Crushed stone granite fraction 40 70 density Stroyinfo. Scope of the main types of rubble

Read also

In the construction of cement expenses, sand and gravel, and so significant, and if you imagine how much they need to fill dams and dams, aqueducts, vololates, multi-kilometer bridges? The value of the solution will fly into a penny, it is better to find a material that can be noticed there, and a fair amount. And it is - this is a crushed stone in the volume in concrete to 70%.

If the optimal humidity is not supported evenly during the entire seal period - despite the periods high temperatures, low humidity and drying wind - almost impossible to achieve a uniform maximum density in all areas of the project. The continuous addition of water is expensive and difficult to control exactly at the workplace, but the inclusion of calcium chloride into the mixture provides sustainability to ordinary evaporation, reduces or eliminates the need for additional water and maintains the necessary optimal moisture content.

This unwatched "wild" stone is produced in various ways, it all depends on the raw materials used to work out.

1. Slag, obtained from metallurgical dumps.

2. Secondary, as a product of the processing of former building structures.

3. Limestone, result of crushing natural organic carbonates.

4. Selected from gravel.

The use of calcium chloride often does not add anything to the total cost of the filled base, because the savings that it exerts during the construction period compensates for calcium chloride cost. Adding calcium chloride to graduated aggregate mixtures allows to achieve maximum density with a small share of the effort required when using simple water. In addition, a granular unit containing calcium chloride reaches greater density with a smaller number of rolls than when using simple water.

5. Granite crushed stone, the most durable, result of a complex technological process.

It is the last one who is considered the highest quality, but also expensive, because for its production it is necessary to blow up the rock, crush the wreckage, sift them and sort them. Depending on the size of the sieve, they are divided into fractions:

Preparation of granular aggregate mixtures

When preparing granulated mixtures based on calcium chloride, it is important that gradation and humidity have been retained within certain limits. This can be done in one of two ways: combining the measured quantities of these materials on the central mixing unit and transportation of the prepared mixture into place of work; Or placement on the road for mixing on site measured quantities of these components, as provided in the specifications.

A typical plant for the production of granulated aggregate mixtures includes stocks of coarse and minor aggregates in bunkers or warehouses and equipment for mixing the corresponding proportions of these materials on the conveyor belt. Calcium chloride is usually added directly to the assembly in the conveyor belt using a vibrator or a similar feeder. The correct amount of water is then added via splashes located above the mixture.

- opening, with particles from 0 to 5 mm;

- baby 2-5 mm;

- small crushes 5-10 and 5-20;

- average 20-40;

- large 40-70;

- skol, or Booth 70-240.

Stone fractions differ in characteristics and, therefore, use. The small material has the cost higher than the large: after all, to grind it, you need to spend more energy, time and work. For massive monolithic structures and maintaining in order of iron and roads, a granite crushed stone is needed 40-70 in considerable quantities.

There are several advantages to prepare specific mixtures on the central mixing unit. The moisture content is so important to achieve density and stability, is easily controlled and supported. The survey is simplified, since one employee at the factory can control the material gradation, moisture content and the amount of calcium chloride. There is an accurate amount control and even the distribution of calcium chloride in the mixture.

- Maximum control provides more homogeneous mixture.

- The possibility of segregation is eliminated.

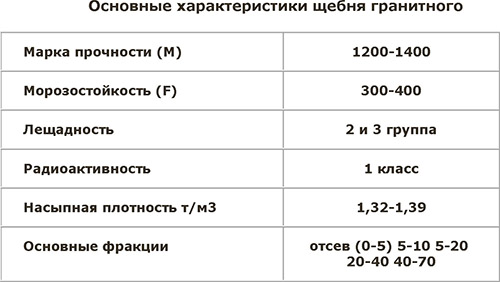

Characteristics

When crushing stone, the fragments are obtained from different quantities and forms. Some more like the cube, and some are on the needles and plates, with a width of less than 3 or more times. The share of such trifles in the total volume is called testicle and rubbing it is classified for:

Although the value of materials mixed with plants is generally recognized, it may be more practical for some projects for the construction of granular aggregate grounds for road marking methods. This method requires more careful inspection and control to ensure homogeneity, since the control of materials and moisture should be maintained in place throughout the operation.

The subbone and the subbone must be in a fully compacted state and must be provided with appropriate drainage to the base of the base. To construct a satisfactory base by the method of the road mixture. Rough and thin material should be placed on a prepared surface, with caution to ensure a uniform distribution of materials. Then, the entire material should be covered with a patrol grader with standard methods, from side to side or mixed with a moving mixing machine until it is thoroughly mixed and uniformly.

- Binding soils should be in a dry and dusty state when placed.

- As a rule, elevators should not exceed 5 inches of compacted thickness.

- cuboid - 0-15%;

- improved - 15-25%;

- normal - 25-35%.

This characteristic is important in the production of concrete. They are much stronger if bulk density Rubble exceeds 1.38 t / m3. There are many voids between plates and needles, therefore, the consumption of sand-cement mixture increases. And the cubes obtained on the conical crushers are better than a trimmer, while the large surface area increases the grip with knitting materials. Granite crushed stone of such a form is durable, like concrete, they have formed (and more durable three times). For compression, the stone withstands 1200-1600 kg / cm2. It is explained by such a very high density - ~ 2.60-2.80 t / m2. Frost resistance of its F300, that is, it will not crush the annual almost three-level freezing and thawing. Waterproof is complete if there are no cracks.

Sorted adjacent mixtures for carrying courses and shoulders

The calcium chloride should be added using a mechanical spreader. Mixed-based calcium chloride mixes are also used for the construction of nasal platforms and for the shoulders of sidewalks on primary roads. Although the characteristics of the mixture for surfaces of this type are slightly different from those that should be used in the bases intended for immediate surfacing, materials can be mixed and applied in the same way. The practice of some departments of highways should use a basic course before laying the surface for riding for up to one year to determine whether any disadvantages are developing.

There is also such a characteristic - abrasibility. It is primarily important when driving. For the crushed stone of the fraction 40-70, it is equal to 22.4%, the mass loss is checked by fragments when grinding them with steel balls in the drum (500 or 1000 revolutions).

Materials and specifications for calcium granulated mixtures

Below is a typical specification for granulated basic basic material. For use in the construction of stabilized nose or basic courses The granular unit should consist of a coarse aggregator consisting of gravel, rubble or slag in combination with ground mortar or stone trifle or any combination of these materials. Requirements are intended to cover only materials that have normal or average values. swelling, absorption and gradation. When other materials are used, appropriate limits suitable for use must be specified.

From abrasability, density (strength), another characteristic of crushing depends on crushing (M200 to M1400, multiple hundred).

Features of use

This stone is indispensable as a placeholder in concrete structures of an impressive size. On the railways, he plays the role of the ballast layer. As a subtype and composite element, the material is suitable for creating highways. In decorative purposes, it is used by different color, structure and granite texture. The variety of colors and color shades is the result of the fact that the composition of this rock in arbitrary relations contains minerals of mica, quartz, polespota, Plagioclase and others. Therefore, its polished mirror surface of red, greenish and gray shades and the grainy structure give the unique view of the palaces, memorials, metro, embankments.

The unit should consist of solid durable particles and do not contain harmful or harmful substances. The fraction passing through sieve No. 40 should have a plasticity of at least 4 or more. The limit of the liquid fraction passing through Sieve No. 40 should not exceed if the depreciation rate should be used as a basis during the year, the plasticity index should not exceed 6, and the liquid limit should not exceed.

The fraction passing through Sieve No. 40 should have a liquid limit of not more than 25 and the index plasticity is no more. Moisture content: The materials specified here must contain sufficient humidity to ensure the seal to calculate the density. This specification follows several public sections of the highway and the American Association of Public Works.

In addition, the use of precisely this granite rubble by 15% reduces the consumption of the solution in concrete and 2.5% - energy consumption. The fragments of 40-70 often go to export. Cause Banalna: They are cheaper than small rubble, so in industrial quantities are grinding to produce the necessary fractions in countries with its deficit.

Use calcium chloride for assorted adjacent mixtures for shoulders and nasal angles

Road mixture. Regular florid calcium chloride must be evenly distributed at a speed of 5 pounds on square meter On an inch compacted thickness. The material must be thoroughly mixed by transverse scattering and roller or several supporting blades, rotary cultivators or other mixers for mixing or other approved methods.

Plant mixture. The finished mixed material should contain 10 pounds of the usual calcium chloride per ton of the mixture. Surface application. If the course should serve as a wearing surface, one pound should be applied per square meter. This should be followed by a half-found in square yards, as required to keep dust.

Why do not take a stone of this size from gravel? The surface area and roughness of similar pieces of granite have a greater clutch with a solution, and emptiness between them is significantly less.

Cost

The most important factors affecting the price within the same fraction is a brand, frost resistance and leggings. Delivery range at the plant or to the consumer also plays a role. The costs of storage and utility costs (heating and water supply) are important, as well as the purity of the material (it is washed or tinged). When comparing prices, you need to pay attention to units of measurement. It is indicated as the price per cube with delivery, and for one ton. For approximate comparison, if you wish to buy, it is necessary to take into account that in 1 cubic meter there is about 1.5 tons of stone.

Regular and anhydrous calcium chloride chloride is harmful when swallowing. Contact with eyes, mucous membranes or skin can cause irritation or burns. When used, work gloves should be worked and avoid dust. When swallowed, drink several glasses of water and then call vomiting.

In case of contact: For the eyes quickly, rinse with plenty of water for at least 15 minutes and consult a doctor. For skin, rinse with plenty of water and rinse thoroughly. Contaminated clothing should be removed as soon as possible and wash it before reapply.

This table indicates prices for different brands Rubble from the granite of the same size in Moscow and the region.

Crushed stone - that's construction materialwhich has a grainy, inorganic structure. The size of grains can reach more than 5 mm. To obtain rubble use rocks, gravel and boulders that are subjected to crushing process.

Regular and anhydrous calcium chloride chloride acts, absorbing moisture, which, in turn, highlights heat. This moisture absorbing property can dry the skin and damage clothes. All glacial chemicals lower water freezing temperature and increase the number of freezing cycles-thawing. This situation can accelerate the appearance of peeling and gluing concrete or a solution of less than one year or dubious quality. Mass compounds are especially vulnerable.

Care should be used when applied near lawns or shrubs, as their damage may occur. Store the place out of the reach of children. Any construction, from a small building, roads, even skyscrapers require high-quality raw materials in large quantities.

The resulting finished product is very valued in the construction area, as it has an extensive area of \u200b\u200buse. Most often in the cooking process construction solutions Apply rubble with fraction 40 70.

For rubble 40 70, high demand in the construction sector is characterized. No wonder this type of material was called the most important. It is from the quality of rubble that the strength characteristics of the structure or concrete mixture will depend on.

We cannot deny the importance sturdy foundationWhen it comes to building business. Good quality aggregate material is undoubtedly fundamental construction block "Literally" any design. Transportation of aggregate by road is simple and economical. Whether it is a small pickup or transportation of gravel and sand, tractor-tractor is widely popular for your overload.

If you hired a company that is in the vicinity of the construction site, and there is no heavy aggregate for loading and unloading, the transportation of pickups will be perfect. Loading and unloading from the pickup is almost easier than any other method. Trucks can get on any road, and one of them will be saved from all hassle.

In the photo - rubble fraction 40 70:

The size of grains starts from 0 and reach 200 mm. The largest grains are used when creating a decor of the facade, fender structures and tracks.

Secondary

The process of obtaining this material involves the processing of construction trash. Concrete, asphalt, brick can be used here. In the course of its manufacture, the standards of GOST 25137-82 are observed. The production process of secondary rubble is similar to that and upon receipt of other options for rubble.

What you need to keep in mind: When you choose a company for cumulative supply and transportation, tell them in detail about their services. In the center of removal of waste, we prefer tarpaulin trucks, as it helps reduce the likelihood of the appearance of loose rock powders during the trip. Tarping truck correctly controls dust and asphalt compound.

Trucks are used to transport a maximum of 20 to 90 tons of stone at a time. They have two pickups. Their main use is to move the stone into the plant's cheat crusher. The aggregates are also transported by rail, and this method is much more economical compared to freight transport. As a rule, rail transportation is popular in areas where the quality of the local stone is bad and unsuitable for construction purposes.

The main advantage is in low cost. If we consider the main characteristics, then on frost resistance and strength, secondary material is inferior natural species rubble.

About where and how the round pebble is used can be learn from this

Secondary cruspat is actively used in the road economy, acts as aggregate for concrete, to strengthen the weak soil. Before purchasing the product under consideration, it is necessary to demand a certificate of quality from the supplier to clearly see high quality purchased product.

About what kind volume weight cement, you can read

Cost per M3.

As for the value of rubble 40-70, then different for each of its kind:

- Granite - 1350 rubles per cube.

- Gravel - 290 rubles.

- Secondary - 1000 rubles.

- Limestone - 150 rubles.

What true density Cement M500 can be found

Crushed stone is a very popular building material for which such qualities like environmental friendliness and low price. High rates of frost resistance and strength allowed rubble to get such a wide range of applications.