you can see the diverse and grades of cement. On each of the bags there is a rather wisdom inscription, "decipher" which without some knowledge is very difficult. On how to choose the correctly choose one or another cement, we will tell below.

Definition of cement brand - we understand the terms

Suppose you are a bag with M500 label (or PC500). In fact, everything is quite simple: the figure 500 denotes that the cement stone made from such a powder is able to withstand the limit marking load of up to 500 kg per 1 cm 3. In other words, the brand is the same as the strength. At the same time, the "four hundredth" material will lose its "five hundredth" colleague of as much as 100 kg per 1 cm 3. Cement and higher quality are manufactured, M550, M600 and even M700. Until recently, the plants produced low-time - M200 or M100, but today the minimum quality is M300.

Another part of the cipher is the letter "D" with numbers from 0 to 20. They reflect the number of additives introduced into the material in percent. Accordingly, the marking of D0 will tell that you are "clean" cement, and D20 will tell about the 20 percent content of additives in it. These additives somewhat change the properties of cement, for example, increasing its moisture or frost resistance.

Also on bags you can meet other designations. Letters "BC" You mean that in front of you, which is used both for masonry and for casting ornamental products. The abbreviation "SS" will indicate a high sulphate resistance of the composition, and "GF" - on increased hydrophobicity (such a composition does not absorb water in the process of transportation and storage during a certain period). The combination of the "WCC" letters denotes that this cement -, and the "pl" indicates the presence of plasticizing additives.

Cement marking on a new standard

Currently, most major cement producers have changed marking according to the requirements of the new GOST. Now instead of the usual designation M400-D20; On bags, you can meet such encodings as (in accordance with the above): CEM II / A - W 32.5 (with the lites "b" or "n") and other similar.

The literal "A" in the encodion indicates the presence of from 6 to 35% of additives, and the letter "sh" - SlagoporTland cement. In the event that there is a letter "P" in the labeling, then in front of you - Pozzolan cement. The letter "B" means fast-hardening, the letter "H" is normal-hardening. Each of these compositions is used for a certain type of work.

- M400-D20 - used in private and industrial construction; The composition is characterized by increased moisture and frost resistance.

- M400-D0 - It is used in the same way as the previous variety of material, but it has a smaller resistance to corrosion and frost. Also used when the concrete is shown used to create underwater structures.

- M500-D20 - in private construction and finishing, as well as for casting monolithic and.

- M500-D0 - for the construction of large industrial structures, to which there are highly high demands on durability and frost and moisture resistance, as well as for urgent rehabilitation and emergency work.

How to determine the cement brand in laboratory conditions?

All major manufacturers experience cement for compliance with the brand in special laboratories, where they check its strength to compression and bending. For the beginning, three control samples are made with parameters 4x4x16 cm. For this solution, which includes 1.5 kg of sand, half aulogram of cement powder and 0.2 liters of water are layered into a special shape and put it on vibrationtol. On the vibrationtol, the form is within three minutes, then it is turned off, and the excess solution is cut from the control samples.

Then the shape together with the samples is immersed in the bath and store there one day. After that, the beams are removed and again laid into the tank with water so that they do not inactor with each other. Samples are stored in water at a temperature of 20 ° C for 28 days (by expiration of two weeks, the water changes).

After that, the control samples are removed from the bath with water, dryly wipe and placed in a special machine, which determines the bending strength. It is installed as a mean arithmetic according to the results of tests of beams. Then go to the test of compression strength. Received as a result of previous tests, halves of beams are compressed by a special press. The total compression strength is also defined as the arithmetic average according to the results of the tests of all samples. The vintage strength of cement is determined in accordance with special tables.

Of course, at home, it is impossible to determine the cement brand, therefore, in order not to be mistaken when it is elected, it is necessary to acquire products of large, long and well-proven manufacturers.

Today, construction without cement is unthinkable, but not many of the treasured construction of the house know about the properties of cement, about marking cement and additives in it. This article is intended to familiarize you with various species Cement for various needs, indicate the feasibility of application different marks Cement for various works, whether it is filling the foundation or plaster walls. After all, the expedient use of cement is not only capable of keeping your funds, but sometimes it is more important to save you from work on errors.

Cement composition (main component)

At cement plants, cement is obtained by crushing limestone (stone), clay and additives. As an additive, a material with irreversible properties is usually used, in case of frozen after mixing with water, such as plaster. It is also possible to apply the stuffed mixture of limestone and clay called - clinker. Now you have learned a little about the main component of cement.

Of course, as you guessed it is not without additives, without different interest ratios, otherwise all cement would be the same or cement would be one for everything that ultimately the same thing. That's precisely on optional additives and labeling, we will talk further.

Marking on cement bags

In fact, on bags with cement, you can see: cement M300, cement M400, cement M500. Currently, the maximum can be found cement with marking M600 and M700, but they are used very rarely, mainly in military construction. On bags with cement, you can also see in addition to the main index of the letter d, after the main marking. For example: cement M500 to, cement M400 D20. Next, we will talk about what such Marking on cement bags means.

Decoding cement marking

To assign a particular grade of cement, laboratory tests of the samples of the batch for strength are carried out. Several rectangular blanks made from a mixture of cement, sand and water. After grappling, hardening and drying, they are exposed to bending and compression. Marking - M actually characterize the strength to the sample compression. A sample (cube cement) is placed in the press and gradually with the recording of the load results are compressed before destruction. The strength of compression is calculated by the average arithmetic for 4 samples showed the best results from 6 taken.

The M500 cement must withstand the load of 500 kg per cubic centimeter, respectively, the M400 cement, the price of which will be slightly lower, withstands the load of 400 kg per cubic centimeter. So, with the notation: Cement M500, M400, M300 we figured out. It remains to know what D0, D20, D80, and other similar codes on packages with cement, after the main marking. If the letter "M" on a container with cement indicates its marking characterizing strength, then "D" - shows the percentage ratio of additives and clean clinker in the cement batch. We told you such a clinker before, in fact, this is the main binding component of cement.

But we will talk about the additives themselves.

Additives in cement

Additives give the cement various additional properties: hydrophobicity, frost resistance, rapid solidification, corrosion resistance, saline water, etc. The inscription Cement M500 D20 suggests that this Party contains 20 percent of any additives. If there are no additives in the batches, the designation of the type of cement M400 D0 is applied to the bags. The possible content of additives may exceed 20%, then such cement refers to a group of slag cements, it is also called SlagoporTland cement.

Together with the designations of the species - cement M400 D20 or M500 D0, additional abbreviations may occur, for example, cement M500-D20-SS. The last two letters indicate which properties are attached to the cement additives introduced into it.

Decoding additives in cement

SS is a sulfate-resistant cement, which is used to build hydraulic structures that will be in aggressive salted water containing sulfate minerals. There are other designations of additives:

- PC is an ordinary portland cement;

- SPC - Slagoportland cement containing additives more than 20% compared with the clinker part;

- BC - white cement used for finishing works;

- VRC - waterproof expanding cement. Used to seal seams in hydraulic structures. Characterized by a rapid time of setting (from 4 to 10 min);

- n - normalized cement (manufactured using a clinker of strictly normalized composition;

- PL - plasticized cement (has increased frost resistance);

- GF - hydrophobic cement. This type of cement, due to the fact that it does not absorb water for 5 minutes, you can carry for considerable distances, it is not so afraid of dampness as an ordinary portland cement. In addition, the hydrophobic cement has high plasticity and frost resistance;

- b - fast-hardening cement (used for urgent repair work).

Now, going to the store and buying a cement of a brand, for certain needs, you will be able to establish that it will be an optimal choice for you or at least you will know what you pay money.

The scope of the application of cement is very extensive: from the kneading porous plaster solutions to the concreting of particularly loaded structures. An important nuance of the technology is the definition of a brand with the necessary parameters and characteristics, an erroneous selection leads to overruns, violation of proportions, laying or fill is obtained by poor quality and after a short period of operation will have to be repeated. The main benchmarks are compressed strength, the presence of impurities used for the preparation of raw materials and thinness of the grinding. The conditions for conducting work and operation, the timing of hardening, the need to enhance the hydrophobic properties and frost resistance of concrete is also taken into account.

On the packaging with the cement, the letter and digital abbreviation, which includes information about the composition and basic characteristics. Marking according to the old GOST 101785 began with the type of mixture (PC - Portland cement, SCC - Slagoportland cement), followed in the form of a three-digit number. The third in the decoding of the brand was an element denoting mineral additives In percentage ratio (no more than 20%), additional properties were indicated after it. The following abbreviations are often found:

- B - fast-hardening cement.

- SS - sulfate-resistant (needed in the construction of hydraulic structures).

- WCRTS - waterproof expanding.

- PL - cement with plasticizers (recommended to increase the frost resistance of concrete structures).

- BC - for decorative cladding.

- N is normalized (with the addition of clinker, guaranteeing the standard of strength).

Since 2003, there has been a new GOST 31108, the decoding of the cement marking is slightly unusual. Initially, the composition is indicated (I - without additives, II - with them). The latter group is separated on the mixture with the percentage of impurities from 6 to 20% (marked with the letter A) and in the range of 21-35% (CEM II B, respectively).

Roman numbers denote the type of impurity: Pozzzolan, granulated slag or composite composition. Only then there is a digital indicator - the class of strength, in the range of 22.5-52.5, after which the norms of compression of the material are indicated - from 2 to 7 days: H - normal-hardening (up to 22.5), C - medium, and b - fast-hardening (from 32.5-53.5). Usually, on the package at the same time there is a new marking and the corresponding old one.

Characteristics and properties of cement

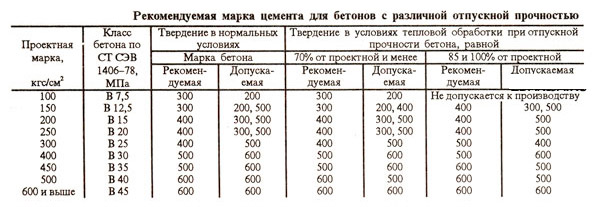

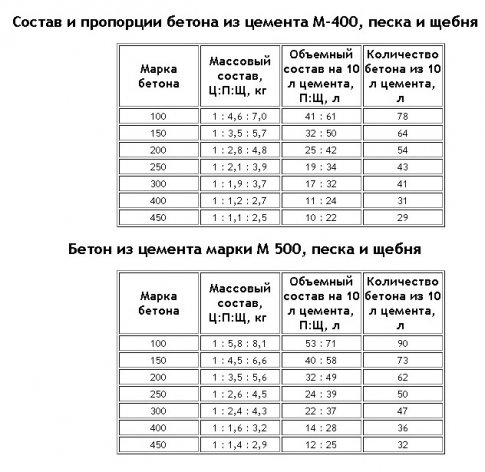

The most important parameter is the maintenance pressure during compression, according to which the stamps are determined by strength. The table shows the link between the old and current designations of this indicator:

| Strength class | Cement Strength Brand (according to old labeling) | Withstand pressure | |

| in MPa | in kg / cm3 | ||

| B22.5 | M300 | 22,5 | 300 |

| B32.5 | M400 | 32,5 | 400 |

| B42.5 | M500 | 42,5 | 500 |

| B52.5 | M600. | 52,5 | 600 |

The most popular brand is a portland cement with a strength class 32.5, as an optimal price / quality ratio. M500 is considered suitable for more responsible buildings: industrial, with special requirements for reliability and durability.

In contrast to concrete, a frost-resistance brand on cement packaging is not indicated, this characteristic is determined by the ratio of V / C, the solidification conditions of the solution and the presence of air-acting impurities in it. For the construction of elements withsting low temperature differences, a portland cement is considered not lower than M500 D0 (that is, without impurities), in particularly complex cases it is necessary to use varieties with additional marking of pl (with plasticizers).

Other important properties and performance features are indicated in the table:

Such properties of cement are also evaluated as resistance to sulfates and corrosion, water resistance. All these indicators are marked separately.

Application of concrete marks

For many purposes, a portland cement is coming from raw materials with a high content of silicates, which guarantees good strength, frost resistance and minimal shrinkage. The exact purpose depends on the type and grinding of clinker and other components that are part of the components. For determining the desired brand cement should be taken into account not only by its properties, but also external conditions Work and operation. The incomplete compounds are distinguished by a higher rate of hardening, depending on the strength, the use of PC-D0 is recommended:

- M400 - for monolithic and precast concrete.

- M500 - in the production of hydraulic structures and plates located in the zone of variable water levels, asbestos-cement products, fill the sidewalks and borders, arrays from concrete, foundations of all types.

- M600 - for concreting prefabricated structures with high quality.

- M700 - to create concrete with the class of strength from B35 and working with high-stranded buildings.

Portland cements with mineral impurities up to 5% have practically the same characteristics as D0, and PC D20 is inferior in useful properties. The latest brand is not allowed when the concrete kneaders with certain requirements for frost resistance (from F200 and above) are at least without air-proof additives. Another kind of portland cement is a quick-hardening, it is recommended when driving high-speed construction (for example, using a sliding formwork). In this case, the strength set to the desired state occurs within 3 days, not 28.

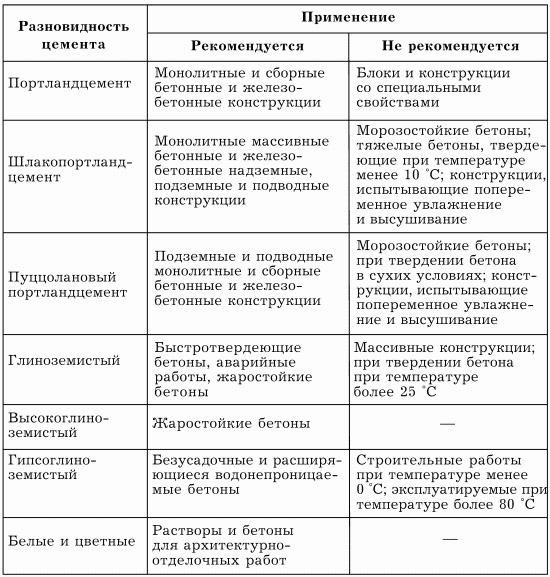

- Slag formulations.

These grades of cement are a mixture of finely crushed portland cement clinker and granulated slags (up to 30-35%). They cost cheaper, but inferior in strength and timing of hardening, their optimal scope of application - hydraulic structures (they do not swell in water) and prefabricated reinforced concrete structures. Also on their basis it is advisable to knead plaster and construction solutions. But a significant proportion of impurities adversely affects frost resistance, as a result, slag cements cannot be used to concrete structures with the requirements above F100 (that is, for foundations). Exception - solutions with air-penetrating additives, subject to work in the mode of alternate humidification and long-term excavation of concrete.

- Almighty formulations.

The characteristic features of these cement marks are the high pace of hardening, weather resistance and sulphate resistance. On their basis, heat-resistant concretes are mixed and expanding building mixes are produced with the addition of gypsum. In private practice, their use is rare, they are sensitive to the conditions for the preparation of solution and operation. The most popular option is the waterproofing of the joints, wells, slab jumpers.

![]()

- Expanding and strain cement.

These stamps are distinguished by a positive linear extension when hardening and high rates of setting. They are economically unprofitable to use for standard concrete structures, the preparation of solutions based on them is carried out in emergency situations. They are also recommended if necessary to create impenetrable moisture, steam or gas structures. This cement group is represented different brands With excellent properties, each has its own characteristics and performance, to buy them for individual purposes follows after a careful study of the supplied certificate.

In 2003, the new GOST on the marking of cement entered into force. (GOST 31108-2003). The main sense of innovation was to summarize the Russian standards for European quality standards. (EN197 - 1: 2000). However, the old regulatory documents and the norms of GOST from 1985 (GOST 10178-85) remained relevant to many domestic producers. As a result, many customers who want to buy cement wholesale or retail are confused in the designations and marking of the material.

Cement marks: Old GOST

The old cement designations included three main brands: 300 hectares, PC 400 D20 and PC 500 d0. The Abbreviation of the SPC means the Slagopard AddCenter, PC is a portogen, the letter d means - additive, index 20 speaks of the maximum percentage of additives 20% of the total volume, according to GOST. Marking D0 - no additives. (Usually, a domain granular slag is used as additives into cement - by-product of the production of the metallurgical industry).

According to the old GOST in cement, the 300 Slag Cement can be from 20 to 80%. Also on the old rules for the designation of PC 550 and 600. The use of building materials had a wide range. For example, the SPC 300 was used to produce low-quality concrete (sewer rings, trays, stairs). The use gave substantial savings in comparison with more dense types of material.

The main running type of cement was PC400. It has an average strength. And the building material with the index 500 was used for the production of high-quality concrete (aerated concrete, ribbon foundations, overlap). Cement 500 The price of which was the highest was needed in cases when it was necessary to get the most easy, but high-strength concrete.

Cement marks: New GOST

In accordance with the charter of the new GOST, 5 cement stamps are provided: CEM 1 - a progressive portland cement, CE 2 is a portion with active mineral additives. Come 3 - Slagoportland cement, and new cement brands - CEM 4 with Pozzolan additives and CEM 5 - composite with various impurities and their configuration (slag, lime, gypsum). The main species that are widely used are the first three categories.

For cements of the second and third group, subgroups A and B are provided, which indicate the number of additives in the mixture. Category A - 6-20% - impurities, and in - 6-35%. The third grade cement has only one designation A - 36-65%. The grade of cement of the first type does not have subtypes. The most common second category through the hyphen is indicated by the name of the active mineral additive.

Literal names: Shlak, and - lime, zola, MK - microcline. Also cement is marked by strength. According to the new GOST there are 4 notation: 22.5, 32.5, 42.5 and 52.5. Prefix - N - normally hardening, b - fast-hardening. For a fast-hardening cement, it is customary to determine the strength of the standard temporary interval - 28 days, already at the age of two days the strength must be no lower than a certain indicator.

Correlation of cement brands according to GOST

It is worth starting with Portland cement PC500 D0 because it is the cleanest and quality cement. It consists of cement clinker (95%) and plaster (5%). Gypsum is a setting stabilizer. Without it, the material quickly hardens and loses its operational properties. According to a new standard of grade of cement, PC 500 and 400 refers to the Class 1 class with the notation: CEM1 42.5 B and CEM 1 32.5 H, respectively. PC 400 D20 according to a new GUTA refers to the class of CEM 2 / A - W 32.5 B.

European cements have the same labeling. Many customers are skeptical about new designations as confusion arises, but on the fact the new marking is more convenient and informative. It is important to note the brand of the SPC300. According to the old standards, it could be contained from 20 to 80% of slags - this is a large range, so according to new designations, this type of material can be interpreted in two versions. If the share of slag is 21-35% - CEM2 / V - W 22.5 N. When slag is more than 35% - CEM 3 A 22.5 N.

Cement is binderwithout which it is impossible to do when filling the foundation. Mixing it with such fillers as gravel, sand, water and crushed stone in certain proportions you can get a monolith capable of withstanding serious loads.

How to figure it out in brands of cement?

To figure out B. specifications and components of this building material and understand which of its species is best suited for the planned foundation, you need to learn to decrypt the marking from numbers and letters on bags with cement.

Old GOST from 1985

According to the old Ghosts on the package first PC or SPC write, which means Portland cement or SlagoporTland cement. PC is a mixture in which calcium silicates prevail. The lion's share of concrete used in the world is based on Portland cement. The SPC is a mixture that contains additives in the form of slag. There is also a magnesial, alumina, acid-resistant and other types of material used to build structures in specific conditions.

Second An element on the package after letters is a three-digit number - from 300 to 600. It means the cement brand by the strength of the sample obtained from this mixture. For example, M 400 means that the test sample pulled out a load of 400 kg per 1 cm 2.

Third There is an element that carries information about the content of active mineral additives in the percentage ratio (for example, D10 - additives 10%). The content of additives should not exceed 20%.

Fourth The element reports that this building material is a b-rapid-hardening (for example, PC 400 D20 b), N - normalized, SS - sulfate-resistant, BC - White cement, WCRC - waterproof, etc. Abbreviation PL indicates the presence of plasticizers. This is the so-called hydrophobic cement, which can be stored even in conditions of high humidity.

Last group of numbers - information about GOST Building Material (for example, GOST 10178-85).

New GOST from 2003

Initially, the name of the composition is: CEM I - means a pure cement without additives, CEM II - a composition containing additives. The second type of CEM II in turn is divided into two groups A and B. Under and understand the mixtures with the content of additives 6-20%, b - 21-35%. The next letter carries information about the type of additive: P - Potszolan, shlage granular slag.

The next digital indicator. It reflects the compression strength class after 28 days after the foundation is flooded. Strength may vary within 22.5-52.5. Next, there is a subclass, which reflects the strength of the material to compress from 2 to 7 days. H is a normally hardening (22.5 - class of strength), b - fast-hardening (32.5-52.5 - strength). The latter are information about Guest. So, the marking of cement CEM II / A-W 32.5B GOST will have decoding - a quick-hardening portland cement having a slag additive - 6-20%.

Cement Brand for Foundation

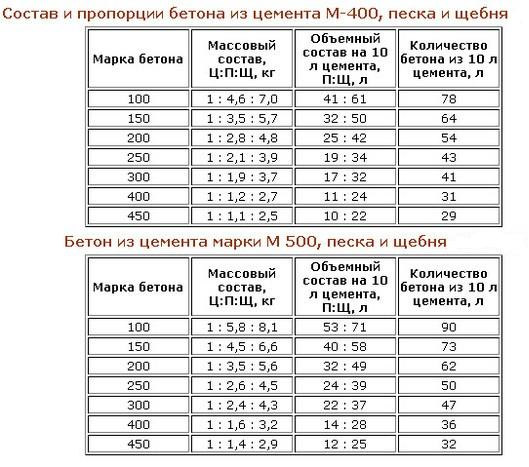

If the foundation is planned on dry ground, the best choice There will be an ordinary portland cement grade 400 or M500. For example, for the manufacture of concrete M350, it will be necessary for PC M 500. In this case, the proportions of the solution will be as follows: on 1 part of the cement - 4 parts of rubble, 2 parts of the sand. Water is added in an amount equal to half 1 part of dry PC.

- In low-rise individual construction uses cement M400 and M400 D20 PC. This is the best price and quality ratio. The foundation erected using this material will meet the high requirements for frost resistance and moisture resistance.

Cement M500 and PC M500 D20 - the optimal option for the construction of grounds for industrial buildings (hypermarkets, multi-storey houses, hangars, etc.). PC M500 D20 has been widely used in the construction of structures in areas with high humidity.

- When choosing a cement brand, be sure to consider general weight future build and load on the foundation, as well as the geology of the site (level and character of the soils), type of base and underground part of the building (ribbon, piles, presence / absence of basement).

- To build a foundation for a house from a bar or a log, a mixture of M250 or M300 is quite sufficient, for the construction of a collection-shield building - M200.

The bases for brick houses, buildings from the precast concrete and other wall materials, should be arranged using a more durable concrete (M350 and higher).

- On rock and sandy soils it is better to use concrete M200-250. Construction on loam and clay use concrete M350 with a higher waterproof coefficient and frost resistance.

- If the house is assumed to the basement device, the base should be poured with concrete M350 and additionally carry out measures for the outer waterproofing.

- In the case when the construction of the building will be produced in areas where groundwater is present with a significant content of salts, when choosing a cement, pay attention to its sulphate resistance. You can use an already finished sulfate-resistant mixture or purchase modifying additives and pour them at the stage of preparation of the solution.

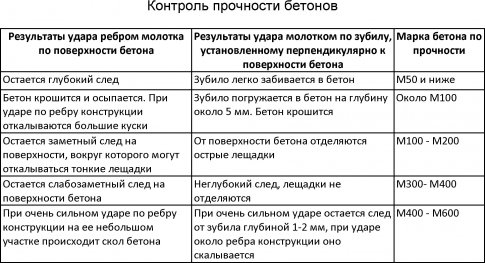

How to determine the brand?

As a rule, this can be done by special designations applied to packaging. But in some cases, when, for example, the packaging is damaged, it is possible to determine the cement brand experimentally.

This will require itself. construction mixture, sand, water, weights with weight designation, cap, steep camera, cement form.

We mix the concrete solution, adhering to the ratio of cement and sand - 1: 3. In this case, the coefficient of the water-cement ratio should be at least 0.4 (per 1 kg of a mixture of 400 g of water).

The resulting solution is fluent in forms with dimensions 4cmx4cmx16cm.

Samples cover with a cap. Carefully monitor maintenance of a sufficient level of humidity (next to the forms, put water tank). Leave the samples for a day under the cap.

Remove the panel and send to the steering chamber. Check the strength of the samples on the bend - set the brooms to two supports, while the center of the bar must remain free. At the middle, put 1 girling until the sample starts collapsed. Remember this weight. Using a special formula and the resulting indicator, determine the load on the compression and the cement brand.

R-daily \u003d p / s * 98 (MPa)

where R - force measured in kg / s; R.-Teeless - durability in megapascals; S. - Surface area kV / cm. To carry out a more complete verification of cement characteristics, devices are used as a granulometer (allows us to determine the fractional composition), IAC-04m devices or contractingometers (to determine the activity of the binder), etc.