Brick ceramic single M 150. Construction brick M150. To the strengths of silicate bricks include

The M-150 brand brick according to the technical characteristics and method of production can be two species - silicate and ceramic. Based on the specifics of the structure under construction, one or another type of product is used.

The technical characteristics of the brick M 150 put it in the leading positions for use in various construction sites. Ceramic brick is a universal building material that is widely used in construction for more than one hundred years. Its popularity ceramic blocks are obliged to their excellent specifications and physical properties.

Always on time, always perfect. Walls from solid ceramic brick Durable and have good noise insulation. In this area you will learn how to calculate required amount Massive bricks for the construction of a wall of masonry. Bricks for the construction of walls are usually 20 cm in length, 10 cm wide and 5 cm in height, but since not all manufacturers respect technical standardization, other sizes are still on the market. It strongly changes the performance of the work, because with big bricks to make a wall faster.

Brick brand M 150

Now brick, as in the distant past, is used in a wide variety of options. construction work When building:

- buokests of buildings;

- carriers and self-supporting walls;

- interior partitions;

- decorative fences.

Due to the fact that there are many configurations of building stone and a large number of manufacturers' companies, the price of brick M 150 lies in a wide range. The minimum component is 6, 6 rubles. a piece.

What does the brick brand M 150 mean? The marking number determines its physical strength. The number in this number corresponds to the maximum pressure, which can withstand each individual product, and causes those object parameters where it is most appropriate. Thus, the M-150 brand means that each square centimeter of the ceramic block can withstand up to 150 kg of pressure of the upper part of the structure. The strength of the product is directly dependent on the density of the brick.

To date, manufacturers produce a line of products with labels from 75 to 300. However, the M-150 brand itself is the most common and proven.

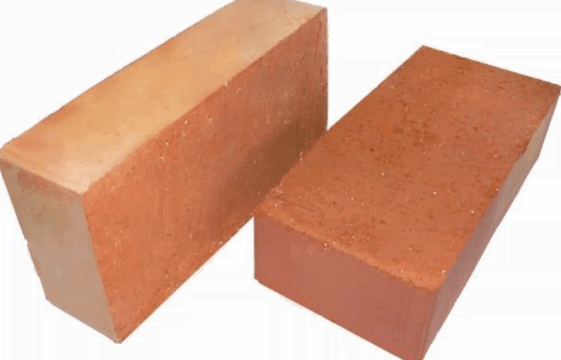

Types of ceramic brick M-150

Ceramic brick M 150

All products of this brand are available in two types:

- working (full or ordinary) brick;

- facing (hollow) brick;

Such separation is caused by the structure of the building brick. Full-time products do not contain emptiness inside and have a rude appearance. Its main appointment is the construction of bases, foundation structures, bearing walls and other structures that require subsequent decoration. It is used to lad out the ventilation and smoke channels.

The construction brick of brand M 150 is its popularity of the Moiler's bricks, it is advantageous to benefit from other building materials. Thus, the weight of the brick M 150, depending on the modification ranges from 2.2 to 3.5 kg. Such a small mass implies convenience for transportation on floors during construction work.

Of the basic qualities of full-scale brick, you can allocate excellent strength and a high thermal conductivity indicator, which allows you to maintain heat in the premises in winter, and in the summer to provide a cool house. The M-150 products also have high sound insulation, so its use is appropriate in cases where it is necessary to reduce the noise level from the outside.

A working single full-length brick M 150 is also used to build bearing walls of houses and other buildings. His difference from the hollow analogue is that it has in its structure of emptiness, significantly reduced the weight of ceramic blocks. Hollow ceramic products Also possess high frost resistance, due to the presence of empty spaces filled with air, which is a bad heat conductor. The price of full-scale brick M 150 varies from 8 to 15 rubles. Piece depending on the modification and manufacturer.

Modern production technologies allow you to produce a brick facing M 150 with a beautiful and impeccable appearance. Such characteristics we determine its application in the facade of facades of buildings, columns, decorative fences.

What a brand or modification was not a building stone, the raw material for its production is clay. The quality and composition of raw materials depends on the region of its production, but in any case, this initial raw material must be uniformly in its structure and with the smallest content of limestone. When firing, the excess limestone contributes to shooting and falling from the surface of the finished stone.

Brick ceramic full-length M 150 can be done in two ways:

- plastic molding;

- dry and semi-dry pressing.

The first method of manufacturing today is the most popular and cost-effective. The peculiarity of production is to use clay, which has in its composition up to 30% of sand preventing excessive shrinkage of finished products. The prepared mass of the clay is moistened to the ferry and is intensively mixed in a homogeneous mass with a complete lack of lumps.

At the next stage, a ray bar is formed with a volume superior to a finished product by 10-15%. After drying, in the process of which the humidity decreases, the products are burned in the oven at temperatures up to 1000 ºС. Private hollow brick M 150, made in this way, has high strength, waterproof and fully complied with GOST.

With the second method, the finished product is although it has a smaller frost resistance, but has a more correct and sharp form. The raw material is selected with certain indicators of humidity (from 7 to 12%). In the production process, the clay is crushed to the powder. The finished powder is subjected to dry or semi-dry press, after which the raw stone is burned in the oven.

Produced products must have a quality passport and comply with approved certificates.

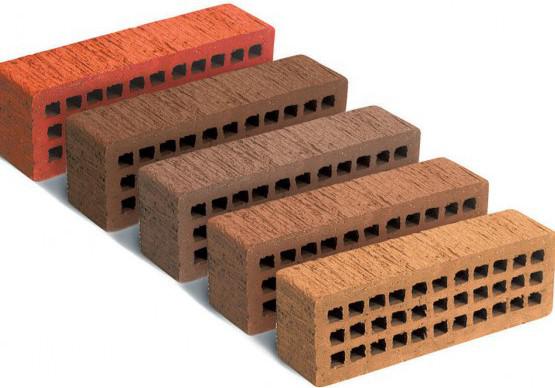

Modern manufacturing workshops allow to produce brick worker and brick facial M 150 different configurations and sizes:

- single;

- half;

- double.

A variety of color shades allows the use of a building stone in the widest range of construction. The most common colors are red, brown, light yellow, straw, as well as more sophisticated - ivory, frost, terracotta.

Brick dimensions M 150, supplied to the market, can be different depending on the modification. The most popular today is a single brick 250 * 120 * 65 mm, used to build capital walls of buildings and foundation grounds.

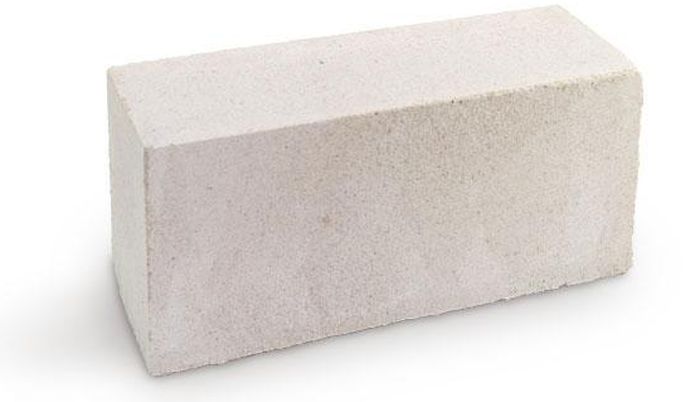

Silicate brick

Silicate brick brand M 150

Brick Silicate M 150 for a long time was called "White" in view of his external view. Building stone production is based on the method of semi-dry pressing of a mixture of quartz sand and lime in the presence of water. Formed raw bricks are treated in an autoclave, where the active exposure to water vapor at high temperature and pressure occurs. The final product of the synthesis of the mixture of hydrosilicates is an artificial stone.

TO strong sides silicate brick relate:

- impeccable appearance;

- high strength indicator, almost not inferior to natural stone;

- fire resistance;

- a small mass of products due to the presence of emptiness;

- high resistance to aggressive substances;

- environmental purity.

The building materials market offers the buyer a wide species series of silicate brick, including single and brick one-hour M 150. In addition, products are presented in various color shades (white, black, yellow, blue). The toned stone is primarily used as a facing material. The wall laid out of such silicate brick has aesthetically nice look and does not require plastering.

In the price of silicate construction, full-length brick M 150 is more profitable than ceramic. Low price Such a stone is due to the speed of its manufacture and using less complex equipment.

A complete silicate brick has a smaller thermal conductivity than ceramic, so it is preferably used to masonry facades. Requirements for construction standards and rules prohibit the use of a silicate stone for structures undergoing moisture. Also, silicate brick is not used to masonry designs experiencing influence high temperatures, such as ovens, fireplaces and chimneys.

Brick selection for upcoming work

When planning work on the construction of a structure or facing of ready-made architectural objects, a question often arises - what to buy brick brand M 150?

Considering the foregoing, the solution to such a problem will depend on the specifics of the future structure. For example, an ordinary hollow brick m 150 is perfect for interior walls. Thanks to its small size, the stones will allow much to save the useful area of \u200b\u200bpremises in the house. In addition, the rooms will be isolated from foreign horses, because dense structure building material Has high soundproofiness.

Silicate tinted brick is an excellent solution for facing the facade of the cottage, a country house. Fences from such products have a chic majestic look, and the combination of blocks of various shades will allow you to implement the most courageous design solutions.

For the construction of interior partitions in private construction, a ceramic single m-150 brick is most popular. Thanks to high moisture resistance, mainly stone is used to masonry walls of toilets and bathrooms. Its face has a ribbed structure for greater adhesion with cement mortar.

The double M 150 brick exhibits high strength properties and is endowed with a low thermal conductivity coefficient, so that the need for it occurs during the construction of warm external walls in private construction. It is also used in the construction of internal commoners in buildings with large areas. This is due to excellent sound insulation properties and a small width of the product.

Construction brick Not in vain uses such a wide demand, because it is characterized by high indicators of strength and durability. In addition, the cost of this product is low, which allows you to build at home to everyone who has decisled construction.

Taking into account the modular sizes of bricks, the design documentation is carried out, dimensions are designated. But the building brick is produced in different typesFor each of which their characteristics and sizes are characteristic. Therefore, consider this when choosing a specific building material.

The presented product has a huge selection of colors and textures. In addition, construction bricks can classify by type of material used. In independence, every kind of artificial stone puts forward qualitative characteristics and sizes.

As a result of the works produced, you will need to often perform repairs, remove dirt and dust from the surface. Besides, clinker stone Presented in a wide range of colors and textures, which allows you to get the original facade. But there is one substantial minus - high thermal conductivity.

![]()

Private full-length

Such a type of artificial stone is used when erecting basement floors, grounds, pillars, basement rooms, outdoor and inland walls. In addition, the ordinary stone got wider prevalence when erecting furnaces, fireplaces, chimneys.

Learn what are the advantages of silicate bricks from this

The scope of the ordinary corrugated product includes the construction of walls, partitions, as well as other structures that will be twisted in the future.

For full-length bricks are characterized by high compressive strength and frost resistance. Sometimes the production of stone is carried out with technical voids. As a result of the activities done, it is possible to reduce the internal stress during the firing.

What is the weight of the chimney brick, you can learn in this

But most often the production process does not imply emptiness. As a result, the resulting product may have low water absorption, high thermal conductivity. During the construction of outer walls from the presented material, it is also worth taking care of additional thermal insulation.

Dimensions

For full-scale bricks, the following requirements must be followed: High compression strength, frost resistance. Since the emptiness in the product is practically disturbing, it has a large conductivity of thermal energy and a low level of moisture absorption. Based on this, it is worth taking care of the additional thermal insulation of the erected design.

On the video - the dimensions of the full-scale brick:

Sometimes there is a need to increase the heat engineering characteristics of the brick wall. Here you should add to the raw material mass, sawdust. During the firing, they will burn out, and form emptiness. As a result, the material acquires porosity and smaller conductivity indicators of heat.

The following dimensions of full-scale brick are actively involved in the construction area:

- single with dimensions 250 × 120 × 65;

- one-time 250 × 120 × 88;

- double - 250 × 120 × 138.

In addition, there are non-standard dimensions of full-scale brick:

Full brick is very beneficial in terms of construction products. Material has high strength indicators, can resist frost. The dimensions of such an artificial stone can be different, so it is advisable to exercise the purchase material only after the project of a future design with printed sizes was drawn up. In contrast, the erected design will not be able to withstand the load elevated on it.