Print foam plastic to concrete. What can be glued to concrete and other materials for concrete?

If concrete buildings have long been famous for its fortress and durability, then heat insulating properties They, unfortunately, are low. The lists of foam solid and industrial designs are solved easily and efficiently this problem. But what kind of difficulty - you need to know exactly what can be glued to the foam to concrete, because this material is afraid of solvents, gasoline or acetone. Here we will look at the best adhesives that are used in assembly work with this excellent material.

How to glue foam to concrete?

- Cleaning mixture of dry powder. There are special adhesives for polystyrene foam slabs (PPS moment, DOBS therm Fix, adhesive for the foam of AnsergLob BCX 39 and others). Also suitable for foam plastic The facade glue and adhesive tiles from ceramics. You will need an additional tool - drill, nozzle, spatulas, buckets. The operating time here is somewhat limited, it does not exceed 2 hours, after which the solution becomes viscous. It is not recommended to dilute it with liquid.

- Silicone sealants or liquid nails. These adhesives are supplied in tubes, for working with mounting guns. They strongly quickly (about 30 minutes), have a good heat resistance and moisture resistance. Due to the fact that the sealant includes harmful components, you will have to work in gloves. This method is suitable for exclusively smooth surfaces.

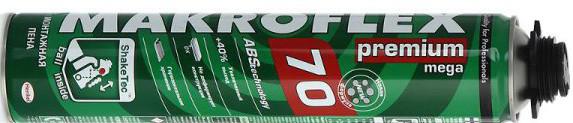

- Glue-foam in cylinders. You can use Ceresit CT 84, Insta Stik adhesive for foam.

- Montagefix-St. other. Additional tools with this method - a mounting gun and a special flushing-cleaner. Considering all the ways how to glue the foam to the ceiling, one can state that this method is almost perfect. The cylinder of high-quality foam will replace the bag of glue, and it is easier to work with it. In addition, it will exceed all the gaps and joints, ensuring better thermal insulation. One disadvantage of foam - the value of the material is higher than in powder compositions.

Almost all listed methods than to glue the foam to concrete to the ceiling can be used in our business. The difference is here in the cost and convenience of work. The only condition is fixed for the reliability of the lips of the umbrellas with dowels, and the gaps and joints arising with adhesive compositions. The reinforcing grid is applied, which is attached to a special solution, and only then the finish

Concrete is very popular and common construction material. New technologies allow you to build buildings of any floor, complexity and configuration with amazing speed. Help in this and mixtures on adhesive basis. It is more difficult to put on the solution than to glue. Concrete to concrete adjacent tight and reliably.

For the subsequent decoration of buildings apply the most different materials. To secure them on concrete surfaces, adhesive materials are also used. The benefits are obvious: they are comfortable in work, less expensive than any other fastener, serve simultaneously and waterproofing, and most importantly - do not physically destroy concrete.

Walling

The presence of a variety of and very reliable adhesives in the market contributes to the development of new technologies in construction. The construction of rapidly contaminated houses from glue gas blocks makes it possible to reduce the construction time and the cost of making a solution.

The question of how to glue concrete to concrete does not cause big problems. Offers of producers of numerous adhesives with excellent waterproof properties allows you to make right choice. Using glue helps to avoid the appearance of "cold bridges". And this in the future saves the owners of housing heating costs up to 30%.

In order to answer the question of how to glue concrete to concrete, climatic conditions should be taken into account. In their characteristics adhesive mixes Can withstand a fairly low temperature, but some of them are used only for the construction of the inner walls.

Another unconditional plus when using glue is an aesthetic look of the wall. After its construction from gas blocks, additional finishes are not required, the seams are almost imperceptible.

Adhesives on the basis are not afraid of aggressive media, exposure to moisture and other unfavorable conditions. When the production workshops are erected with similar characteristics, the question of how to glue concrete to concrete can be solved quickly.

Work with foam

Which only buildings and facilities are not insulated today by foam! Even old, long-built structures can be insulated with this light, durable material with excellent thermal insulation properties.

Before sticking the foam to concretely any other surface, it should be carefully cleaned from dirt and, if necessary, align. It is important to choose glue.

The easiest and reliable will be the use of universal glue, specially designed for foam. It provides a reliable clutch of plates with concrete. To enhance the effect, experts advise to apply notches on the surface of the foam. Convenient packaging in the form of cylinders allows economically to use glue. It is applied by stripes at a distance of up to 30 cm.

You can use and apply a special modification for concrete walls.

It is not recommended to glue the "moment" brand with glue, it will destroy the stove. It will not be possible to plant insulation and plaster, he just falls off. To solving the question of how to glue foam to concrete, it is necessary to approach very carefully.

How to glue penplex

So what to glue the penplex to concrete? There are several options:

Printing polystyrene foam

Cold concrete walls are durable, but cannot ensure the preservation of heat in the room. To eliminate this disadvantage, the technology of wall insulation is used.

Popular material for insulation is the polystyrene foam. The ease of installation makes its use attractive. The ability to fix polystyrene foam to concrete without the use of auxiliary fasteners, and only with the help of glue, significantly reduces the costs of work.

Two types of glue are used: specialized and universal. What to glue expanding polystyrene to concrete depends mainly on the variety and brand of insulation. Extruded expanded polystyrene can only be glued with specialized glue. For other species, universal glue is well suited.

The right choice of adhesive composition is very important. It is dangerous to conduct experiments on the introduction of new components or the use of the product of unknown origin. Chemical components of glue can be aggressive with respect to polystyrene foam and simply dissolve it.

Before starting work, the concrete surface is prepared: clean, plastering and ground.

Linoleum

Very convenient and reliably fix linoleum on glue. How to glue the linoleum to concrete, will prompt the store managers, where the flooring will be purchased. Linoleum producers strongly recommend glue to buy with it.

Usually linoleum is fixed on concrete with mastic. Her advantages:

- You can choose the desired quality, in accordance with the type of linoleum. The tissue base of the linoleum requires the use of dispersion glue, and in the absence of the base, use synthetic mastic.

- The compositions of all adhesives have excellent characteristics of waterproofing properties, strength, water resistance.

- Sustainable environmental impact.

In addition to its composition, mastic is different in their intended purpose. There is a mastic for fixing, which has increased stickiness and economical flow, and the one that should be applied to the floor to a flat layer throughout the area for continuous gluing. The thickness of the layer depends on the brand of mastic.

Features of using glue

There are several nuances when using adhesive-based mixtures. These include:

- mandatory fixation within a few minutes of glued surfaces;

- flammability and toxicity of adhesive mixtures;

- before the surface of the surface must be aligned, cleaned, and, if necessary, and treated with a special impregnation;

- rapidly frozen material requires practical experience and accurate adhesive dosage.

Such material as polystyrene foam is becoming increasingly popular, since it is inexpensive and very effective insulation. In this regard, many materials lose expanded polystyrene foam. It should be noted that it is also not a complicated thing to glue, it is for everyone. If the polystyrene foam is planned to be glued to the outside of the building, it is very important here that the adhesive agent has such quality as frost resistance (especially this is true in those regions of the country where frosts are frequent natural phenomenon).

Scheme of insulation of facades polystyrene foam

The question of how to glue foam to concrete is very relevant because such material is becoming increasingly popular due to its unique qualities.

Glue polystyrene foam can be different waysIt is important to consider when choosing different nuances.

The scheme of insulation house expanded polystyrene

For gluing foam, you need the following:

- special adhesive for foam (you can take glue for ceramic tile or "liquid nails");

- the spatula (will be needed if it is necessary to make a putty wall);

- as an alternative to glue, you can use a special foam.

As you know, the walls of the concrete are cold, it means that they need insulation, in this regard it is difficult to find the material better than the polystyrene foam. In order for such a material to be stuffed with concrete, it is necessary to pre-prepare a concrete wall for this, it must be carefully cleaned from different types of pollution, old solutions, and the like. Only in this case the adhesion will give the desired effect. It happens that the wall on which the foam is placed is planned, has a large number of different defects. Then it must be placed ( sand-cement For this it is suitable as it is impossible), and then you need to treat everything with impregnation.

Printing special foam

Facade insulation scheme

The methods of gluing foam plastic to concrete there is a lot, but one of the most common is a special foam in order to glue expanding polystyrene foam. Such foam contains basic polyurethane, it is available in special mounting cylinders. If you plan to use such cylinders, then before this you need to purchase a special flushing, thanks to which the composition in the tube will not dry. Polyurethane mixture has several advantages:

- installation is carried out quickly and without any difficulties;

- the adhesion of sheets and foam balls with a concrete surface is carried out as high quality as possible;

- the cost of such installation is low;

- you can handle the seams between each concrete slab if the distance between the plates does not exceed 2 mm.

However, if such a glitter is selected, maximum caution should be observed, since if such a foam falls into the eye, it can lead to the most negative consequences.

If you need to glue polystyrene foam to concrete, it should be borne in mind that today is not one-tent of the stamps of such material, they have differences in hardness and density. The polystyrene foam today is given proper, so its varieties are becoming more and more. In this regard, when choosing a adhesive, it is necessary to take into account what brand the polystyrene foam will be glued.

Mounting by other means

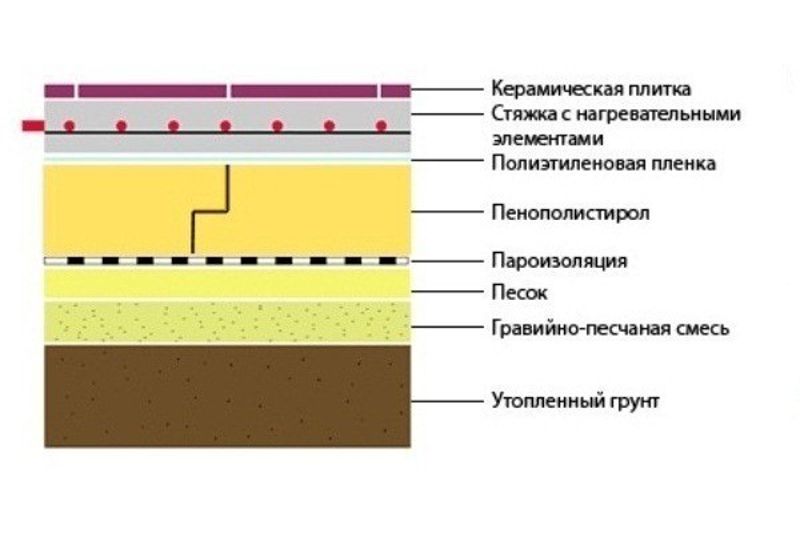

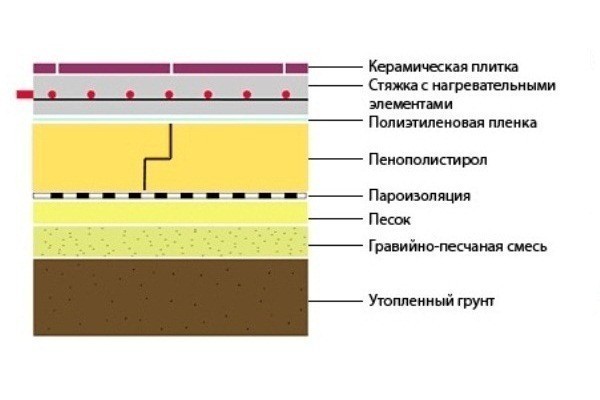

Floor insulation scheme polystyrene

You can use glue, which is specifically produced for foam plastic, the facade glue is suitable, which is characterized in that the racks to frosts, adhesive mixtures for ceramic tiles are also suitable. It is possible to take sealant from silicone as adhesive tools, liquid nails for walls are suitable. It is very important to take into account the following circumstance: whatever adhesive means is used, it should in no case contain acetone, gasoline and other organic solvents that affect the polystylene.

Foam sheets are glued in a chess order, it is necessary to begin glue from the bottom up. As for the amount of glue, it is not worth saving on it, it should cover at least 40 percent of the surface of the sheet. When the gluing process is carried out, it is important to ensure that air stoppers do not occur (it sometimes happens when the wallpaper is glued). Foam sheets, when glued, should be most tightly pressed to each other, they must also be tightly pressed to the surface of the concrete wall. At the same time, it should be borne in mind that the joints should not be sized between sheets, they can then be filled with sealant.

It is not necessary to use the "moment" glue, which not only does not stick to the polystyrene foam, but also can spoil it. In order to glue such a material to the concrete surface, it is necessary to apply 5 portions of glue in different places on it (the most common option is in every corner for serving and one in the middle). If you need to increase the service life, you can still stick with dowels with umbrellas. But in this case, you need to wait as much time as it is necessary in order for the composition to reduce.

After the polystyrene foam will be passed onto the concrete, it is very important not to touch the sheets, otherwise it is possible to move individual elements even before everything finally dries.

Such a material as a polystyrene foam is becoming increasingly popular, since it is inexpensive and very effective insulation. In this regard, many materials lose expanded polystyrene foam. It should be noted that it is also not a complicated thing to glue, it is for everyone. If the polystyrene foam is planned to be glued to the outside of the building, it is very important here that the adhesive agent has such quality as frost resistance (especially this is true in those regions of the country where frosts are frequent natural phenomenon).

The question of how to glue foam to concrete is very relevant because such material is becoming increasingly popular due to its unique qualities.

You can glue polystyrene foam in different ways, it is important to consider when choosing different nuances.

For gluing foam, you need the following:

- special adhesive for foam (you can take glue for ceramic tiles or "liquid nails");

- the spatula (will be needed if it is necessary to make a putty wall);

- as an alternative to glue, you can use a special foam.

As you know, the walls of the concrete are cold, it means that they need insulation, in this regard it is difficult to find the material better than the polystyrene foam. In order for such a material to be stuffed with concrete, it is necessary to pre-prepare a concrete wall for this, it must be carefully cleaned from different types of pollution, old solutions, and the like. Only in this case the adhesion will give the desired effect. It happens that the wall on which the foam is placed is planned, has a large number of different defects. Then it must be placed (the sand-cement solution is suitable for this, it is not better), and then you need to handle impregnating everything.

Printing special foam

The methods of gluing foam plastic to concrete there is a lot, but one of the most common is a special foam in order to glue expanding polystyrene foam. Such foam contains basic polyurethane, it is available in special mounting cylinders. If you plan to use such cylinders, then before this you need to purchase a special flushing, thanks to which the composition in the tube will not dry. Polyurethane mixture has several advantages:

- installation is carried out quickly and without any difficulties;

- the adhesion of the foam with a concrete surface is made as high quality as possible;

- the cost of such installation is low;

- you can handle the seams between each concrete slab if the distance between the plates does not exceed 2 mm.

However, if such a glitter is selected, maximum caution should be observed, since if such a foam falls into the eye, it can lead to the most negative consequences.

If you need to glue polystyrene foam to concrete, it should be borne in mind that today is not one-tent of the stamps of such material, they have differences in hardness and density. The polystyrene foam today is given proper, so its varieties are becoming more and more. In this regard, when choosing a adhesive, it is necessary to take into account what brand the polystyrene foam will be glued.

Mounting by other means

You can use glue, which is specifically produced for foam plastic, the facade glue is suitable, which is characterized in that the racks to frosts, adhesive mixtures for ceramic tiles are also suitable. It is possible to take sealant from silicone as adhesive tools, liquid nails for walls are suitable. It is very important to take into account the following circumstance: whatever adhesive means is used, it should in no case contain acetone, gasoline and other organic solvents that affect the polystylene.

Foam sheets are glued in a chess order, it is necessary to begin glue from the bottom up. As for the amount of glue, it is not worth saving on it, it should cover at least 40 percent of the surface of the sheet. When the gluing process is carried out, it is important to ensure that air stoppers do not occur (it sometimes happens when the wallpaper is glued). Foam sheets, when glued, should be most tightly pressed to each other, they must also be tightly pressed to the surface of the concrete wall. At the same time, it should be borne in mind that the joints should not be sized between sheets, they can then be filled with sealant.

It is not necessary to use the "moment" glue, which not only does not stick to the polystyrene foam, but also can spoil it. In order to glue such a material to the concrete surface, it is necessary to apply 5 portions of glue in different places on it (the most common option is in every corner for serving and one in the middle). If you need to increase the service life, you can still stick with dowels with umbrellas. But in this case, you need to wait as much time as it is necessary in order for the composition to reduce.

After the polystyrene foam will be passed onto the concrete, it is very important not to touch the sheets, otherwise it is possible to move individual elements even before everything finally dries.

Materials can be glued together in the composition of the composition, it is only necessary to choose a suitable adhesive base. It would seem how to connect concrete and metal, or attach glass to it, but it is performed using special glue solutions and funds. During the construction of houses and subsequent decoration, various surfaces are supposed to be accompanied to concrete, including concrete to concrete and the reliability of their clutch sometimes depends not only to the decorative part, but also the stability of the walls of the room.

In the process of construction, the moments appear under which the need to glue concrete structures among themselves. Concrete is an artificial stone that can be glued with epoxy or furyl adhesive compositions.

For the stiffness of the design from the old concrete, the upper layer is knocked down, and then carefully determined, and small particles of dust, garbage are eliminated from its surface, and the portion of the composition containing glue and hardener is eliminated. It is distributed over the surface of the gluing with a spatula or tassel and a new concrete construction is immediately stacked on it. For its gluing, resin compounds are used, which are used in the cold method.

Select binder with plastic, as well as plastic and PVC panels

To glue the latter to the concrete surface, a multipurpose "moment of germing" is well suited, which can high-qualityly glue these two surfaces.

Plastic with concrete is connected by the usual building glue "Titan", which has excellent adhesion and moisture resistance.

Also, "liquid nails" will be well suited for gluing plastic surfaces. This glue can be purchased as a dry mix, which consists of cement and polymers.

For a reliable clutch of two different designs, it is necessary to clean the concrete surface, sharpen and align it, otherwise the smooth plastic surface will not stick. The PVC panels are pressed to the concrete plane using the construction level and are aligned along the entire length, the adjustment of their location can be carried out within an hour. The glue fully solidifies only three days later.

In construction, it will not be superfluous to know about

Tree, Laminate, Fanora, Parquet and Sandwich Panel

Modern adhesive materials allow you to glue with concrete even wooden surfaces. Before holding this work, it is necessary to prepare a cement surface and walk along it with a special primer, which will save in the subsequent joints from the accumulation of dirt and moisture.

So that the parquet board was securely fixed to the floor, epoxy or polyurethane glue is used. The latter consists of a hardener, solvent and filler. It happens both in solid and in liquid state. Most often used in the form of a liquid rapid-lifting mastic. It has good hermetic and electrically insulating properties, but with sharp air drops in the room it is better to replace it with epoxy glue.

Ruberoid

At the beginning of construction, literally at the final stages of the construction of the foundation, the question arises of its sealing, which can provide runneroid. It is attached to concrete with bitumen mastic. It is applied with a roller on a cement surface. Then, together with the rubberoid, it is heated for a better clutch and glued, overlapping under the brand goods.

Metal with stone

Even such incompatible materials can be glued. A two-component epoxy composition can act as their reliable binder. It contains:

- a mixture of epoxy resin with filler and plasticizer;

- connection of thixotropic additive and hardener.

In this one, you can emphasize what the foundation is suitable for the house of aerated concrete.

To obtain glue, these two components are mixed immediately before carrying out construction work And applied to the prepared planes.

Linoleum and glass with concrete

They are glued to the cement wall with the help of bilateral construction scotch. To reliably fix them, it is necessary to prepare a work plane: clean, align and primed. In the case of gluing linoleum, it is not necessary to lay it on the old coating. It is necessary to remove it and perform if it is necessary, a new screed so that the floor is smooth.

Everyone who wants to build a house from a durable material, such as concrete, it will be important to know about all homobletone blocks.

On the estimated placement of linoleum, glass or mirrors stick tape with a liner. When working with an outdoor coating, it is removed gradually by gluing with the canvas parts. And for the glass, the tape is completely released from the liner and immediately stick it to the adhesive base, dust does not get.

Organit

This material is nothing but the stove Fiberboard. They are often used as outdoor coating, Therefore, it becomes necessary to fix them to the concrete surface. For these purposes, many use PVA glue, only if it is elected, it should be noted that water-based composition is not suitable for such works. Since when drying glue, water will fall into the stove and may be blocked.

For such responsible works, it is also possible to use CS-3 or rubber mastic "KN-3".

Tripping tricks with isolon and foil

Isolon - gasket material used for tightness, heat and noise insulation, and foil - reflective view with metallized coating. They are used for the insulation of the premises. Their fastening to concrete is feasible with the help of a mounting foam, but it is necessary to stock in large quantities in the case with isolon, since this porous material absorbs part of the composition in itself.

More economical options can be adhesives on acrylic and rubber-based, which can be applied point, it does not suffer from this reliability, and the air gaps will only be a plus. Foil can be glued even a double-sided scotch, but the concrete surface on the site of its fastener should be smooth and smooth.

What is different and what better aerated concrete or foam concrete.

Ceramic and tile

They both consist of clay. The tile is one of the varieties of ceramic tiles, so their fasteners for concrete will be made equally. The selection of glue for it depends on its size. For small tiles do not buy expensive glue compositionThey will fully withstand the usual glue, for example "Economy". With large dimensions, "moment-installation" is suitable, but for beauty you should choose the white color so that the stakes of the slabs do not look outdated. There are special mixtures for gluing tile.

Before fastener on a concrete surface, special notches are made, and then the plane is coated with primer - this is a necessary condition for increasing the adhesion of concrete. In the process of gluing the tile, the remnants of the adhesive when pressed it to the wall will go out through the seams, they must be immediately removed, so that there are no frozen divorces and protrusions on the decorative surface.

New technologies allow us to attach, it would seem such incompatible materials. When carrying out the gluing process, work surfaces should be carefully prepared and choose the fitting glue. Some of it can only be used for internal workAnd others are well served in an aggressive environment. Compliance with the priority of work and the right choice of materials will guarantee an excellent result.