Wall panels bathroom. Technical characteristics of PVC panels. Dimensions of sheet PVC panels

Read also

Wall plastic panels are one of the most practical and unpretentious materials for finishing.

They are distinguished by low weight, it is extremely simple in the installation - nor professional tools nor special skills are needed, very diverse in appearance and need minimal care. Replace them in case of damage is not difficult. Therefore, they are so often used for interior decoration.

In appearance, and often in size, the material cannot be distinguished. But the ceiling plastic finish is thinner - 4-5 mm and less durable, because it is not exposed to large mechanical loads. But the walls cannot be said, so the wall panels are thicker and stronger.

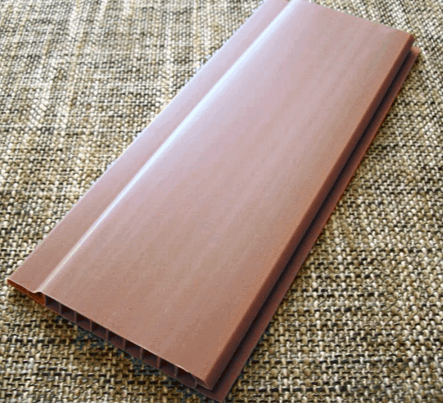

By the method of connecting the lamellas with each other, the material is divided into three groups.

- Seamless - The grooves are connected in the groove and at a competent installation form a completely smooth smooth surface with low-speed joints. The quality of the material is strongly affected by the quality of the material: the slightest deformation of the panels turns the joint into a good visible uneven seam.

- Relief - suture. As a rule, the distillation is imitated for which such a connection is characteristic. Seam is well noticeable and is part of the design. The lamellas of this species possess the greatest rigidity and are very resistant to mechanical damage.

- Option with chamfer - By type of compound, it is a seamless material, but on the ends of the product, a decorative deepening is a chamfer, which makes a flat surface embossed.

On video - dimensions wall panels PVC:

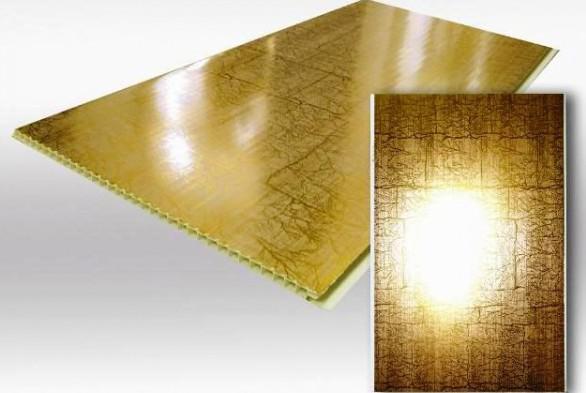

Color palette and imitation of various natural materials Makes PVC lamellas of a real find for designers. However, the method of applying the image on the surface or staining affects the quality of the finish.

This feature is distinguished by three categories.

Dimensions

The PVC finish classifies both by the form factor, characterized by sizes and, accordingly, the form.

Rachet

Lamed - or roll, most often mimicing the lining, and therefore have the corresponding dimensions. They look like familiar finishing boards:

Wall

The thickness of the wall panels is standard for any form factor and is 8-12 mm.

Others dimensional parameters It has wheels seamless pattern:

- length - 260, 270 and 300 cm;

- width - from 15 to 50 cm.

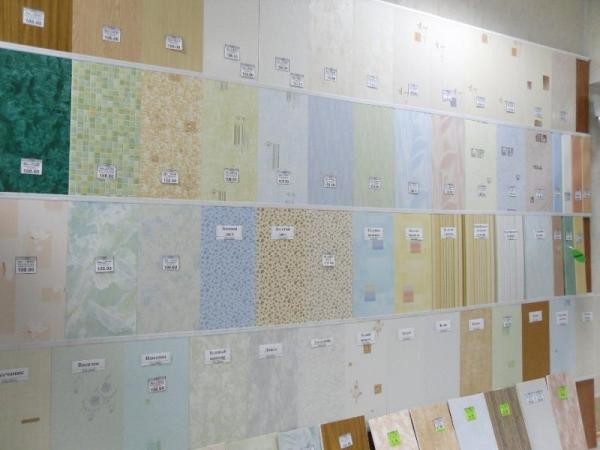

Tile

Tile material is usually seamless, as it simulates stone surfaces, plastered, as well as tiles. The design is extremely varied - from any shade to any pattern or picture formed by the tile laid in the desired order.

The most popular sizes include the following:

- 30 * 30 cm - often combined: monophonic and with a pattern, monophonic and imitating stone;

- 98 * 98 cm - Used to create paintings and complex drawings.

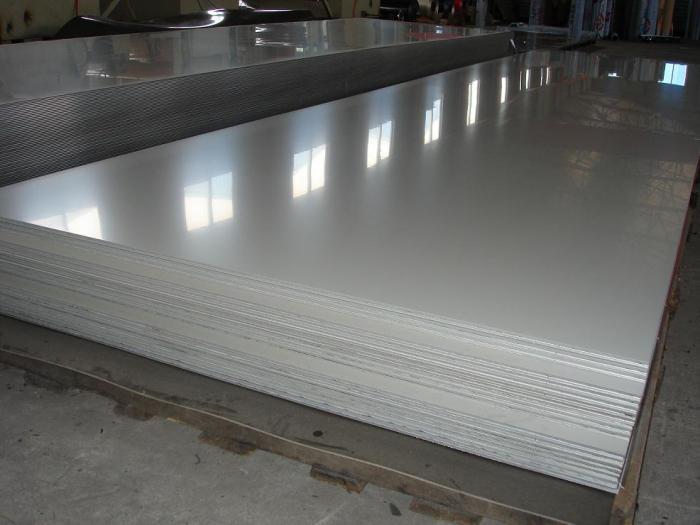

Leafy

Sheet finish is characterized by the largest dimensions. For laying on the walls, this is the least laborious option, as it covers a large area. The design can be very original:

- length - from 98 to 244 cm;

- width - from 50 to 122 cm;

- the thickness of the sheet material is usually less than - 3-6 mm. Otherwise, the mounting element is a sheet, it turns out too heavy.

On video - wall mounting pVC panels:

Installation

Due to its large ease of the PVC panel can be mounted directly on the wall, if it is smooth enough. In practice, such a method is used infrequently, since the installation on the frame has more advantages: better heat and sound insulation, there is no need to carefully align the walls, it is allowed not to remove the old finish - wallpapers, paint, and so on.

Construction of carcass

In housing, depending on the operating conditions of the room, three types of construction are used.

Installation of finishes

Volume required material Approximately determined by dividing the area of \u200b\u200bthe wall on the PVC product area - rail, plates or sheet. To reduce consumption, take into account the laying method - vertical, horizontal, diagonally. The result of calculations increases by 15% - errors when assembling or poor-quality panels in the batches are always possible.

Before installing, it is desirable to give the material to get used to the microclimate of the room - to withstand in the room for about a day.

In addition to the casing panels, you will need enough items. The inner corner is needed anyway, and also the starting and finishing profile, if the laying is made horizontally. To disguise the jacks between the wall and floor, the wall and the ceiling will need a plinth.

- Installation starts from the corner towards the opening - window or door. The first is installed inner corner.

- The lamella is cut down the length, the plates - depending on the laying method.

- Plastic lamella or tile are inserted into the corner profile and secured on the crate. You can use construction brackets, but the best option There are bellows - they are planted on the lower part of the groove, and the mount is made through the holes in the beammer. This method does not injure the panels and provides non-rigid fixation.

- All subsequent lamellas are installed in the usual way - spikes in the groove. The panels must be shy tight, so if necessary, a rubber hammer is used.

Seamless material requires careful fit and verification of the verticality of each lamella. Otherwise, the seams will be noticeable.

After the plating of the entire room, the jack between the floor and the wall is masked by a plinth. For sealing the seam between the ceiling and the wall use more decorative ceiling plinth. However, everything solves the design of the room, it is possible that you will need the same finish.

Manufacturers and prices

The manufacture of plastic finishes is a process from a technological point of view. Mostly the cost of products depends on the size and decor. However, there are exceptions if it comes to a special material. The choice is huge here.

A large range of PVC wall panels in Lerua Merlen.

The PVC panels are not in vain are considered one of the most popular methods of finishing both residential rooms and work premises. A variety of appearance and affordable cost allow you to update the rooms even with the most modest budget. Perhaps you will also be interested in what is part of mDF panels. The link describes. Also read. You can see photos of PVC wall panels for the bathroom, - photo of the corridor finishes with wall panels.

Despite a lot of variety finishing materialsPlastic panels are highly popular with the design of the premises. They have different parameters and appearance. Specifications Any type of this material is similar, as well as its installation.

Raw materials for the manufacture of plastic panels

This material is made of plastic dense structure. It is called different polyvinyl chloride. It has excellent operational properties and characteristics.

Varieties according to the method of application

To date, there are different plastic panels. Dimensions and prices also have differences. It all depends on the type of material. So, the PVC panels can be:

- wall;

- ceiling.

Some of the species of this material can be universal.

There are also some different differences. There are such wall plastic panels according to the method of closing the surface:

- reference;

- high.

Ceiling panels can only basic. They are used to decorate the walls.

The size of plastic panels for walls, which are used in the main decoration of the room, are:

- length - 2.5-3 m;

- width - 1-1.5 m;

- thickness - 0.8-1 cm.

The reference plastic panels have such parameters:

- width - 1-1.5-2 m;

- length - 1-1.3 m.

It should be noted that the dimensions of the plastic differ from the walls. They have a length of 2.5 and up to 4 m. The width reaches 10-50 cm. The most common parameters in the design of the ceiling surface are considered panels with a width of 25 cm and 4 m long.

Types of PVC panels

The size of the plastic panel depends on its type. There are several ways to make material. He can be:

- in the form of strips - plastic lining;

- sheets;

- in the form of plastic tiles.

The surface of plastic panels

To date, the design of PVC panels can be any. They can be only one shade and have a variety of interesting pictures. The surface itself also varies. It:

- matte or glossy;

- structured or smooth.

Specifications of PVC panels

Plastic panels Possess excellent properties. It is for this reason that they began to be used in the decoration of the room for a long time. Immediately the scope of the material was the kitchen area. Ceiling surfaces were performed by plastic clap. Over time, the lining began to be mounted on the wall. There is a wide range of its sizes and shades.

Advantages of plastic lining:

- moisture-resistant;

- practical;

- easy to install;

- durable;

- wear-resistant.

It is also worth noting the fire resistance of the material and its inability to be exposed to temperature differences. All this is due to the dense structure of the plastic. It has no pore.

Due to the fact that the main advantage of plastic panels is moisture resistance, they can be mounted indoors with high humidity. Only here there are certain rules according to which the surface preparation is carried out and the inner insulation of the room.

The practicality of plastic is due to the simplicity of care. Since the material is not able to absorb pollution, its surface is easily cleaned with a simple wet rag. For some surfaces, cleaning and detergent can be used.

Important. You should not use abrasive agents that can damage glossy plastic panels.

The service life of the panels reaches 80 years. It all depends on the material producer and the quality of products. For this reason, it is better to acquire plastic for finishing the premises only from proven sellers. It is worth noting that throughout the service life and proper care PVC panels do not change their external design. The surface does not fade into the sun, which makes it possible to use them in the finish of the facade of any structure. For this, specific panel parameters are selected.

The material also has simple installation. Works can be performed independently.

Dimensions of plastic panels in the form of lining

This type of material is most commonly used in the room decoration. It can be mounted on a special crate. The work process itself is rather simple. Conducted by these material parameters.

The size of the plastic panel in the form of a strip, which has a hollow structure, with certain ribbins, can be any.

Panel Width:

- 10 cm;

- 25 cm;

- 30 cm.

Length of material:

- 300 cm;

- 450 cm;

- 600 cm.

Panel thickness:

- 0.5 cm;

- 0.6 cm;

- 0.8 cm;

- 1 cm.

Important. These are most often selected such dimensions of plastic or bathroom: length - 300 cm, width - 25 cm, thickness 8 cm.

Plastic lining can be standard type and euro. Different materials are different only in their sizes. The structure itself and their production is the same. Eurostrights are considered to be panels that have large sizes and a certain number of edges in the hollow structure.

Note. The size of the plastic panel of the European standard in width reaches 50 cm, and in length - 5.5-6 m.

Dimensions of sheet PVC panels

In the design of such premises, like a living room, a bedroom, a kitchen area and other, a sheet panel plastic (PVC) is used. Its dimensions can be:

- length - 1.5-4.05 m;

- width - 0.8-2.03 m;

- thickness - 0.1-3 cm.

Sizes of plastic plates

No less often used PVC panels in the form of tiles. They can be mounted both on the wall surface and the ceiling.

Plastic Panel Size:

- 30x30 cm;

- 98x98 cm.

Depending on the size of the material, it is selected and methods for its installation.

Cost of material

Immediately it is worth noting that the cost of plastic panels depends not only on their size. The name of the manufacturer plays a big role. The more popular in the construction market, the more expensive the material will be.

The size of PVC panels also plays a big role. For example, the cost of plastic lining is installed for 1 square. m. But for sale leaf panels Possible and individually. Plastic in the form of plates is also valued per square meter.

To date, the average cost of plastic lining is 1-5 dollars. USA. Other prices are installed for sheet material - 10-60 dollars. US for a sheet. Plastic plates can have rates that range from 8 to 15 dollars. US for 1 square meters. m..

How to choose the desired size?

Initially, when choosing PVC panels, the premises parameters are taken into account. For example, for finishing walls that have a height of 2.75 m, it will be more logical to select a panel with a length of 3 or 4 m. You can give preference and plastic plates.

So, let's say, the width of the ceiling is 3 m. Accordingly, the selection of plastic panels can be based either on sheet materialOr on the lining. Sheets should be 1.5 m wide, and the lining - 30 cm. This will make it possible to completely close the surface and at the same time have a minimum of waste.

Types of fastening of plastic panels on any surface

To date, there are two ways to attach plastic panels on the surface:

- on the crate:

- on glue.

For example, the installation of plastic lining or leaf PVC panels can only be performed on the frame. Conducted by large sizes of material. They need to be securely secured on the crate.

The frame itself is made of wood or metal profiles. Its height depends on surface irregularities. On the frame structure, plastic panels can be mounted self-staples or stapler.

Only plastic panels in the form of plates are fixed on glue in most cases. Pre-surface is prepared: it is leveled, cleared and processed by special means. Glued panels close.

You can glue on the surface and other types of plastic panels that have large sizes. Only at the same time it is necessary to initially project the surface adhesive solutionTo ensure its clutch with the material.

When repairing in wet premises, many are chosen as a facing material PVC panel, the size and design of which make it possible to create predominant presentable surfaces. The most in demand plastic panels for decoration of such premises, like a bathroom, toilet, kitchen, corridor and balcony. Quite often, PVC panels are used for the inner and external finishing of street buildings. Facing stalls, shops, warehouses and sheds by this material, takes a little time and significantly saves funds.

Device and properties of plastic panels

Plastic panels are made of polyvinyl chloride by extrusion.

Products consist of two plates interconnected rigids. One of their plates is the front side, which has a decor corresponding to the developed model. PVC panels are specifically made so that their connection is durable and imperceptible. For this, their side edges are equipped with protrusions and grooves.

Plastic panels possess such advantages:

- Presentable appearance. Modern design allowed creating surfaces with a high artistic component.

- Waterproof. Polymer rails do not absorb moisture and resistant to mold.

- Sufficient mechanical strength. This factor makes it possible to wash the finished planes using a specific pressure.

- Flexibility that avoids breakdowns during transportation and installation.

- Low specific gravity. The carrier surface does not turn out to be an additional load.

- A variety of parameters, textures and color gamut products. This quality makes it possible to deploy fancy designers.

- Environmental purity. PVC panels can be used in any premises, including in hospital wards and kindergartens.

- Easy processing and installation. You can cut the material by an ordinary stationery knife.

- The ability to disassemble the finished surface. It will be useful if you need to access communications or to replace fragments suspended ceiling or walls.

- Non-hatching. The material does not support burning.

- Low price. Plastic products are available to all segments of the population.

- Durability. Plastic panels installed indoors can serve several dozen years. Large range of operating temperature. Products do not lose their qualities, both in the frost and in the hot medium.

Large demand and distribution received panels of such sizes.

Large demand and distribution received panels of such sizes. Plastic panels have certain disadvantages, which are that their surface can be easily scratched or selling. In addition, the material is deformed and melted from strong heating.

Plastic panel parameters

PVC panels are usually used to finish the ceiling. But there are wall plastic panels used to cover vertical surfaces.

The size of plastic panels is quite diverse:

- The length of the panels is 270, 300, 595 and 1200 cm. This allows you to finish the surface of a large area without junctions. The most common plastic panels have a length of 595 cm. They are suitable for both apartments and large premises. For the convenience of transporting the panel are cut on the desired segments at the place of sale.

- The width of the products varies from 10 cm to 50 cm. As a rule, the rails are 10 cm wide and 12.5 cm have a visible connection. They mimic wooden lining. With a width of 18 cm and more, almost invisible slit remains at the jock. The most common PVC panels are 25 cm wide. They are quite easily bent and do not create excessively frequent seams.

- The thickness depends on the purpose. Plastic ceiling panels have a thickness of 5 mm to 8 mm. For them, strength does not matter. Wall products have a large thickness and the number of rigidity ribs. This allows them to confront the shocks that can be applied by negligence along their surface.

For connection and attachment of the rails, profiles from PVC are manufactured, the dimensions of which are adapted to their parameters. Various profile models have a length of 270 cm to 600 cm. The size of the opening corresponds to the thickness of the facing material.

Decor of plastic panels

Since all rooms have a certain interior and configuration, not every facing is suitable for their finish. Before purchasing goods, it is worth familiar with his varieties.

The surface texture at PVC panels is this:

- Glossy. A similar surface looks pretty presentable. It has a good reflective surface. Glossy ceilings Perfectly look like in utility rooms and in residential rooms. A certain minus are divorces that remain on the glossy surface.

- Matte. Such material is used by adherents of classics for lining of their housing. Since such plastic has a low cost, it is widely used to decorate economic objects and utility premises in the field of trade.

- Textural. Embossing on the surface gives the ceiling its character and individuality. As a rule, various ornaments and symmetric patterns are used.

Pretty large color gamut of this product. Coloring panels can be the most diverse.

Manufacturers offer such coloring options:

- White. This color is the most versatile. It fits well in the premises of any type.

- The black. Used to separate planes and creating contrast effect.

- Color. It is carried out by applying a monochrome kaper or blurred combinations of several shades.

- Under the tree, stone, skin and other materials. Such models look quite elegantly and exotic.

- With drawing. Sky, flowers, insects and animals can be depicted on the panels.

- Panel. A single image is collected from several fragments. The picture can be applied by the usual or holographic way.

Such models will satisfy the most refined taste.

Related records: