The density of the granite and construction crushed stone of a different fraction. Bulk density of different types of rubble

Rubble is the stones obtained by artificial crushing large gravel, pebbles, boulders, mountain breeds, Slags of domain and waste asbestos production, PEMZ, waste during the extraction of ferrous and non-ferrous metals. The secondary is obtained by processing the construction trash - concrete, bricks, asphalt.

Having a rough surface, it provides excellent grip with cement-sandy solution and indispensable when the foundations, railway mounds are erected in road construction. The density of rubble (one of the main parameters from which the strength directly depends) is the mass ratio to the volume it occupies is measured in kg or T per m3.

Density building rubble It depends on which breed it is produced. For example, 1 m3 of granite weighs 2,600 kg, and tight limestone - 2,700-2,900 kg / m 3 (depends on the number of quartz impurities, dolomite and other minerals).

There are air between individual pebbles (grains). Because of this, 1 m3 with voids can not weigh the same as the same amount of non-aggregated rock. Therefore, there is such an indicator as a density of a bulk crushed stone - the ratio of its total mass to the volume, which it occupies (in a natural, unplicable form). The smaller the fraction, the above.

This indicator takes into account:

- in the process of indulging concrete mortar, since the more it is, the less the cement is required and more funds will be saved;

- during transportation - to calculate the load capacity and requirements in transport, depending on the dimensions of its body;

- when storing and stored - in order to determine the size of the repository.

To determine this indicator there are special capacity up to 50 liters of a certain form, which weighed before and after filling from a height of 1 m and alignment to it with its riding. The difference between these results is divided into the volume of the vessel and the bulk density of the rubble kg m3 is obtained. Measurements are made in special laboratories and are reflected in the quality passports of this party.

You can independently produce required calculationsIf you take the construction trough for the mixing of the solution. Multiple the length of length and the width of the tank, learn its volume. Weighing an empty trough and filled with brown with edges, calculate the difference - this is the mass. Dividing the second number on the first, get the desired indicator.

There is also the concept of the true density determined in the laboratory measurement of the mass of the unit of the volume of crushed and dried material. Thus, the presence of emptiness filled with air is eliminated. Used when calculating porosity. For example, bulk and true density Rubble 5-20 is 1 320 and 2,590 kg / m 3, respectively.

Indicator for various species

- granite - 1320-1690 (bulk density of the granite rubble fraction 20-40 - 1370-1400, 40-70 - 1380-1400, 70-250 - 1400);

- gabbro-diabase - 1440-1580 (depending on the fraction);

- limestone - 1250-1330 (fraction 10-20 - 1250, 20-40 - 1280, 40-70 - 1330);

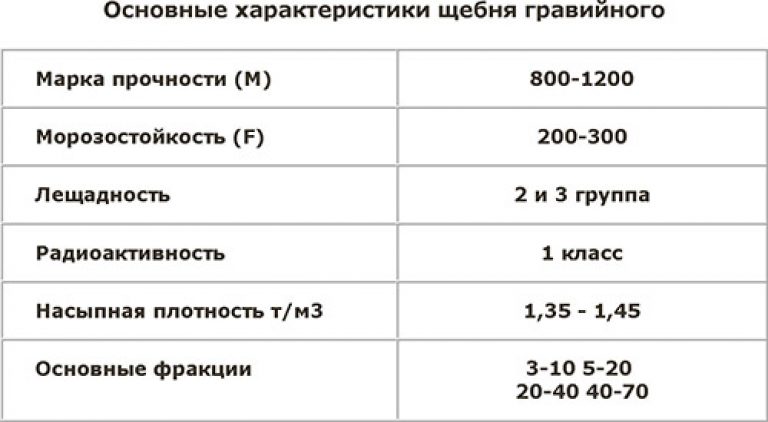

- gravel - 1350-1450 (fraction 0-5 - 1600, 5-20 - 1430, 40-100 - 1650, more than 160 - 1730);

- slag - 800;

- ceramzite - 210-450 (fractions 20-40 - 210-340, 10-20 - 220-440, 5-10 - 270-450);

- secondary - 1 200-3 000 (from crushed concrete - 1 170-1 310).

Rubble grades and their density

| M 250. | up to 250 kg / m 3 |

| M 300. | 250-300 |

| M 350. | 300-350 |

| M 400. | 350-400 |

| M 450. | 400-450 |

| M 500 | 450-500 |

| M 600 | 500-600 |

| M 700. | 600-700 |

| M 800. | 700-800 |

| M 900. | 800-900 |

| M 1000. | 900-1000 |

| M 1100. | 1000 1100 |

The 800-1200 brands are considered durable, 1400-1600 are high strength.

Crushed stone is the necessary building material that is used in the construction of foundations and roads. Due to large wrecks of boulders, large gravel and the rest of the rocks are given to create cement mortar, which has a high clutch density. The most important parameter of this product remains density. It shows weight relationships to volume. Thanks to this, the indicator is a predominant effect on other qualities.

Currently distinguish the type of density: bulk and true. For each fraction of this material, its indicators of the presented characteristics are characteristic. The granules have air layers, as a result of this, its extraction is another than 1 m3 of the unfinished breed.

What is the difference between crushed stone from gravel, you can learn from this

The smaller the size of the granules will be, the more they will be specific density . Based on this, the bulk density will also take high indicators. This criterion depends on how many solid and durable mineral seals in it.

What volume weight Crushed to fractions in the table can be found in this

To determine the bulk density, it is necessary to use an empty container, which will leave 50 liters. Initially, the container is sent to the scales. The desired indicator can be calculated using the formula represented:

P \u003d (M2 - M1): V,

in which P is the density of the material, M2 - the weight of the container with rubble, M1 is the mass of empty tank, V is its volume.

It is necessary to conduct such experiments in special laboratories. There in the process involve special forms and dimensions, which are regulated by GOST 9758-86. However, calculate the bulk density of rubble. In this case, you will need a trough in which you will carry out the kneading solution. First, measure the weight of the empty container. Now put rubble into the container and send again to the scales. The calculation should be carried out according to the above formula. But in the formula there is another parameter - this is the volume of packaging. To calculate the volume of the container, you need to take length, width and height and multiply.

An indicator of bulk density in the construction sphere is very difficult to overestimate. It needs to know exactly and be sure to take into account when preparing a solution. If it takes high values, the amount of cement used is reduced. You will also be able to save money on the transportation and storage of the bulk material.

The value of the bulk density is many times different from the true one. To determine it, you need to use laboratory equipment. Initially, it is necessary to crushed the crushed stone, dry and get rid of the existing voids. After such events, you must weigh the dry material. For various fractions there is its own bulk density.

And other technical data is shown in this article.

Table 1 - for rubble of various fractions

Granitis

To date, it is considered the most popular. Its density can reach the value of 1300-1700 kg / m3. Granite crushed stone classified by fractions. Distinguish such groups of material:

Other species

In addition to granite rubble, which today has been widely popular, limestone, slag and gravel material involve in the field of construction. For each of the presented options are characterized by qualitative characteristics and bulk density.

Unique bulk material consider limestone crushed stone. It is characterized by high strength, frost resistance, ecological purity. For fractions 5-40 mm, the following characteristics are characteristic:

- bulk density - 1300 kg / m³;

- beshech - no more than 12%;

- the presence of dust is up to 2%;

- the presence of weak rocks is up to 9%;

- strength grade - M600-M800;

- porosity - no higher than 7.3%;

- the level of humidity is not more than 4%;

- water absorption - 2.5%;

- frost resistance - F-150.

The following type of rubble is gravel. It is used as a filler to obtain blocks from concrete and reinforced concrete, construction of monolithic structures, slabs of overlapping. For him, the following characteristics are characteristic:

- volumetric bulk mass -1400 kg / m3,

- strength grade - 1200,

- frost resistance - F-350.

For slag rubble The average density can reach 800 kg / m3. For strength, the corresponding marking is characteristic. The most durable can be attributed M800-M1200, and to high strength - M1400-M1600. For a secondary rubble, the density will reach 1200-3000 kg / m3.

Crushed stone - important material in construction, which has a wide range of applications. An important parameter of the quality of this product remains its bulk density. But for each type of rubble, this indicator is yours. It is determined by the laboratory method, but it is absolutely easy to do this at home. It is defined for sure, then you will be able to avoid the subsequent shrinkage, and therefore, extend the service life of the construction.

Crushed stone - bulk material, inorganic and grainy, obtained by artificial crushing. It is divided into primary and secondary. This is an important fact. Primary - Recycling Result natural stone: pebbles, boulders, pumice and other materials. The secondary is obtained when crushing the garbage of construction, such as concrete, asphalt, brick.

Method of receipt

For the production of rubble, the following method is used: the mining breed, mined in the career, is crushed to a certain state by scratching. When recycling the above-mentioned construction waste, a mechanized crusher is used.

Application area

Due to the high adhesive properties, i.e. the ability to firmly gripped with the surface, crushed stone is used in cement-sand compositions, in urban planning, in the construction of buildings, in the construction of automotive and railways.

Features of the material

Allocate the following main properties:

These values \u200b\u200bfully characterize the specified material. We further consider such a property as the density of rubble. This is an important definition.

Leather density

This property is directly related to its strength. Under the density understand the ratio of mass to volume. It is measured in tons or kilograms per cubic meter (t / m³, kg / m³). There is a true density of rubble, excluding empty space, general and bulk, i.e. in an infertable state. Each of them has the appropriate value.

The true density of rubble is determined by the laboratory. That is, the mass of units of small and dry material is measured. This method eliminates the presence of emptiness filled with air. So determine the porosity.

The term rubble "is used to designate the ratio between mass and occupied volume, taking into account the free space between the particles. This parameter is required when calculating the composition concrete mix.

Density measurement

In this case, there are several ways to determine:

- With the help of a measuring vessel.

- Using tables.

Consider the first way

To implement this process, a measuring vessel of a cylindrical form with a volume of 5 to 50 liters is completely filled to the formation of a cone at the top. Then the surplus is removed from above. Vessel is weighed. To determine the density of rubble, calculate the difference between the full and empty vessel, which is divided into the volume of this container. There is nothing complicated here. The formula in this case is as follows:

- PH \u003d (m 2 - m 1): v,

where M 1 is the mass of the empty vessel; M 2 - with rubble, V is the capacity of the measuring tank.

Main criteria

To properly measure bulk density, comply state Standard, this is:

- The use of only specialized vessels, that is, a certain form and size.

- The size of the container directly depends on the size of the grains.

- Crushed in no way is specifically compacted, since in this case the material will have other indicators.

- The total density is necessarily above the bulk.

The results obtained in the laboratory indicate the accompanying passport of a particular party.

In addition to rubble, in a similar way, concrete and other materials are calculated. At the same time take into account the volume, graininess and space between the particles.

Definition using tables

This calculation of the density of these materials is also important. For large volumes or in cases where the error is about 1% is not critical, resort to the help of measuring tables with conditional coefficients for translation. Plus this method is a saved time and simplicity. Minus - approximate, inaccurate result.

| Type of rubble | Fraction, mm. | Bulk density kg / m³. | Mark. |

| Granitis | 20-40 | 1370-1400 | M 1100. |

| 40-70 | 1380-1400 | M 1100. | |

| 70-250 | 1400 | M 1100. | |

| Limestone | 10-20 | 1250 | M 1100. |

| 20-40 | 1280 | M 1100. | |

| 40-70 | 1330 | M 1100. | |

| Gravine | 0-5 | 1600 | M 1100. |

| 5-20 | 1430 | M 1100. | |

| 40-100 | 1650 | M 1100. | |

| more than 160. | 1730 | M 1100. | |

| Slag | 800 | M 800. | |

| Ceramzite | 20-40 | 210-340 | M 300. |

| 10-20 | 220-440 | M 200, m 300, m 350, m 400 | |

| 5-10 | 270-450 | M 250, m 300, m 350, m 450 | |

| Secondary | 1200-3000 | M 1100. |

It should be remembered that the bulk density is the quality of natural, natural, eliminating the possibility of subsequent tamping to eliminate emptiness.

Building materials, it is one of the basic parameters. From this depends the strength of the final product and the indirect definition of voids filled with less durable composition from other elements.

In the manufacture of concrete mixtures is guided by the rule: the higher the value of the fraction, the lower the parameters of the bulk density. Knowing its indicators allows you to save significantly. For example, with a low value of the fraction and a high bulk, it will be required an order of magnitude less. With the knowledge of precise volumes, transportation and storage are simplified. It becomes possible to calculate the material for transportation. Also in this case, you can take into account the carrying capacity of the transport.

Density coefficient

We will deal with this definition. The technical quantity used during measurements in the volume of rubble is called this: the coefficient of bulk density of rubble. This is an important parameter. Its other of its name is the coefficient of seal or translation (meaning the passage of mass into the volume, and vice versa).

Example

Suppose the car brought crushed stone to the construction site. How to carry out the necessary measurements? To do this, the volume of cargo and body is calculated along the border of filling. Then the obtained values \u200b\u200bare multiplied by the seal coefficient. It is clear that the numbers will be different due to the "morning" cargo while driving, but it cannot lose weight. In the first case, taking into account the shrinkage, it can be said that this is the overall density of rubble or value close to it. In the second - bulk.

For a better understanding, take another life example. Bought some sugar. Let's say a kilogram. They fell asleep to the sugarians, received the primary volume. Shocked, knocked, tamped. Measured. Received the final volume as a result.

Influencing factors

It is important to know. The density affects the breed from which crushed stone. With the same amount - 1 m 3, the weight of granite will be 2.6 tons. However, limestone due to the impurities of quartz, dolomites, etc. - 2.7-2.9 tons. With the same weight, the volume will differ.

As a result, a large, uncovered rock breed takes less space than recycled. This is due to the space between the elements. About the difference in volumes with the same mass will be the true and bulk area of \u200b\u200brubble. This is a reliable fact. For example, the true density of the granite rubble with the fraction (grain size) from 5 to 20 mm will be 2590 kg / m 3, and the bulk of the same material will be 1320 kg / m³. Thus, knowing this definition, you can significantly save on a decrease in the costs of the concrete mortar, as well as on the means of transportation and storage places.

Other parameters

In this case, you can select the following:

- The fraction is the grain size of the material. There are standard (5-10 mm, and so on.), Non-standard (10-15 mm, over 15 to 20 mm, etc.) and eurosreb (3-5 mm).

- Brand rubble in strength. Several types are isolated. Namely: normal strength M 800-1200; high - M 1400-1600; Middle - M 600-800; weak - m 300-600; Minimum - M 200.

The entire combination of fraction, brand and baseline rock will affect bulk density.

Crushed stone FR. 5-20 inquired in private and industrial construction, such a size of fractions is optimal in the preparation of concrete and w / w, fill screens and foundations, backfilling of roads. On his remaining performance (strength, frost resistance, specific gravity, Beshechy) influence the raw materials and method of manufacture, they are necessarily taken into account when acquiring and kneading the solution. Special attention requires a bulk density - the ratio of mass to occupied volume, the accuracy of the proportions and the properties of the prepared concrete depends on this indicator.

The value and influence of the characteristics

Correctly take into account the volume of emptiness between grains of rubble is quite difficult, the weight of the weight of 1 m3 rubble or gravel in a natural and dry state is many times less than its middle density. The reason is obvious - when grinding, the resulting fractions have a different shape and are poorly adjacent to each other, part of the material replaces the air. For comparison: a solid piece of granite has a density of at least 2600 kg / m3, in a fragmented form, rubble weighs no more than 1,470 kg with an equal volume.

Knowledge accurate weight It is necessary when calculating the capacity of the premises for storage and carrying capacity of transport, it is necessarily taken into account during the preparation of concrete. When using rubble 5-20 with a high value of bulk density, cement consumption is reduced and the operational characteristics of the solution increase. As a result, this magnitude is taken into account along with the storage storage.

The exact measurements of this indicator are carried out in the laboratory using special barrels weighed before and after filling. It is its manufacturer who indicates the sale. For its definition on its own (in the absence of a certificate), the capacity is selected, the volume of which is easy to calculate and the weight of rubble is 5-20 (the weight of the container is torn). The desired value is obtained by dividing and used in the selection of proportions of the remaining components. The porosity and real density are impossible to find at home, if necessary, their accounting is repelled from reference data or the results of the manufacturer's laboratory tests.

How much will weigh the cube rubble fraction 5-20 different species?

The mass of crushed materials depends primarily on the type of raw material. With an equal size of fractions of 1 m3 of soft tuff weighs almost twice as smaller and high-strength rocks. The average weight of the granite rubble is 1.37 tons per 1 m3, limestone - 1.3. A more clearly relationship between the base and bulk density is reflected in the table:

For each variety, there is an optimal scope of application: the limestone in the range of 5-20 mm refers to the shallow grinding and is used in the manufacture of lime, piece of small-sized concrete, kneading mixtures. Granite with such grain is almost universal, in characteristics it is suitable for concrete any varieties, including industrial. The reduced range will be relevant when using rubbing in a dry state, with an equal size of the fractions, it can vary depending on the placement of production and shape.

An important factor is the bodybus, it is it that determines the boundaries of the range specified in the table. This characteristic directly affects the volume of air between fractions, and as a result - on the bulk density of the material. The difference between the weight of 1 m3 rubble cuboid and needle shape 5-20 mm reaches 20%, it affects its drawdown and sorbing properties. The first variety is used in the manufacture of heavy brands of concrete and fill structures experiencing significant weight and mechanical loads. The second refers to low-grade, with an equal size of fractions crushed stone with high grains. incorrect form When backing in B. construction solutions requires more cementOtherwise, the quality of the adhesion of the filler will be low.

The exact value of the density and bulk mass is necessarily indicated by the manufacturer in the attached documentation. But it may change during transportation or storage in unsuitable conditions (with a set of humidity). The percentage of water absorption in each breed is its own, it is directly related to the porosity, the testicle (the grains of needle and irregular shape accumulate more moisture than cuboid) and roughness, on average any crushed stone FR. 5-20 mm will increase its weight by 10-15% with prolonged location in a room with high humidity (not to mention the open-air storage and rope under the rain).

In order to avoid errors in the selection of proportions, the bulk density of the construction crushes is rechecked in a dry state.

The company "KULSYSTEMS" sells crushed stone granite fractions 5-20, 20-40 and 40-70mm

General

Crushed stone granite -granite (occurred from Italian granito - grainy; in ancient Russia, he was called "wild stone") - this is a solid rock, having a grainy structure. The formation of granites occurred throughout the history of the Earth, and now it is the most common rock.

Granite rock is a magma thrown on the surface of the Earth and hardened, consisting of well-formed crystals polespota, quartz, mica, etc. And it has a color red, pink or gray, recoverable from the prevail in it and mica. Blinds are usually obtained by explosion of a monolithic rock, then they are crushed in the car, and the resulting crushed stone is sifted by fractions. This is the last stage of the production of rubble. Crushed stone is assessed by the quality of its fractions. The smaller the rubble fraction, the more expensive it is, because More works were spent on his crushing. The main fractions of the granite rubble are: 5-15, 5-20, 5-40, 20-40, 40-70 mm.

Rubble indicators.The most important indicators of the rubble granite are:

- compression storage

- beschy (content in granite particles needle form)

- density

- fraction.

Group rubble. Depending on the brand, crushed stone is divided into the following groups:

- high strength crushed stone - M1200-1400

- durable crushed stone - M800-1200

- crushed stone middle strength - M600-800

- crushed stone weak strength - M300-600

- crushed stone very weak strength - M200.

In most types of construction, crushed stone granite is optimal building materialbecause Its main properties - strength, frost resistance, density, water absorption and water saturation. For example, modern gtales are forbidden to use during the trinity of roads and road coatings Any rubble, except granite.

Character characteristics:

Frost resistance rubble is characterized by the number of cycles of freezing and thawing. It is allowed to estimate the frost resistance of rubble in the number of saturation cycles in sodium sulfate and drying solution. By frost resistance, crushed stone is divided into brands: F15; F25; F50; F100; F150; F200; F300; F400.

Frost resistance rates of rubble are determined by testing freezing and thawing or saturation in sodium sulfate solution and drying.

The construction mainly use crushed stone with a storage brand of at least F300.

Strength rubble Characterize the limit of the strength of the initial rock in compression, the crushed ground rate during compression (crushing) in the cylinder, and wear in the sheal drum. These indicators imitate resistance stone material When exposed to vehicles passing along the road and mechanical impacts in the process of construction of road structures (styling and sealing rollers).

In crushed, the content of weak breed grains is normalized with the limit of the strength of the initial breed when compressing in a water-saturated state up to 20 MPa. According to GOST 8267-93, crushed stone M1400, M1200, M1000 should not contain grains of weak rocks in the amount of more than 5%, crushed stone M800, M600, M400 more than 10%, rubble grades M300 and M200 more than 15% by weight.

Enjoy the greatest demand granite crusp The strength of M1200 is less commonly used high-strength granite crushed stone or basalt crushed stone with a storage brand M1400-1600. It is mainly used in the production of heavy high-strength concrete, in carrier bridge structures, foundations.

Loys of rubble. In the crushed it, the content of the grains of the lamellar (lamb - it happened from the word "bream", i.e. flat as bream) and needle forms. The grains of lamellar and needle forms include such grains, thickness or width of which are less than three times or more. In the form of grains, crushed stone is divided into four groups (grain content of plate and needle forms,% by weight):

- I group "Cuboid" up to 15%,

- II group "Improved" from 15% to 25%,

- III group "Normal" from 25% to 35%,

- IV Group "Normal" from 35% to 50%.

It should be noted that "Beshechy" is one of the most important characteristics of the quality of rubble. The smaller the testicle, the better the crushed stone. The use of a cube-shaped crushed stone gives the most dense rambling.

The presence of grain grains with a plate and needle forms leads to an increase in the inter-rigid emptiness in the mixture. This in turn leads to an increase in the consumption of the binder component, and this entails additional material costs. In addition, cuboid grains have greater strength than the grains of lamellar and needle forms. Consequently, the use of cuboid rubble in production is economically more expedient.

Adhesion and grain composition of rubble. One of the specific characteristics of rubble is adhesion. This parameter reflects the assessment of the quality of the clutch of bitumen binders with the surface of the rubble. It should be noted that the color of the grip is affected by the color of the rubble. The best adhesion indicators gives gray and dark gray crushed stone.

Grain composition each fraction should meet the requirements of GOST 8267-93 "Crushed stone and gravel from dense rocks for construction work" Based on the requirements of this GOST, it follows that in the rubble faction that is supplied to construction, for example, 20-40mm, the amount of grains of the size of the smaller 20mm should not exceed 10%, and the grains are larger than 1.25 * D (50mm) not more than 0.5%. These requirements are necessary for strict observance of the grain composition of individual fractions. Compliance with these requirements is reflected in the ravings.

The content of dust and clay particles: In the crushed it, the content of dust and clay particles (less than 0.05mm) is normalized. In addition, lump lumps are isolated with particle size from 1.25mm to the greatest grain size of the rubble grain of this fraction at a mixture of fractions. For all types and brands of rubble for strength, clay content in lumps in the total amount of dust and clay particles should not exceed 0.25% by weight. In rubble of magmatic and metamorphic rocks, the content of dust-shaped and clay particles by mass should not exceed 1%, in crushed it from sedimentary brands from M600 to M1200-2%, and brands from M200 to M400-3%.

Other types of crushed stone and artificial analogues are superior to its qualities. It has high strength, is a high-quality aggregate for a concrete mix, and this material is well handled. The disadvantages of the granite rubble include a high natural radioactive background.

Our company offers crushed stone granite with the following characteristics:

Character characteristics

|

1.34 -1.37 t / m3 |

|

|

1.37 - 1.4 t / m3 |

|

|

1.4 - 1.5 t / m3 |

|

|

Frost resistance | |

|

Mark for strength |

1400 kg / cm3 |

|

Brand of wear | |

|

not more than 0.25% |

|

|

Connections of harmful components and impurities |

corresponds to GOST 8267-93 |

Scope of granite rubble:

Thanks to its physico-technical properties granite crusp Widely applied in construction.

Granite crushed stone 5-20. - One of the most sought-after species. At such a crushed stone the price is highest. It is used for the manufacture of industrial concrete. In addition, crushed stone 5-20 can be ideal for the construction and arrangement of road surfaces in settlements, in the territories of construction sites. Crushed stone with fractions of this size during installation of all sorts of industrial facilities, to cover the zones of production complexes, etc.

Granite crushed stone 20-40 Ideal for creating temporary and regular roads in cities and other settlements. When erecting embankments on railways without a rubble of this fraction, it is easy not to do, and the high frost resistance of granite reduces the frequency of the laying to a minimum. In addition, granite crushed stone 20-40mm is actively used to produce concrete, as a reinforcing material in foundations, during the construction of various residential and non-residential structures.

Granite crushed stone 40-70 has the most low priceHowever, it does not diminish its in demand in industry and construction. In addition, rubble 40-70mm is often used as a semi-finished product, which is repeatedly crushed and sorted on crushed stone with smaller fractions.

Bulk density

The amount of rubble supplied is determined by volume or mass. Screwdow varied in wagons and cars.

Crushed stone shipped in cars or cars, weighed on rail or automotive scales. The amount of rubble from units of mass per unit of volume is counted according to the value of the bulk density of the rubble, determined by its humidity during the shipment.

The volume of rubble supplied in the car or car is determined by its measurement, the resulting volume is multiplied by the seal coefficient when transporting it, which depends on the loading method, the range of transportation, grain composition. The maximum permissible value of humidity and the coefficient of the seal, which should not exceed 1.10, are established in the contract for the supply.

Questions and answers:

Question: What is the usual radioactivity of rubble?

Answer: Radioactivity rubble is the most important characteristic that usually begins to discuss the quality of construction crushed stone with the buyer. If products should be suitable for everyone without exception of construction work, which must be confirmed by the relevant certificates and sanitary and epidemiological conclusions, research of special laboratories, this means that the entire granite crushed stone and other types of high-strength crushed stone belong to the i-th class on radioactivity (less than 370 bc / kg). For the construction of roads, crushed stone II class on radioactivity (more than 370bc / kg) is suitable.

Question: How can I check the quality and number of shipments delivered to me?

Answer: Acceptance of goods in quantity and quality (in the sense of appearance and contamination) occurs in the body of motor vehicles, i.e. While the bulk cargo is in the body, you have the right to measure it and inspect appearance. If the material is already unloaded, you are not entitled to make complaints (in accordance with GOST 8267-93). Therefore, we strongly recommend that you carefully treat the acceptance of the product, especially in the amount of quantity. There are some subtleties related to the seal coefficient.

TO oeffusion seal (Purchase.) – this is a regulatory number defined by GOST and taking into account, how many times the bulk material has seal (and, therefore, it has decreased and its visible volume) during transportation. The seal coefficient is taken into account in the measurements of the volume of the supplied bulk material (soil, peat, sand, crushed stone, ceramzit, etc.). For example, the machine comes to your object with rubble. You need to measure the volume of the body (DHSHV, where "B" is equal to the level of material, not height of the sides). The resulting volume must be multiplied by the seal coefficient (according to GOST 9757-90 for the crushed stone of the purchase. \u003d 1.10).

In case the bulk cargo is delivered with the so-called "slide" above the board, 2M 3 is always added to the resulting volume. This is the average value of this volume, adopted in all suppliers of nonmetallic materials.

Question: What is the difference between gravel crushed stone?

Answer: Crushed stone from rocks - inorganic grainy bulk material with grains of over 5mm, obtained by crushing rocks, gravel and boulders and subsequent rushing products of crushing.

Gravel from rocks - inorganic grainy bulk material with grains of more than 5mm, obtained by harsh natural gravel-sand mixtures. Gravel grains - rounded, rubbed - angular. The fractions of the crushed stone and the gravel may have a different one.

Question: How much weighs 1 cube rubble?

Answer: Middle Weight cubic meter Rubble 1.4 tons. Weight depends on rubble material, granite - heavier, limestone easier. The rubble fraction practically does not affect its weight.