The bulk weight of gravel. How much weighs the cube cube depending on the fraction

In this article, consider how much weighs the cube cube. Crushed stone is a bulk material obtained as a result of crushing rocks, boulders and gravel.

Most often it is used in construction (for example, for the manufacture of concrete) or to create a road mound. The purpose of rubble can be completely different depending on its properties and a number of other indicators.

How to calculate a mass of cubic meter rubble

Moreover, even having information and after performing all complex calculations, the calculated mass will not be accurate - the weight of the crubbed cube value is approximate.

Therefore, you can familiarize yourself with the Dependency Table approximate mass cubeble cube from his appearance.

| Type of rubble | Cubic meter mass, kg |

| Granite crusp | 1470 |

| Tercular crusp | 1150 |

| Tufy crusp | 800 |

| Marble crusp | 1500 |

| Limestone crusp | 1300 |

| Slag crusheden. | 1500 |

In order to answer the main question " how much weighs the cube cube? ", It is necessary to consider a group of properties that affect the mass of the cubic meter of rubble.

1) The main of these properties is the rubble fraction. Under the fraction is meant the maximum allowable size of a single stone or grain. That is, according to the laws of physics, the smaller the size of the grain, the smaller between them the distance and the more weigh the cubeble cubic meter.

There are two types of fractions, each of which includes several sizes of individual stones:

- Standard fractions:

- 3-8 mm in diameter (also this fraction is called eurochepan);

- 5-10 mm in diameter;

- 5-20 mm in diameter;

- 10-20 mm in diameter;

- 20-40 mm in diameter;

- 25-60 mm in diameter;

- 20-70 mm in diameter;

- 40-70 mm in diameter.

- Non-standard fractions:

- 10-15 mm in diameter;

- 15-20 mm in diameter;

- 70-120 mm in diameter;

- 100-300 mm in diameter.

2) An equally important property is a type of rock, that is, the material from which crushed stone is obtained after crushing.

So, cubic meter rubbishobtained from more dense mountain breeds, weighs more than the same rubble cubic meter obtained from porous material.

The variety of varieties of crushed stone is primarily determined by the fact that there are many rocks, of which this chitter can be made. The most popular materials to obtain rubbish are:

- Granite. It is considered one of the most durable rocks, used in the construction of houses, road highways and railway tracks.

- Gravel. Gravel crusp less durable than granite. Used for the manufacture of foundations, concrete and roads.

- Limestone. Used in road construction and in the manufacture of reinforced concrete structures.

- Building trash (bricks, concrete, asphalt) is used to create a secondary rubble. It is used in strengthening soils, in road works and in the manufacture of concrete.

- Metallurgical slags. Crushed stone from them applied in road construction and in the manufacture of concrete.

Less common areas, marble and touched crushed stone.

3) the third important property of rubble - his beshech. Beshech is called the percentage of the total mass of rubble, which reflects the content of flat and needle grains in it.

4) The shape of the rubble also plays a role. There are three main forms:

- Cuboid;

- Improved;

- Normal.

The most advantageous option is a cuboid rubble, since it is precisely with this form of grain that the "empty" space remains.

5) Water absorption also plays an important role in the calculation of the mass of the cubic meter of rubble. So, crushed stone obtained from porous rocks is able to absorb up to 10% moisturewhich has a property evaporate.

Due to these processes (absorbing rubble moisture and its evaporation), the mass of the cubic meter of rubble in different weather conditions can vary significantly.

I hope you liked the detailed answer

One of the most necessary building materials - Crushed stone, refers to the so-called bulk substances, the units of which are determined by the volume. Depending on the physical characteristics, the origin and size of the particles, the crushed stone will have different weight With an equal volume, so in construction it is important to properly translate the volume into the mass and vice versa. You can give a hint how to do this, as well as a brief excursion for the main types of this material and the areas of its use you can find in this article.

You can analyze and distinguish this material in several indicators. Firstly, this is its origin. Rubble happens granite, gravel and limestone. As already clear from the name, granite crushed stone produced by crushing rocks. Its density will be the maximum in the area of \u200b\u200b2600 kg / m³.

Gravel crushed stone is less durable, but also often used in construction industry. A lime variety has minimal strength and density among them, therefore it is used mainly to create plates and building blocks, where relatively light weight will be an advantage.

To find out the weight of the cubic meter of the material, it is necessary to analyze the following indicators:

- Density of material It is determined by its origin, for the granite rubble it will be the highest possible indicator. The density of granite rubble - the value is not constant, because during production remnants of ore mines can be used, as well as stronger and heavy quartz rocks.

- Volume weight It takes into account the porous structure of rubble, so this indicator will be slightly lower than the previous one.

- Bulk weight It is characterized by a more real criterion, because the distances between the stones in the container were taken into account. Volumetric weight depends not on the density, but on the size of the stones.

On the video tells how much the cube cube weighs:

Approximate data is reduced to the table, when calculating you can use these numbers.

And the features of its application is indicated in this article.

The main indicators of the type of rubble:

In the comprehensive calculation, it is better to take into account other indicators of this material. Main criteria Consider further.

Application of material

In industrial construction, granite crushed stone is commonly used, which is advantageous with high strength characteristics. From the type of structures and destination, it may be advisable to use lighter and affordable types of this material.

Main spheres of crushed stone in construction:

- Concrete solutions of various purposes: from monolithic foundations, before the formation of individual pension and gas blocks.

- Road construction: for substrate asphalt and paving pedestrian sidewalks. Even when creating a conventional garden track, this material is used.

- Formation of ripples of railways.

- For running races at airports.

- Drainage and hydraulic structures.

- Landscape design: creation of decorative embankments and flower, artificial reservoirs.

As can be seen, the use of rubble is wide, especially since the variety of forms and colors will allow to use even in decorative purposes. The main purpose of such a material is the strengthening of concrete solutions is successfully used in house construction.

Concrete from cement M 400, proportions of the mixture:

| No. P / P: | Brand concrete: | Concrete volume, l: | ||||

| Rubble, kg: | Sand, kg: | Rubble, l: | Sand, l: | |||

| 1. | 100 | 70 | 46 | 61 | 41 | 78 |

| 2. | 150 | 57 | 35 | 50 | 32 | 64 |

| 3. | 200 | 48 | 28 | 42 | 25 | 54 |

| 4. | 250 | 39 | 21 | 34 | 19 | 43 |

| 5. | 300 | 37 | 19 | 32 | 17 | 41 |

| 6. | 400 | 27 | 12 | 24 | 11 | 31 |

| 7. | 450 | 25 | 11 | 22 | 10 | 29 |

Concrete from cement M 500, the proportions of the mixture:

| No. P / P: | Brand concrete: | Mass composition for 10 kg cement: | Volume composition for 10 liters of cement: | Concrete volume, l: | ||

| Rubble, kg: | Sand, kg: | Rubble, l: | Sand, l: | |||

| 1. | 100 | 81 | 58 | 71 | 53 | 90 |

| 2. | 150 | 66 | 45 | 58 | 40 | 73 |

| 3. | 200 | 56 | 35 | 49 | 32 | 62 |

| 4. | 250 | 45 | 26 | 39 | 24 | 50 |

| 5. | 300 | 43 | 24 | 37 | 22 | 47 |

| 6. | 400 | 32 | 16 | 28 | 14 | 36 |

| 7. | 450 | 29 | 14 | 25 | 12 | 32 |

The finished concrete makeup is distinguished by a fortress and durability, an important role in which solid fillers play: sand and crushed stone of various fractions.

Physical characteristics and cost of expense

The varieties of this material are not limited to the three types listed above. There is also gradation on rocking, career and sedimentary rocks, as well as a separate type of rubble - recycled from the waste of building materials: bricks, concrete or asphalt.

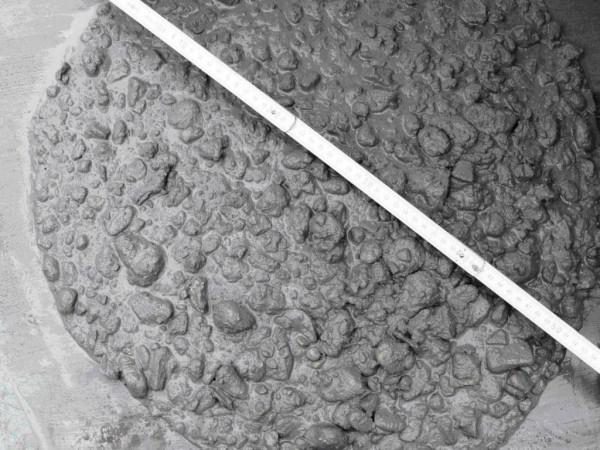

Crushed stone is also characterized by configurations, if we take into account the method of obtaining from mountain and limestone rocks, the stone will have many sharp edges and plate components. On the other hand, if we take into account the production of crushed stone obtained from stones that were constantly in contact with water, rounded forms of such a material will be more suitable for decorative purposes.

The magnitude of the prevailing amount of rubble in the mixture is distinguished:

- The smallest particles, the average size of which is not more than 5 mm - screening.

- Middle crushed stone with a fraction from 5 to 25 mm.

- Large type of rubble, stones size from 25 to 40 mm.

The main thing is that it is necessary to find out before buying this fraction of rubble, from which the bulk volume and mass will depend on. If you need to quickly calculate how much rubble is added to the cement mortar, you can use the following table.

Rubble consumption on m³:

| No. P / P: | Fraction size, mm: | Required quantity, kg / m³: |

| 1. | From 0 to 5. | 1500 |

| 2. | From 0 to 40. | 1530 |

| 3. | From 3 to 10. | 1450 |

| 4. | From 5 to 20. | 1370 |

| 5. | From 20 to 40. | 1410 |

| 6. | From 20 to 60. | 1450 |

| 7. | From 20 to 60. | 1480 |

| 8. | From 20 to 90. | 1470 |

| 9. | From 40 to 70. | 1600 |

Similar figures, of course, approximate, as well as any company will not be able to reliably handle the homogeneity of the size of the stone particles. These data will help to navigate when forming cement solutionsBut there is a special category - a decorative crushed stone, commonly used for finishing floors of floors, for example, in corridors of public places. For such a case, it is necessary to accurately calculate the level of rubble per square, so the previous table is not useful here.

Decistance of decorative rubble per 1 m²:

| No. P / P: | Fraction size, mm: | Bulk mass, kg / l: | Thickness of the finished layer, mm: | Required quantity, kg: |

| 1. | From 3 to 5 mm. | 1,3 | 20 | 26 |

| 40 - 50 | 65 | |||

| 80 - 100 | 130 | |||

| 2. | From 5 to 10 mm. | 1,4 | 20 | 28 |

| 40 - 50 | 65 | |||

| 80 - 100 | 130 | |||

| 3. | From 10 to 20 mm. | 1,5 | 20 | 30 |

| 40 - 50 | 75 | |||

| 80 - 100 | 150 | |||

| 4. | From 20 to 40 mm. | 1,65 | 40 - 50 | 82 |

| 80 - 100 | 165 |

A characteristic feature of this material will be a huge range of colors, so any combination will be appropriate and beautiful. The formation of the finishing layer requires more skill of the artist, therefore the accuracy of calculations here will be more important.

The main rule of successful construction is a good choice of building materials. The advice of our article will help you choose the optimal type of rubble, and also to calculate its required quantity in advance.

Granite has a rather dense structure. Due to this, the strength of rubble from this rock breed Has a high indicator. In the production of high-strength concrete and products from it, a granite stone is used, which gives additional weight material.

In order to correctly and on time to organize the supply of granite rubble to production or construction object, it requires the correct calculation of the transport capacity and the number of equipment units.

First of all, you need to know how much weighs the cube cubeTo prevent the car's advantage or another type of transport. To calculate the weight, this indicator is needed such as the bulk density of the granite rubble. This value characterizes the ratio of the material volume, to its weight, including external and internal voids.

For granite rubble, the volume of volume weight depends on its fractional composition. The larger the grain, the smaller the value of the volume weight. This can be determined on a small experience.

Experimental way to transfer cubes in tons

Take a liter jar or other container into which you first embark on crushed stone with a large grain. After that, weigh the hitch. Then, empty the jar and fill it with a material with a shallow fraction, and weigh again. According to the results of weighing, it can be understood that the container with a large stone weighs less, since the increased grain size takes more space, leaving among themselves aircraft emptiness. From here, this conclusion can be made that the larger the grain fraction, the smaller the bulk weight of the material.

Knowing an indicator bulk density, It is possible to calculate how much 1 cube rubble weighs, for this you need to multiply both values. For example, the bulk density of the aggregate 1600 kg / m³, therefore, cube rubble weighs 1600 kg. Suppose it is required to purchase in 15 cubes. You can first learn from the supplier of rubble about the value of bulk density. If, for example, this digit is equal to 1550 kg / m³, which means 15 x 1550 \u003d 17250 kg of material. Therefore, a dump truck is required with a carrying capacity of at least 17 tons.

Applied in practice the value of the mass of rubble

Most often, when translation of rubble from cubes in tonsThe developers apply the average value of the bulk mass of the material that ranges from 1500 to 1600 kg / m³. Although it is better to use the laboratory indicator found at the production and processing of granite.

Technology and laboratory workers on manufacturing factories concrete mix and reinforced concrete products, also conduct tests to determine the bulk density of the aggregate. Plant technologist It is necessary to know the rules for the transfer of crushed stone cubes into tons to calculate the dosing of materials on the production of concrete. When moving from winter dosage, this indicator is also taken into account.

One of the difficult moments in construction is the calculation of materials. And very often in construction used crushed stone different markswhose cube needs to be calculated. And for this you need to know the tabular data. We save you from this difficult operation by entering data into a calculator, which in a few seconds will calculate you all.

So, we present to you the calculator, which by the way will calculate the sand (construction, river). To calculate the volume of rubble (or other bulk material to choose from), its masses, enter the data into the calculator below:

While there is a calculation, you can watch advertising, as well as read comments below.

Did you like the calculator? Or helped? Click the like on the right or save on the wall for yourself and friends, maybe they are also looking for this information or come in handy later.

Where to find out how much 1 cube rubble, 1 cube sand, 1 cube gravel or other bulk building material?

Below we will give a sheet of specific weight with bulk materials based on which the calculator was performed. You can use it, to control the calculations or self-calculation according to your own task.

| Name of bulk material | Weight material in 1m3, kg |

Bucket weight (12 l), kg |

|---|---|---|

| Construction Sand (GOST 8736-93) | 1550-1700 | 18,5-20,4 |

| River sand | 1630 | 19,5 |

| PGS - sand-gravel mixture | 1600 | 19 |

| Gravel | 1400 | 17 |

| Ceramzit | 250-800 | 3-9,6 |

| Crushed stone granitis | 1470 | 17,5 |

| Crushed stone sandstone | 1300 | 15,5 |

| Terricon crushed stone | 1150 | 14 |

| Crushed stone tuffs | 800 | 9,5 |

| Crushed stone marble | 1500 | 18 |

| Crusp limestone | 1300 | 15,5 |

| Slag crushed stone | 1500 | 18 |

| Lime Gashenaya | 2210 | 26,5 |

| Lime Negashoye | 3370 | 40 |

| Gypsum | 2200-2400 | 26,5-29 |

| Cement | 1300 | 15,6 |

| Varrimikulite strolled (GOST 12865-67) | 100-200 | 1,2-2,4 |

| Clay Valyal (Floridine) | 670 | 8 |

| Clay wet (removed shovel) | 1600 | 19,2 |

| Clay wet (removed by excavator) | 1820 | 21,84 |

| Clay refractory (shamot, 20 "c) | 1600-1900 | 19,2-22,8 |

| Clay dry rammed | 1750 | 21 |

| Clay dry (removed shovel) | 1070 | 12,8 |

| Clay dry (removed by excavator) | 1090 | 13,08 |

| Chernozem (removed by excavator) | 1400 | 16,8 |

| Chernozem (arable layer 0-30cm) | 1000-1200 | 12-14,4 |

And maybe you are interested in how much the rubble bucket weighs? Even such a small volume is specified in Table 1 for convenience and in our calculator above. The only difference, the volume of the bucket in the table - 12 liters, and the volume of the bucket in the calculator - 10l.

If vibrotambovka or rink is running, then the coefficient of sealing the bulk building material is 1.3

There were still questions, how to calculate the volume of rubble? Write your comment below, we are interested. And also, maybe there are ideas how to modify the calculator so that the calculations are even more comfortable.Write. Share a page with friends in the social network, click Like below! By this, thanks for this, and we still develop useful things, watching the growth of likes.

Small crushed stone from solid rocks is one of the widespread building materials. Its properties determine the strength and manufacturability of the erected structures, buildings and roads.

The physical characteristics of the rubble defining the amount of weight units of the bulk material in a single volume is called specific weight. Nutally determined by υ division value of the weight P of rubble in a certain volume, by the value of this volume V.

Υ \u003d p / v

Units of measuring specific gravity are Newton / meter cubic N / m3. Do not be confused specific gravity rubble with its density.

The proportion takes into account the presence of voids between the grains of a bulk material. This characteristic allows you to accurately determine the weight of the rubble in a freely satched state.

It is influenced by technological and natural factors. The crushed stone deposits are distinguished by the mineralogical composition and density of rock. Atmospheric humidity and surroundings in places of production and storage increases rubble weight. The size of the fractions and the leachy of rubble affects the density of the contact of the grains and change the weight of rubble.

Due to the impermanentness of the values \u200b\u200bof the share of the rubble, it is impossible to create tables in advance with the exact values \u200b\u200bof this characteristic. Therefore, it is recommended to calculate the proportion for each case separately, or clarify the value from the supplier, or check in the rubble certificate.

The importance of this characteristic is undeniable when calculating need quantity Materials are for both concrete mix, because the more specific weight, the less the consumption of cement, and for the sinking of a certain volume of the crushed stone layer in the base of the foundation or road. Knowing the proportion of rubble and carrying capacity can also be calculated by the need for transportation and place for storage of rubble.

The proportion is often confused with density. Mixing concepts occurs due to the non-strict use of words in those areas where the discrepancy between these concepts is not fundamentally, and their numerical values \u200b\u200bcoincide.

The characteristic takes into account the presence of emptiness in the material. Specific densityFor bulk materials, the amount of voids between the grains of rubble characterizes the amount of voids between the grains of rubble, the value of which P, calculated as the division of the mass M of the rubble on its volume V.

P \u003d M / V

Units of measurement of bulk density are kilogram / meter cubic kg / m³.

The bulk density of rubble on average, without clarification by fractions, is 1.38 t / m3. In the calculations, it is very convenient to use a bulk weight to determine and transported volume of rubble, its average value for rubble is 1.6 t / m3. This means that 1 cubic volume meter accommodates 1.6 tons of rubble.

Table of bulk density of discraining and fractions of granite rubble:

The exact values \u200b\u200bof the bulk-density of the rubble are indicated in the quality certificate of rubble.