Seal coefficient GOST. The best sandy gravel mixture. In practice, this is a simple procedure.

The seal coefficient of rubble is an important indicator that is required for the formation of an order for the supply need quantity materials (rubble consumption per 1 m3) and to predict further shrinkage of the layer of a certain fraction after its load building structures, as well as the stability of the facilities erected with their use. This parameter allows you to determine whether it is possible to reduce the volume of the material and if so, then how many times (this is required, for example, to find out the coefficient of the rubble seal 20-40 during the trump).

The stone should be solid, durable without defects and the desired size as needed on site or by specification. The blood on which crushed stone should be laid should be cleaned from all bulk materials, aligned, irrigated and sealed before laying rubble. Cable or tube trenches, if necessary, must be made before working out.

Above the prepared surface, the stone must be installed as close as possible and well packaged and firmly installed. Stones must be full height and must be laid in such a way that their foundations have the largest area lying on the subclass.

It is important to understand the difference between the bulk density of rubble (kg per m3) and then how much this material is constructed during the trump.

Each of the types of rubble has its own labeling, which is indicated in the SNiP standard and GOST 8267-93. There you can find methods for determining the seal coefficient. Sealing rubble has a direct dependence on a plurality of factors, including its characteristics. Thus, it is important to consider:

After proper laying of stones, the intervals between them should be carefully filled with karst portico or a larger chips to get a bard, a compact surface. The spread of loose reeds or crushes is prohibited. Then the surface should be water and seal with mechanical or sufficiently heavy wooden tampon and logs.

After seal, give the necessary slope or level and dense base, and the surface should look clean. When laying and sealing the casing, it is necessary to carefully ensure that concrete surfaces in contact with the solution are not damaged. Grainy materials used to support this study are restored particle size materials for road coat. It produces crushed granular materials for road foundations, as well as aggregates used to produce bituminous mixtures and concrete cements.

- density;

- beschy;

- grain (fraction);

- frost resistance;

- radioactivity.

On the basis of these characteristics, a solution is made in favor of which materials are more suitable for a specific type of work. It is also noteworthy that in accordance with construction technologiesIt is customary to distinguish between several types of density: medium, true and bulk density of rubble.

Then the removed material was thoroughly stirred to eliminate the phenomenon of segregation of the finest particles. The number of material selected is approximately 300 kg - was determined taking into account the total number of tests that must be fulfilled, and considering that the materials can be used several times during the study. The removed material was placed in bags of 25 kg to ensure that all samples had the same form.

Before the restoration of the materials studied, the natural granulometry of the granite material was determined and a sedimentation test was carried out to determine the size of the particles of the shallow fraction. It showed that the material consists of 57% of large aggregate, 39% sand and 4% of small particles. This also indicates that the sample has a coefficient of curvature 4 and the coefficient of uniformity. From the distribution of grain size, the material is classified as a homogeneous gravel in accordance with the unified classification of soil.

Why is the seal of rubble?

There are quite high strength indicators and when creating a base, for example, for the road or foundation of the building, it is enough to simply dissolve. However, this is not at all. Grains derived as a result of crushing mountain breeds Material features a completely arbitrary form. That is why in the process of frustration of any space between adjacent elements, air emptiness are formed, which contribute to a significant decrease in the level of resistance of the material to the loads. Due to the grain seal losing mobility, which contributes to a significant reduction in the size of the void and an increase in the strength of the rubber base.

Then the material was washed and separated by standard sieves: 20 mm, 14 mm, 10 mm, 5 mm, 5 mm, 25 mm, 630 mm, 315 mm, 160 mm and 080 mm. These procedures were performed in order to more accurately restore the granulometry and control the number of small particles present in the analyzed samples.

This granulometric curve is characterized by a percentage of fines of 7% and the coefficient of homogeneity approximately. After that, these materials were divided into two groups characterized by changing the coefficient of homogeneity and, on the other hand, a change in the percentage of fines. Variations were made to analyze the impact on the hydraulic properties of materials.

At the construction site, the seal coefficient of the crushed stone 20-40, 40-70 and other fractions are fairly easy to find out. To do this, measure the height of the vehicle sides and the total amount of the material delivered. The resulting number is multiplied by the percentage of seal. Also knowing the coefficient of seal, it is not a lot of work to determine the required amount of rubble materials for one or another specificity construction work. To make an independent calculation, it is enough to know the following parameters:

The second group includes four particle size, which are characterized by a variable percentage of small particles and a constant coefficient of homogeneity of materials. Their distribution is presented in the figure. The characteristics of the restored materials used in this study and discussed above are presented in the table. This table presents a wide range of the values \u200b\u200bof the content of thin particles and the coefficient of the homogeneity of the materials used in the framework of this study.

The characteristic of the materials was first consisted in determining the percentage of a large fraction, that is, particles of more than 5 mm and small fractions, that is, particles from which were determined specific gravity large fraction and thin material fraction. The absorption value of each material was calculated using various masses obtained during density tests.

- base thickness after sealing;

- the proportion of rubble (must be specified in the quality certificate);

According to current standards, the values \u200b\u200bof the seal coefficient of the rubble may be as follows:

- sand and gravel - 1,2;

- construction sand - 1.15;

- keramzit - 1.15;

- gravel crushed stone - 1,1;

- soil - 1.1 (1.4);

- etc.

Unit of measurement of the seal coefficient of rubble - ton / cubic meter (T / M3).

Then the definite value of the surface area of \u200b\u200bthe little things was determined using a spectrophotometer to see the effect of the specific surface on the winding of the flow of water. The method used is described in the chapter. The specific surface values \u200b\u200bobtained, as well as other results of the physical characteristics for each of the materials are presented in the table.

These values \u200b\u200bare added values \u200b\u200bof the characteristics obtained from studies performed earlier. According to this classification, based on the internal and production characteristics of the materials, it was possible to classify the granite material in class 1a. This class is characterized by the upper limit of the internal characteristics of 15% of the loss of particles and 35% for the Dough in Los Angeles and according to production characteristics with a value of 25% or less flat particles and 40% of the elongated particles. Therefore, the material has excellent mechanical strength and has a low content of flat elongated particles indicating that the strength and rigidity of the carriage part will not be significantly affected by the production characteristics of the material.

When choosing rubble, it is important to take into account such an indicator as a seal coefficient. This criterion shows how much it is possible to reduce the volume of the material, while maintaining the same mass due to the tamper or natural shrinkage. This indicator is used to determine the amount of aggregate, both when buying and directly in the construction process.

Alternative sealing options for rubble

It should be noted that the hardness of the material is the characteristic that Dore considers an important property to maintain the integrity of the characteristics of aggregates exposed to construction activities, depletion caused by the passage of heavy vehicles and wear caused by the effect of tires on the surface.

How to determine the coefficient of the seal of rubble when traaming independently

The next step was to determine the curves of the sealing of restored materials. The seal curve shows the dependence between the density and the content of water in this material. This curve is particularly interested in the fact that each material has its own curve for this sealing energy, and on the other hand, in its upper part, which allows the water content in which reaches the maximum dry bulk density. It should be noted that the mass content of water establishes the relationship between the mass of water present in the sample, and the mass of dry material.

Due to the fact that after the rambling the bulk weight of the rubble of any fraction will increase, it is necessary to immediately take into account the material of the material. And in order not to buy superflore, a correction factor is required.

The coefficient of sealing (kU) is a very important indicator that is necessary not only for the proper compilation of materials, but also in order to provide a further shrinkage of the gravel layer after its burden by building structures. Moreover, knowing the seal coefficient, one can predict the stability of the construction objects themselves. In view of the fact that the rashching coefficient is, in fact, the degree of reduction in volume, it may vary depending on the 4 factors:

The seal curve is obtained from the determination of the maximum density of the samples with different water content. The test consists of sealing a sample of a material passing through a sieve of 20 mm, and having a given water content in a cylindrical form with a diameter of 4 mm and an altitude of 4 mm. The seal is made in five homogeneous layers with a dynamic sealing energy generated by a blow of a metal hammer with a thickness of 5 kg, which drops out with a free drop from a height of 457 mm 56 times on the layer.

Energy seal is a measure mechanical energyapplied to the mass of the material. This equation takes into account the mass of the hammer, the height of the fall, the number of layers and the number of blows on the layer. The proctor demonstrated that the seal is a function of four variables: dry density of the soil, water content, sealing energy and soil type. According to the cholester and Kovach, for the same soil type, an increase in the energy of the seal leads, on the one hand, to an increase in the maximum density of dry soil, and on the other hand, the optimal water content.

- Method and load parameters (for example, from which height is performed).

- The peculiarities of transport, by which the material is delivered to the object, and the distance to the construction site - after all, even the fixed mass as a result of the sediment under their own weight is gradually compacted.

- The rubble fractions and the content of smaller grain grains than the lower boundary of the specific class of rubble.

- Beschy - needle stones give a smaller shrinkage than cubes.

It should be remembered that the strength of concrete structures, the foundations of buildings and roads directly depends on the accuracy of determining the degree of seal. However, it is also not necessary to forget that the platform on the site is often performed only on the upper layer, and in this case the calculated coefficient does not always correspond to the actual shrinkage of the base. Especially often this happens when not professionals are engaged in construction, and lovers. In accordance with the requirements of technology, each layer of frustration must be specified and checked separately.

This phenomenon is illustrated in FIG. 17, in which it is noted that the graph of the optimal line, that is, the line connecting the optimal values \u200b\u200bobtained for the same material with different sealing energies should seem to be a constant saturation curve.

Main characteristics and scope of rubble

Curves of the sealing of these materials were divided into two groups. In the first group shown in FIG. 18, reduced materials that have percentage of small things equal to 7%, and change the coefficient of homogeneity. The second group shown in Figure 19 shows the sealing curve with a percentage percentage of 7% and the coefficient of homogeneity.

Another parameter that must be taken into account is that the degree of tamping is calculated for the mass, which is compressed without lateral expansion, that is, limited to the walls, which does not allow it to spread. At the site, such conditions for filling of any fraction of rubble are not always created, so a small error is preserved. This fact should be taken into account, first of all, when calculating the sediment of large structures.

It is generally recognized that the maximum density of the material is highly dependent on the size of the material particles. This effect can be observed on the curves shown in FIG. 18, where it is observed that the density value increases with the coefficient of the homogeneity of the material. In the same way, it can be seen that the optimal density of these materials increases with a decrease in the optimal water content. Thus, the greatest value is obtained with a coefficient of homogeneity 88 with optimal water content of 2%.

FIG. 18 It can be noted that the experimental points obtained to determine the seal curve for some reduced materials are located on the dry side of the proctor curve. The phenomenon is observed in FIG. 20 and is due to the fact that for compacted samples with a high content of water, excessive water is displaced at an optimal value. As a result, the point that would be when the water content so that the star before sealing after the seal was in the water content below and close to the optimal one.

Seal during transportation

It should be noted that finding some standard compressibility value is actually not easy, since too many factors have an impact on it. (All of them are listed above). The coefficient of the seal of the rubble supplier may indicate in the accompanying documentation, although GOST 8267-93 and does not require it directly. However, during the transportation of gravel, especially its large parties, often detect a significant difference in volumes when loading and on a construction site where it was delivered. Therefore, the correction coefficient, which takes into account the seal of the rubble, is necessarily introduced into the Agreement and is controlled in the reception item. The only mention in the current GOST: the seal coefficient, regardless of the fraction, should not be higher than 1.1. Suppliers certainly know about it, and in order to avoid returns, try to make a small margin. Measurements are often resorted during an acceptance when the crushed stone is delivered to the construction site, as they are ordered by non-tons, but cubic meters. For this truck body with a rubble located in it, you need to measure from within a tape measure, after which it is possible to calculate the volume of delivered gravel, and then multiply it to the coefficient of 1.1. Such a calculation will allow to approximate how many cubes were covered in the body of a truck before shipment. If the number obtained, taking into account the seal, the figure will be less than that indicated in the accompanying documents, it means that the body of the car was not sucked. Equal or more specified in the documents - you can safely unload crushed stone.

Types of rubble and specifications

Analysis in FIG. 18 also makes it possible to note that the value of the content of water added to the material more affects the density value when homogeneity coefficient increases; This is reflected in the less elongated form of the seal curves. FIG. 19 shows the effect of increasing the percentage of small particles on the density of materials having a uniform uniformity coefficient. It is assumed that the maximum density of granular materials is obtained when the pores are filled with fine particles. The corresponding percentage of small particles for filling the pores provides direct contact between large particles without significant changes in the volume of emptiness of a large skeleton.

Seal on site

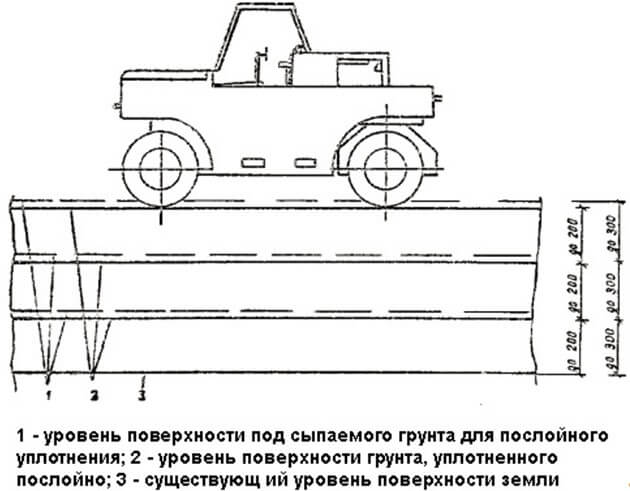

It should be noted that the number above is 1.1 - is taken into account only during transportation. On the construction site, where the rubble grab is performed artificially, with the use of vibratory or roller, this coefficient may increase to 1.52. At the same time, performers need to know exactly the degree of shrinkage of gravel snowpad. Usually this parameter is in the project documentation. However, if in the exact value there is no need, use the averaged indicators that are listed in SNiP 3.06.03-85:

Why do you need to know the value of the seal coefficient?

Adding a larger amount of small particles will lead to loss of contacts between large particles, which will lead to a decrease in the maximum density of the material. On the other hand, it can be seen that the difference in percentage of small particles does not significantly affect the density result. From these values \u200b\u200band using the apparent values \u200b\u200bof the material density, the porosity and the degree of saturation for optimal sealing conditions are calculated. Similarly, the water content was calculated in the optimal state. Finally, it can be concluded that the materials restored after the seal can ideally have a porosity between 146 and 292 and the maximum saturation degree from 9% to 8%, which confirms that the compacted materials are in a state of partial saturation.

Crushed stone fraction 40-70, as a rule, has a seal 1.25-1.3 (if its brand is not lower than M800). M600 - from 1.3 to 1.5. For small and medium-sized classes, 5-20 and 20-40 mm, these indicators are not installed, since they are often used only when the upper carrier layer is collapsed from the grains of 40-70.

Laboratory research

The seal coefficient is customary to count on the basis of the data of laboratory tests, during which the mass of the rubble is subjected to a tamper and verification on various adaptations. There are several methods: substitution of volumes (GOST 28514-90); Standard layer-by-layer seal of rubble (GOST 22733-2002); Express methods using one of three types of denneters: static, water-blank or dynamic.

The results are obtained either immediately, or after 1-4 days, depending on which method is selected for the study. The cost of one standard test sample is 2500 rubles. You need to spend no less than five such samples. If the data is urgently needed, for example, during the day, express methods are used according to the results of the selection of minimum 10 points. The cost of each point is 850 rubles. In addition, you will have to pay for the departure of the laboratory assistant to the place - about 3 thousand rubles. However, without accurate data on the construction of large objects can not do. In addition, solid construction organization It is necessary for official documents that confirm compliance with the Contractor of the Project requirements.

Is it possible to find out the degree of rambling yourself?

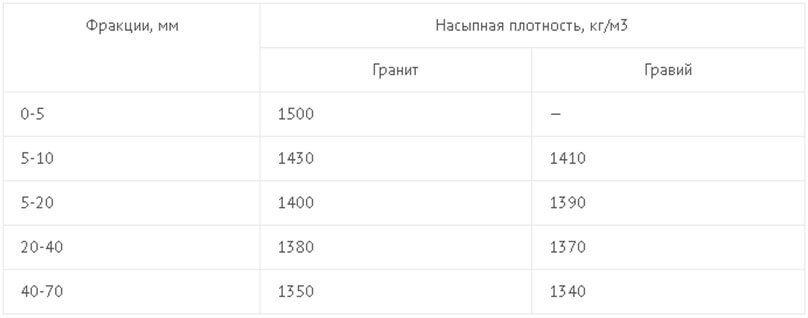

Yes, the coefficient can be defined both in the field and for the needs of private construction. To do this, you must first find out bulk density For each size: 5-20, 20-40, 40-70. It directly depends on the mineralogical composition of the material, but at the same time slightly. Much greater influence on volume weight have rubble fractions. To calculate, you can use the averaged data:

More accurate density data for a specific rubble fraction can be defined by laboratory, either by weighing the known volume building rubble followed by a simple calculation:

Bulk weight \u003d mass / volume.

After that, the mixture is riveted to the state in which it will be used on the site, and measured with a roulette. And then again produce the calculation of the formula above, receiving 2 in the end different densities - Before and after the tamping. Objectively, we obtain the seal coefficient for a particular material. With the same weight of the samples, you can simply find the ratio of two volumes - the result will be similar. It is necessary to pay attention to the fact that if the indicator after the traam is divided into initial density, then the number obtained in the response will be greater than the unit - in fact, this is the reserve coefficient for sealing. In construction, they are used if the end parameters of the gravel pillow are known and to order, it is necessary to determine the amount of rubble of the selected fraction. When reverse the calculation, the value is less than one. However, these numbers are equivalent and it is important to understand when calculating, which one should take.