Decorative stone for interior decoration - subtleties of choice and installation advice. Facade panels for a stone.

V last years interior wall decoration is becoming more and more popular natural materials such as:

- a natural stone;

- brick;

- wood;

However, finishing with these materials is quite an expensive pleasure and not everyone can afford it, and working with such material is very difficult and time-consuming. decorative panels for interior decoration imitating natural stone, brick or wood.

The quality of manufacture of such panels is such that at first glance it is impossible to distinguish them from natural counterparts, and the cost is much less.

In the modern construction market, you will be offered a stone look made by various manufacturers from different countries. All of them differ in the composition of the materials from which they are produced, in the manufacturing technology and different ways installation.

One of the successful solutions was the use of fiberglass in the production of wall panels.

Fiberglass has many positive characteristics that have helped it gain popularity:

- It is very durable and lightweight material... High strength is provided by a layer of fiberglass, which reinforces the entire inner side of the panel.

- In order to establish the production of a certain type of panels, a prototype is first made from natural material and fastened with a binder mortar.

- Such a natural model in the future is a stamp for the manufacture of subsequent ones.

- Harmless dyes give an absolute similarity to natural material.

- From fiberglass, you can create a wide variety of panel surfaces: from absolutely flat to imitation of rough, untreated stones.

Fiberglass panels can be used to decorate walls in homes and offices, create unique interiors in hotels and restaurants. They are great for decoration exhibition halls, theatrical scenery and filming pavilions.

Fiberglass panels have many positive characteristics:

- It is a very lightweight and durable material.

- It is easy to assemble and dismantle. It can be used repeatedly.

- Plastic panels can be mounted on wet plaster or concrete.

- To create additional sound and heat insulation, it is enough to lay a layer of the appropriate material between the panel and the base.

- Fiberglass panels are an environmentally friendly product that is completely harmless to health.

- It does not fade over time.

- This material is not afraid of moisture, is not subject to decay and mold.

- It does not support combustion, is fireproof, and almost does not emit toxic substances in case of fire.

- If we add here also the low cost, then we get an almost perfect finishing material.

Different types of panels can reproduce a wide variety of masonry reliefs:

- For example, a panel called Torn Limestone reproduces masonry from wild limestone.

- Such a relief can be used for both exterior cladding and for interior decoration of walls and individual elements of premises (columns, arches, fireplaces, etc.).

- Panels imitating the "Mountain slate" finishing stone look good. The deep relief of the panel makes it possible to maximize its resemblance to its natural counterpart.

- Decorating rooms with panels with such a relief can radically change its interior.

- The panel "Jurassic Stone" reproduces the relief of masonry from rectangular stones, chipped structure and various sizes.

The color scheme of these panels is fully consistent with the style of ancient walls. Panels with marble and travertine texture are in good demand.

Panels like marble or travertine are used for finishing both the walls of the premises and individual elements (finishing of internal and external corners,). Also, these panels are used for interior decoration in combination with other reliefs.

Brick wall panels

Panels that closely imitate brickwork are produced in many countries. Their use in wall decoration indoor spaces is gaining popularity.

Brick wall panels acquired their attractiveness on the basis of the advantages they have:

- You can assemble wall panels with your own hands.

- One wall panel covers an area of up to 3 m², which significantly speeds up finishing work.

- The main advantage of wall panels is their low cost. After all, the production of this finishing material is mainly used by waste from the woodworking industry (shavings, sawdust, branches, bark).

Polyvinyl chloride (PVC) panels are even cheaper. The quality of such panels is excellent, and in appearance they are almost indistinguishable from natural brickwork.

The brick wall panel is a flat chipboard of the following dimensions:

- width - 2440 mm;

- height - 1220 mm;

- thickness - 6 mm;

Wall panels made from the wood fiber of the eucalyptus tree, which contains its own oils and resins.

The panel is formed under high pressure and temperature. This releases lignin, which is a binding agent.

In this case, the front side is stylized as brickwork and covered with acrylic paint.

Such panels are used in hallways. They are perfect for making theatrical decorations, for decorating exhibition halls.

They can sheathe balconies and loggias from the inside.

Maintenance of such panels is very simple. It is enough to occasionally walk on the panels with a soap rag and your walls will always be clean and fresh.

Wood-effect wall panels

Wall panels made of wood chipboard (chipboard) are created by pressing with high temperature from large sawdust or shavings. As astringent formaldehyde resin is introduced into the composition of chipboard panels.

Therefore, chipboard panels are not recommended for decoration of residential premises.

Chipboard panels have many disadvantages:

- The strength of such panels is inferior to that of wood.

- From temperature extremes, the chipboard panel can collapse.

- Such panels do not tolerate high humidity.

- The panels crumble during processing.

Wood-effect fiberboard wall panels are also produced by pressing at a high temperature.

But in the manufacture of fiberboard, synthetic binding resins are not used, as in the production of this material lignin is released, which is an astringent substance. Fiberboard panels are not afraid of high humidity, they can be mounted in any room.

Just avoid direct ingress of water.

Fiberboard panels are mounted on the lathing. This is a simple job and you can do it yourself.

Wall panels MDF imitation wood is a relatively new finishing material. They are made from MDF boards.

These boards are created by dry pressing small chips at high temperatures using lignin, which is released from the wood chips during the manufacturing process, as a binder.

All rooms with any level of humidity can be sheathed with these panels. The MDF material is strong enough with good sound and thermal insulation properties.

There are panels with refractory impregnation.

Types of wall panels

Tiled panels are produced in rectangular shape. The size of the side of the square is from 30 cm to 90 cm.

Thanks to the square shape of the panels, by choosing different patterns and combining colors, you can create a unique composition on the wall. Such panels are fixed to the wall with glue or clamps.

There is one more feature of tiled panels - they are interconnected according to the groove-groove scheme. To connect the panels to each other, you must use inserts.

Tiled panels are made from the following materials:

Rack panels are assembled from individual planks up to 30 cm wide.Their length can reach up to 240 cm.

These are such long and thin slats. Such panels are good for finishing rooms of a small area or those with many corners.

Due to their size, sheet wall panels have gained wide popularity in interior decoration. One panel covers almost 3 m² of walls. Which significantly speeds up the finishing work.

The dimensions of such panels are:

- height - 1220 mm;

- width - 2440 mm;

- thickness - from 3 to 6 mm;

It is not enough just to build a house, it is necessary to carry out quite serious work on its interior and exterior decoration. After all, if this stage of the work is not performed properly, then it will be problematic to create a comfortable, cozy and truly homely atmosphere in the premises. Manufacturers of finishing products offer a wide range of various products, however, choosing a specific facing material should be responsible and thoughtful. For example, to create a luxurious exterior and at the same time save a budget, you can use a decor option such as stone wall panels. This material is distinguished not only by its high aesthetics, but also by many positive characteristics. In addition, it can be used both for facing surfaces in the open and for finishing indoors.

Features and advantages of the material

As you know, natural stone is an elite coating, and therefore the price for it is quite high. However, today an excellent alternative has been found to such a product - an artificial stone. What is it? First of all, it should be noted that in appearance such a synthetic product is practically indistinguishable from a natural mineral. Besides, decorative rock comes in the form of panels that are easy to assemble and handle. The walls are decorated with stone on the basis of various materials and has a wide range of applications. For example, this decor option can be used in the kitchen area or in the bathroom, that is, in a humid environment, in unheated rooms, in particular, on the balcony or in the corridor and even in living rooms, and products are also appropriate for outdoor decoration.

Advantages of wall panels:

- long operational life (up to 50 years);

- realistic appearance;

- design diversity;

- wide scope of use;

- moisture resistance of products;

- affordable cost;

- environmental Safety;

- ease of care;

- ease of installation;

- high strength and wear resistance of the material;

- fire safety;

- possibility of reuse after dismantling;

- resistance to aggressive environmental factors, including UV radiation, negative temperatures, precipitation, and so on.

Due to these advantages, panels imitating natural stone, products are increasingly used for decoration of public institutions, for example, restaurants, hotels, office buildings, shopping centers, and they are also popular in everyday life. At the same time, you can buy both panels for interior decoration and for exterior. It is worth saying that the scope of application is not the only parameter by which finishing bezels differ. There are several main types of material that you should know about before purchasing.

Varieties of panels

Products can be classified according to several criteria. The most popular is the division according to 3 main criteria. This is the material of production, purpose and configuration, that is, size and shape. Let's consider these parameters in more detail.

| Criterion | Designation | Characteristic |

| Manufacturing material | MDF | At the heart of the material are small wood particles, which are firmly connected into a monolithic sheet by hot pressing, the finished product has additional properties fire resistance and sound absorption. |

| Fiberboard or chipboard | For production, wood shavings and sawdust are used, the finished product has high performance characteristics, however, the material does not tolerate high humidity conditions, and therefore an additional protective layer is required. | |

| Fiberglass | The most demanded material in modern conditions, since this product is non-toxic, completely safe from an environmental point of view, moisture resistant, and also has an increased service life, which is why it is often used for facade decoration. | |

| Scope of application | Interior decoration | The peculiarity of the products is that the products have less weight and size, but more design possibilities. |

| External finishing | The panels are highly resistant to aggressive environmental factors, and can also have an additional heat and sound insulation layer. | |

| Configuration (shape and size) |

Sheet | These are rectangular products, the length of which is 2 or more meters, and the width is from 1 m, are used for quick installation of premises with large dimensions. |

| Plate | Products of a square or rectangular shape, most often, are small in size, for example, products with parameters of 300x300 mm are considered popular, it is convenient to cover a bathroom or kitchen with such plates. | |

| Rail | Such fragments are called "stone sidenig", slats can have a variety of sizes, while the length is much greater than the width, and also made to order with non-standard parameters. |

Which product to choose for surface finishing should be decided based on design tasks, as well as the required qualities of the material.

Installation of front panels

The peculiarity of the installation of panels lies in the fact that a ventilation gap must be left between the main wall and the false panels, which allows moisture to freely pass through the walls and not settle on their surface. It should be borne in mind that finishing the facade involves quite significant preparatory procedures.

Facade preparation

At this stage, it is required to level the surface of the facade of the house, and, if necessary, insulate the walls. It is not recommended to use foil-clad materials as thermal insulation, since they violate the vapor permeability of the structure. The best option for attaching false panels is to mount them on a crate. The frame for the subsequent fixation of the artificial stone can be made of wooden slats or a metal profile.

Important! Before installation, wooden products must be protected from moisture, fungi and fire with special compounds.

The step of the lathing will depend on the size of the panels, that is, the strips from each other horizontally should be at a distance of the same height of the product. In the case of installing large-sized sheets, the pitch of the lathing should be reduced to avoid sagging of the facing material. A lathing frame is installed on top of a heat-insulating and sound-absorbing layer. It should be checked for evenness in each plane using a building level.

Fastening panels

To mount the facade panels, it is necessary to use fasteners with anti-corrosion characteristics, this will help to avoid rusty smudges during operation. In the event that the cladding is carried out in winter or at subzero temperatures, the panels must be kept in a warm room until installation. Such a measure will maintain the flexibility of the finishing material and will make the installation procedure easier. It is recommended to fix the panels from left to right and from bottom to top. The finishing of the house with panels begins from the corner of the building.

Unlike stone products, synthetic products can be cut fairly easily with ordinary hand or power tools. Therefore, if you need to adjust the fragments to size, you should mark the exact parameters with a ruler and a marker, and then just make a cut. It is important to follow the resulting pattern so that the decor of the house looks as natural as possible and really resembles natural stone. Modern cladding panels have special strips for screwing in screws or driving in nails, so fixing products to the frame should not seem difficult.

When the paneling of the house is complete, the necessary accessories should be installed. In particular, corner elements and cornices are referred to as additional elements.

Attention! When fastening the corner panel with an overlap, it must cover the facade slabs by at least 15 mm.

It should be borne in mind that when the ambient temperature changes, the products may change their size. To compensate for contraction and expansion, it is recommended not to tighten the fixing screws by about 1 mm. It is most convenient to do this as follows: screw in the self-tapping screw to the end, and then unscrew it half a turn.

Installation of panels for interior decoration

Stone slabs for interior decoration differ from facade slabs in that special adhesives can be used to fix them. However, in the case of cracks, chips, irregularities and other defects on the surface of the walls, experts recommend creating a crate from wooden bars or a metal profile. If the base is even, then the installation of products can be carried out according to an accelerated scheme.

Preparing the walls

The surface is cleaned of oil and grease stains, old finishes, dust and other contaminants. Then a layer of primer is applied to the base. If it is necessary to level the walls, you should plaster them with a special starting compound or putty small defects finishing putty... The specific option depends on the original appearance of the surface. If carried out plastering work, then the panels can be glued only after the mixture has completely dried.

Installation of wall panels

It is recommended to purchase the material in advance and keep it in the conditions of the room to be finished for at least 48 hours. The work begins with the markup. It is very important to mount the bottom row as evenly as possible, this will allow you to complete the work without problems. The cladding itself resembles the installation of tiles, that is, according to the instructions, it is divorced adhesive composition, if the glue is realized in a pasty consistency, then just stir it before use. Further, the mixture is applied to the surface of the wall, and, if necessary, tiles made of artificial stone are also coated. The panel should be carefully pressed against the wall, but be careful not to squeeze out all the adhesive. Further, the next fragment is also fixed, and the procedure is repeated until the entire surface is laid out. It is important to check the rows with a spirit level to avoid skewing or unevenness.

Installation of decorative elements

When all the walls are completely glued with panels according to the design plan, you should proceed with the installation of the overlays on the corners, as well as the fastening of the upper and lower decorative elements... The installation of wall panels on the lathing practically does not differ from the fastening of front panels.

Attention! To achieve the perfect imitation of a stone surface, it is worth paying enough attention to fitting the pattern. It is best to lay the piece out on the floor and make sure all the elements fit together. Such a procedure will help save time in the future, and will also allow you not to spend money on rework.

Stone panels do not require special maintenance. However, observing simple rules, you can significantly extend the service life and maintain their excellent appearance for a long time. It is important to choose products based on their operating conditions. For example, for wet rooms, the best choice is moisture resistant plastic panels under a stone for interior decoration, and heat-resistant MDF products are perfect for decorating an apron in the kitchen. If there is a special protective film on the panels, it is recommended to install only on glue, since self-tapping screws or nails can damage the protective surface and the lined layer will not cope with its functions. To maintain a beautiful appearance and protect from dust, wet cleaning of the lined walls should be carried out every 2-3 months.

Stone paneling is a great way to decorate the exterior or interior of your home. In addition, the products not only improve the aesthetic appearance and make the building luxurious, they also protect against noise and improve the thermal insulation characteristics of the room. Such products have an affordable cost and it is easy to tile the house with it even on their own. Similar virtues make false panels an indispensable finishing material that will surely last for many years.

Surely, every owner of a house or apartment wants his interior to be unique and beautiful. Modern finishing materials allow even the most daring design dreams to come true. For example, stone panels for interior decoration create such a realistic masonry effect that they can only be distinguished from natural material upon careful examination.

Material for decorative panels

For interior decoration, they are made of modern and high-tech material called fiberglass. It can imitate almost any texture, both smooth and rough, and environmentally friendly dyes give it the color you need. Wall panels made of fiberglass for interior decoration under a stone are made by stamping, when first a prototype of a panel is made of natural material, and then panels are produced in its likeness, completely repeating all the features of the texture of a natural sample.

Panels for interior decoration can imitate a huge number of different materials and species. All this allows you to choose exactly the option that is most relevant for a particular interior. For example, panels for natural slate or marble are very popular.

Interior with decorative panels

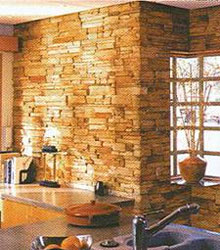

Plastic panels imitating natural stone for interior decoration are rarely used in interiors in order to completely decorate a room with them. This option is possible only for panels with a smooth texture, which does not violate the geometry of the wall and does not visually conceal the space. Usually, such panels are used in a very dosed manner, for finishing one wall or several sections on different walls. As a wall for decoration, the one to which you want to draw special attention is usually chosen. So, in living rooms, either the wall behind the sofa or the opposite wall behind the TV is often finished, and in the bedroom it is usually the surface behind the head of the bed. If wall panels under a stone for interior decoration are used on several walls, then usually only part of the surface is covered. So, with a similar material, you can decorate the columns or corners of the walls, equip an apron that covers the walls in the room approximately to the middle, or come up more creatively and place the panels in such a way that it seems that the masonry accidentally peeps through the upper covering of the walls.

Stone-look wall panels are great for wall decoration. Due to its excellent performance properties and attractive appearance, the material can be used in various rooms.

What are the wall panels made of?

Stone-look wall panels are made of various materials:

- fiberglass;

The most popular are fiberglass and MDF boards. They have excellent performance properties. Chipboard cladding is not so durable and has low resistance to moisture and temperature extremes.

Fiberglass wall panels are used for wall decoration in apartments and private houses, in offices, hotels and restaurants. Due to its moisture resistance and resistance to temperature extremes, the material can also be used for cladding bathrooms and kitchens.

Fiberglass stone panels for interior decoration have the following advantages:

- high strength, which is provided by a layer of fiberglass located on the inner side of the plates;

- lightness: low weight greatly facilitates the installation process;

- you can mount the material on any surface;

- environmental Safety;

- durability: the cladding retains its original appearance for a long time;

- fire safety;

- ease of installation and dismantling;

- possibility of repeated use;

- low cost;

- a variety of colors and textures;

- insulation and sound insulation can be laid under the panels.

Often, MDF panels are used for wall decoration. The popularity of cladding is associated with a number of advantages:

- lightness: it facilitates installation and allows you to clad lightweight partitions;

- ease of installation and dismantling;

- durability: wall plates retain their original appearance for a long time, do not deform;

- ease of care;

- a wide range of colors, textures.

However, when using MDF, it should be borne in mind that constantly high humidity leads to swelling of the plates, their deformation.

Interior use

With the help of stone panels, you can transform any interior. They fit perfectly into the living room, corridor, kitchen, bathroom. A variety of colors allows you to choose the best option for any style. Boards can be combined with others finishing materials... The wallpaper is suitable for them, decorative plaster, natural wood and much more.

When decorating walls, it is important to adhere to the following recommendations:

- When decorating a corridor, you should choose a material of light shades with a small pattern, that is, the pattern should imitate a small stone.

- When decorating a living room, it is better to choose a wall cladding that combines two or three shades of stone. In this case, the room will seem warmer and more comfortable. In the living room, as a rule, not all walls are faced, but niches, arches, decorative portals, and so on.

- In dark rooms, it is worth using a cream, sand color finish. Of great importance is also correct organization artificial lighting.

- If slabs of dark shades are chosen for cladding, then the interior should have furniture, textiles in light shades.

A few words in conclusion

Stone-look wall slabs will create a spectacular and unusual interior. However, you need to pay attention to each element. You can verify the aesthetic appearance of the finish by looking at the photo using the material in the interior.

Besides attractive appearance, the plates have excellent performance characteristics.

They are durable, strong, easy to install and easy to maintain. Resistance to various influences allows the material to be used for wall cladding in various rooms, including in the bathroom and in the kitchen. Installation is easy to do by yourself. And all this requires minimal financial and time costs.

Related entries: