Mechanical properties of building materials

Building materials and products are classified according to the degree of readiness, origin, appointment and technological basis.

According to the degree of readiness, the construction materials and construction materials are distinguished - finished products and elements mounted and fixed on the site of work. Building materials include wood, metals, cement, concrete, brick, sand, mortar for stone masonry and different plasters, paints and varnish materials, natural stones, etc. Construction products There are precast concrete panels and designs, window and door blocks, sanitary and technical products and cabins, etc. Unlike products, construction materials are subjected to processing - mixed with water, compacted, saw, teshut, etc.

By origin, building materials are divided into natural and artificial. Natural materials - it's wood, rocks (Natural stones), peat, natural bitumens and asphalt, etc. These materials are obtained from natural raw materials by simple processing without changing their initial structure and chemical composition. Artificial materials include brick, cement, reinforced concrete, glass, etc. They are obtained from natural and artificial raw materials, by-products of industry and agriculture using special technologies. Artificial materials They differ from the initial raw materials in both the structure and the chemical composition, which is due to the fundamental processing of it in the factory conditions.

The largest distribution was obtained by classifications of materials for the purpose and technological basis.

For appointment, materials are divided into the following groups:

Structural, which perceive and transmit loads in building structures;

Thermal insulation, the main purpose of which - to minimize the transfer of heat through the construction structure and thereby ensure the necessary thermal regime in the room when minimum costs Energy;

Acoustic (sound-absorbing and sound insulation) - to reduce the level of "noise pollution" of the room;

Waterproofing and roofing - to create waterproof layers on roofing, underground structures and other structures that need to be protected from water or water vapor;

Sealing - for sealing joints in prefabricated structures;

Finishing - to improve decorative qualities building structures, as well as to protect structural, thermal insulation and other materials from external influences;

Special purpose (for example, refractory or acid-resistant), used in the construction of special structures.

A number of materials (for example cement, lime, wood) cannot be attributed to any one group, since they are used in pure form, and as raw materials for other building materials and products. These are the so-called general-purpose materials. The difficulty of classifying building materials for the purpose is that the same materials can be attributed to different groups. For example, concrete is mainly used as a structural material, but some kind of species have a completely different purpose: especially light concrete are heat insulating material; Especially heavy concrete - material special purposeused to protect against radioactive radiation.

According to the technological basis, the materials are divided, given the type of raw materials from which the material is obtained, and the type of manufacture, to the following groups:

Natural stone materials and products are obtained from rocks by processing them: wall blocks and stones, facing plates, architectural details, butter for foundations, crushed stone, gravel, sand, etc.

Ceramic materials and products - are made of clay with additives by molding, drying and firing: brick, ceramic blocks and stones, tiles, pipes, faience and porcelain products, tiles facing and for flooring, ceramzite (artificial gravel for light concrete) and Dr.

Glass and other materials and products made of mineral melts - window and facing glass, glass blocks, fibrofilitis (for fences), tiles, pipes, products from satalles and slagositallov, stone casting.

Inorganic binding substances - mineral materials, predominantly powdered, forming a plastic body when mixing with water, over time, acquires ancient state: cements of various species, lime, gypsum binders, etc.

Concretes are artificial stone materials obtained from a mixture of binder, water, small and large aggregates. Concrete with steel reinforcement is called reinforced concrete, it resists well, not only compression, but also bending and stretching.

Construction solutions - Artificial stone materials consisting of binder, water and small aggregate, which over time transition from the tough in ancient state.

Artificial non-Russian stone materials - are obtained on the basis of inorganic binders and various aggregates: silicate brick, Gypsum and gypsum concrete products, asbestos-cement products and structures, silicate concrete.

Organic binders and materials based on them are bitumen and degenid binders, roofing and waterproofing materials: rubberoid, pergamine, isol, brize, waterproof, tol, gluing mastic, asphalt concrete and solutions.

Polymeric materials and products are a group of materials obtained on the basis of synthetic polymers (thermoplastic and thermosetting resins): Linoleums, Rail, synthetic carpets, tiles, wood-free plastics, fiberglass, foams, poroplasts, celloplasts, etc.

Wood materials and products are obtained as a result of mechanical wood processing: round forest, lumber, blanks for various carpentry, parquet, plywood, plinths, handrails, door and window blocks, glued structures.

Metal materials are the most widely used in the construction of ferrous metals (steel and cast iron), steel rolling (2-ways, chawllers, corners), metal alloys, especially aluminum.

Therefore, for a deeper understanding of the properties of materials, their rational use in the study of the "Building and Products and Products" subjects, a technological feature is based on and only in some cases consider groups of materials for their intended purpose.

This group of properties constitute, firstly, the parameters of the physical condition of materials and, secondly, the properties that determine the ratio of materials to various physical processes. The first is the density and porosity of the material, the degree of grinding of powders, to the second - hydrophysical properties (water absorption, humidity, water permeability, water resistance, frost resistance), thermophysical (thermal conductivity, heat capacity, temperature expansion) and some others.

True density p and - the mass of the units of absolutely dense material, i.e. without pores and emptiness. It is calculated in kg / m 3, kg / dm 3, g / cm 3 by formula:

where m is the mass of material, kg, r; V A is the volume of material in a dense state, m 3, dm 3, cm 3.

The true density of each material is a constant physical characteristic that cannot be changed without changing its chemical composition or molecular structure. So, not organic Materials, natural and artificial stones consisting mainly of silicon, aluminum and calcium oxides, the true density is in the range of 2400-3100 kg / m 3, in organic materials consisting mainly of carbon, oxygen and hydrogen, it is 800-1400 kg / m 3, wood - 1550 kg / m 3. The true density of metals fluctuates in a wide range: aluminum - 2700 kg / m 3, steel - 7850, lead - 11300 kg / m 3.

Average density p with- the mass of the unit of material in natural condition. with pores. It can be dry material, in a state of natural or other humidity, indicated in GOST. Medium density (in kg / m 3, kg / dm 3, g / cm 3) are calculated by the formula:

where m. - mass of material, kg, r; V E. - material volume, m 3, dm 3, cm 3.

The average density of bulk materials - rubble, gravel, sand, cement, etc. - called bulk density. The volume includes pores directly in the material and emptiness between the grains.

The average density of most materials is usually less than their true density. Separate materials, such as steel, glass, bitumen, as well as liquid, have almost the same true and average density.

Relative density d. - attitude middle density Material to standard density. Water was accepted at a standard substance at a temperature of 4 o C, having a density of 1000 kg / m 3. Relative density (dimensionless value) is determined by the formula:

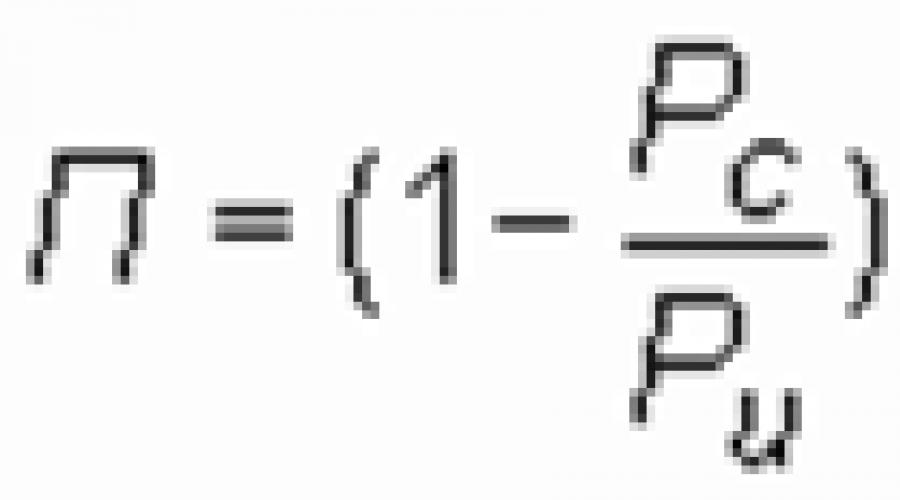

Porosity P - The degree of filling the volume of the material by pores. It is calculated in% by the formula:

where P s, p and - average and true density material.

For building materials Pranges from 0 to 90% .

For bulk materials, emptiness is determined (intercolored porosity). True, average density and porosity of materials are interrelated values. They depend strength, thermal conductivity, frost resistance and other properties of materials. The approximate values \u200b\u200bof them for the most common materials are shown in Table. 1.1.

Humidity W. - water content in the material at the moment. It is determined by the water ratio contained in the material at the time of taking a test for testing, to the mass of dry material. It is calculated in% by the formula:

where m Vl, m s - mass of wet and dry materials,

Water resistance - The ability of the material to maintain its strength when saturated with water. It is assessed by the cranmatum softening coefficient, which is equal to the ratio of the strength of the material of the material when compressing in a saturated water condition R.In, MPa, to the strength limit of dry material R.Dry, MPa:

TOSome \u003d R.IN / R.Dry

For different materials TOSome \u003d 0 ... 1. So, the clay with moisture does not have the strength, it TOSize \u003d 0. Metals, glass fully retain strength in water, for them TOSomething \u003d 1. Building materials with a softening coefficient less than 0.8 are not used in a humid environment.

Table 1.1.

The main mechanical properties of materials include strength, elasticity, plasticity, relaxation, fragility, hardness, abrasibility, etc.

Strength - The ability of materials to resist destroying and deformations from internal stresses arising from the impact of external forces or other factors, such as uneven sediment, heating, etc. It is estimated to estimated the strength limits. This is called the voltage arising in the material from the operation of the loads causing its destruction.

The limits of the strength of materials during compression, racetrack, bending, cut, etc. They are determined by the test of standard samples on test machines. The tensile strength of compression and tension R szh (P), MPa, is calculated as the ratio of the load that destroys the material P, N, to the area cross section F, mm 2:

The tensile strength of the bend R and, MPa is calculated as the ratio of the bending moment M, H x mm, by the time of the sample resistance, mm 3:

Stone materials work well on compression and significantly worse (5-50 times) for stretching and bending. Other materials are metal, wood, many plastics - work well both on compression and stretching and bending.

An important characteristic of materials is the coefficient of constructive quality. This is a conditional value that is equal to the ratio of the strength of the material R, MPa, to its relative density:

The coefficient of constructive quality for heavy concrete brand 300 is 12.5; Steel brands ST5-46, oak wood when stretching - 197. Materials with a higher coefficient of constructive quality are more efficient.

Elasticity - The ability of materials under the influence of loads to change the form and dimensions and restore them after stopping the load.

Elasticity is estimated to be the limit of elasticity B UE, MPa, which is equal to the ratio of the greatest load that does not cause residual deformations of the material, P UP, H, to the area of \u200b\u200bthe initial cross section F 0, mm 2:

b UP \u003d P UP / F 0

Plastic - the ability of materials to change its shape and dimensions under the influence of loads and save them after removal of loads. Plasticity is characterized by relative elongation or narrowing.

The destruction of materials can be fragile or plastic. In case of fragile destruction, plastic deformations are insignificant.

Relaxation - the ability of materials to spontaneous reduction in stresses with constant influence of external forces. This occurs as a result of intermolecular displacements in the material. Relaxation is estimated by a period of relaxation - time, for which the stress in the material decreases in E \u003d 2.718 times, where e is the basis of the natural logarithm. The relaxation period ranges from 1 x 10-10 seconds for materials of liquid consistency and up to 1 x 10 10 seconds (decades) in solid.

Hardness - The ability of the material to resist penetration into it more solid material.

For different materials, it is determined by different methods. So, when testing natural stone Materials Use the MOOS scale composed of 10 minerals located in a row, with a conditional figure of hardness from 1 to 10, when a solid material having a higher sequence number scratches the previous one. Minerals are located in the following order: Talc or Chalk, Gypsum or Stone Salt, Calcite, or Anhydrite, Platical Pepat, Apatite, feldspar, Quartzite, Topaz, Corundum, Diamond.

Hardness of metals, concrete, wood, plastics are evaluated by pressing a steel ball, diamond cone or pyramid in them.

The hardness of the material does not always correspond to the strength. Thus, wood has strength, the same with concrete, but significantly less hardness.

Abrasion - The ability of materials to collapse under the action of abrasive efforts. The abrasibility and in G / cm 2 is calculated as the ratio of weight loss with a sample M 1 -M 2 in g from the effect of abrasive efforts to the abrasion area F in cm 2;

And \u003d (M 1 - m 2) / R.

Determined and by testing samples on the abrasion circle or in the shelf drum. This characteristic is taken into account when appointing materials for floors, staircases and sites, roads.

Wear - The properties of the material resist the simultaneous effect of abrasion and shocks. Wearing material depends on its structure, composition, hardness, strength, abrasion. Wear determine on samples of materials that are experiencing in a rotating drum with steel balls or without them. The greater the loss of the mass of the test of the test material (as a percentage of the initial mass of the sample), the less its wear resistance.

Fragility - The property of the material is suddenly collapped under the influence of the load, without a prior noticeable change in shape and sizes. The fragile material, in contrast to the plastic, cannot be given when pressing the desired form, since such a material under load is crushed into parts, it crumbles. Fragple stones, glass, cast iron, etc.

Mechanical properties characterize the body's ability to resist the action of external forces or other factors (for example, temperature), internal voltages in it. The main mechanical properties of building materials: strength, hardness, wear resistance, deformability (elasticity, plasticity).

Strength is a material property under certain conditions and limits to perceive the load or other effects that cause internal stresses in it without destruction.

The particles of which consists of solid material are held in equilibrium by the forces of mutual clutch. If an external force F is applied to any sample material, for example, stretching (Fig. 2.3), then its effect will be evenly distributed on all particles of the material: the material will turn out to be in a stressed state. Voltage will cause a change in distances between particles - the material will begin to deform (in our case - stretch).

To determine the value of voltages A (MPa), i.e. the internal forces per unit of the cross-sectional area of \u200b\u200bthe material and the external force arising in the material when an external force appeased to it (KN) are mentally made a transverse section of the sample. In order for the sample halves remained in equilibrium, the external force F should counteract the inner force equal to it. A A, where a (m2) is the cross-sectional area of \u200b\u200bthe sample of the material, from where a \u003d f / a.

Fig. 2.3. Scheme for determining stresses and in a bar when stretching it

The higher the elastic modulus of the material, the less it is deformed. Thus, the elastic modulus of rubber 10 ... 20 MPa, and steel - 2 * 105 MPa, it means that under the action of the same force, the deformation of the steel will be 10 times less than rubber, other things being equal.

With an increase in the current voltage force in the material, increase and can exceed the grip strength of particles - the material collapses.

In practice, the destruction of the material begins significantly earlier than the moment when the stress in it is reached by theoretical limit. This is explained by the fact that real materials Many defects of the most different level (starting from molecular and ending with macrodfects, such as cracks).

The material strength is characterized by the value of the strength of the R - voltage in the test sample of the material at the time of its destruction.

Depending on the nature of the application of force FH, the type of voltages differ in compression, stretching, bending, crest (cut) (Fig. 2.4).

The strength limit of the material is determined on the samples, the shape and dimensions of which set the standards for this material. So, to assess the strength of concrete, samples of cubes are taken in size 150x150x150 mm. The cement brand is determined on samples of 40 x 40 x 160 mm. To determine the strength of rocks, samples-cylinders are usually used.

The tensile strength of concrete during compression is usually 10 ... 50 MPa. To destroy a concrete cube with a size of 150 x 150 x x 150 mm with RCX - 10 MPa, it is necessary to apply the force f \u003d rcxa \u003d \u003d 10 (0.15 x 0.15) \u003d 225 kN (22.5 T). Therefore, special machines equipped with a mechanism for a sample and measuring devices are used to test materials. Thus, the tensile strength is determined using hydraulic presses that develop an effort to 10 kN (100t) and more (Fig. 2.5).

For testing for strength, the sample is installed on the bottom plate of the press, clamp the top stove and include the oil pump. The oil meter is observed for increasing oil pressure, fixing the pressure at which the destruction of the material begins.

Fig. 2.4. Sample loading diagram when determining the strength of the material for compression (A), stretching (b), bending (B) and slice (g)

The tensile strength is calculated by the same formula.

Estimated formulas for bending and rocking have a different appearance.

The strength in compression, tension and bending in the same material can vary greatly.

In natural and artificial stone materials, compression strength is 5 ... 15 times higher than when bending and stretching. Wood, on the contrary, bending strength is higher than compression strength (1.5 ... 2 times).

The value of the kr for different materials ranges from 0 (unreleased clay) to 1 (glass, steel, bitumen).

Elasticity and plasticity. If you take two balls - rubber and clay - and start compressing them, they both under the action of the applied force are deformed. As soon as the force is stopped, the rubber ball restores its shape, and the clay will remain strain.

Materials leading themselves like a rubber ball, i.e., restoring their shape and sizes after removal of the load, are called elastic. The quantitative measure of elasticity is the elastic module E, discussed earlier.

The higher e of the material, the greater the effort required for the deformation of the material. Ideally elastic materials are practically no. At high loads, especially the attached long time, almost all materials detect plastic deformations; As it is customary to say: the material begins to "flow".

Materials leading themselves like wet clay, i.e., retaining deformations after removal of the load are called plastic. Accordingly, reversible deformations are called elastic, and irreversible - plastic.

Elastic materials include natural and artificial stone materials, glass, steel; To plastic - bitumens (at positive temperatures), some species of plastics, lead, concrete and mortar mixtures before solidification.

Hardness - the ability of materials to resist the penetration of other materials into them. The hardness is relative, since the hardness of one material is estimated relative to the other. The easiest method of determining hardness is on the hardness scale (see Table 4.1). This scales include 10 minerals located in increasing hardness, ranging from talc (hardness 1) and ending with a diamond (hardness 10). The hardness of the material under study is determined, consistently scratching it with minerals in the hardness scale.

Typically, hardness is determined on special devices. Thus, to assess the hardness of metals and other solid materials, the methods of brinell or rockella, based on indulgence under a certain load in the test sample of a ball of hardened steel or diamond cone. In the diameter of the imprint, the number of HB hardness is calculated (for brinell) or HR (by Rockwell).

The high strength of the material does not always talk about its hardness. So, wood strength is compressed with concrete, and with bending and tension many times superior to it, significantly inferior to concrete in hardness.

Wear - change in the size, mass and condition of the material of the material due to abrasing and impacts. Wear can be abrasive, cavitational, etc.

Wear resistance in building materials is estimated mainly for aggregates used in road concrete. The assessment is carried out on the loss of mass samples of the material when it tests according to the standard method in the sheal drum.

The abrasibility is the property of the surface layer of material to resist abrasive wear. The abrasibility depends on the combination of the properties of the material: hardness, plasticity, elasticity, etc. The abrasability is not estimated by the calculated path, but is determined experimentally. For various materials, different, but strictly regulated by the standards methods. For example, the abrasability of concrete is determined by the circle of the abrasion of the LCA using quartz sand as an abrasive (Fig. 2.6); The abrasability of the linoleum - with the help of rotating drums, covered with emery paper (Fig. 2.7). The abrasability is assessed by the loss of mass or the thickness of the material samples after the standard test cycle. The abrasion rate is very important for materials used for floors, stairs, etc.

Full-text search:

Home\u003e Cheat Sheet\u003e Construction

. Mechanical properties of building materials

Strength - The properties of the material resist the destruction of the internal stresses arising in it when exposed to external forces. In constructions, building materials under the action of loads are experiencing various deformations and their corresponding voltages: compression, stretching, bending, cut, etc.

Depending on how the materials behave under load, all of them are divided into plastic (carbon steel, aluminum, copper) and fragile (concrete, natural stones, cast iron, etc.).

Various materials in different ways resist deformations.

The measure of the strength of the materials is the strength limit. Tensile strength - The maximum voltage at which the destruction of the sample of the material occurs.

The strength of the compression R szh or the tensile strength of R p, MPa is equal to the ratio of the destructive load F of the cross section of the sample BUT, Subjected to the test, and is calculated by the formula (STB 4.206-94)

Cross-section area of \u200b\u200bthe sample, mm 2.Bending Strength Sample of rectangular section under the action of one concentrated force applied in the middle of the sample, calculated by the formula

where I. - distance between supports, mm; B I. h. - The width and height of the cross section of the sample, mm.

I - on compression: a - dense natural stone;

b - porous natural stone; in concrete;

g - brick (cube glued out of two halves); II - on bending:

a - cement mortar; b-brick;III - on stretching: steel

complies with GOST requirements. For testing materials on compression, the samples are manufactured in the form of a cube or cylinder, on stretching - in the form of a prism or rod or in the form of eight (for bitumen), to bend - in the form of beams (prism), bricks (in nature) on two supports. Test samples before destruction in laboratories on the hydraulic press or discontinuous machines.

Various materials have an unequal strength of compressive strength: from 0.5 (peat plates) to 1000 MPa and more (high-strength steel).

The strength of structural building materials is characterized by a brand (M), which, as a rule, coincides with the minimum permissible limit of compressive strength. Material stamp is an essential indicator of its quality.

For stone materials, the brand is determined by the limit of compressive strength (in some cases, taking into account

P  the roar of materials depends on the structure, porosity, humidity, structure defects, duration and nature of the application of the load, medium, temperature, surface state and other factors. Often, a constructive quality coefficient (KKK.K.) is used to assess the effectiveness of structural building materials, which is numerically determined by the ratio of the strength of compressing to the medium density of the material:

the roar of materials depends on the structure, porosity, humidity, structure defects, duration and nature of the application of the load, medium, temperature, surface state and other factors. Often, a constructive quality coefficient (KKK.K.) is used to assess the effectiveness of structural building materials, which is numerically determined by the ratio of the strength of compressing to the medium density of the material:

The best structural materials have high strength at low medium density. For example, for aluminum K.K.K. \u003d 4.61; For wood K.K.K. \u003d 0.8; For steel K.K.K. = 0.5 ... 1.0; for plastics kkk.k. \u003d 0.5 ... 0.25.

Hardness - The ability of the material to resist the penetration of another, more solid.

The hardness is determined by the structure of the material. Quantitatively, the hardness indicator (the number of HB hardness) is estimated in various ways. The bitumen hardness is determined on the penetrometer device in the depth of penetration in the needle bitumen under load. The hardness of the painting film is determined by the pendulum device. The hardness of wood, metals, concrete, plastics and some other materials are determined by pressing a steel ball (Brinell method) or a solid tip (in the form of a cone or pyramid). In this case, the hardness of the material characterizes its ability to resist plastic deformation on the surface of the sample. When pressing a ball of a certain diameter of hardened chromium steel on the material surface, a spherical imprint is formed.

C. ![]() isll hardness is determined by the formula

isll hardness is determined by the formula

The hardness of the stone building materials, natural stones and minerals is evaluated by the MOOS hardness scale (includes minerals in the order of increasing hardness from 1 to 10), represented by ten minerals, of which each previously followed by its sharp end (Table 1.3).

The hardness affects the material being processed. High material strength does not always indicate its high hardness. For example, wood strength in compression is equal to concrete, and in terms of bending exceeds it, however, wood hardness is significantly less than that of concrete.

The characteristic of hardness is important when choosing materials for coating floors, stairs, road coatings, while determining the method of mechanical processing of the facial surface of the materials.

Abrasion - The property of materials is reduced in volume and mass under the action of abraging efforts. The abrasion resistance is determined for the materials that are subjected to abuser during operation. This is an important property for floors, staircases, road coatings.

Abrasibility and calculated by the formula

g.  de t, T. 1

-

Mass sample, respectively, before and after the test, r;

de t, T. 1

-

Mass sample, respectively, before and after the test, r;

BUT - Square of an aburable surface, see 2.

Elasticity Call the body's ability to restore the original shape and dimensions after removing the load, which caused these changes. The greatest tension to which only elastic deformations arise in the material, called the limit of elasticity. Each material has a constant characteristic - an elastic module E, PA or MPa. The elastic module characterizes the stiffness of the material, i.e. His ability to resist elastic deformations.

Elastic are rubber, sealing gaskets, paints and varnishes, steel, wood and other materials.

Plastic - The properties of solid material change without destruction form and dimensions under the action of the load and save them after its removal. Plastic are clay dough, concrete and mortar mixtures, bitumen with positive temperatures, lead, etc.

Fragility - The property of solid material is suddenly collapped under the action of external forces without pre-residual deformation.

crystalline, glassy, \u200b\u200bbut also polymeric materials. Most materials with a decrease in temperature become fragile (bitumens, some plastics, metals).

Low-carbon steel, plastic at room temperature, becomes fragile with strong cooling. Fragile materials include glass, ceramic products, cast iron.

Shock viscosity orresistance to impact - Property characterizing the resistance of the material to destruction or deformation when hitting. Fragile materials are badly resisting strike.

Strike resistance is important for materials of road surfaces, as well as structures subjected to dynamic (shock) loads.

For roll materials (finishing, wallpaper, etc.) important properties are discontinuous strength (with incision), strength in puncture, jelly, etc.

Wear - The destruction of the material with the joint action of abrasion and impact. Wearing material depends on its structure, composition, hardness, strength, abrasion. Breeding strength is estimated by a mass loss expressed as a percentage. Wear important for floor materials, stairs, road surfaces, paints and varnishes.

Special properties of building materials

Special properties include: rheological and chemical and technological properties.

Rheological properties are called structural-mechanical.

Riology - Science of deformations and fluidity of substances. Object of rheology - liquid and plastic substances. In rheology, liquids are considered to be substances that, under the action of the applied force, are unlimited deformed, i.e. Teach. Ideally solid bodies Under the action of power, elastically (reversible) is deformed and restore its shape after the end of the force. Real materials, including concrete and mortar mixtures, paints, mastic combine the properties of liquid and solids. Depending on the prevalence of one or another property, they speak of viscous or plastic viscous mixtures.

The main rheological characteristics include: viscosity, limit shift voltage, thixotropy.

Viscosity - Internal friction of the fluid that prevents the movement of one layer relative to the other. The viscosity is characterized by the dynamic viscosity coefficient) and is measured in Pa · s.

In construction, they use mostly plastic viscous mixtures (building solutions, paints, plaster, cement dough, etc.). According to its properties, plastic viscous bodies occupy an intermediate position between liquid and solid bodies. So, the dough can be cut with a knife (which cannot be done with liquid), but at the same time the dough takes the shape of the vessel in which it is placed, i.e. behaves like a liquid.

Watching a mortar mixture or paint under load, it can be noted that at low loads, they behave like solids, showing elastic properties. With increasing load, they appear irreversible plastic deformations. With a further increase in the load, these mixtures begin to flow as viscous fluids.

Limit stress shift - The magnitude of the internal stresses at which the material begins irreversibly deformed (flow), i.e. turns into a viscous liquid. This indicator in building mixtures is also called structural strength.

In structured systems, the structure of the structure of structure proceeds gradually: first more slowly, then accelerated, and with further an increase in the voltage or deformation rate (flow), the structure is completely destroyed. The reason for the destruction of the material structure is a violation of the internal communication between its particles under the stresses.

Many plastic viscous mixtures with repeated (dynamic) effects can reversibly lose the structural viscosity, temporarily turning into a viscous liquid. This property called tiksotropia , Characteristic for mixtures based on mineral binders (concrete and mortar mixtures), paints and mastic. The physical basis of thixotropy is the destruction of structural bonds inside a plastic viscous material. After the cessation of mechanical exposure, the material again acquires structural strength.

The phenomenon of thixotropy is used in the vibration absorption of concrete mixtures and applying ass and paint compositions with a spatula or brush. In construction laboratories, the rheological properties of mixtures are estimated in relation to the conditions of their use in construction. In this case, not specific rheological characteristics (viscosity, limit stress of shift, etc.), and generalized indicators: the consistency of the binding test, is a solution of dissolved or concrete mix etc., using special devices and methods for determining.

Chemical properties They characterize the ability of materials to resist the destructive effects of salts, acids, alkalis, oils, oil products, with which they can be in contact during operation. The main chemical properties are chemical, corrosion and biological resistance, adhesive ability, environmental purity.

Chemical resistance - The ability of materials to resist the devastating effect of alkalis, acids dissolved in water and gases.

Resistant to acids and salts solutions are plastics based on polyethylene, polystyrene, polyvinyl chloride. High acid resistance is distinguished by carbon steel, cast iron, granite, stone casting from basalt, slagositalla. Squares include chromiumkel steel, brass (nickel), concrete on the alumina cement.

Corrosion resistance - Property of material resist corrosion, i.e. The destruction caused by the action of an external aggressive environment.

Corrosion (from lat. corrodo. - Eating) is chemical and electrochemical. A favorable environment for the development of chemical corrosion is water as fresh and sea. Electrochemical corrosion is formed as a result of the effects of solvents, acids, alkalis. Corrosion undergo metals, concrete, rocks. Corrosion of rocks and stone materials is their dissolution under the influence of the chemical exposure of water. Corrosion of concrete is the destruction of cement stone from the action of fresh, mineralized water.

corrosion-resistant. -Ceramic materials with a dense sharp, glass, asbestos, alloyed steel, titanium and aluminum alloys, many plastics, etc.

Biological resistance - The ability of materials to resist the influence of the processes of the vital activity of bacteria and other living organisms (biological corrosion).

The chemical properties of materials include adhesion ability . Adhesion (from lat. adhasio. - adhesion) - the grip and the relationship between the surfaces of solid or liquid materials in contact with the surfaces of various solid or liquid materials.

Adhesion ability is manifested in resistance to the separation or separation of contact materials. A quantitative assessment of adhesion is a separation force, attributed to a unit of contact area.

High adhesive ability is bituminous and targeted, magnesia and other binders. This property is used in the manufacture of roofing, waterproofing materials, fibrolite, xylolite (floors for floors); It is of great importance when gluing, welding, applying protective-decorative coatings (paint and varnish, enamel, etc.).

In connection with the extensive introduction to the construction practice of synthetic polymeric materials, an important characteristic of the quality of building materials is their environmental purity (Ecology).

Under environmental cleanliness should be understood as the absence of toxicity, harmful biological action on people.

The composition of plastics includes stabilizers, polymers and other components that have a sharp strong smell and can cause pollution of the external environment. When performing paintwork works, poisonousness (toxicity) of some pigments containing lead compounds, copper, arsenic should be taken into account. There are norms of extremely permissible concentrations of harmful substances and methods of toxicological standardization of raw materials, semi-finished products and finished products. The use of environmentally dirty materials with high toxicity, buildings and structures are strictly prohibited.

According to the Ministry of Health of the Republic of Belarus, the coefficient of wood ecology is 1.0; cellular gas silicate - 2.0;

ceramic brick - 10.0.

Technological properties of building materials

Technologies call the properties of the material to perceive certain technological operations in order to change the shape, size, surface nature. Develop raw materials and receive benign products from the source materials with the accepted technology using technological equipment.

Constability of the concrete mixture characterizes its ability to fill out the form and compact with vibration. The disappointment of the mortar mixture characterizes its ability to fit the thin layer on the porous base and fill it with all its irregularities.

Technological properties of wood are characterized by ease of processing: it can be cut, strict, drill, score nails, glue, etc. Due to the high processability of polymeric materials, the formation of plastics is carried out in various ways: extrusion, injection molding, calendering and rolling, pressing. The wide range of metal products is obtained in various ways: rolling, drawing, pressing, etc., which is explained by high plastic properties and plasticity of materials.

Aesthetic (decorative - artistic) properties

Color - the visual sensation caused by the effects of electromagnetic radiation streams in the range of the visible part of the spectrum reflected by the surface of the material or passing through it.

The human eye is able to distinguish to three hundred different shades of achromatic and tens of thousands of chromatic colors.

As a standard, approved International Lighting Commission (IOC), a coordinate system was adopted, the main colors of which are three real non-reproducible colors denoted by XY., Z. and selected so that the real colors are inside the corresponding color triangle. Color defined by three coordinates XY and z is accepted as a whole. Color coordinates are calculated using the measurement data using special instruments: spectrophotometers, comparators, colorimeters.

The main characteristics of color - color tonality, lightlock and saturation.

Color tonality Shows what section of the visible spectrum is the color of the building material. Quantitative color tones are measured by wavelengths.

Svetlota It is characterized by the relative brightness of the surface of the building material, determined by the reflection coefficient, which represents respectively the ratio of the reflected light flow to the incident.

Color saturation - The degree of distinction of chromatic color from the achromatic of the same lightness.

Color Atlases - Albums or sets of a large number of achromatic and chromatic casts, pre-systematized.

Card file color standards - A set of cards of various colors, each of which is assigned a specific number. At the same time, each card has two sockets, in which glossy and matte pastors are inserted on a triacetate film of 115x6 mm inserted. The size of each card is 130x180 mm. Color characteristics of cards in each batch in front of the release are measured using a photoelectric colorimeter. There are certain rules for storing cards and use them. The maximum life of their operation is 5 years.

Texture - the visible structure of the surface of the building material, characterized by the relief and the degree of gloss. Empty textures are embossed and smooth, matte, glossy and brilliant.

Picture - Various in shape, size, location, color separate components on the surface of the building material. Natural drawing on wood surface or natural stone called Texture.

Coordination of sizes in construction

Geodesic work in construction can be considered as a comprehensive technological process, accompanying all stages of the construction of the structure, during the implementation of which two interdependent tasks are resolved:

ensuring the construction of an object in accordance with the geometric parameters established in the project documentation;

ensuring the spatial interconnection of the parameters of elements and structures with an accuracy that ensures the functioning of the construction site.

Thus, the dimensions of elements and structures, their geometric bond in the structures determine the volumes, accuracy and methods of geodetic measurements.

The most important rules that determine the geometric constructions and ensuring typing and standardization in the design and construction of construction objects, serves Modular coordination of sizes in construction (MKRS), establishing the multiplicity of all sizes and dimensions Basic module M, for which 100 mm is taken. It is advisable to apply a rectangular modular spatial coordination system (Fig. 1, a), but Kosomgolny, centric (Fig. 1, b) and other systems are also allowed.

The coordination system depends on Volume and planning Decision of the building (facilities), determined by the appointment of the object. We list the main elements of the volume and planning solutions of the construction site:

step - the distance between the axes of the walls and other supporting structures (depending on the direction in terms of the step can be longitudinal and transverse);

span - The distance between the axes of the carrying structures in the direction corresponding to the longitudinal sizes of the main bearing designs of overlapping or coating. Depending on the structural scheme, the span in the direction coincides with the transverse or longitudinal step;

height of the floor - The distance vertically between the floor levels of the adjacent floors, and in the upper floors and one-storey buildings - the distance from the floor level to the top of the simulatory overlap, in the case of Cebidnaya - to the bottom of the main supporting structure.

When appropriate the coordination dimensions of volume and design elements, along with the basic, derivative modules of the modules of the KM:

enlarged (multimodules) 60m; Zom; 15m; 12m; 6m and zm, respectively, equal to 6000; 3000; 1500; 1200; 600 and 300 mm;

By configuration By Volume-planning solution: 1. Sectional 2. ...

Crib by philosophy: answers to exam tickets

Cheat Sheet \u003e\u003e PhilosophyCrib by Philosophy: Answers to Exam Tickets 1. ... (His works of painting, sculpture and architectureWorks by mathematics, biology, geology, anatomy ... distinguish from the animal and by flat nails and by Smile, I. by Mind, I. by religion, etc. But ...

Crib by Stories (5)

Cheat Sheet \u003e\u003e HistoryParties of a specially organized prosecutor's office (from 1722); " Crib by domestic history"3) were formed by the central ..., sculpture and architecture This period was influenced by European classicism. " Crib by domestic history "...

Mechanical properties characterize the ability of the material to resist the destroying or deforming effects of external forces.

Mechanical properties are strength. Elasticity, plasticity, fragility, impact resistance, hardness, abrasibility. In addition, under the influence of external forces (loads), materials in buildings and structures may experience such internal stresses as compression, stretching, bending, slice, and other stresses are measured in physical quantities.

The strength of the material is characterized by the strength limit (with compression, bending, stretching, cut). The strength limit is called the voltage corresponding to the load at which the sample of the material is destroyed.

The strength of building materials is usually characterized by a brand, the value of which corresponds to the magnitude of the strength of the compression obtained by testing samples of standard sizes. The strength of the compression of building materials varies widely from 0.5 (torphiplitis) to 1000 MPa and above (high-strength steel).

Elasticity refers to the property of the material to restore the original shape and dimensions after removing the load, under the action of which the forms of the material are deformed. As an example of elastic materials, you can call rubber, steel, wood.

Plastic - This is the ability of the material under the influence of active efforts to change their forms and sizes without forming breaks and cracks and maintain the changed shape and sizes after removing the load. An example of plastic materials is a clay dough, preheated asphalt.

Fragility - The property of the material instantly to collapse under the action of external forces with minor deformations (for example, glass, ceramics).

Resistance to impact - The ability of the material to resist shock influences.

The hardness of the material is called the property to resist the penetration of the other, more solid material. Of the natural stone materials, the smallest hardness along a ten-ball scale of hardness of minerals has a talc (1), the largest diamond (10).

Abrasion Called the ability of the material to decrease in volume and mass under the influence of abrasive efforts.

The properties of building materials resist abreter and shock loads must be considered when selecting materials for road surfaces, floors of industrial buildings, for steps, stairs, bunkers.

The main properties of building materials on which they determine the possibility of their use in the elements of the building are strength, density, thermal conductivity, humidity and water permeability, frost resistance, fire resistance.

Strength - Measure of the material resistance to destruction under the action of stresses arising from the load. Building designs are experiencing certain loads, under the action of which they are compressed, stretched or bend.

Density - the value measured by the ratio of the mass of the substance to the unit of its volume in the natural state (kg / m3), i.e., with the existing pores and voids. The denser material, the less emptiness and pores, the greater its density. The weight of structures, thermal insulation qualities and durability depend on the material density.

Thermal conductivity - the amount of heat passing through the fencing with a thickness of 1 m, with an area of \u200b\u200b1 m2 with a constant difference in the temperature of the outer and inner air 1 ° C. The smaller the thermal conductivity, the better the thermostatic quality of the material.

The thermal conductivity of materials depends on the density and degree of humidity. Materials having less density and humidity have less thermal conductivity.

Humidity - moisture content in material. Humidity is determined as a percentage of the mass of absolutely dry material. The smaller the humidity, the less the density and thermal conductivity and the above material strength.

Passenger - The value characterized by the amount of water passing for 1 h under constant pressure through 1 cm2 of the test material. For example, the water permeability of the junction of the outer wall panels is tested in a special chamber on the action of oblique rain at a certain wind force. For roofing materials (for example, tol, rubberoid), the water permeability is characterized by time during which water under pressure passes through the material and appears on the other side of the sample.

Frost resistance - The ability of materials in a saturated water condition to resist destruction in repeated freezing and thawing. Test materials for frost resistance is made in special chambers. The brands of frost resistance products indicate the number of kept freezing cycles and thawing in a water-saturated state.

Fire resistance - material ability to withstand action high temperatures without loss of strength. The limit of fire resistance of structures from various materials is estimated at time (in h), which withstands the design to loss of strength or stability. The material from which the design is made is characterized by its ability to ignite, burn or smolden after removing the source of fire. Materials that under the influence of fire or high temperatures are not ignited, are not smoldering and not charred, called non-heat. Materials, burning and the drainage of which stops after removing the source of fire, are called challenges, and which are lit and smoldering after removal of the source of fire - combed.

Hardness - The ability of materials to resist the penetration of other materials into them. The hardness is relative, since the hardness of one material is estimated relative to the other. The easiest method of determining hardness is on the hardness scale. This scales include 10 minerals located in increasing hardness, ranging from talc (hardness 1) and ending with a diamond (hardness 10). The hardness of the material under study is determined, consistently scratching it with minerals in the hardness scale.

Typically, hardness is determined on special devices. Thus, to assess the hardness of metals and other solid materials, the Brinell method is used, based on indulgence under a certain load in the test sample of a ball of hardened steel. By the diameter of the imprint from the ball, the number of HB hardness is calculated.

The high strength of the material does not always talk about its hardness. So, wood, although in terms of compression strength is equal to concrete, and when bending and stretching exceeds it, it has a much smaller than that of concrete, hardness.

Wear resistance - The ability of the material to resist the effects of friction forces and impacts from moving objects. Determine it on special devices equipped with abrasive nozzles and modeling the real wear process. Wear resistance - an important property of materials used for floors, roads, etc.