The most durable plaster for the facade. What plaster choose - plaster or cement? Manual applying plaster

Finishing facades of buildings and other building structures exposed to ultraviolet, precipitation, temperature fluctuations. Under these conditions, not all materials are able to maintain strength and aesthetic appearance. Stucco for outdoor work is one of the most popular solutions for the design of external walls. It not only retains its qualities under the influence of weather factors, but also protects wall structures from premature destruction.

Single-layer walls - from what and how to build them

One layer can be built only from plates with polystyrene inserts. The walls of the recess are profiled in languages \u200b\u200band grooves on the front surfaces, you can. Stored in a sad gray color of the floor and plaster. The glazed barrier also did not add color or did not protect it from the sun. Despite the fact that the table and chairs installed on it were not encouraged to relax.

Plinths: assembly foam

Many people are afraid that clinging behind the facade can damage the walls at home and make them become raw. Wrong because the facade of the plant does not hurt. Damage to the facade neither polystyrene foam nor gypsum will fall under the severity of lifting plants. Most of the recommendations that are addressed to the Polyurethane users, comply with the requirement not to interrupt the foaming process. And this is a good idea to fill empty spaces, for example, when installing doors, windows or filling holes in the walls.

Characteristics of plasters for outdoor work

The solutions have a certain set of qualities:

- high adhesion to mineral bases;

- low capillary moisture absorption;

- vapor permeability;

- minimum shrinkage;

- high performance of moisture and frost resistance;

- resistance to weather factors.

The combination of these parameters ensures the durability of plaster for the facade. The better the mixture, the less you will have to make cosmetic repairs.

Types of plaster compositions for walls

They require well-thought out technology and especially reliable. It is also important to take care of good building insulation. Here the walls were erected from silicate blocks, isolated polystyrene with a thickness of 15 cm and completed with acrylic plaster. Veranda and terraces. The most popular materials for the construction of the wall are ceramics, cellular concrete, silicates and clay concrete. Warming is made from mineral Wat or polystyrene. Walls can be solitary, double or triple. Single layers - walls without heating, built from.

Application area

- alignment under putty;

- alignment under painting;

- repair, seaming of seams and chosel;

- decorative design of facades (coat-fur coat);

- thermal insulation "wet" method.

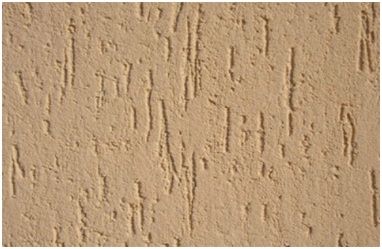

Fragment of plastered outer wall

Facades - scratches and cracks on plaster

Thin-layer thin-walled thin-walled plaster is applied to the reinforcing layer of mineral wool or polystyrene. Such plasters have a thickness of just a few millimeters, so it is easier than random. Mix and align them together, as a rule, wet, with different types of solutions. The work is made at the construction site. Walls can be made as single-layer, two-layer or three-layer. Not only their strength, but also their strength.

On both sides there were plasters with a thickness of several centimeters with a flexible mixture of calcium-based aggregate. Matte or polystyrene foam. However, if the frost is durable and durable, in the spring it can be crushed, that you will need to relax or delete. If the basement walls of base houses are already raised, they must be isolated and grounded from both sides.

Features of working with plaster for outdoor work

- the humidity of the base is not higher than 8%. Conduct work in warm dry weather. There should be no wet spots and drills on the walls, otherwise the solution slides or sucks;

- the base temperature is not lower than + 5 ° C. Under such conditions, the moisture in the solution does not freeze, but binds to the main component, ensuring the strength of the coating. There are plasters for a wet facade, with which you can work at negative temperatures. In their composition, antiorious additives, a special mark is on the package;

- natural drying. During the drying period, the facade must be protected from the action of the wind, the sun of precipitation. Please note that the textured mixtures will dry longer than smooth. Also, time must be increased with a large thickness of application. Some solutions for a complete durability require up to 7 days.

Dilution: most often due to errors

As a result, the cracks in the plaster and even the walls are caused by the floor failure under the influence of the load, including the floor, furniture, equipment. The size of this bending can sometimes be up to several centimeters. This leads to the fact that the ceiling "presses" the wall to the bottom.

Glass house with a unique view

Concrete blocks were isolated by foam polystyrene. The facades were separated by a silicon plaster of the smallest fraction painted in a beige color.

Old house - Isolate or stucco

You must also pass the windowsill. External window sills must be deleted - in any case, they will need to be replaced on a wider scale to set the finished facade by 3-4 cm and have a corresponding gradual fall.The house is decorated with plaster for outdoor work.

The price of plaster for external work depends on the brand, composition, form of release and packaging mass. You can get a free consultation by our specialists by calling the specified phones.

Outdoor plaster at home is the necessary coating of its outdoor designs. External building fences are affected directly ambient. Atmospheric phenomena, such as rain, snow, wind, winter air, summer heat and sunbeams - all this negatively affects the surface of the walls of the house. To protect the house from all this, people came up with plaster. Today, facade plaster for outdoor work is presented in the market. building materials In a large assortment. About what kind of outdoor plaster are and how to apply it correctly, it will be discussed below.

We choose projects for energy-efficient houses.

Mushrooms and mold, which are marked with black spots on the walls. This condition may continue even for several years, so it is necessary to dry it. A radical way to get rid of moisture is to dismantle the floors, trim the sands, replace the moistened polystyrene.

Bathroom accessories: Shelving devices

Fill over during installation, for example, from polystyrene blocks, which requires high time and time. In a more expensive version, Stelas already has pre-prepared blocks of polystyrene foam, so its body is much more convenient. Such blocks can be glued directly after plaster reinforced plaster.

Types of facade plaster

Initially plaster for facade work Used in the form of simple water mixtures of sand with cement, plaster or lime. Modern species facade plaster, thanks to the introduction newest technologies In the production of building materials, they differ significantly from their high-quality characteristics from simple finishing solutions.

Consumption of the mixture per square meter

Choose plaster or cement-limestone plaster? Or so-called dry drywall plasterboard? We must answer this question by analyzing the use of the premises that we intend to use for gypsum. Whether it is a residential or basement, an office or a warehouse, an attic or the first floor. Each of the available solutions have their own advantages.

Cement-limestone plaster has its advantages when used in areas with high mechanical damage. These types of plaster products are more expensive in the process of execution, but they have best applications In public buildings, schools, kindergartens, warehouses or in basements and garages. The advantage of cement-limestone plaster is a very high water resistance, the ability to use in wet rooms, such as baths, pools, dryers, high frost resistance and vapor permeability of plaster.

The inclusion in all types of facade plaster for external works of special additives of wall coating has gained greater strength, began to be easily applied to fencing and acquired high resistance to aggressive environmental impacts.

In addition to the protective role, the facade plaster for external work began to execute the function decorative coating External fence at home.

The disadvantage is the costs associated with the manufacture of this type of plaster. In the case of cement-limestone plasters, additional plaster is required to achieve the required smoothness. This suggests a twice cost of manufacturing and higher material costs.

The disadvantage of plaster is aggressiveness that causes corrosion of steel components. When using gypsum, such elements must be protected from corrosion protective coloring, varnishing or galvanizing. Gypsum plaster Not suitable for premises with constant humidity, such as pools or bathrooms. Gypsum plaster is also not suitable for open-air use.

From the value of the solid filler fraction, the structure of plaster is divided into thin, medium and coarse texture.

The relief shape and pattern depends on the type of tool (roller, spatula or spatter). There are quite original ways to decorate the facade of the building. Moving a twisted piece of fabric with circular motions, get original embossed drawings. The variety of various techniques for processing raw plaster has no limits.

You can take a simple principle. Domestic cement-lime plaster when the house is made according to traditional technology - bricks from materials providing high vapor permeability, such as brick emptiness, leaning ceramic emptiness and outer insulation of mineral wool. As a finite part, we use mineral plaster, painted in mass or silicate or silicone paint. This is a more expensive method, but more efficient. Gypsum plaster is used for walls made of limestone materials, such as Surorex or silicates.

Exterior decorative plasters are separated in their composition. These are such types of facade plasters, such as acrylic, mineral, silicate and silicone finishing materials.

Acrylic

The manufacturers use aqueous dispersion of various synthetic resins as the main binder material. One of the advantages of acrylic plaster for external work is its ability to "breathe". After exposure to atmospheric precipitation (snow, rain), the walls dry quickly, without delaying in its structure an excessive moisture. This explains the durability of wall decoration.

The outer walls are insulated with polystyrene foam and stacked acrylic plaster and inside plaster plaster. Internal plaster can be of two types. The first is traditional, cement-limestone plaster. They are more difficult and have a beautiful rude texture, but their disadvantage is that it is difficult to restore invisible local damage. You must apply a thin layer of plaster on the entire surface of the wall, as it is almost impossible to combine the layers of the texture unnoticed.

Plaster facade on a wooden base with your own hands

The second - plaster plaster, very smooth, giving the effect of "ideal", but they are soft and susceptible to damage. Components of traditional cement-lime plasters are cement, sand, lime and water. This sand presence makes it even coarse after roughing. This feature of traditional plaster makes it desirable in some interior styles or used for some decorative effects.

Acrylic facade plaster is sold in the trading network in finished video. Sell \u200b\u200bready-made mixture, packed in plastic shoulder weighing 15, 25 and 30 kg.

The surface texture of acrylic plaster can be of different colors and various reliefs. The color of the facade plaster depends on the dye, which is added to the finished white composition. The surface relief of the wall is formed by the technique of applying a solution on the facade of the building.

Traditional plaster is more resistant to mechanical damage and water vapor. Cement and lime solutions can be applied manually or mechanically. There are many different impurities that change or improve their properties. For example, Belaya cement plaster It has a brighter color, which makes it perfect for lightweight or white paint. Traditional plaster are best suited for dry rooms, with high humidity or for risk of mechanical damage. They are ideal for situations where the leveling surface must be aligned.

Popular popularity among the population has acquired a finish of the house with their own hands outdoor plaster In the style of "Coroed". The relief of the walls of the wall imitates the structure of the tree, damaged by the bug of the core.

The pattern is obtained by rolling solid particles in the finishing solution. This effect is achieved by vertical movements of the spatula for not yet frozen plaster.

They are an excellent substrate for all types of wall coverings and paints. Second Type internal plaster Currently, the most popular gypsum plaster. Gypsum creates a microclimate, adjusting moisture inside. Gypsum plaster allow the perfectly smooth surface of the walls and ceilings without the need for additional plasters. Ready surfaces are white, ready for coloring.

Gypsum plaster is less resistant to mechanical damage. The plaster is less durable than cement that is binding in traditional plaster. It is not resistant to water and constant moisture. In situations where the level of humidity exceeds 80%, the plaster loses its strength.

Mineral

The basis of the mineral mixture is white portland cement, lime hydrant, quartz sand or marble crumb. Plasticizers and special water repellent additives are included in the composition. Plaster has a number of advantages:

- This is the cheapest out of street plasters. Low price Mineral mixture is due to the absence of expensive components in it.

- The composition is sold in the form of a dry powder in paper bags. In contrast to the finished solutions, the mineral mixture can be stored for more than 2 years.

- The coating can withstand sharp differences in ambient temperature.

- Absolute immunity to the formation of mold and reproduction of malicious microorganisms.

- Mineral plaster outdoor walls is performed easily and quickly.

- Adhesion finishing material Allows facing insulated facades with the most different types of heat insulation.

The disadvantage of this coverage is that it cannot perform the role of decorative finishes.

Silicate

Silicate plaster is obtained by heat treatment aquatic solution Potassium and sodium silicates (liquid glass) in the autoclave. The mixture is saturated with mineral fillers, plasticizers, coloring substances.

The wall decoration with silicate solutions is quite popular among the population. Attracts this material with its high quality characteristics:

- universality of use on any surfaces of building structures (concrete, brick, plasterboard, etc.);

- silicate coating gives the wall to "breathe"; That is, the finish has high vapor permeability;

- not led by shrinkage and deformation;

- high resistance to negative impacts of the atmosphere;

- it is good to form the desired relief of its surface;

- high fire resistance;

- low price attracts a large number of consumers.

Silicate solution is supplied to the trading network in the finished form. Silicate finishing in plastic vendors weighing 25 kg. Mostly silicate decorative plaster For external work, it is made with the texture of the "Coroed" and "Shuba".

Silicone

How to choose a facade plaster for outdoor work, always tells the sales assistant in any construction supermarket. If the question is not in the field of limited financial resources, then it is worth choosing a silicone facade coating at home.

The mixture based on silicone resins has absorbed all the positive qualities of the above materials. In addition silicone plasters The walls of the house allow you to create colorful panels on the facade, which will benefit any exterior of the house, even the most unwaspid look.

One of the most important advantages of silicone finish is that the plaster has a stretch property. Such quality of the finishing material guarantees the absence of even the slightest cracks on the facade for 15 to 20 years.

Plastering works on finishing facades

The technology of plaster works is practically independent of the composition of the finishing solution. The principle of applying a solution to external enclosing structures in all cases is the same. To produce a high-quality finish of the facade, you need to cook for this required tools And equipment:

- capacity for solutions;

- mixer or drill with screw nozzle;

- dry mix, water or finished solution;

- pigment;

- spatulas and grain;

- snapshots or scaffolding.

The production of finishing works consists of the following steps:

- Building forests are erected in compliance with safety regulations.

- Walls are processed by primer.

- Veser with a finished mixture open. The contents are thoroughly mixed.

- If a white solution, then dye adds during stirring. Adjusting the amount of paint, achieve the desired shade of the color of the plastering solution.

- In the process of plastering, use the finished mixture from one batch and the same pigment.

- A solution is uniformly imposed on the cell. Then the mixture on the wall is thrown by a sharp movement.

- Depending on the planned thickness of the decoration layer, the walls of the polymer or metal grid are reinforced.

- As soon as the surface of the plaster begins to collapse, they produce a decorative finish of the walls of the walls.

- There are various decor techniques. To do this, use special grouts, spatulas and even textiles.

Upon receipt of the desired color, the number of paint per unit volume of the solution is fixed. In the next kneading, the same proportions of the components are observed. Otherwise, you can get a spotted facade with various walls in a shade.

Video: Finishing of the house with outdoor plaster with their own hands in the style of "Coroed"

Features of plascape facade with a thick layer

When the facade decorative plaster is required for external work (more than 30 mm), they are applied as follows:

- Light galvanized profile cut into the desired cuts.

- The profile is installed on the walls vertically every 1.5 m. Such racks are called beacons, which are fixed close to the surface of the wall or at some distance in accordance with the thickness of the future plastering layer.

- Walls are ground.

- In some cases, make a rough finish simple cement-sandy solution. The solution is thrown into the fencing of the cell. Special surface equalization is not required.

- After the primary layer is driving, proceed to the finish decorated coating of the facade.

- At the bottom between the beacons lay a decorative solution with a uniform layer for the entire length of the span.

- The rule is a little more than 1.5 m long, leaning on the sides on the beacons, pull the plaster up.

- Moving the rule up, the worker produces oscillatory movements to the tool from side to the side. This allows you to evenly distribute the solution across the entire width of the span between the beacons.

- According to the instructions indicated on the prepared mixture, after a while, the plaster grouts.

- If the finish was made with a white solution, then the facade is painted in the desired color.

Mechanized Facade Watching Method

A modern mechanized installation allows for one working shift to shock the facade of a 2-storey building. The principle of operation of the equipment is that under the pressure of the compressed air, the solution from the tank is supplied to the nozzle, with which the plaster is applied to a uniform layer around the facade of the building.

The use of a mechanized method of finishing the facades is cost-effective when performing large volumes of work. Outdoor plastering This type is produced in the warm season.

Both with a manual application of the solution on the facade and in the mechanical supply of the mixture, the final decorative design of the wall surfaces is equally produced, in addition to the design of the surfaces of the walls under the "fur coat".

To correctly select one or another type of finishing material, you need to take into account such factors such as local climatic conditions, the volume of work (wall area), the cost and qualitative characteristics stucco

The combination of colors gamma with the relief of the plastered surface makes it possible to create original beautiful outer walls in full harmony with the architecture of the facade.