The difference between the slag block from foam block. What is better shellucas or slagoblock: comparative characteristics. Several nuances of using various compositions.

In the market, wall materials are presented in a wide variety, so before developers there is a difficult task of choice. Highly popular in low-rise construction (house, garage, sauna) enjoy light artificial stones - foam blocks, gas blocks and slag blocks. But in order to select the most appropriate option, you must compare their physicomechanical properties and specifications.

Shlakoblock or foam block - what material is better?

It creates an incredibly durable wall. And very inexpensive, without the need for a qualified work force. There are all kinds of blocks in different dimensions. In some parts of the country, 14 and 16 block widths are also available. As you can imagine, the greater the width of the block, the greater the cost of the wall.

You also have a standard block, and then there is a decorative block, which is more expensive. Most people saw a decorative block in their lives a thousand times, but do not understand what it is. There are also reinforcing requirements that can be applied in your area to the block wall. This means installing fittings and filling the cells with a solution to strengthen the walls. This is determined by local building standards. This increases the cost of blocks.

The slagoblock consists of a light filler - slag, portland cement is used as a binder, and the additives are sand, explore or gravel. The density depends on the aggregate fraction: the larger, the material is easier. The volume of one slag block is equal to 4-5 bricks, which means that construction will move very quickly, while the masonry solution is saved. The cost of such blocks is lower compared to the analogues.

There is also a block specifically designed to fill concrete into a block, complete with reinforcing channels. Once again, finish working with reinforcement channels. Away from the wrong ideas about dark, wet, stale structures, today's specific houses can be designed to withstand extreme weather, increase the costs of heating and cooling, as well as strengthen noise pollution - and do it well.

Concrete blocks familiar rectangular blocks are the traditional building material and the most widely used concrete construction system, especially in Florida, where they provide an affordable price. Today's concrete blocks now work with improved isolation and construction technologies for cost-effective results.

For the production of foam block, a light porous foam concrete is used, which consists of a portland cement with the addition of sand, water and a foaming agent. Artificial stone is manufactured in two ways: filling into special forms or sawing monolith from cellular concrete to blocks of the desired size. The wall element happens:

According to the Portland Cement Association, the blocks now include isolation in several ways, from mixing it to a pre-molded cement before filling out open cavities with bulk fillers or foam inserts. Terms: Regional preferences can make this product not so easily accepted in some parts; Standard dimensional aspects of blocks may mean that some of the more exotic home projects will require more time and can affect the performance of construction teams.

The best for: houses in areas with high wind; Wide recognition areas, such as Florida. Removable forms in this system isolation and reinforcement steel are placed inside removable wall forms of aluminum, wood or steel. Then concrete is poured into forms. As soon as concrete is cured, the forms are deleted.

- Heat insulating - D300-D500.

- Structural heat insulating - D500-D900.

- Structural - D1000-D1200.

Main characteristics

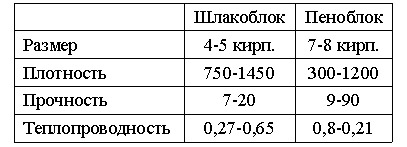

To give preference to foam block or slagoblock, you must familiarize yourself with all the properties of both materials, after which it will be possible to compare and determine which stone is better. The table below shows the specifications of wall blocks.

In one, removable shapes are poured onto the walls, and in another concrete poured for the floor and the ceiling also "for the formation of a monolithic envelope," said Randy Frimif's president. Pros: external and interior walls may be pouring simultaneously; Concrete interior walls can be textured or leveled for drywall; wind-resistant; Forms can make an outer wall similar to brick or textured paint.

Features of using materials

Cons: Regional preferences and acquaintance with this system can make it inaccessible in some areas. Best of all: houses in areas with high wind, especially with designs, in which concrete floors, ceilings and walls are used. Panel systems exist two panels: precast concrete and inclined concrete. With prefabricated homes on a concrete plant, outdoor walls of the house with gross holes are made. Installed isolation of foam, steel reinforcement and electrical wiring added. The panels are transferred to the site, raise the cranes and attached to the foundation and to each other.

All these stones parameters are well affected by the operational characteristics of the buildings of various purposes. Foam block is suitable for the construction of houses, as it is able to maintain heat in the winter, and the coolness is in the summer. In addition, the foam block is not afraid of dampness, since the humidity of the air is regulated due to the porous texture (such properties are inherent only by wood).

With inclined concrete wall panels Also cast, but the casting is made on the spot. This method required a rather wide open site that could fit the walls to the place. After proper positioning, the walls are connected to the rest of the design.

Pros: Creating in factory conditions provides a high level of quality that does not depend on the working conditions and weather; wind-resistant; Fast setting is possible if the site is properly prepared for any system; Both systems capable of accommodating curvilinear panels; The system in place eliminates the cost of transporting panels.

Advantages and disadvantages

The construction of slag and foam blocks is popular thanks to the following features of the wall material and numerous advantages:

Cons: the availability of the prefabricated plant may limit availability; The option of inclination is best working with a large, flat, open site; The site should be able to place large cranes. Best of all: houses of modern design in open places. Insulating concrete forms with this system concrete poured into constant forms. Forms are made of insulating material, or blocking blocks, panels or boards. Panel and boards are interconnected by plastic or metal ties and blocks with special grooves or bonding teeth.

1. High strength and reliability;

2. Good sound and thermal insulation;

3. Favorable microclimate at any time of the year;

4. Fireproof and refractory (up to 4 hours the stone is able to withstand high temperatures, does not crack and does not burst);

5. Resistance to temperature drops;

6. Low shrinkage coefficient;

Choose your own mother's danger. Almost 90 percent of us have the opportunity to consider fire, wild fires, seismic or severe winters. Sundberg believes in the power of design solutions. Pros: High Energy Efficiency; Storm resistance; Good design flexibility, because polystyrene forms can easily be cut for user structures; Forms light and easy to work; Provides some flexibility after pouring concrete to add electrical and some small plumbing runs due to thickness of foaming materials.

7. Ability to withstand heavy loads;

8. Environmental purity of the source materials (full security and compliance with European standards);

9. Economicity - no upstream of a powerful foundation, additional insulation;

Best of all: houses in which isolation is important, since this system provides the greatest isolation with the help of internal and external layers in the smallest steps. National team construction mixture represents airtight, inorganic Material. When applied concrete mix Expands and captures small air pockets for light product. While the block size is most common, the product can also be cast in reinforced panels for walls, floors and roofs.

The total advantages of concrete has many home design options. Since it is ne. structural material, and style, specific houses are not limited in how they appear. The reality is that if you drive past concrete houses, you cannot say any difference. Owners of a particular house can usually save on them due to fire resistance. "If the insurance agent understands the construction, savings can be even higher due to disasters, termites and pest resistance," says Thompson.

10. The ability to build buildings on unstable soils and independently, without resorting to the help of specialists;

11. Fast masonry, thanks to large sizes;

12. Easy processing (well cuts, drilled, diverted by conventional tools - with a hacksaw or saw, as well as the wall under electrical wiring and communications compared to the slag stone);

Concrete may include recycled content in a mixture, receiving additional support from those interested in the construction of green. Here are some other advantages that provide all specific forms. This particular system is popular in Europe, but still relatively unknown in the United States.

While the block size is most common, the product can also be cast into reinforced panels for walls, floors and roofs. FROM.; Homemade structures with significant point loads may require special equipment, since the light weight of the product may not have sufficient carrying capacity. The best for: houses in warm climatic conditions, which will benefit from the insulation of air pocket and do not require additional isolation. Costs concrete systems are more expensive from the very beginning. Typical concrete systems are usually added from three to five percent on average to the price of the house, says Thompson. Keep in mind that this is a one-time financial hit, but savings are eternal.

13. Availability - low cost;

14. Durability.

The disadvantages of foam concrete include:

- violations of production technology, as a result, the material is broken and unsuitable for construction;

- water absorption, which is why there is a premature destruction of stone.

All these shortcomings are easy to eliminate, if you protect the walls of the house, garage or bath with high-quality finish. In order not to make a mistake in the reliability of the blocks, it is better to buy from proven manufacturers that guarantee high quality and strength.

The resulting energy efficiency more than compensates for this increase. When checking relative costs, it is important to compare apples with apples. Some factors affecting costs include. Concrete price in your area The price of a concrete system in your area. Local labor tariffs Competitiveness of the local market. Crew experience. House design. Local construction standards and rules. "In Florida, where you have strict building rates associated with wind activity, the design of wooden frames can cost much more expensive to satisfy these requirements," says Thompson. "When the cost of the house of the wooden frame rises, the concrete structure can be equal to or even less than the identical wooden frame of the house."

Why better build from foam block?

An overview of the characteristics and features of slag and foam blocks makes it possible to choose the most suitable option. Comparing all the advantages and disadvantages, it becomes clear how economically beneficial and practical is foam block. The garage or the bath erected from the light stone will not only serve for a long time, but will not create problems in the process of the entire operational period.

Consider opportunities. Here are some tips to consider if you are considering a specific question for your next house. Visit the construction sites on which the counterparties that you consider use various concrete wall systems. Ask links and talk with those homeowners about whether the builder was in time, sooner or later with his project and whether the project was included in the budget. Know that good planning is essential. He says it is important to have subcontractors such as plumbing or electricians familiar with specific construction methods or open. Make sure you have the time required in order to be satisfied with the designs and the options you chose. At the design stage, outputs, windows, service runs and coarse holes should be taken into account. Keep in mind that the future remodeling is possible, but is slightly complicated. Since concrete is stronger, more steps will be involved. Nevertheless, says Thompson, the addition, even with a wooden frame, will be stronger, because it will receive lateral support from specific systems. The remodeling of most interiors will look like other houses, as the inner walls are usually wooden. Remember that if you have chosen home design based on a wooden frame, but you want to go with a concrete wall, the thickness of the concrete wall, which may have a difference of six inches, will affect the plan.

- Talk to them about what system makes sense for your site.

- The creators of the interviews that use the system you need.

- Ask your experience to live with this type of concrete system at home.

A small structure can be erected in a few days and it will take significantly less labor costs and the amount of masonry solution compared to the same volume, but from the brick. When building a building from foam blocks there is a significant savings on the foundation. A durable and reliable bundle between stones creates special glue, and so that the "cold bridges", the layer thickness should not be more than 1 cm. Stone sides of foam blocks allow you to perform high-quality outdoor cladding And for these purposes, different finishes can be applied.

Guided by these practical signs and inspiring ideas, you can imagine the beauty, comfort and utility of your backyards and residential premises in the fresh air, which makes them attractive and pleasant to your home. Most of the houses are traditionally built of wood, and the concrete block is commonly used for schools and other institutions. However, the concrete block can be useful and building materials at home. Studying the advantages and disadvantages of the most common building materials can help you make a reasonable choice regarding your next project for remodeling or construction.

The abundance of building materials in the current market often puts in a dead end. What to choose to build walls of individual construction or industrial buildings? Product range is quite wide, but what is hidden over the name and what kind building material Prefer? Our article discusses the difference between the two fairly popular species: foam block and slagoblock. What is the difference and what material will be preferable to tell you our article.

For the manufacture of foam block, a certain composition is used, the main components of which cement, sand and a special foaming agent are used. Due to this, the structure of the blocks becomes as if saturated with air bubbles - pores. Such innovation showed itself perfectly, because thanks to air items, the material acquires additional heat capacity.

Advantages of using foam blocks:

- Strength.

- Resistance to temperature differences.

- Available cost.

- Durability of construction.

- The possibility of trouble-free gasket communications.

- There is no need for additional insulation outside.

On the video - the manufacture of foam block:

A big plus when choosing foam blocks will be the possibility of manufacturing plates of various sizes right on the construction site. To do this, you can use a wooden formwork or special forms. The accuracy of the size will not be too high, but the cost of transportation will be reduced.

Among the disadvantages it should be noted a fairly significant consumption of the fastening composition, which is not always appropriate. Also, foam blocks are quite massive and require the attraction of additional labor, which, however, is characteristic of most building materials of this kind.

Making slagoblock

The production of slagoblock involves the use of special vibropressive machines. In prepared forms poured cement mortarTo ensure additional characteristics, slag, material burning waste and ash are added. Often you can meet slag blocks with the addition of stone, granite, chopnque dropping and other inclusions.

Pluses of slag blocks during construction:

- Available cost.

- The possibility of self-making.

- Moisture resistance.

- Different composition of the components gives the material amended characteristics.

The physical properties of this material are directly dependent on the production of raw materials, therefore, it will be difficult to give an accurate characteristic. Usually classify "heavy" and "light" blocks, which include various brands cement.

In the photo - a house from the slagoblock:

"Heavy" slag blocks are used mainly to build ground floors and when bookmarking the foundation. "Easy" variety of material goes to the construction of walls. A feature of construction from this material can also be called various additives, thanks to which the blocks acquire additional properties. It describes in detail the pros and cons of houses from slag blocks. You can familiarize yourself with the size and price of slag blocks.

On the video - the manufacture of a slag block:

Several nuances of using different compositions

- The addition of a slag of large size will increase the thermal conductivity and makes the material more porous and easy.

- Selecting slag of small size weightlifting block. Usually this kind is not used in the construction of residential premises due to the high thermal conductivity of the structure.

- Often, fine wood sawdust is added. This makes blocks more "clean" and is often used for a residential building. Minus - the need for additional waterproofing, so the costs of outdoor finish building.

The versatility of this embodiment of the building material is difficult to overestimate, but at the same time it will have significant disadvantages. Many manufacturers are added to the composition of unsuitable substances, clean and the safety of the use of which there are quite serious concerns.

Also, such a material is not too suitable for individual construction due to good thermal conductivity, which will increase the cost of heating the building. Partially cope with the problem will be able to external insulation, but will not completely eliminate. Slagoblocks are more suitable for the construction of utility rooms and industrial buildings. This will significantly save consumption estimates and give the constructed set parameters.

What's better

An obviously faithful answer will not be able to give no one. If we consider the issue under several angles, more advantages in the use of foam block. Nevertheless, the popularity of the second material also does not cause doubt. If we consider what is cheaper, then the cost of ready-made slag blocks is an order of magnitude less, which often becomes a priority when choosing a suitable material.

By comparing the technical characteristics, it is also impossible to come to an unambiguous conclusion, some heat loss inherent in slag block material to some extent relate to both foam blocks, so the exterior warming does not prevent and for this material as well.

Summing up, it is safe to say that for the construction of residential buildings it is preferable to use foam blocks due to the low thermal conductivity of the material. The slagoblock is better to apply for the construction of subsidiary and industrial facilities for which this indicator will not be so important. An option is allowed to use the combined composition of the materials: to lay the foundation and basement to use a slag block like a cheaper and strong material, and when the walls are built, foam blocks are used.

The video tells that better foam block or slag block: