Determination of the softening coefficient (water resistance) of the material. The main properties of natural clays. Ceramic Product Production Technology

§ 1. Physical properties

Density. Medium density ρ m. call the ratio of mass t of body or substance to the entire volume occupied by V., including pores and emptiness available in them, kg / m 3 (g / cm 3):

ρ m. = m / V.

True density - the limit of the mass ratio to the volume when the volume is consistent with the point in which the density of the body or substance is determined (i.e., without taking into account voids and pores).

True density of building materials, g / cm 3

Asbestos ............................ 2.35 - 2.6 asbestos cardboard ............ ..... 1,2 basalt ........................... 2.8 - 3.2 Concrete: Heavy .... ..................... 1.8 - 2.5 easy ..................... ..... 0.5 - 1.8 Water .............................. 0,99823 Wax ... ........................... 0.95 - 0.99 gypsum ............... ............... 1.81 clay ............................. 1, 5 - 2.6 gravel ............................ 1.8 - 2 granites .......... ................. 2.5 - 2.95 limestone ......................... 1.9 - 2.8 Lime: Negarent ....................... 3.1 - 3.3 Hair ......... ............... 2 - 2.4 hydraulic ................... 2.2 - 3 rosin .... ...................... 1.07 Brass ........................ .... 8.5 - 8.6 Magnezit .......................... 3.1 - 3.4 copper .... .......................... 8.96 chalk .................... ........... 1.8 - 2.6 marble ............................ 2.5 - 2.8 PEMZA ............................. 0.4 - 0.9 Sand ........ ..................... 1,2 - 1.6 cm Ola ............................. 1.07 - 1.1 Salonic acid (38%) ..... ... 1,19 cement .......................................... 2.2 - 3.2 Slagosital ....... ................ 2.6 - 2.75

Bulk density - The ratio of mass of granular materials, materials in the form of powder to the entire volume occupied by them, including spaces between particles.

Material material density in natural condition, i.e. with pores and voids, are determined as follows: Take the sample made of the material of the correct geometric shape (cube, cylinder), weigh and measure its volume. To determine the density of the porous material, it is pretty thin, and then in the laboratory conditions determine the volume occupied by the resulting powder using the Le Chatel instrument. If the material is powdered, then it is determined by its bulk density with a funnel or an inclined plane and a volume vessel with a volume of 1 liters.

W. porous materials (Ceramzitobeton, mineral wool) average density less than the true density, in dense (steel, granite, glass, bitumen) is almost equal to true density.

The density of the mortar mixture is determined with an error of no more than 5 g using a cylindrical vessel with a capacity of 1 liters. The vessel is filled with a mortar mixture with some excess. In the mobility of the mixture to 6 cm, the solution is compacted on the vibrationboard for 30 s, more than b cm - 25 times with a steel rod with a diameter of 10 - 12 mm. Then they cut the excess mixture to heaven with edges and the vessel weigh.

The presence in a solution mixture of a certain amount of air in the form of the smallest bubbles increases the mobility and water-holding capacity of the solution, increases its waterproof and frost resistance. To increase the air content in the solution, hydrophobic additives are used (oxidized petrolatum).

Density indicator R Determine the formula

P \u003d m / ρ,

where m. - mass of material, r; ρ - true density Material, g / cm 3.

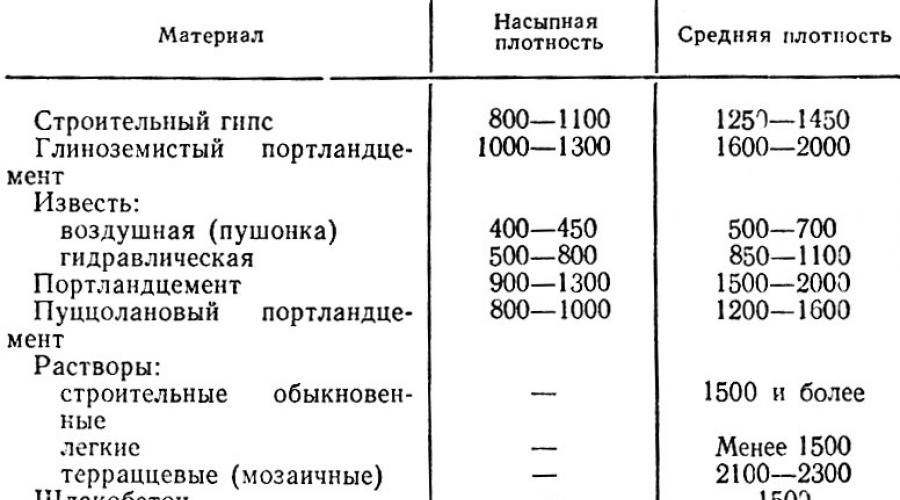

In tab. 1 shows the average and bulk density of building materials.

Table 1. Middle and bulk density of building materials, kg / m 3

Porosity Material is the degree of filling its pores. The basic properties of materials are dependent on porosity: density, strength, water absorption, thermal conductivity, frost resistance, water permeability, etc. The porosity indicator is determined by the formula P = 1 - Rwhere P - indicator of porosity; R - density indicator.

Passenger - This is the ability of the material to pass water under pressure. The degree of water permeability depends on the porosity of the material, form and sizes of pores. Waterproof can be considered dense materials with small closed pores, in particular special concrete and solutions.

It must be borne in mind that the water permeability is the negative property of the material. For example, in the water permeable concrete, the water leans filter through it, and sometimes it makes it harmful substances that reduce the strength of concrete or completely destroy it.

The magnitude of the water permeability is characterized by the coefficient of water permeability TO in which equal to quantity Water pasted for 1 hour through a sample with an area of \u200b\u200b1 m 2 and a thickness of 1 m.

Water absorption - The ability of the material to absorb and hold water in the pores. It is characterized by the amount of water that absorbs dry material when immersed and withstanding in water, referred to the mass of dry material (mass water absorption W. c) or to the volume of material in a dry state (volumetric water absorption W. 0). Water absorption depends on the density of the material and structure of the pores.

Water absorption reduces the strength and frost resistance of the material. To reduce water absorption artificial materialsWhen they are made, they seek to obtain evenly distributed, minor closed pores (for example, in a cellular concrete).

Water absorption is calculated in% by formulas

where m. dry - the mass of dry sample, r; m. V is a variety of water sample, r; V. - Dry sample volume, cm 3.

Water absorption of various materials varies widely. For example, massive water absorption ceramic tiles For the inner cladding of the walls, up to 16% comes, ceramic tiles for floors do not exceed 4%, and concrete - 3-4%.

The degree of lowering the strength of the material saturated with water is characterized coefficient softeningTOsamplewhich is determined by the formula TO Some \u003d R. us / R. CYX, where R. NAC - the strength of the material saturated with water, MPa; R. Such is the strength of dry material, MPa.

The softening coefficient takes into account when building construction Work in wet conditions or exposed to water. The magnitude of it for different materials 0 (unreleased clay) to 1 (glass, steel, bitumen, granite).

Materials with a softening coefficient greater than 0.7 are considered waterproof. These materials are allowed to apply in building structures that are erected in water and wet places.

Moisture report - This is the ability of the material to highlight water when humidity decreases ambient, heating, air movement. The moisture date is determined by the amount of water in%, lost by the standard sample of the material per day at the relative humidity of the ambient air of 60% and the temperature of 20 ° C.

Thanks to moisture, building structures dry out: water evaporates until the equilibrium is achieved between the humidity of structures and air. Such a state of equilibrium is called air-dry.

Thermal conductivity Called the ability of the material to transmit heat from one of its surface to another.

The thermal conductivity of the material is characterized coefficient of thermal conductivitywhich is equal to the amount of heat in Joules passing in 1 hour after 1 m 2 of the material with a thickness of 1 m with a temperature difference on opposite surfaces 1 ° C. The coefficient of thermal conductivity depends on the composition and structure of the material, its porosity and humidity. For example, the thermal conductivity coefficient of crystalline materials is higher than the materials of mixed structure or amorphous. In the materials of greater porosity, the thermal conductivity coefficient is low, since the heat is transmitted not only through the pore walls, but also a cut bubble bubbles, prisoners in the pores

An increase in the average temperature at which heat is transmitted from one surface of the fence to the other, leads to an increase in the coefficient of thermal conductivity of some materials, especially with major pores. The thermal conductivity of the materials increases sharply when they are moisturized and even more when the water is freezing in the pores of the material, since the thermal conductivity coefficient of water in 20 - 25, and ice is 80 times greater than air.

Thermal expansion of materials It is characterized by a change in linear dimensions and volume with an increase or decrease in temperature.

The linear dimensions of the sample of the material (for example, length) with a change in its temperature are determined by the formula l T.= l. 0 (l.+α t.), where L T.- sample length at t 0 s, mm; l. 0 - sample length at 0 ° C, mm; t. - sample temperature, ° C; Aα - the coefficient of linear expansion of the material.

Linear expansion coefficient It is equal to relative elongation of the material when it is heated to 1C.

The volume of the material sample when it changes its temperature is determined by the formula Vt. = V. 0 (1 + β t.), where V T.- the volume of the sample at T ° C, mm 3; V. 0 is the volume of the sample at 0 ° C, mm 3; t. - sample temperature, ° C; α - the coefficient of volume expansion of the material.

Volume expansion coefficient It is equal to the relative change in the volume of the material when it is heated at 1 ° C.

When the materials are heated, their density changes occurs. Density of material Pρ. t., g / cm 3, at temperatures t. ° C is Rρ t.\u003d ρ 0 (1+ b T.), where R 0 - material density at 0 ° C, g / cm 3; t. - sample temperature, ° C; β - Volume expansion coefficient.

Heat extensibility Material is characterized coefficient of mastering heat. It depends on the heat capacity of the material, its average density, as well as on the rate of temperature change at the material of the material.

The coefficient of heat assimilation takes into account when choosing materials for floors. For the standard, the coefficient of absorption of heat oak parquet floorsequal to 5. Coatings with a coefficient of more than 5 are considered cold, less than 5 - warm.

The floors in residential, public, auxiliary and heated industrial buildings and structures should have an indicator of thermal activity of not more than 42 kJ / m 2 x h 1/2 x ° C.

Heat capacity - The properties of the material absorb a certain amount of heat when heated and highlight it when cooled. The heat capacity is characterized by the coefficient of heat capacity C, equal to quantity Heat in joules necessary for heating 1 kg of material by 1 ° C.

Thermal capacity coefficients of materials, KJ / kg x ° C

Natural stone materials .......... 0.92 Concretes ................................ 0 , 84 Stool construction .................... 0.46 Wood pine ..................... ..2.52 Water .................................. 4.2

Paro-, air- and gas permeability Materials are characterized by the amount of steam, air or gas pasted through a sample of certain sizes at a given pressure.

Building materials with great porosity, especially thermal insulation, have increased gas and vapor permeability, although not only the total porosity magnitude, but also the size and nature of pores affects the degree of vapor and gas permeability. To eliminate this phenomenon, it is necessary to arrange gas and countertile layers in the enclosing structures.

The gas permeability of materials should be taken into account when erecting structures working at a considerable solution (pipes, furnaces), and vapor permeability is in the designs of the premises, the temperature of which is lower than the ambient temperature (for example, refrigeration chambers).

Gas and vapor permeability of materials must also be taken into account when performing facing and flooring.

Frost resistance - This is the ability of a material or product in a saturated water condition to withstand multiple alternate freezing and thawing without visible signs of destruction (cracks, separation, chipping) and a significant reduction mechanical strength and masses.

By frost resistance, materials are divided into brands. For example, a stamp of solution (concrete) in frost resistance denotes the number of cycles of alternate freezing and thawing, at which a decrease in the strength of concrete samples does not exceed 25% with a mass loss of no more than 5% (GOST 5802 - 78). Samples subject to freezing are saturated with water for 48 hours and placed in the refrigeration chamber at a temperature not higher - 15 ° C.

The coefficient of frost resistanceTo N M., concrete or hardened solution through N cycles of freezing and thawing are determined by the formula

where R N Szh.- urgency in compressing samples undergoing freezing and thawing during n. Cycles, MPa; R. E SJ. - Strength when compressing samples at an equivalent age, MPa. Equivalent age of samples T E. Determine the formula

T E. = but + 0,2n.,

where but - Duration of hardening samples before freezing, day.

Fire resistance - Property of building materials resist the effects of high temperature. According to the degree of flammability, non-aggravated, challenges and combustible materials are distinguished.

Non-burnable are not lit and are not subjected to significant deformations under the influence of fire or high temperature (brick, concrete).

The difficulties are not burning, but are subject to significant deformations under the influence of fire or high temperature (steel, granite, gypsum).

The combustible flammable under the action of fire or high temperature and continue to burn after removing the heat source (wood, only reference).

Fireproof - the property of materials to resist for a long time, not melting, exposure high temperatures (Over 2000 ° C).

Fireproof depends on the chemical and mineralogical composition of the material and is determined on standard samples heated at a certain speed.

Sound absorption - The ability of the material to weaken the intensity of the sound when it passes through the material due to the conversion of the energy of the sound wave into other forms of energy (for example, to thermal).

Sound permeability - This is the property of the material to skip the sound, noise. There are two types of noise transmitted by walls and overlaps: shock and air. In order to isolation of premises from noise, building structures must have sound absorption. To repay air noise, the design must have a certain mass. Impact noises are well absorbed by porous materials.

The intensity of the sound wave Or the power of the sound is equal to the average energy, carrying the wave for 1 s after 1 cm 2 of the material surface.

Sound insulation coefficient In decibels, they define as the ratio of the power of the sound falling on the partition, to the power of the sound passed through it.

The physical condition of the material, in particular its humidity, has a greater effect on the size of the sample strength. The strength of most natural and artificial stone Materials In a dry state, higher than in rich water. Property of materials Save strength in a water-saturated state is called water resistance And characterized coefficient softening which is determined by the formula:

K p \u003d , (20)

Tensile strength in the compression of water-saturated samples, MPa (kg / cm 2);

The strength of the compression of samples dried to constant mass, MPa (kg / cm 2).

In accordance with GOST 30629-99 to determine the strength in compression in a saturated water, samples of materials from mountain breeds After measurements, it is placed in a vessel with water room temperature so that the water level in the vessel was above the top of the samples at least 20 mm. In this position, the samples should be withstanding for 48 hours. After which they are removed from the vessel, removed moisture from the surface with a damp cloth and each sample is tested on the press according to the method described above. For tests also take at least 3 samples. According to the results of the test, the conclusion of the water resistance of the material and the field of its application is made. Construction material It is considered waterproof if its softening coefficient is at least 0.8.

Determination of flexural strength

Bending Strength Defined on hydraulic presses, or on special test bending machines, for example, MII - 100. Samples manufactures according to GOST on the material under test. For example, when testing cement, gypsum, samples - beams 40x40x160 mm samples (Table 1), and when testing wood - beams with a size of 20x20x300 mm (Table 1). The load on the sample can be transmitted by one or two cargoes according to the schemes that are given respectively in Table 1.

Before testing samples on them, marks the locations of the application of loads and support, determine the size of the section in the locations of the application of the loads (width and height cross section). Then, if the test is carried out on the press on the bottom support plate, two support rinks are strengthened, which are not installed by the standards test sample. There is an upper bar between the top stove and the sample, which is transmitted by the bending load. After testing on the press, the destructive bending load p is determined, and the magnitude of the strength of the bend is immediately determined on the MIA 100 machine. In the first case, the tensile strength is determined by the formulas:

a) when one concentrated load and sample - a rectangular bearing

R is from\u003d, [MPa (kg / cm 2)], (21)

b) at two equal focused loads, located symmetrically axis of the beams in 1/3 span

R Zong \u003d , [MPa (kg / cm 2)], (22)

where:

L is the distance between the supports, M (cm);

but- distance between points of application of loads, M (cm);

b. - width of the cross section of the beam, M (cm);

h. - Height of the cross section of the beam, M (cm).

The final result of the tensile strength is calculated as the mean arithmetic test results of 3 samples.

Definition of coefficient

Constructive quality Materials

The coefficient of constructive quality material (K.K.K.) material characterizes its design properties. The coefficient of constructive quality is determined by formulas:

K.K.K. \u003d., [MPa], (23)

where: R. - the strength of the material, MPa;

ρ 0 - the relative density of the material (the average density divided by the density of water) is substituted into the formula in the form of a dimensionless value.

The most effective structural materials have higher durability at low medium density. Enhance kkk.K. It is possible to achieve a decrease in the average density of the material and an increase in its strength.

Definition of frost resistance

Frost resistance It characterizes the ability of a saturated material of the material to withstand multiple alternate freezing and thawing. The main cause of the destruction of the wet material during freezing is pressure on the pore walls of the water during its freezing, which makes tens and hundreds of MPA and leading to the destruction of the material.

The definition of frost resistance of materials from rocks is produced in accordance with GOST 30629-99. For this prepare samples of cubic shape with an edge of 40-50 mm or a cylindrical - diameter and a height of 40-50 mm.

The test is carried out in the following sequence. Samples are placed in a bath on the grille in one row and poured with water with a temperature of 20 + 5 0 with so that the water level in it was above the top of the samples by 20 mm. After exposure of the samples for 48 hours, water is drained. Five samples are tested by compression according to the standard method, the bath with the other samples is placed in the refrigeration chamber and adjust the temperature to minus 17-25 0 C. With the steady temperature within minus 17-25 0, the samples are withstanding 4 hours, after which the bath is removed from the chamber and poured a flow or changeable water with a temperature of 20 + 5 0 C, and withstand to completely thawing samples, but not less than 2 hours. One freezing and one thawing is considered for one cycle.

Test cycles repeat and depending on the expected value of frost resistance for this material after 15, 25, 60, or more cycles of five samples are subjected to compression tests for the previously outlined method.

According to the results of the tests, the loss of the strength of the samples by the formula is calculated:

D \u003d 100., [%] (24)

where: R c f - average arithmetic value of compression strength

five samples in saturated water, [MPa (kg / cm 2)];

The average value of the compression strength of five samples

after their test for frost resistance, [MPa (kg / cm 2)].

If the average value of the loss of the strength of five samples during compression after the alternate freezing and thawing does not exceed 20% with the number of cycles, then such a material corresponds to the corresponding brand for frost resistance. With loss of strength of more than 20%, the material does not correspond to the corresponding brand for frost resistance. Frost resistance can also be assessed by weight loss with samples from the subject material. In this case, after saturation, the samples (at least 5) are weighed, and then after the corresponding number of freezing cycles, the exhaust is again weighed. According to the results, they calculate the loss of mass samples by the formula:

D \u003d 100., [%] (25)

where: m 1. - sample macca to testing, g;

m 2. - Mass sample after testing, G.

The limit of frost resistance is considered the largest number of cycles, which material stood under the loss of mass is not more than 5%.

Water absorption is the ability of the material to absorb and hold water in the pores. Determine water absorption by weight and volume.

Water absorption by weight in M \u200b\u200b(%) is calculated by the formula

where m N. - the mass of a saturated water of the sample, r; m S. - Mass of dry sample, G.

Water absorption in volume In O. (%) - the degree of filling the volume of the material with water, which characterizes mainly its open porosity, ─ calculated by the formula

, (19)

, (19)

where V 0 - sample volume, cm 3; ρ B. - water density (1g / cm 3).

Knowing water absorption In M. and density ρ 0 , you can calculate water absorption by volume

. (20)

. (20)

The test is produced on samples in the form of cubes with an edge 100 or

150mm or in the form of cylinders having the same diameter and height. The determination of water absorption of material on samples that have an irregular geometric shape and a mass of at least 200 samples are dried to a constant mass, and then placed in a container filled with water with such a calculation so that the water level in the tank was above the top level of the laid samples by approximately 50 mm. In this case, the samples are laid on the gaskets so that the sample height is minimal. The water temperature in the tank must be (20 ± 2) ° C.

Samples weighed every 24 hours with water with an error of no more than 0.1 g . With each weighing, the samples, taken out of the water, are pre-wiped with pressed vigor. The mass of water flowing from the pores of the sample to the scale of the scales should be included in the mass of a saturated sample.

Water saturation is produced until the results of two consecutive weighing will differ from no more than 0.1 g. .

Water absorption by mass and volume is calculated by formulas (18) - (20).

The water absorption of the material is also determined by the boiling method of samples. At the same time, the samples are boiled in a vessel with water. The volume of water should not less than twice the volume of samples installed in it. After every 4 h boiling, the samples are cooled in water to room temperature, wipped with moist cloth and weighed. The test is carried out until the results of two consecutive weighing will differ from no more than 0.1%. Calculation of water absorption leads to the above formulas.

Results.

The macrostructure is the structure of the material visible to the naked eye.

For the most common building materials with a conglomerate structure (suit), it is formed by the combination of microstructure binder and half-or other species (fibrous, plate, angular, etc.) of coarse aggregate particles, and it also contains a capillary part. Mlowered aggregates are selected with the smallest volume of inter-rigid voids, which saves the binder in the consumption of the binder in conglomerates. For this purpose, grainy fillers are pre-separated on the sizes fractions in order to then be a test selection or calculation to find the content of each fraction with a dense mixture thereof. If large particles, for example, rubble or gravel, are approximate, which is in contact directly with each other or through thin interlayers of the binder, then the structure formed is called contact. If there is a separation of particles in layers of a binder of a significant averaged thickness, then the macrostructure is customary to call Porphional.

Essential is the separation of structures on optimal and non-optimal. Optimalreferred to the structure if the particles in it are distributed evenly in volume (phases, components, pores, etc.); There are no or contain few defects of the structure as stress concentrators or the accumulators of the aggressive medium; There is a continuous interlayer of the binder in the form of a spatial mesh, or the matrix with a minimum ratio of C / F, referred to as conditionally phase. Non-optimal Called structures that do not satisfy at least one of the above compulsory optimality conditions.

Microstructure of building materials.

The microstructure is a structure visible to an optical microscope (2-4 r lubricated.).

The microstructure and the kinetics of its changes are studied using optical methods, electron microscopy, differential-thermal analysis, radiography, etc. The relatively simple measurement produced on the observation plane is set. Ready by the content of some key element in the material volume.

Depending on the nature of the bonds of contact particles, homogeneous microstructures distinguish coagulation, condensation and crystallization. Coagulative The structures are called, in the formation of which relatively weak molecular interaction forces between particles are involved - van der Walsa clutch forces acting through the layers of the liquid medium. Condensation The structures arising from the direct interaction of particles, or under the influence of chemical compounds in accordance with the valence of contacting atoms, or under the influence of "ionic and covalent bonds. Crystallization (or crystalline) referred to as the structures formed by crystallizing the solid phase from the melt or the solution and the subsequent directly punishment of individual crystals into the durable aggregate, including under the influence of chemical bonds.

The concept of medium density, methods for determining.

The average density is the physical value determined by the ratio of the mass of the material to the entire volume occupied by them, including pores and emptiness. It is not the magnitude of constant and varies depending on the porosity of the material.

Determination of the average density of the material on the sample of an irregular geometric shape: the volume of the sample of an irregular geometric shape is determined by the method of hydrostatic weighing, which is based on the action of the Archimedian law. In accordance with this law on the body, immersed in the liquid, the ejecting force acts equal to the weight of the fluid in the amount occupied by the body. Therefore, the volume of the sample is determined by the volume of fluid displaced. (The sample is covered with paraffin in order to isolate the material from the penetration of fluid in the pores and emptiness)

The concept of O. bulk density, Definition methods.

The bulk density is the mass of the volume of the material volume in a free-rapid state (in bulk volumes included interlenetrating emptiness): ρ n \u003d m n / v

where M n is the mass of the material in a bulk state, r; V n - bulk volume, cm 3.

The bulk density is defined both in the loose-sufficiency state and compacted. In the first case, the material falls asleep in the vessel from a certain height ("standard funnel"), in the second, is compacted on the vibrationboard (30-60 seconds).

The concept of true density, methods of determination.

True density - the mass of the material volume of the material in absolutely dense state (without pores and voids). ρ and \u003d m / v n; V A \u003d V-V P

where m is the mass of the material in absolutely dense state, r; V A is the volume of the material in absolutely dense state, cm 3; V is the volume of material in the natural state, cm 3; V P - pore volume concluded in the material, see 3. (in the pycnometer we measure the mass of the material, the mass of water and the mass of material with water)

Porosity (open and closed). The output of the calculation formula.

Porosity - the degree of filling the volume of the material by pores. Porosity - the value is relative, expressed as a percentage or fractions of the material volume.

where V pore is the pore volume in the material, cm 3 (m 3); V is the volume of material in the natural state, cm 3; V A - the volume of the material in an absolutely dense state (without pores), cm 3; ρ 0 is the average material density, g / cm 3; ρ and - true material density, g / cm 3.

Porosity can be expressed as percent:

![]()

Open pores increase the water absorption and water permeability of the material and worsen its frost resistance. An increase in closed porosity due to open increases the durability of the material, reduces its thermal conductivity. The total porosity consists of open and closed. Open porosity is numerically equal to the volume water supply of material. Having determined water absorption in terms of volume and porosity of the material, you can easily calculate the closed porosity.

The saturation coefficient of pores is water - the ratio of volumetric water absorption to porosity: to H \u003d in V / p. This coefficient varies from 0 (all the pores are closed in the material) to 1 (all pores are open). The more n, the higher the proportion of open pores.

Properties of materials in relation to water action.

Water absorption called the property of the material to absorb and keep water in

direct contact with her. Quantitative expression of water absorption

characterized by mass or bulk water absorption. In the laboratory conditions, the sample is gradually immersed in water or by boiling in water reach full water absorption. Samples are kept in water for a certain period or to constant mass. The magnitude of water absorption by mass,% is the ratio of mass absorbed by water to the entire mass of dry material and is determined by the formula

WMAS. \u003d [(MB - MC ) / MC] · 100.

The magnitude of volumetric water absorption,% is the mass ratio

absorbed water to the whole volume of the body and is determined by the formula

In about . \u003d [(MB - MC) / Ve] · 100.

Increased water absorption of building materials reduces strength, increases

mass, increases thermal conductivity, reduces resistance to action

aggressive media, contributes to the appearance of dampness in residential premises.

Water resistance - the degree of decrease in the strength of the material in its limit water

fusion; It is numerically characterized by a softening coefficient determined by

Cramp. \u003d RNA / RISU,

where RNAs is the tensile strength when compressing the material in saturated water

condition, MPa; Rysh is the tensile strength when compressing the material in a dry state, MPa.

Frost resistance - the ability of the material in a saturated water condition to withstand

multiple alternate freezing and thawing without visible signs of destruction and a significant reduction in strength. The freezing of the test samples is performed at a temperature - 17-20ºС, the thawing is carried out in an aqueous medium, the temperature of which is maintained in the range of + 17 - 20 º FROM.

The degree of frost resistance is characterized by the largest number of cycles of alternated

freezing and thawing, which can withstand the appropriate samples without

reducing the strength of compression by more than 15% and without loss of mass by more than 5%. Material stamps on frost resistance are as follows: MPZ 10; MRZ 15; MPZ 25; MRZ 50;

MRZ 100; MPZ 150; MRZ 200; MRC 300.

Water absorption. Methods of its expression, calculation formula

Water absorption is the property of the materials of the absorption and hold the water with direct contact with it. It may be massive and volumetric. Mass water absorption (in m) is the ratio of the mass absorbed by water under standard conditions to the mass of dry material in%. Surrounding water absorption (in V) is the ratio of the volume of water with a water-faced material under standard conditions to the volume of material in a dry state in%.

The ratio between mass and volumetric waterworking:

![]()

Softening coefficient. Evaluation of the quality of material with it.

The softening coefficient is the ratio of the strength of the material saturated with water to its strength in a dry state. It is an indicator of water resistance material. The water resistance is the ability of materials to maintain its operational properties with a long exposure of water, can lead to water sorption materials, to their swelling or chemical. Interaction with water

The strength of the material in a dry state is always higher than the strength in a water-saturated state, since water penetrating into the pores, creates internal voltage in the material, which removes its strength. This is taken into account by the softening coefficient, which is a quantitative water resistance characteristic:

where r is the strength of the material in saturated water, MPa; R dry - material strength in a dry state, MPa.

If to R.<0,8, то материал не водостойкий.

The coefficient of constructive quality. Evaluation of the effectiveness of materials.

To evaluate the strength efficiency of the material, the coefficient of structural quality is often used (K.K.K.), which is determined by the formula:,

where R is the tensile strength, MPa; D - relative density.

The most effective are materials having the smallest density and the highest strength.

Frost resistance of materials. Mark for frost resistance.

Frost resistance is the property of water-saturated or solid salt solid to withstand multiple alternating freezing and thawing without significant signs of destruction and reduction of strength.

The high-quality characteristic of frost resistance is a frost resistance brand (F), which shows the number of cycles of alternate freezing and thawing the material saturated in the liquid medium, in which the loss of strength and mass does not exceed the values \u200b\u200bspecified in GUT and slips.

![]()

![]()

where ΔR n, Δm n is the loss of strength and mass of the sample saturated in the liquid medium after I cycles of freezing and thawing,%; R n, M n is the strength of compression (in MPa) and the mass (in g) of the sample after n cycles of freezing and thawing; R 0, M 0 is the tensile strength (in MPa) and the mass of the sample (in g), saturated in the liquid medium, until freezing.

For each material, stamps on frost resistance are installed. The brand is indicated by the letter F, after which the minimum number of cycles is specified, which must withstand the material (for example, F100).

The frost resistance brand for severe cement concrete is the number of cycles of alternate freezing and thawing a standard standard sample, in which the loss of strength does not exceed 5%, and for the concrete of road and airfield coatings, in addition, weight loss is no more than 3%.

The ratio between the brands of concrete on frost resistance established by various methods is given in GOST 10060-95.

For samples that do not have visible traces of destruction after a given number of freezing and thawing cycles, a frost resistance coefficient is calculated:

Properties of materials in relation to heat action.

The heat capacity is the property of the material to absorb a certain amount of heat when heated, with the increase in heat capacity, heat is released more during the cooling of the material.

Fire resistance - the ability of the material to withstand the action of high temperatures while maintaining the structure of the bearing capacity and stability over a relatively short period of time (fire). For fire resistance, materials are divided into three groups: non-aggravated (brick, steel, marble), challenges (fibergolite, asphalt concrete), combustible (wood, rubberoid).

Thermal conductivity of materials. Coefficient of thermal conductivity.

Thermal conductivity is the ability of the material to transmit a heat flux through its thickness, resulting from the temperature difference on the surfaces that limit the material. Depends on the porosity, the nature of the pores and the type of material, humidity and the average temperature at which heat is transmitted.

The thermal conductivity is estimated by the amount of heat passing through a sample of a material with a thickness of 1 m, with an area of \u200b\u200b1 m 2 in 1 hour with a temperature difference on opposite surfaces 1ºС

where τ - time, q is the amount of heat, δ - thickness, f - area

formula Nekrasova:

where D is the relative density \u003d ρ CP / ρ H2O

Thermal conductivity of air \u003d 0.023 W / m * ºС; water \u003d 0.78; Ice \u003d 2.3.

The thermal conductivity of the material is taken into account with the heat engineering calculations of the thickness of the walls and overlaps of heated buildings, as well as the determination of the required thickness of the heat insulation of the hot surface and the refrigerator. Located with thermal resistance of a layer of material R (m 2 * ºС / W): R \u003d Δ / λ

Material moisture. Influence of humidity on the properties of materials.

Gigroscopicity is the ability of the material to absorb and condense moisture from the ambient air. Estimated by humidity.

Humidity is the moisture content in the material at the moment.

![]()

where m cell is a mass of material in a natural state, r; M - Mass of dry material, G.

With increasing moisture, the heat capacity increases, frost resistance is worse.

Mechanical properties of materials.

Strength is the property of the material to resist, not destroying, internal stresses and deformations that occur under the action of external factors (power, thermal, etc.).

Strength of compression, with bending.

The coefficient of constructive quality is the conditional coefficient of the effectiveness of the material equal to the ratio of the indicators of the strength of RSG (MPa) to the relative density of the material (dimensionless value). The higher K.K.K. material, the more efficient material, because It has high strength at low medium density.

Hardness - the ability of the material to resist the penetration of a more solid body into it. Defined by Brinell (for steel): ![]() ,

,

where p - the load with which was given to the ball; D - the diameter of the ball; D - the diameter of the imprint.

The hardness of fragile materials (for example, natural) is determined on the hardness scale - the Moos scale: Talc, Gypsum, Calcite, Fluoraitis, Apatite, Ortoklaz, Quartz, Topaz, Corundum, Diamond.

The abrasability is the ability of the material to decrease in mass and volume under the action of abrasive efforts. Abrasion is determined by special machines (circles of abrasion, sandblasting machines, etc.) and express the loss of the mass of the sample, referred to the area of \u200b\u200babrasion: ![]()

Mechanical wear - the ability of the material to decrease in mass and volume under the action of drums and abrasive efforts. ![]()

Elasticity - the ability of the material to spontaneously restore the original shape and sizes after the termination of the external forces.

The elastic module - characterizes the stiffness of the material. What it is higher, the less plastic material (Jung module).

Fragility - the property of the material to collapse under the action of loading without noticeable plastic deformation.

Plasticity - the ability of the material to change the form and dimensions for the action of external forces, not destroying, and maintain them after removing the load (clay).

Strength of materials on compression and bending. Loading schemes, calculated formulas.

Strength - The property of the material to resist internal stresses and deformations, which occur under the action of external factors (power, thermal, etc.), not destroying.

The strength of the material is assessed by the strength of the strength, which is conditionally equal to the maximum voltage, which appears in the material under load, caused the destruction of the material.

In practice, the tensile strength is determined by the destruction of standard samples in compression, bending or breaking.

Compressive strength:

- cross-sectional area of \u200b\u200bthe sample, m 2 (or cm 2).There is the following dependence between units of measurement:

, ![]()

Better tensile strength for rectangular beams:

where M. izg - bending moment; W. - The moment of the resistance of the cross section of the beam.

For rectangular cross section, the moment of resistance is:

with one concentrated symmetrical relative to the support support:

with two concentrated symmetrical relative to support support:

, ,

, ,

where is the length of the beams, m; l. - the distance between the supports, m; b. and h. - Accordingly, the width and height of the beams.

Emptiness. The output of the calculation formula.

Emptiness - This is the proportion of inter-rigid voids in a bulk volume of material.

Estimated formula:

![]() ,

,

where - void, share or%; V. empty - the volume of voids in the bulk volume of the material, cm 3; V. - volume of material, cm 3.

Wallout can be expressed in%:

Emptiness - the most important characteristic of the correctness of the selection of the grain composition of aggregates for concrete, on which the consumption of binder (cement, bitumen, etc.) depends. In practice, void lies within 26.5 - 47.6%.

The main properties of natural clays.

Clay materials are an OGP, weathered weathered products that have a fine-disperse structure, which, regardless of their chemical and mineralogical composition, with water mixing, are capable of forming a plastic dough, passing after firing into a waterproof and durable campanery body.

Properties of clays:

Plasticity is the ability of clay test under the influence of external mechanical impacts to take a certain form without breaks and cracks and maintain it after removing these effects.

Number of plasticity: P (L) \u003d W (T) -W (P)

where w (p) is the amount of water,% necessary to obtain the test; W (T) - The size of the water required to give clay yielding test,%

Maloplastic - P (L)< 7

Measoplastic - P (L) \u003d 7-15

High-pile -p (l)\u003e 15

Binding ability - the property of clays, binding grains of non-substantiated materials, forming enough durable products when dried up - raw

Shrinkage clay reduction of linear dimensions and volume of clay raw materials during drying (shrink air - 3-12%) and firing (fire shrinkage 2-8%).

The sintering of clays - the property of clay compacted during the firing with the formation of a stone-like shard

Firefinder clay - the property of clay to withstand the action of high temperatures, not melted

Additives, regulating the properties of clay.

Expressive additives - shame, sand, ash of CHP; Impaid to reduce the plasticity of clays, their air and fire shrinkage.

Burning additives - wood sawdust, brown coals, coal waste; Increase the porosity of wall materials, contribute to the uniform sticking of the sharp.

Plasticizing - high-pile clay, surface-active substances (SDB, PRS, etc.); Increase the plasticity of skinny clay.

Floating - field Schpates, iron ores, dolomite, magnesite, etc.; To reduce the sintering temperature of the clay.

Classification of ceramic materials.

Ceramic materials are artificial stone materials obtained from clay raw materials by forming products with their subsequent drying and firing.

For destination: Facade (facial brick, tiles), wall (brick, stones), floor tiles, roofing (tile), heat-insulating (cellular ceramics), concrete aggregates (clay, aglopeoritis), etc. By appointment, ceramic brick is divided into: construction (ordinary), facing and special.

According to the method of manufacture: distinguish plastic molding bricks or semi-dry pressing.

According to the structure of the shard: distinguish products with porous and with a sharp shard, as well as coarse and fine ceramics.

Under the finishes of the surface: modern ceramic brick can be almost any, from white to black, and even inhomogeneous color. For the construction brick, the color is not fundamental, for the facial is one of the main parameters.

Technology production of ceramic products.

Career works: mining, transportation and storage of clay during the year outdoors in the scene to destroy its natural structure in order to increase the plasticity and molding properties of clay.

Preparation of molding mass: crushing, grinding, screaming (dropout), moisturizing.

Forming products.

Plastic molding (humidity 18-22%) - produced from plastic clay masses on ribbon presses. From the mouthpiece of the press there is a continuous clay bar, which is automatically cut into products of the specified size. Mold brick, tile, tile, pipes.

Semi-dry pressing (humidity is 6-11%) - is made from prescriptions on hydraulic presses operating automatically. The pressing pressure ranges from 15 to 40 MPa. Molds brick, tile, pipes, refractory and acid-resistant products.

Casting (humidity up to 40%) - a certain amount of slip is automatically poured into collapsible forms. Molds move through the conveyor, the ceramic mass is rapidly dries due to water suction with a porous form. After a set of certain strength, the product from the form is removed, protected and sent to drying. Putting plumbers.

Drying raw - it is produced up to 5% humidity in dryers of various designs (chamber, tunnel, roller).

Firing products - before sintering the clay mass. 900-1000ºС.

Quality control ceramic brick According to external features.

Due to the drying and firing, ceramic brick is inevitably subjected to air and fire shrinkage, which is not allowed to obtain brick of strictly defined geometric sizes. Therefore, GOST 530-2007 provides for permissible deviations along the length, width and thickness of the brick, and also regulates the presence of chopping corners, curvature of ribs and faces, the presence of cracks.

There is a larger (brick has a brightest tone compared to the standard and when hitting the hammer makes a deaf sound, the strength of it is small) and the facing (the brick is melted, heavily twisted, has an increased thermal conductivity), as well as a brick containing lime inclusions ("Dutiks") causing brick destruction in masonry.

The number of bricks subjected to inspection by external features is determined by the volume of the party according to GOST530: if the volume of bricks batch from 10001 to 35,000 pieces, then the sample is 80 pieces; If more than 35,000 pieces, then 125 pcs. The acceptance level of defect is 6.5%.

Definition of a ceramic brick brand.

The brand of ceramic bricks characterize the strength of strength in compression and bending test of samples selected by indicators external view. 10 pieces. For compression test and 5 pcs. - Bending.

The tensile strength is determined on samples consisting of two whole bricks or its halves. Bricks or halves are laid by beds on each other, the last surfaces of the section in opposite sides.

The reference surfaces of the plastic molding brick are aligned with cement mortar, semi-dry pressing brick test dry.

Prior to test, the samples are withstanding three days indoors at a temperature of 20 ± 3 0 s and relative humidity of 60-80%.

It is allowed to align the support surfaces of the plastic molding bricks using gaskets from technical felt, rubberry plates, cardboard and other materials.

The test of the bending brick is performed on whole bricks, like beams freely lying on two supports and loaded in the middle of the span (Figure 3).

Supports must be located at a distance of 200 mm from each other.

Figure 3. Big Brick Test Scheme

In the places of reference and application of the load, the surface of the plastic molding brick is equalized by cement or plastering solution or laid gaskets. Before the test, the sizes of the cross section of the brick are determined up to 1 mm.

Question 23. Determination of the brand of ceramic bricks.

The brand of ceramic bricks characterize the strength of strength in compression and bending test of samples selected according to the appearance of the appearance. 10 pieces. For compression test and 5 pcs. - Bending. Tests are carried out in accordance with GOST 8462-85.

The tensile strength is determined on samples consisting of two whole bricks or its halves. Bricks or halves are laid by beds on each other, the last surfaces of the section in opposite sides.

The reference surfaces of the plastic molding brick are aligned with cement mortar, semi-dry pressing brick test dry.

Prior to test, the samples are withstanding three days indoors at a temperature of 20 ± 3 0 s and relative humidity of 60-80%.

It is allowed to align the support surfaces of the plastic molding bricks using gaskets from technical felt, rubberry plates, cardboard and other materials.

The strength of the compression of a separate sample is calculated by the formula:

where R. Szh. - tensile strength, MPa;

BUT - sample area, m 2;

TO - a large-scale brick factor with a thickness of 88 mm, equal to 1.2.

The average strength limit value is calculated with an accuracy of 0.1 MPa as an average arithmetic value of the test results of five samples.

When calculating the strength of the thickened brick (88 mm thick), the test results are multiplied by the coefficient of 1.2.

When calculating the strength of the brick, aligned with pads, apply a correction coefficient, which is expressed by experience:

where R 1 is the average value of the compressive strength (bending) when testing 50 samples on cement mortar;

R 2 is the mean value of compressive strength (bending) when testing 50 samples on gaskets.

With bending

The test of the bending brick is performed on whole bricks, like beams freely lying on two supports and loaded in the middle of the span (Figure 3).

Supports must be located at a distance of 200 mm from each other.

Figure 3. Big Brick Test Scheme

In the places of reference and application of the load, the surface of the plastic molding brick is equalized by cement or plastering solution or laid gaskets. Before the test, the sizes of the cross section of the brick are determined up to 1 mm.

The tensile strength of a separate sample is determined by the formula:

R. Izg =,

where R. Izg - tensile strength, MPa;

l. - the distance between the supports, m;

b. - width of the brick, m;

h.- Height (thickness) of brick, m.

For the final value of the bending strength, the arithmetic value from the test results of 5 samples, calculated with an accuracy of 0.05 MPa, is taken.

If one of the samples has a strength, characterized by more than 50% in a large or smaller side of the average value, then this result is not taken into account and the arithmetic average of four strength values \u200b\u200bis taken.

Question 24. Positive and negative wood qualities as a structural material.

Among natural species Raw wood ranks third after coal and oil.

The most important types of raw (non-treated) wood are logs (sawn timber), layered wood for the production of chip and wood fibers, as well as veneer.

Wood, having a fibrous structure and greater porosity (30-80%), is a hygroscopic material and absorbs moisture from the atmosphere. Depending on the temperature and humidity of the air between it and the wood, there is a hygroscopic equilibrium, which determines the moisture content of the wood. Gigroscopic wood moisture is 30%.

Wood is characterized by relatively high strength at any density, low thermal conductivity, ease of processing, ease of fastening of individual elements, high frost resistance and satisfactory resistance to many chemical reagents. The disadvantages of wood include hygroscopicity, hydrogenation and fire, anisotropy (heterogeneity of physicomechanical properties in different directions), the presence of vices. To assess the quality of wood as raw materials to obtain various building structures, its macro- and microstructure are studied, determine physical, mechanical and operational properties, as well as vices.

Positive properties of wood:

1. Low density: spruce, pine, linden, aspen - 0.46-0.6 g / cm3; Birch, oak, larch - 0.61-0.75 g / cm3; Kizil - 0.91 g / cm3

2. High strength. Wood is best working on bending and has a high coefficient of constructive quality (K.K.K.) characterizing the strength efficiency of wood.

3. Low thermal conductivity. The thermal conductivity coefficient of dry wood, on average is 0.16 - 0.30 W / m0s.

4. High engineering wood as a building material.

5. Beautiful fibrous structure.

6. Environmental purity.

Negative wood properties:

1. ignorance.

2. Gigroscopicity.

3. Harriness.

4. The anisotropy of the properties, due to the fibrous structure.

5. Moisture deformations.

6. Foreign structures.