Wall panels for stone for interior decoration. Facade panels under the stone.

IN last years The internal wall decoration by natural materials is becoming increasingly popular with such as:

- a natural stone;

- brick;

- wood;

However, the finishing of these materials is quite expensive and not everyone for the means, and it is very difficult to work with such a material and a long time. There is a way from such a position if you use the wall decorative panels for interior decoration, imitating natural stone, brick or tree.

The quality of the manufacture of such panels is that at first glance they cannot be distinguished from natural analogues, and the cost is much smaller.

In the modern construction market, you will be offered under the stone made by various manufacturers from different countries. All they differ among themselves with the composition of materials from which they are produced by manufacturing technology and various installation methods.

One of the successful solutions was the use of fiberglass in production wall panels.

Fiberglass has a multitude of positive characteristics that helped him gain popularity:

- It is very durable and light material. High strength provides a fiberglass layer, which is reinforced by the entire inner side of the panel.

- In order to establish the release of a certain type of panels, the prototype from the natural material is first made and fastened with a binding solution.

- Such a natural model is further a stamp for the manufacture of follow-up.

- Absolute similarity with natural material appreciate harmless dyes.

- From fiberglass, you can create a wide variety of surfaces of panels: starting from absolutely even to imitation of coarse, untreated stones.

Fiberglass panels can be searched for walls in homes and offices, create unique interiors in hotels and restaurants. They are well suited for registration exhibition halls, theatrical scenery and shooting pavilions.

Fiberglass panels have many positive characteristics:

- It is very easy and durable material.

- It is easily mounted and dismantled. It can be used repeatedly.

- Plastic panels can be mounted on raw coating or concrete.

- To create additional sound and thermal insulation, it is enough to lay a layer of the corresponding material between the panel and the base.

- Fiberglass panels Environmentally friendly product, completely harmless to health.

- He does not fade over time.

- This material is not afraid of moisture, is not subject to rotting and mold.

- It does not support combustion, fireproof, with fire almost does not release toxic substances.

- If you add a low cost here, then we will receive almost the perfect finishing material.

Different types of panels can reproduce a wide variety of stone masonry reliefs:

- So, for example, the panel, which is called "Ripped limestone", reproduces stone masonry from wild limestone.

- Such a relief can be used as for outdoor facingand for the interior decoration of walls and individual elements of the premises (columns, arches, fireplaces, etc.).

- They look good panels, imitating the finishing stone "Mountain Slate". The deep relief of the panel allows its similarity to its similarity to the natural analogue.

- Finishing the premises with panels with such relief can radically change its interior.

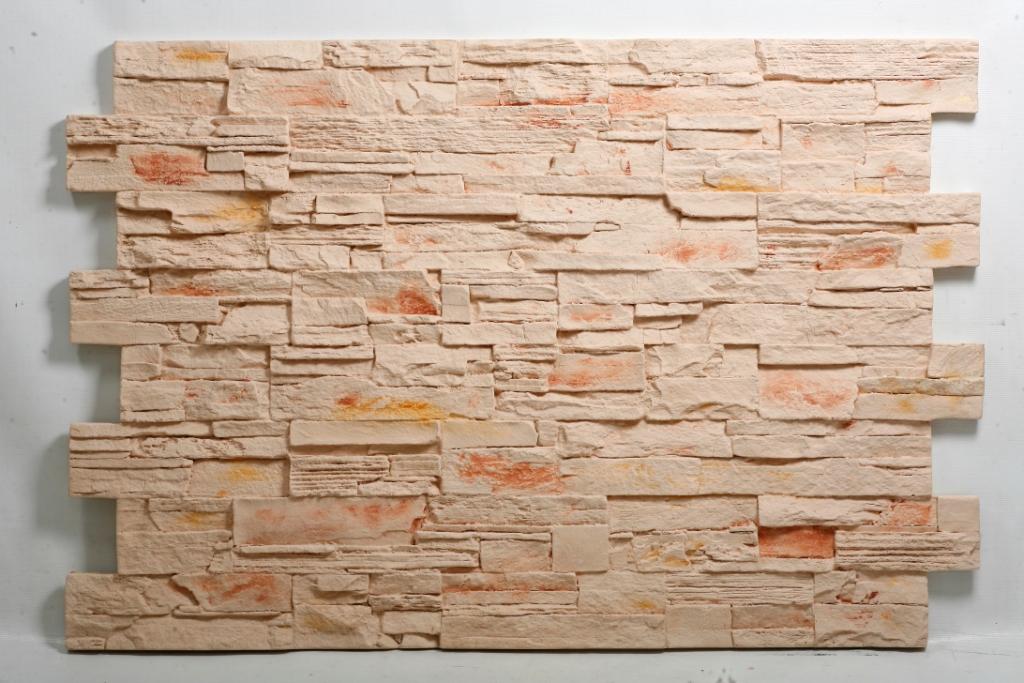

- The "Jurassic Stone" panel reproduces the relief of masonry from the stones of the rectangular shape, the cooler structure and various sizes.

The color solution of these panels is fully consistent with the stylistics of the vintage walls. The panels with texture under marble and travertine use good demand.

Panels for marble or travertine are coated as walls of premises and individual elements (finishing of internal and outer angles). Also, these panels are used for interior decoration in combination with other reliefs.

Wall panels under the brick

Panels exactly imitating brick masonryReleased in many countries. Their use in wall decoration interior premises It is becoming increasingly popular.

Its attractiveness wall panels under the brick acquired based on the advantages they possess:

- Mix the wall panels with your own hands.

- One wall panel closes the area to 3 m², which significantly speeds up the finishing works.

- The main advantage of wall panels is their low cost. Indeed, the production of the woodworking industry (chips, sawdust, branches, bark) is mainly on the production of this finishing material.

The panels from polyvinyl chloride (PVC) are even cheaper. The quality of such panels is excellent, and in appearance they are almost impossible to distinguish from genuine brickwork.

The wall panel under the brick is a flat chipboard plate of such sizes:

- width - 2440 mm;

- height - 1220 mm;

- thickness - 6 mm;

Wall panels produce from the wood fiber eucalyptus, which contains its oils and resins.

The panel is formed under high pressure and temperature. This distinguishes lignin, which is a binding substance.

In this case, the front side is stylized under the brickwork and is covered with acrylic paint.

Such panels are performed, holls. They are well suited for the manufacture of theater decorations, for the design of the exhibition halls.

They can be seen from the inside balconies and loggias.

Caring for such panels is very simple. It is quite occasionally walking along the panels of a soap rag and your walls will always be clean and fresh.

Wall panels under the tree

Wall panels from chipboard (chipboard) under a tree are created by pressing at high temperatures from large sawdust or chips. As binder The formaldehyde resin is introduced into the panels from the chipboard.

Therefore, the chipboard panels are not recommended for decoration of residential premises.

The panels from DSP have a lot of flaws:

- The strength of such panels is inferior to wood strength.

- From temperature drops, the chipboard panel can be destroyed.

- Such panels do not tolerate high humidity.

- When processing the panel crumbs.

Wall panels made of wood-fiber plates for wood are also made by pressing at high temperatures.

But in the manufacture of DVP, synthetic binders are not used as the production of this material is highlighted with lignin, which is the binder.

It should only not allow direct water from entering.

The DVP panels are mounted on the cheek. This is a simple job and you can make it with your own hands.

Wall MDF panels for wood relatively new finishing material. They are made of MDF plates.

These plates are created by dry pressing with small chips at high temperatures. In the quality of the binding agent, lignin is used, which is released from wood chips in the production process.

With these panels, you can sow all rooms with any level of humidity. Material MDF is quite durable with good sound and thermal insulation properties.

There are panels with refractory impregnation.

Types of wall panels

Tile panels are available rectangular shape. The size of the side of the square is from 30 cm to 90 cm.

Due to the square shape of the panels, selecting various drawings and combining the colors can be created on the wall a unique composition. These panels are fixed to the wall on glue or cleimers.

There is another feature of the tile panels - they are connected to each other according to the groove-groove scheme. To connect panels with each other you need to use inserts.

Tiled panels are made of such materials:

The panels are recruited from individual sheets width up to 30 cm. The length of them can reach up to 240 cm.

These are such long and thin rails. Such panels are well separating the rooms of a small area or those who have many corners.

Due to its size, leafy wall panels have gained wide popularity in the interior of the premises. One panel closes almost 3 m² walls. What significantly speeds up finishing works.

The dimensions of such panels are:

- height - 1220 mm;

- width - 2440 mm;

- thickness - from 3 to 6 mm;

It is not enough to simply build a house, it is necessary to carry out quite serious works on its internal and external finish. After all, if this stage of work is not done properly, then create a comfortable, cozy and truly homely atmosphere in the premises will be problematic. Manufacturers of finishing products offer a wide range of a wide variety of products, however, choose a specific facing material should be responsible and thoughtfully. For example, to create a luxurious exterior and at the same time save a budget, you can use this option of decor as the panel on the stone wall. This material is distinguished not only by high aesthetics, but also a multitude of positive characteristics. In addition, it is possible to apply it both to clamp surfaces in the open air and for finishing in closed rooms.

Features and Benefits of Material

As you know, natural stone is an elite coating, in connection with which the price of it is quite high. However, today a similar product was found an excellent alternative - artificial stone. What is it? First of all, it is worth noting that in appearance, such a synthetic product is almost indistinguishable from the natural mineral. Moreover, decorative rock Produced in the form of panels that are easy to mount and process. Finishing walls under stone based on various materials and has a wide scope of application. For example, this option of decor can be used in the kitchen area or in the bathroom, that is, in a wet environment, in unheated rooms, in particular, on the balcony or in the corridor and even in residential rooms, as well as it is appropriate for the outdoor finish.

The advantages of wall panels:

- long operational period (up to 50 years);

- realistic appearance;

- designer manifold;

- wide scope of use;

- moisture resistance of products;

- affordable cost;

- environmental Safety;

- ease of care;

- ease of installation;

- high strength and wear resistance of material;

- fire safety;

- the ability to reuse after dismantling;

- resistance to aggressive factors of the medium, including UV radiation, negative temperatures, precipitation, and so on.

Due to the benefits of natural stone panels, products are increasingly used to decorate public institutions, such as restaurants, hotels, office buildings, shopping centers, and they are also popular in everyday life. You can buy both panels for interior decoration and external. It is worth saying that the scope of application is not the only parameter for which the finishing false panels differ. There are several major varieties of material that should be found before purchasing it.

Panel varieties

Classify products can be classified by several features. The most popular is the division of 3 main criteria. This is the material of production, purpose and configuration, that is, size and form. Consider these parameters in more detail.

| Criterion | Designation | Characteristic |

| Material of manufacture | MDF | The basis of the material is small wood particles that are firmly connected to the monolithic sheet by the method of hot pressing, finished products have additional properties Fire resistance and noise absorption. |

| DVP or DPP | For production, wood chips and sawdust are used, the finished product is distinguished by high performance characteristics, however, the material does not tolerate the conditions of high humidity, and therefore an additional protective layer is needed. | |

| Fiberglass | The most popular material in modern conditions, since this product is non-toxic, is fully safe from the environmental position, moisture consists, and also has an increased service life, due to which it is often used when finishing the facade. | |

| Scope of application | Interior decoration | The peculiarity of products is that products have a smaller mass and size, but broader design capabilities. |

| Exterior finish | Panels have increased resistance to aggressive environmental factors, and may also have an additional heat and sound insulation layer. | |

| Configuration (shape and size) |

Sheet | These are rectangular products, whose length is 2 or more meters, and width from 1 m, are used to quickly install rooms with large dimensions. |

| Plate | Products of a square or rectangular shape, most often, has small sizes, for example, products with parameters 300x300 mm are considered popular, such plates are comfortable to sneak the bathroom or kitchen. | |

| Rail | Such fragments are called "Stone Saydnig", rails can have a variety of dimensions, while the length is significantly higher than the width, and also manufactured to order non-standard parameters. |

Which product to choose to finish the surface is to decide on the design of the design tasks, as well as the required material quality.

Installation of facade panels

The feature of the panel installation is that between the main wall and false panels, it is necessary to leave the ventuzor, allowing moisture to freely pass through the walls and do not settle on their surface. It is worth keeping in mind that the facade finish involves quite significant preparatory procedures.

Facade preparation

At this stage, it is necessary to align the surface of the facade of the house, and if necessary, insulate the walls. It is not recommended as thermal insulation to use foil materials, as they violate the vapor permeability of the structure. The optimal option for fastening false panels is the installation of them to the crate. Frame for subsequent fixation of artificial stone can be made of wooden rivers or from a metal profile.

Important! Wood products before installation must be protected from moisture, fungi and fire with special compositions.

The shadow step will depend on the size of the panels, that is, the planks from each other horizontally should be at a distance of one height of the product. In case of installation of large-sized sheets, the shaft step should be reduced to avoid the stamp material. A crescent frame is installed on top of the heat-insulating and noise absorbing layer. It should be checked by its evenness in each plane using a construction level.

Fastening panels

To mount the front panels, it is necessary to use the fastening elements with anti-corrosion characteristics, this will help to avoid rusty slopes during operation. In the event that the lifting is carried out in winter or at a minus temperature, the panels are required to keep in the warm room before mounting. Such a measure will support the flexibility of the finishing material and make the installation procedure more simple. Fasten the panels are recommended to the left and below to the top. Starts finish at home by panels from the corner of the structure.

Unlike stone products, synthetic products are quite easily cut by a conventional manual or electric tool. Therefore, if necessary, adjusted fragments for size, it should be noted the exact parameters of the ruler and the marker, and then just make the cut. It is important to follow the resulting pattern so that the home decor looked as natural as possible and really resembled a natural stone. Modern facing panels have special planks for screwing screws or ripping nails, so the fastening of products on the frame should not seem complex.

When the house finishes is completed, you should install the necessary accessories. In particular, the additional elements include corner elements and eaves.

Attention! When mounting the corner panel of the mustache, it should close the front plates at least by 15 mm.

It should be borne in mind that when the surrounding temperature changes, the product can change their size. To compensate for compression and expansion, it is recommended not to bring fastening screws by approximately 1 mm. It is most convenient to do this as follows: screw the screws to the end, and then unscrew it to the half-turn.

Installation of panels for interior decoration

Plates for stone for interior decoration differ from the facades in that special adhesive compositions can be used to fix them. However, in the case of the presence of cracks, chips, irregularities and other defects on the surface of the walls, experts recommend creating a crate of wooden bars or a metal profile. If the base has an even look, the installation of products can be carried out according to an accelerated scheme.

Preparation of walls

The surface is cleaned from oil and fat spots, old types of finishes, dust and other contaminants. Then the primer is applied to the base. If it is necessary to align the walls, they should be launched by their special starting composition or sharpen small defects. finish spacure. The specific option depends on the initial type of surface. If carried out plasteringYou can only glue the panels after a complete drying of the mixture.

Installation of wall panels

It is recommended to acquire the material in advance, and to withstand it in the conditions of the premises of at least 48 hours. Work begins with marking. It is very important to mount the lower row as soon as possible, it will make it easily complete the work. The cladding itself resembles the installation of the tile, that is, according to the instructions, divorced glue compositionIf the glue is implemented in a pasty consistency, then it is enough to stir it before applying. Next, the mixture is applied to the surface of the wall, and, if necessary, tiles of artificial stone are also labeled. The panel should be carefully pressed against the wall, but try not to squeeze all the glue. The following fragment is also fixed, and the procedure is repeated until the entire surface is posted. It is important to check the ranks using a level to prevent distortions or irregularities.

Installation of decorative elements

When all the walls are fully planted with panels according to the design plan, it should be started to install overlays on the corners, as well as to the top and lower fastening decorative elements. Installation of wall panels on the crate is practically no different from the fastening of the front panels.

Attention! To achieve perfect imitation of the stone surface, it is worth paying enough attention to the fitting pattern. It is best to post a fragment on the floor and make sure that all the elements come to each other. Such a procedure will help save time in the future, and will also allow not to spend on the alteration.

Panels for stone do not require special care. However, observing simple rules, it is possible to significantly extend the service life and maintain their excellent appearance for a long time. It is important to choose products based on the conditions of their operation. For example, for wet rooms, the optimal choice is moisture-resistant plastic panels For the stone for the interior decoration, and for the design of the apron in the kitchen, heat-resistant products from MDF are perfect. If there is a special protective film on the panels, it is recommended to install only on glue, since the screws or nails can damage the protective surface and the lined layer will not cope with its functions. To maintain a beautiful view and protection against dust, a wet cleaning of lined walls should be carried out every 2-3 months.

Finishing with panels under stone is a great way to decorate the exterior or interior of the house. In addition, products not only improve aesthetic appearance and give the structure of luxury, they also protect against noise and allow to increase the thermal insulation characteristics of the room. Such products have an affordable cost and it is easy to bind the house even own forces. Similar advantages Make a false panels an indispensable finishing material, which will probably last for many years.

Wall panels for stone are great for decoration walls. Thanks to the excellent operational properties and attractive type, the material can be used in various rooms.

What wall panels are made of

Wall panels for stone are made of various materials:

- fiberglass;

Plates from fiberglass and MDF were the greatest popularity. They are inherent in excellent performance properties. The cladding of the chipboard is not so durable and has low resistance to moisture and temperature drops.

Wall plates made of fiberglass are used to decorate walls in apartments and private houses, in offices, hotels and restaurants. Due to moisture resistance and resistance to temperature drops, the material can also be used for lining bathrooms and kitchens.

Panels for stone for interior decoration made of fiberglass possess the following advantages:

- high strength, which is provided with a layer of fiberglass, located on the inside of the plates;

- easy: small weight significantly facilitates the installation process;

- mounting material can be mounted on any surface;

- environmental Safety;

- durability: Facing retains the initial view for a long time;

- fire safety;

- ease of installation and dismantling;

- the possibility of repeated use;

- low cost;

- variety of colors and textures;

- under the panel you can lay insulation and sound insulation.

Often, panels from MDF are used to finish the walls. The popularity of cladding is associated with a number of advantages:

- easy: It facilitates installation and allows you to sneak light partitions;

- ease of installation and dismantling;

- durability: Wall plates keep the initial species for a long time, do not deform;

- ease of care;

- a wide range of colors, textures.

However, when using MDF, it should be noted that constantly elevated humidity leads to swelling of the plates, their deformation.

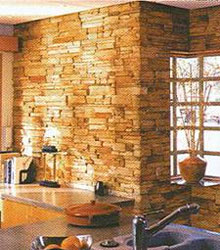

Use in the interior

With the help of panels for stone, you can transform any interior. They perfectly fit into the living room, corridor, kitchen, bathroom. The variety of colors allows you to choose the optimal option for any style. Boards can be combined with others finishing materials. It is suitable for wallpaper decorative plaster, Genuine wood and much more.

When finishing the wall, it is important to adhere to the following recommendations:

- When making a corridor, you should choose the material of light shades with a small pattern, that is, the drawing must mimic the small stone.

- When decorating the living room, it is better to choose a wall facing, combining two or three shades of stone. In this case, the room will seem warmer and cozy. In the living room, as a rule, not all walls, but niches, arches, decorative portals, and so on.

- In dark rooms it is worth applying a decoration of cream, sandy color. Of great importance and proper organization artificial lighting.

- If dark shades slabs are chosen for cladding, then in the interior there should be furniture, textiles of light shades.

Couple words in conclusion

Wall plates for stone will create a spectacular and unusual interior. However, it is necessary to pay attention to each element. Make sure the aesthetic form of the finish can, looking at the photo using the material in the interior.

In addition to an attractive appearance, the plates have excellent performance.

They are durable, durable, feature ease of installation and ease of care. Resistance to various impacts allows the use of material for lining of walls in various rooms, including in the bathroom and in the kitchen. Installation is easy to spend independently. And all this requires minimal financial and time costs.

Related records:

Every year, decorative facing panels are becoming more and more popular. Moreover, their assortment is able to satisfy any, even the most unusual requirements.

General

Immediately it should be said that not all decorative panels are suitable for use inside residential premises.

Here are the basic requirements that they must answer:

- The coating should be strong enough and at the same time have elasticity and flexibility.

- An important point is the environmental friendliness of the product.

- The coating must wear the temperature differences well.

- Mandatory condition is moisture resistance.

- The coating should be unpretentious in care and resistant to synthetic detergents.

Dignities of panels

Decorative panels for interior wall decoration have quite a few positive qualities:

- Capable to hide construction defects walls.

- Allow you to perfectly align the walls.

- It is plausible to imitate natural materials, such as brick, stone, tree, etc.

- In the cavity between the material and the wall you can hide all communications, including wires, ventilation systems, cables, etc.

- The use of these materials allows you to increase sound and heat-insulating quality premises.

- Easy to install with your own hands.

Types of coatings

The form

In form, decorative panels exist three types:

- Sheets - these products have the largest dimensions, their length and width is 1220 per 2440 mm, and the thickness can reach 6 mm.

- Tile - have a square form of 980x980 mm or 300x300 mm.

- Rack - This coating is recruited from the rails, their dimensions are different widths 900 - 3000 mm, length 130 - 300 mm and thickness 8 - 12 mm.

Materials

As for the materials, the products usually do from:

- Polyvinyl chloride (PVC);

- Wood;

- Wood chipboard (chipboard);

- Wood and fibrous plate, etc.

Panel imitating stone

Recently, decorative panels for stone for interior decoration are very popular. And you can use for the facing of individual decor elements, or create whole wall compositions with them.

Different manufacturers are used to produce these products. different compositionsBut they all reliably imitate natural material.

In addition to an attractive appearance, the material has such advantages as:

- Stability ultraviolet radiation, i.e. Does not fade in the sun.

- Resistance to large temperature differences.

- Resistance to high humidity.

Distribution panels with eucalyptus fibers

Separately, it should be said about the panels obtained by pressing the eucalyptus wood under high temperatures, the production of which is established in the United States. Externally, they resemble a stone laying with the extender.

In the process of their manufacture, a lignin substance is distinguished, which, when frozen, forms a very strong connection. As a result, according to compression strength, this material is comparable to concrete.

Among other advantages, the following points can be distinguished:

- The material is environmentally friendly, since it does not contain synthetic resins.

- It is characterized by high moisture resistance, so you can make facing in rooms with high levels of humidity.

- The front side exactly repeats the texture of granite, marble and some other stones.

- Acrylic material coating provides him with resistance to synthetic detergents.

Fiberglass panels

Also, fiberglass panels deserve separate attention, since they are a universal eliminator material. They are not afraid of mold, no fungus, they are subject to corrosion. In addition, the coating is not amenable to burnout and is characterized by good strength.

Thanks to these qualities, they can be used to finish almost any premises. In addition, the price of such panels is significantly lower than on products from Feds.

Brick imitating panels

Products from MDF.

This material is made by dry drying wood chips. It should be said that they have practically the same properties as the elevated plates from the fiberboard. This is due to the presence of lignin, which is used as a binding substance.

By order, the coating may have refractory properties, which significantly expands areas of their application.

Products from PVC

PVC coatings that imitate brickwork are also very in demand during the interior of the premises.

Among their advantages, the following points can be distinguished:

- A large range, thanks to which you can find the imitation of masonry of any type.

- Large service life.

- The coating is hygienic, since it is not exposed to microorganisms and it is easy to disinfect.

- Have good heat and sound insulation properties.

- Capable to withstand large temperature differences.

- The cost of products is lower than coatings from MDF.

- Maximum simple installation instructions.

Tip!

With better to perform from plastic guides, as they do not rot and do not rust.

Tile panels

The main difference of these panels from the above materials is that they are mounted not on the crate, but directly to the surface of the wall or ceiling with glue, however, if the surface is uneven, then you can also mount on the frame.

Between the tiles are connected using special grooves. Such tiles can be manufactured from all of the above materials.

Decorative panels

Racial plates are essentially boards that are mounted on the crate. Such. Between themselves, they are also connected by the "Ship-Paz" method, which simplifies their installation.

In the photo - Rush panels

Tip!

In order for the rush facing to have a finished look, appropriate fittings need to be needed, including external and internal corners, plinth, etc.

Output

As we can see, a large selection of types of materials for interior decorations are presented. different characteristics and different external species. Therefore, you should choose the panels in accordance with the tasks assigned to them, as well as given our own financial capabilities and personal preferences.

Additional information on this topic can be obtained from the video in this article.

SimpleBuild realizes the front panels under the stone produced by the manufacturers of "Royal Stone", "Alta Profile" and others. The catalog contains materials, effectively imitating the surface of the malachite, rocky stone, granite different species (Siberian, Karelian), etc. We carry out the delivery of facade panels in Moscow, it is also possible to send to the regions. Experienced Symplbilde experts will be happy to help you choose the materials for the covering of a particular building, tell about the features of each of them. In addition, we have a wide range of challenges (profiles, planks, etc.) under the stone, which will allow you to create a beautiful harmonious design of the outer surface of the building.

Main advantages

From natural analogues, such a finish is beneficial for the following basic features:

- lower price. This makes facade panels cost-effective and affordable for a wide range of buyers building materials;

- small mass. The panel for the facade under stone creates a noticeable lower load on the base, which ensures reduction in the cost of construction;

- spectacular appearance. Decorative facade panels under the stone externally do not differ from natural materials And therefore can be used to design the most respectable buildings. You can get acquainted with the photo in the SimpleBuild directory;

- practicality in operation. To care for the panels for finishing facades under the stone is noticeably easier than the natural analogues. It is possible to wash them from dust using a directional water jet;

- infertility external influences. A natural stone It can absorb moisture and foreign substances, facades from it - to turn moss. Panels are resistant to similar factors. At the same time, they retain the basic advantages of natural materials: non-combustibility, strength, resistance to rotting.

To buy facade panels under the stone, add them to the "basket" or contact Simplbilda according to any of the contact numbers.