New material for roof roofs. Modern Roofing Materials for Drunk Roofs - Traditions and Innovations

Read also

- A variety of roofing materials

- Tiled roofing

- Metal types of coatings

- Economical blood varieties

No wonder the developers of private housing are looking for the cheapest roofing material. After all, the cost factor plays an important role in choosing a suitable roof. However, the cost-effective price should not go to the forecloser without taking into account other factors: the architectural device of the roof, the appointment of the building, the weight of the roofing material and the budget allocated for these purposes. That is, it should always be from the highest ratio of price / quality.

When choosing a roofing material, you need to take into account the roof architecture, the designation of the structure, the weight of the material and its cost.

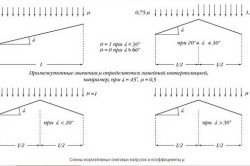

It is impossible to discount and the fact that the load from the roof is not only from the weight of the rafted and roofing material, but in the winter period from the weight of the snow hitting on the roof of snow and from constant wind loads in the area. For the middle strip of Russia, the last two indicators are usually taken equal to 200 kg per M.KV. The angle of inclination should be taken into account.

How to cover the roof of the house so that everything suggests and is cheaper? After reading the variety of existing coatings on the market, the choice will be done not as difficult.

Requirements for roofing.

Roofing material should be:

- high strength;

- durable;

- resistant to atmospheric phenomena (frost, heat, moisture, solar radiation, oxygen exposure);

- good sound and warm by an insulator;

- anti-corrosion;

- fire-resistant.

A variety of roofing materials

Back to the category

Tiled roofing

Ceramic tile without additional fixation can be used for roofs with a slope of 22-60 degrees.

Tile belongs to the number of the oldest roofing coatings. At home in the old quarters of Europe, it is covered with a given type of roof with motley colors. Previously, only ceramic tile was made, now the range of material is much more extensive.

These products are small (size of one plate - 30 by 30 cm), past firing in the furnace and acquired a brown-red shade. The glazing tile looks more attractive, and it is more convenient during operation: neither snow or rain moisture will hold on it. The weight of one thing after firing is over 2 kg.

The shape of the elements is different: wavy, tape, groove, groove, etc. and at the same time and the mounting options will be different. But the properties of all products are among themselves. When laying, they are trying to put tiles so that the plate close the bottom on one third.

The use of tiles is suitable for buildings of any floor with a slope of the roofing rope in the range of 22-60 degrees. With a larger slope, provide additional mechanical fixation of each tile by either a screw or nail. With a weak bias, it includes a high level of roof ventilation and waterproofing.

Advantages: The coating is reliable, durable, not fuel, frost resistance over 1000 cycles is not amenable to corrosion, it has a good indicator of noise insulation, just in repair (only damaged areas are changed, without resorting to the dismantling of the whole roof). The minuses include the severity and fragility of the material, the need for waterproofing, the use of additional fastenings and enhancing the crate when the roof configuration is complex.

Tiles cement-sandy.

Cement-sand tile is very similar to ceramic, but its price is significantly lower.

The sand and cement mixture hardens under pressure and is covered with icing (not always). So prepare this tile. It does not distinguishable from ceramic products. 1 m.KV Square is equal to weight 35-45 kg. Recommended for the closure of the roofs with a slope of 20º-60º. For her, you need a substrate in the form of a carpet of waterproofing. Price - from 10 to $ 20.

Advantages: Resistance to external influences (incl. Ultraviolet), high frost resistance. Over the years, dials strength. Minus - heavy material, can give up to 10% scrap during transportation.

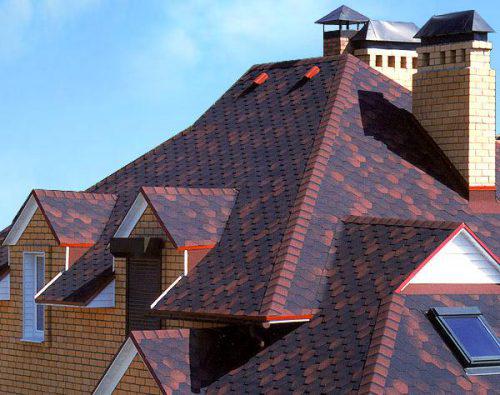

Bituminous tile

The bitumen plate in the manufacturing process is coated with cellulose, fiberglass or polyester. The shade is achieved by staining. Sheets have dimensions of 30 per 100 cm, the weight of them is 8-12 kg on M.KV. Price - from 8 to $ 10 per M.KV. Acquire for structures with inclination over 12º. Requires a substrate from moisture-resistant plywood. The flexibility of the bitumen material allows you to use it on arbitrary configurations of roofs with different rounds. The bitumen-rubber layer with the influence of the Sun gluits the leaf plates in one monolithic surface.

Pluses include: durability, not resistant to rotting and rust. Local disassembly and subsequent repairs are allowed. It is appropriate for triangular, rounded and multicate roofs. Protects against noise. Selection of colors and materials. Not included in the category of elite coatings, as fuel and loses the saturation of the color from ultraviolet.

Back to the category

Metal types of coatings

Metal tile.

It is not clear why this metal sheet is stamped like a tiled coating, tiled. The sheet is galvanized from two sides steel with a polymer layer. Thanks to this layer and the resulting tint, this coating was called this way. Sheet weight - 3-5 kg \u200b\u200bon M.KV. Cost - $ 7-15 per meter. Purpose - for roofs with inclination Over 15º. Little slope requires sealing of sheets of sheets. Installation of sheets: along the slope - by 250 mm and more, across - on 1 corrugation.

With a budget deficit, this choice is considered the most optimal in almost any situation.

The material is easy in laying, resistant to shocks, little weighs and is cheap. But it's not worth waiting for protection against noise.

Proflists.

The most simple variety of metal coatings, represented by wavy sheets of galvanized steel. Waves have different heights, width and shape. The minimum of the slope for the proflists is 10º. For him, it is necessary for a doom with a pergamin, strengthened self-drawing. It is permissible to lay sheets and over the previous coating (for example, rubberoid).

Material is used mainly for buildings with 1-3 floors. The advantages are: accelerated and easy installation, durability, reliability. But no noise and thermal insulation.

Fold metal roofs: made of steel, aluminum, copper.

They are made from even not processed sheets. Steel can have a layer of galvanizing or polymer. Fasten by clutch folded edges. Minimum slope - 20º. Require a substrate to rafted an anti-condensate film. Steel is simple, cheap and not prestigious. Rust if there is no coating.

From copper roofing looks more attractive: initially bright yellow-red color, gradually covered with greenish patina. At the same time, the material in addition to protection against corrosion acquires some nobility.

However, the price of copper and aluminum is not cheaper.

Easier all aluminum roof: it weighs 2-3 kg on M.KV. Steel Sneaken - 4-5 kg \u200b\u200bon M.KV. And copper is heavier all - 10 kg per m.

Despite decorativeness, fire resistance, low weight and the ability to give a different shape, the folding material does not insulate enough from noise and heat leaks and not shockproof.

The arrangement of the roof is an important stage in construction. Here you need to competently choose the roofing material, based on climate, design features and your own wishes. Today, the building market literally pested a wide range of roofing materials. To facilitate your choice, check out the most popular and high-quality materials further.

Roofing material is an important element to protect the house from various external influences. Today, the market can be found on the market:

- Piece;

- Rolled;

- Mastic;

- Sheet;

- Film

Sheet roofing

Metal tile.

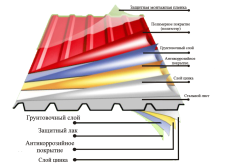

This material is distinguished by its strength, but at the same time low noise insulation. For the manufacture use steel sheet of different thickness. From above, the sheet is covered with galvanized, which in turn is also covered with a special varnish. Thanks to him, the surface of the galvania is not amenable to damage. There are two more layers under it: primer and aluminum. Weigh metal tile little, 1 m2 accounts for 3-5 kg. What does the metal tile of Venice look like, you can see

In the photo - metal tile:

Metal tile is used in the arrangement of the roof in private and industrial homes. A false roof looks very beautiful when layers of mch at an angle impose on a flat roof.

It has a long service life up to 50 years. The cost is 400-100 rubles, which is not so expensive. The advantages of the material include:

- Easy installation;

- Strength due to which the material withstands large mechanical loads;

- Ease, which allows you to install yourself;

- Simplicity of transportation;

- Affordable price.

From the disadvantages you can allocate sound system and a large amount of waste.

Roofing professional flooring

In the photo - roofing professional flooring

In the photo - roofing professional flooring This material is represented as a steel profiled sheet coated with a layer of galvanizing and polymer. It can be represented in a rectangular or wavy form. The wave is produced in the form of a trapezoid and rectangle.

Benefits include ease of installation, long service life up to 50 years and low cost. But to the conscience of sound system, as you have to spend extra money on the soundproofing of the roof.

The cost of the professional flooring is 600 rubles.

Ondulin

This material is characterized by its attractive appearance. To obtain it, cellulose fibers are used with impregnation from bitumen and polymer components. Today, Ondulin is very often called euroshifer. From above, it has two layers of paint. Mass of one sheet is 6 kg. Its value is 850 rubles. But what is best to use Ondulin or professional flooring, will help you understand the information.

Applied ondulin for roofs on economic buildings or when implementing a complex roof due to its flexibility. Often, Ondulin becomes an excellent replacement of an old coating.

- Environmental friendliness;

- Water resistance;

- Long service life, up to 40 years;

- Hygienicity;

- Low weight, thanks to which the process of installation and transportation occurs simply;

- High strength that allows you to withstand heavy loads;

- Resistance to the effect of chemical compositions;

- High soundproofing;

- Low cost.

Has Ondulin and a number of minuses:

- Exposed to fire;

- After a couple of years, the color of Ondulina burns out, and the material itself loses its attractive look;

- Under the influence of high temperatures, the material becomes soft, resulting in an unpleasant smell of bitumen.

As happens, you can see on the video in this article.

For those who want to learn about what the size of the sheet metal tile for the roof is to follow the link and read the contents of this

How the styling of metal tile of Monterrey occurs and what technology will help to understand this information:

But what is best to use ondulin or metal tile, will help you understand the information from this

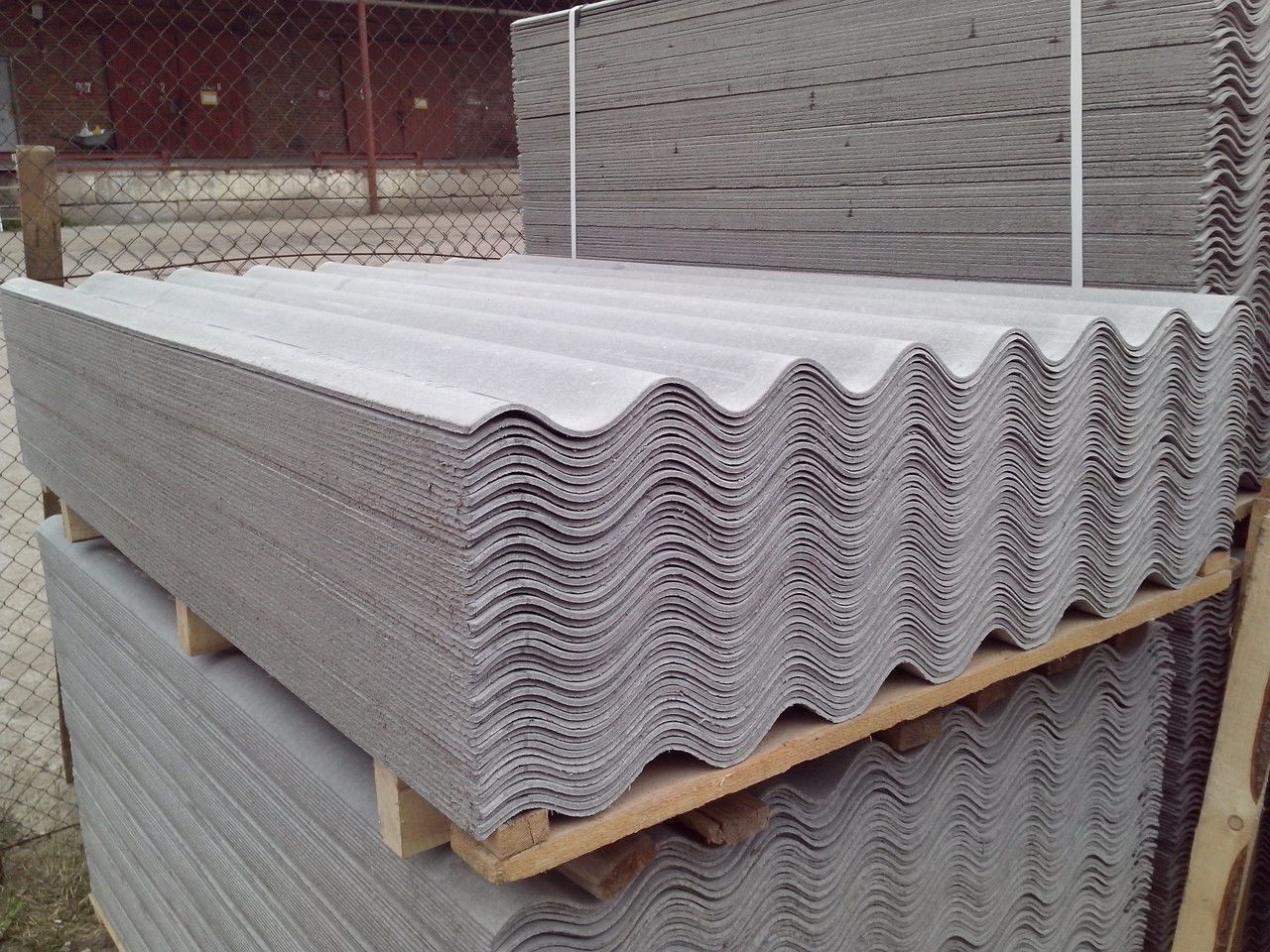

Slate

This roofing material is the most popular and inexpensive. With its manufacture, portland cement and asbestos were used. The mass of one sheet is 10-15 kg, and the following dimensions: 175x113x175 cm. The number of waves in one sheet can reach 6-8.

Using slate when arranged roofing for a barn, baths and summer toilets. In private construction, the material is also used, although recently it has become rare. Schifer cost is 150-200 rubles.

The benefits of material include:

- Long service life up to 40 years;

- Easy installation;

- Not subjected to burning;

- Low cost.

The disadvantages include the following:

- The composition has asbestos, which is harmful to human organism. But since it is present in small quantities, then there can be no talk about a big danger to a person.

- Fragility that complicates the process of transportation and installation.

- High hygroscopic qualities. Sheefer experiences moisture, as a result of which loses all its properties.

Folding roofing

Steel

This material is made of steel sheets with zinc coated. Often steel roof has a polymer coating. Sheets are equipped with a special compound - Falk. It is from it that the method of fastening sheets is depends.

Use steel roof when arranging roofs at production facilities and administrative buildings. The value of the material is 300-350 rubles.

The main advantages include:

- Flexibility;

- Smooth surface;

- Does not file the influence of fire;

- Long service life up to 30 years;

- Low weight;

- Resistance to the effect of frost;

- Aesthetic appearance.

By minuses include:

- Damage arises when hitting;

- When installing, it is necessary to provide for the creation of the heat insulating layer;

- Mounting is characterized by complexity, so it will not work independently;

- Sound conductivity;

- Ability to accumulate static electricity.

Copper and aluminum

The thickness of these materials can reach from 0.3 m. Copper sheet weighs -5-10 kg, and aluminum - 3-5 kg.

- Resistance to corrosion;

- Strength;

- Aesthetic appearance;

- Long service life up to 80-100 years;

- Will not hang out the influence of fire;

- Environmental purity.

- Safety.

The only disadvantage of such a roof remains a high price, which is 1,800 rubles.

Soft roof

Flexible tile

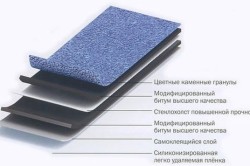

For its manufacture, a glass cholester, impregnated with bitumen with modifiers, was used. For top coat, shale or basalt crumb used. Material use when arranging the roof of non-standard form. The cost is 430 rubles. It will also be interesting to learn whether

- Flexibility;

- Excellent sound insulation;

- Opposes the formation of corrosion;

- Modern design;

- Affordable price.

The minuses are detached:

- Under the influence of low temperatures can give a crack;

- At high temperatures, the smell occurs, as if the material melts;

- Exposed to fire.

Hydroisol (flooring)

When creating a material, fiberglass, glass cholester and polyester are used. The basis of the material is an oxidized bitumen with the addition of a modifier. Thanks to him, the hydroizol acquires elasticity. The polymer layer and the sprinkler layer.

The material found its application with the arrangement of a flat roof of multi-storey houses. The cost is 120-150 rubles.

The advantages of the material include:

- Long service life;

- Low weight;

- Ecologicaly clean;

- He opposes the influence of fire, water and noise.

Among the minuses are only one: it is necessary to create special storage conditions - in a vertical position and away from the heating devices.

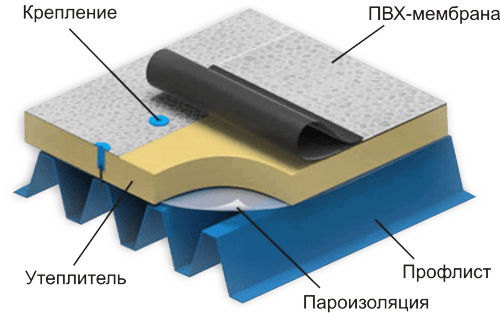

Flat membrane roof

This type of material can be presented in several types:

The benefits of material include:

- Long-term operation;

- Can be used to arrange the surface of any area;

- Resistance to the effect of water;

- Installation can be conducted at any time of the year;

- High strength.

But there is a material and its cons. Before installing it, it is necessary to prepare the basis. It is also forbidden to use organic oils and solvents. The cost of PVC roof is 300 rubles.

Piece roofing materials

Ceramic tile

To create this material, a long firing method is used at high temperatures. Tiles have a lot of weight (the unit can weigh about 2 kg). Apply for mounting the roof of residential buildings.

Benefits include:

- Excellent sound insulation;

- Not exposed to fire;

- Long service life, up to 150 years;

- Opposes negative environmental influences;

- Attractive appearance;

- Porous structure due to which the material is able to "breathe".

By minuses include:

- High weight;

- Fragility;

- Installation is characterized by complexity and complexity;

- High price.

But how to use snowstanders on the roof of the metal tile and how to choose them, it is described in this

Bulk (Mastic) Roof

This material is represented as a fluid that is obtained on the basis of oligomers. In the air takes a firm state, while retains elasticity. Apply the material during the arrangement of the roof in the terrain where the winter is harsh, and in the summer high temperatures air. The cost is 120-150 rubles.

Benefits include:

- Environmentally friendly composition;

- When it is used, it turns out a seamless coating;

- Resists the effect of low and high temperatures;

- The service life is 15 years.

How to choose Material

What material can be called the best? To be exactly sure as the roofing material used, you need to consider several tips:

- Life time. This indicator is one of the most basic, since your roof should not be subject to frequent repair and care. Not only the type of material is influenced by the durability, the quality of the installation. The undoubted leaders here are the metal tile, professional flooring, slate and Ondulin.

- Features and roofing. If you need to build a roof for household buildings, then you should not buy expensive material. A suitable option will be the usual slate. If it is necessary to arrange a residential building, then it is necessary to approach the choice. If you have facilities, you can use copper or aluminum roof.

On the video calculation of roofing material for the roof:

What cheapest

If we talk about the cheapest roofing material, then, undoubtedly, it is slate, metal cleaning and a floor roof. And although the price they themselves are low among all abundance, qualitative characteristics Quite good.

The choice of roofing material is painstaking work. It is necessary to take into account a number of features, both the most material and the characteristics of the design itself. It is also necessary to take into account the financial side. If you have no money for the purchase of expensive material, then it can be immediately selected from the rest and choose between what you can afford.

Professional flooring is currently enjoying great popularity in both private developers and industrial. This modern finishing material Produced and as roofing, and as an external wall decoration.

It is stainless steel sheets profiled for greater rigidity and durability with special ribs. The height of the rib can be different. The roofing professional flooring, in contrast to the wall, which has low ribs, so that the profile height is at least 2 cm. After all, this material is designed to protect the roofs, and therefore significant loads are experiencing during operation. This height allows you to optimally combine the strength of the material and such an important factor as the savings of the steel. As a result of the economy, the final cost of this sheet is reduced. To date, professional flooring can be called the cheapest of all high-quality modern

Most often for roofs applied galvanized corrugated roofing. Conventional steel sheets after installation require mandatory staining, which is necessary to prevent corrosive processes. The galvanized professional flooring of the implementation of such works does not require, since already in the production process is covered with a layer of zinc, which reliably protects it from rusting. Sometimes professional flooring designed to protect the roofs of private houses has another additional protective layercompleted

Professional flooring roofing has such wonderful qualities as high strength, and consequently, durability, unpretentiousness, aesthetic appearance. In addition, it is very easy to install. If we compare metal-friendly with other popular, then with the same thickness, it is much stronger than any of them. On the roof made of such sheets, you can walk completely without fears.

Professional flooring roofing has such wonderful qualities as high strength, and consequently, durability, unpretentiousness, aesthetic appearance. In addition, it is very easy to install. If we compare metal-friendly with other popular, then with the same thickness, it is much stronger than any of them. On the roof made of such sheets, you can walk completely without fears.

Caring for this material is very simple. All that is needed is to wash it with water from the hose every year. Produced corrugated roofing of a wide variety, usually bright and saturated colors. Therefore, you can pick up such a coating that will be perfectly combined with the color of the outer walls.

The lightness of this material is the ability to choose the sheets of almost any size allow you to mount the roof very simple. In order to do it quickly and correctly, no special knowledge and skills are required. The length of the corrugated roofing can be up to 12 m. By purchasing the sheets suitable for the project, you, without spending special efforts, get the roof of excellent performance, light and beautiful.

The lightness of this material is the ability to choose the sheets of almost any size allow you to mount the roof very simple. In order to do it quickly and correctly, no special knowledge and skills are required. The length of the corrugated roofing can be up to 12 m. By purchasing the sheets suitable for the project, you, without spending special efforts, get the roof of excellent performance, light and beautiful.

Apply this material both to protect the roofs of residential buildings and to cover the economic buildings. It is better to use it on the roofs with a slight slope of the skate. He will protect perfectly interior From such adverse factors like rain and snow. Thanks to the profile, the sheets can withstand a very large snow pressure.

The finish for the house requires careful and thoughtful in all parts of choice. This is especially true of such an important element of the design, as professional flooring can become an excellent choice that optimally combine such important conditions as quality and price.

The choice of roofing material for the roof should begin at the design stage of the foundation. The roof can have a fairly large weight that will have to keep rafters. The roof and rafters hold the walls, and all this together rests on the foundation. Therefore, if the builder has an image of the roof in the head, he must imagine well, as what he will do it, how much it will weigh, where and what will be supporting supports.

Even at the planning and drawing stage, it is worth thinking well as the roof will be built, how much it will weigh, where and what will be supporting supports.

And vice versa. If the walls are already erected, you need to calculate the weight of the roof, based on permissible load On them, and only after that choose the design and material of the roof.

We must not forget that the roof carries not only the weight of rafters and the roof material, but also the snow attacked on it, yes plus the load from the wind. In our areas ( medium strip Russia) usually believe that the load of snow cover and wind on the roof is 200 kg / sq. M.

A complex multicate roof imposes significant restrictions on the choice of the roof material. The angle of inclination of the roof is also important.

The third factor on which the choice of material for the roof depends is the desired durability and strength. And the fourth factor is the price.

By making the choice of material for the roof, it is necessary to take into account all factors: the weight, the roof architecture, the appointment of the building, the budget. You always need to look for the best price / quality ratio..

Characteristics of roof coating

Any roofing material ideally should have:

- high strength;

- durability;

- resistance to all atmospheric phenomena (heat, frost, solar ultraviolet, moisture, exposure to oxygen);

- good heat and sound insulation;

- anti-corrosion properties;

- fire resistance.

Types of roofing materials

Tile

Tile is one of the oldest types of roofing materials. All old houses in Europe have this beautiful coating of cheerful colors, giving such a charm to old cities. Once there was one kind of tile - ceramic. Today the choice of material is much wider.

Ceramic tile is the hardest type of roofing materials, but it is durable and looks very noble and aesthetic.

This is a 30x30 cm clay plate, burned in the oven. After firing, it acquires a saturated red-brown shade. If you have a glaze before firing on the tile, then the tile will turn out more elegant, water will be easier and sliding the snow. One such tile after firing weighs more than 2 kg.

On the shape of the tiles are very diverse: tape, wavy, grooves, grooves, etc. All these species are attached differently, but they are about the same properties. It is necessary to lay the plates so that the top overlap the bottom for about a third.

They use tile in houses of any floor with an angle of the roof of the roof from 22 degrees to 60. If the slope is greater, you need to additionally strengthen each tile with a screw or nail. With a smaller slope, you should take care of improving the roof ventilation and its waterproofing.

Pros. Ceramic tile is reliable, durable, frost resistance of more than 1000 cycles, does not burn, not subject to corrosion, it has good noise insulation, local repairs are possible (replacing the spoiled tiles without paving the entire roof).

Minuses. Heavy, fragile. With a complex roof design, it requires additional fasteners, enhancing the crates, waterproofing.

Cement-sand tile

The composition of the material is clear from the name. This mixture is grabbed under pressure. It can be covered with icing and looks like a ceramic tile. Weight 1 sq. M - 35-45 kg. It is recommended to cover the roofs with a slope of 20-60 degrees. The waterproofing carpet is littered through it. Price 10-20 dollars.

Pros: Resistant to external influences, including ultraviolet, has a high frost resistance. Over the years this material is becoming stronger.

Cons: heavier ceramic tiles, when transporting can be up to 10% scrap.

Bituminous tile

In the manufacture of the bitumen plate is coated with fiberglass, cellulose or polyester. The desired color is obtained by applying special paint. It has the type of leaf of 30x100 cm, weight is 8-12 kg / sq. M. Price - 8-10 dollars / sq.m. Suitable for roofs with a slope of more than 12 degrees. Under the coating you need to raise the waterproof plywood.

Bituminous tile saves flexibility due to which it can be used on the roofs of an arbitrary shape with any roundings. In addition, the bitumen rubber layer under the influence of solar heat gluits all sheets on the roof into a single waterproof carpet.

Pros: It does not break, not rust, does not rot and does not be fading. Local repairs are possible. It is possible to fit on the roofs of any form - acute-angular, rounded, multi-seed. Good noise insulation. Diverse colors of material.

Cons: Not considered an elite material, it burns well and fades in the sun.

Metal roofs

Metal tile.

Device diagram metal tile.

In fact, the metal tile is no tile, but a metal sheet, laid out in the form of a laid tiled coating. The sheet is made of galvanized steel with polymer application, which gives the color "under the tile". Weighs a sheet of 3-5 kg \u200b\u200b/ sq.m, costs $ 7-15 per m.

Use metal tile on the roofs with a slope of more than 15 degrees. With a smaller slope, it is necessary to seal the joints of the sheets. Mount the sheets of the mustache along the slope of 250 mm or more, across the skate - for one corrugation. The use of this material is possible literally anywhere, from arbors to high-rise buildings, which makes it a choice of almost predetermined with a limited budget.

Pros: simplicity and installation speed, stroke resistance, low price, low weight.

Cons: Bad noise insulation.

Professor

The easiest kind of metal roofs made of radial steel wavy sheets. Waves can be of different shapes, heights and widths. The minimum bias for a profile of 10 degrees. Under it fell pergamine, fasten with self-drawing. Professional flooring can be put right on top of the old roof, for example, rubberoid. Professional flooring is used, as a rule, for low buildings, in 1-3 floors.

Pros: simplicity, installation speed, strength, durability.

Cons: Bad heat and noise insulation.

Fold roofs of steel, copper, aluminum

Copper folding roof over time only darkens and becomes even more noble in appearance.

Move from smooth sheets without coating. Steel sheets can be galvanized or polymer coated. They are mounted on the roof by engaging with folded edges. Minimum bias 20 degrees.

On rafters under the sheets you need to put an anti-condensate film. Steel roofing is simple, indestructible and cheap. No coating is subject to corrosion. The impictory whole looks like a copper roof: a bright red-yellow color first, then it is covered with a greenish patina, which gives all the appearance of the house some nobility. Patina protects copper from corrosion. But copper and aluminum roads.

The easiest aluminum roof is 2-3 kg / sq. M. Then there is steel - 4-5 kg \u200b\u200b/ sq. M. Copper is the hardest - up to 10 kg per m.

Pros: fire resistance, decorativeness, the ability to give any shape, low weight.

Cons: Bad noise and thermal insulation, low impact resistance.

The cheapest types of roofing materials

Slate

Slate is wavy asbestos cement plates with a size of 1.2x0.7 m, weighing 10-15 kg / sq. M. Sheets laid on the roof of the roofing of a mustache, feeding them to the nails. Under nails it is necessary to put a waterproofing gasket. In addition, we need a lining pergamine layer. Not so long ago, it was one of the main coatings, now it is used, as a rule, for auxiliary buildings. Although nothing prevents them from covering them and cottage. Price 2-3 dollars / sq.m.

Pros: Bending strength, convenient to process, low price.

Cons: Fragility, asbestos are harmful to health, ugly, accumulates moisture, because of the time it can grow moss or mold on it.

Bituminous Wavy leaf (used in use) can be applied as a substrate - waterproofing for other roofing materials.

It looks like a real slate: the same wavy sheets of 1x2m and weighing 3-5 kg \u200b\u200b/ sq.m. Get, impregnating the cellulose fiber distilled bitumen. This material is also called a flexible slate. Due to flexibility, it can be used on complex rounded roofs. In addition, the flexible slate can be raised on almost flat roofs, with a slope of 5 degrees. Only the shap in this case should be solid.

Pros: Easy, can have any color, convenient to work.

Minus: burns out, loses the shape under the hot sun, burns, frost resistance of only 25 cycles.

Ruberoid

Ruberoid not so long ago was the most common material for garden houses. An excellent choice of roof for shield summer buildings, boardy sheds and various canopies built without special architectural sings.

Pros. It is an easy and cheap rolled material, easy to handle. In order to wish it on the roof, you do not need any special skills or high time.

Cons: Malaya strength and briefness. After two or three years, the roof will have to be pressed, and a maximum of five years to overlap it again. Ruberoid may in the first year pierced the branch unsuccessfully from the tree. It is recommended for conventional one-bounce, not too steep roofs.

Elite and expensive roofs

Roofs from natural materials

With modern fashion, everything was naturally unexpectedly fell into the number of elite roofs of such unreliable, but expensive coatings like duncas, straw or reed. Despite fashion trends, it is unlikely to make sense to use such an unreliable and flammable material. But the summer verandas of a cafe under the reed roofs attract visitors better than neon advertising. In other words, it is very specific material, before using which you need to think well.

If you really want to have an elite, natural, but reliable roof, better pay attention to the slate. Once from the shale did the roofs of the castles. Slate - a natural stone. Each of its roof record is handed to manually. The material is heavy, but they can cover the roofs of any form.

Not only the house, but also the barn on the site should be covered with good roof - it will protect everything from rain and snow that is in it. How can you cover the roof of the barn and what are the advantages and disadvantages of certain materials?

Materials

Now there are many roofing materials on sale. Which one to choose that the roof of the barn was durable, durable and at the same time? What is the roof better for the shed?

Professional flooring (Professionalist)

The material is profiled metal sheets, galvanized or with color polymer coating. Waves on a sheet can be of different shapesThe professionalist is produced different types:

- wall

- roofing

- carrier,

These species differ in rigidity. Also selling challenges for designing joints.

Pros of the professional leaf:

- low price

- easy installation,

- durability.

- a lot of waste in the device roofing complex geometry,

- condensate.

Ruberoid

Most cheap Material, Used for many years. It is a roofing cardboard or glass cholester, soaked in bitumen with additives. Ruberoid based on glass cholester is stronger.

- low price,

- flexibility,

- easy installation.

- need to lay in several layers,

- not the most attractive appearance,

- gulf.

Asbesto-cement slate

This material is also known for a long time. It may be flat or wave, suitable for roofs with a slope of 20-5 degrees.

- does not burn,

- not subject to corrosion

- durable.

- fragile,

- heavy,

- asbestos in the composition.

Metal tile.

It is a stamped metal sheets imitating tile. There are different colors and metal of different thicknesses, the tile is not a thick of less than 5 mm thick.

- aesthetics

- easy installation,

- durability.

- condensate,

- a lot of waste

- high price.

Ondulin

Cellulose material with bitumen top layer and various impregnations.

- ease,

- aesthetics

- resistance to temperature drops.

- combustion

- low strength

- a short service life (warranty - 15 years).

As for the prices, the cheapest material is runner. Next comes a wave slate, a flat slate is about 2 times more expensive and comparable at the price with Ondulin and professional flooring. Metal tile has an even higher price as bituminous tile.

How to make a roof

First of all, set the solo system. For the roof, the shed usually use wooden bar. 40 * 120 mm and 50 * 50 mm.

Single roof make, if you do not need an attic room. It is tilted in one direction and must perform the edges of the shed by 20 cm to protect the walls from the rain.

The slope is created by racks nailed to the upper bruse strapping. You can also put an additional bar from top of the facade. If you build a new barn, you can immediately foresee, so that one wall is above another.

Snow is delayed on a single-sided roof, so the rafter should be enough, and they should be strong.

If a shed of a small size and will be covered lightweight materials, then a single-piece roof can be made from a large chipboard.

The bartal roof is better with the precipitation, but not suitable for areas with strong winds. It allows you to make a crady in the barn.

First install beams, then rafters and bitch. Then make the crate. For this board nourish the rafter. The cheek can be solid - it is required for soft roofing materials, such as rubberoid or ondulin, and can be done in 50 cm increments.

Roofing from professional flooring

Professional flooring is a popular material for the roof due to a moderate price and the possibility of self-installation without special skills.

The barn can be covered with a cheap galvanized straightener, but if you want to make it a roof of a barn from the professional foot under the color of the roof of the house or just more beautiful, you can buy a more expensive professional sheet with a polymer coating.

Important! The root with a slight bias must be covered by a straightener of greater thickness.

The professionalist laid on the bracket of the Vangest (if the slope is less than 12 degrees, then the backstage is made at least two waves) and screw the screws. Use special roofing selflessness with lining. Start stacking a straightened from the bottom row, taking into account the sinks and the adolescence. The size of the allen also depends on the angle of inclination:

- a bias of 12-15 degrees - Fall from 20 cm,

- the bias of 15-30 degrees - Fall 15-20 cm,

- the slope is greater than 30 degrees - overlap 10-15 cm.

If the roof is double, then on the upper facing board Fasten the end corner, and after it is installed - the cornice bar.

If the task is to overlap the old roof, in some cases the old roofing material can not be removed. If the doom is strong, and it is put on it soft roof, such as Ruberoid, then professional flooring can be put straight on top of the old crate.

Important! So that the professionalist is not corrosion, the screws of screws are treated with special anti-corrosion compositions.

Roofing from Ruberoid

Ruberoid may not only act as an independent roofing material, but also as waterproofing before coating by other materials.

If you are roofing from the frontierdoor, it must be kept in several layers:

- for a flat roof - 5 layers,

- when bias less than 15 degrees - 4 layers,

- when bias up to 45 degrees - 3 layers.

Ruberoid put across the skate, starting below. The first row should hang from the roof by 5 cm, the remaining rows are put with the allen.

Insulation

If the shed heated, for example, if animals contain in it, it is necessary to insulate both the shed and its roof. Inexpensive I. available way Insulation of the roof is a fusion of sawdust with lime. The flooded layer of sawdust over time is compacted, therefore a mixture of sawdust, lime and gypsum (5%) or sawdust and clay are used. In this case, it turns out a porous layer that does not give a shrinkage and does not lose thermal insulation properties. The video shows how to fasten the roof of sawdust.

The roof for the shed is quite covered with your own hands. The most common materials are a professionalist and rubberoid. And it is possible to insulate it using a cheap and affordable material - sawdust.