How to glue a rolled foam to concrete. How and how to glue the metal to concrete: cleaning the elements, the preparation of glue, the priming of concrete. Features of sticking of foam, drywall, rubberoid, plastics, rubber. Gluing polystylene liquid gva

Read also

Such material as polystyrene foam is becoming increasingly popular, since it is inexpensive and very effective insulation. In this regard, many materials lose expanded polystyrene foam. It should be noted that it is also not a complicated thing to glue, it is for everyone. If the polystyrene foam is planned to be glued to the outside of the building, it is very important here that the adhesive agent has such quality as frost resistance (especially this is true in those regions of the country where frosts are frequent natural phenomenon).

Gluing material on mounting foam

It should be at least five degrees Celsius, perfect twenty. Universal glue without solvents and water. To create decorative items with transparent finish. For plastics and materials treated with the surface, it is recommended to perform a bonding test.

Professional dispersion glue with high initial adhesion in all rooms, where at least one surface absorbs.

Adhesive for heavy-duty clutch.

Replaces screws and pins for nails both inside and outside.

Anchors with a polyester resin without styrene work both with solid and hollow materials, where it is impossible to use stretching centering pins.

Scheme of insulation of facades polystyrene foam

The question of how to glue foam to concrete is very relevant because such material is becoming increasingly popular due to its unique qualities.

Glue polystyrene foam can be different waysIt is important to consider when choosing different nuances.

Light, universal and fast use. Very high chemical resistance. Suitable for underwater use. German and French certification. Very good thermal and mechanical properties.

Styrene-based resin resin resin.

Chemical anchor for extreme loads. Vinyl ether Unstable chemical solution. Higher strength parameters. The optimal selection of glue is extremely important to achieve the correct effect and satisfaction with the work. When choosing glue, we need to pay attention to the types and dimensions of the surfaces that we will use which type of glue should be used, which type of glue we will use, and some glue characteristics.

The scheme of insulation house expanded polystyrene

For gluing foam, you need the following:

- special adhesive for foam (you can take glue for ceramic tiles or "liquid nails");

- the spatula (will be needed if it is necessary to make a putty wall);

- as an alternative to glue, you can use a special foam.

As you know, the walls of the concrete are cold, it means that they need insulation, in this regard it is difficult to find the material better than the polystyrene foam. In order for such a material to be stuffed with concrete, it is necessary to pre-prepare a concrete wall for this, it must be carefully cleaned from different types of pollution, old solutions, and the like. Only in this case the adhesion will give the desired effect. It happens that the wall on which the foam is placed is planned, has a large number of different defects. Then it must be placed ( sand-cement For this it is suitable as it is impossible), and then you need to treat everything with impregnation.

The type of surface to which glue will be applied

Materials that can be used glue, very different: wood, metal, glass, leather, paper, cardboard, plastic, ceramic tile, polystyrene, ceramics, rubber, building surface, mirror and much more. Many adhesives are universal adhesives and can be applied on most surfaces. Adhesives for polystyrene foam can only be used for polystyrene foam, which does not dissolve it. There are also areas where it is almost impossible to glue constantly, for example, teflon, polypropylene, oily surfaces.

Printing special foam

Facade insulation scheme

The methods of gluing foam plastic to concrete there is a lot, but one of the most common is a special foam in order to glue expanding polystyrene foam. Such foam contains basic polyurethane, it is available in special mounting cylinders. If you plan to use such cylinders, then before this you need to purchase a special flushing, thanks to which the composition in the tube will not dry. Polyurethane mixture has several advantages:

Shape and size of the glued surface

Depending on whether the surface is glued with a small or large and smooth or irregular, various types of glue are used. If the surface is small, you can use cyanoacrylate adhesives for small repair. These adhesives are associated very quickly and firmly, but they do not have the ability to fill the surface.

Will the glue site be exposed to moisture or chemicals?

When you need to fill the gap between the glued elements, we usually use neoprene and acrylic, polymer or additional adhesives, mounting adhesives and foams. If it is exposed to moisture, use waterproof adhesives, such as neoprene, epoxy resin, polyurethane, polymer.

- installation is carried out quickly and without any difficulties;

- the adhesion of sheets and foam balls with a concrete surface is carried out as high quality as possible;

- the cost of such installation is low;

- you can handle the seams between each concrete slab if the distance between the plates does not exceed 2 mm.

However, if such a glitter is selected, maximum caution should be observed, since if such a foam falls into the eye, it can lead to the most negative consequences.

Neutral glue colors are very different. Depending on whether the place of gluing should be the same or not necessarily visible, you can use transparent or simple glue. Neoprene I. polyurethane adhesives Especially toxic and have an unpleasant smell. Large glass surfaces can be glued with colorless silicones.

The strength of glue and forces acting on the surface to be bonded

Gluing sections are usually exposed to many types of forces: stretching, shift stress, break. They are often exposed to shocks, vibrations, bending. Especially two-component epoxy adhesives Extremely durable. Neoprene adhesives are also very durable, but they have limited resistance to the break.

If you need to glue polystyrene foam to concrete, it should be borne in mind that today is not one-tent of the stamps of such material, they have differences in hardness and density. The polystyrene foam today is given proper, so its varieties are becoming more and more. In this regard, when choosing a adhesive, it is necessary to take into account what brand the polystyrene foam will be glued.

Thickening time and gluing

Sealing time: This is the time required for evaporation of the solvent contained in adhesives, which gives it a smooth consistency. Compliance with the delay time between the application of glue and the assembly is especially important for contact adhesives, primarily neoprene.

When using their surface to be glueding, you should glue and glue for a while so that the glue can adapt to the surface, break and wait 10-20 minutes to the final press. Connection time: After it has expired, the connected elements can remain in a vertical position without supporting them.

Mounting by other means

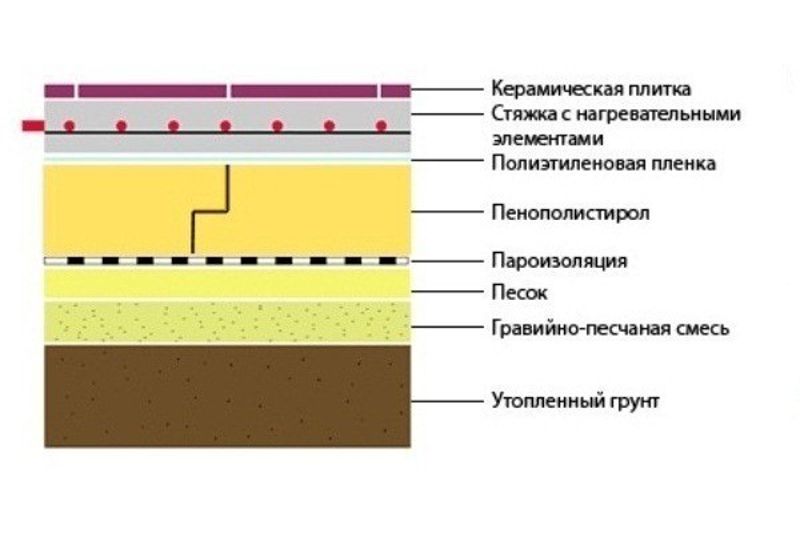

Floor insulation scheme polystyrene

You can use glue, which is specifically produced for foam plastic, the facade glue is suitable, which is characterized in that the racks to frosts, adhesive mixtures for ceramic tiles Also fit. It is possible to take sealant from silicone as adhesive tools, liquid nails for walls are suitable. It is very important to take into account the following circumstance: whatever adhesive means is used, it should in no case contain acetone, gasoline and other organic solvents that affect the polystylene.

Drying time: The maximum adhesion of glue is achieved after complete drying of the glue. Only after that you can talk about the full strength of the connection of the elements. Adhesives can be thin, thick, gel, powdered, foam. Gel adhesives do not merge from glued surfaces. Dense adhesives are more difficult to spread from rare, and often the clamping surface must be pressed more often. Construction adhesives Usually have a powder shape.

Glues for small repair

Adhesives can be divided into three main groups according to the application. They are used to connect mostly small areas. Most of these adhesives dry out very quickly. With these adhesions, the space between the glued surfaces is impossible to fill. The glue site is usually strong.

Foam sheets are glued in a chess order, it is necessary to begin glue from the bottom up. As for the amount of glue, it is not worth saving on it, it should cover at least 40 percent of the surface of the sheet. When the gluing process is carried out, it is important to ensure that air stoppers do not occur (it sometimes happens when the wallpaper is glued). Foam sheets, when glued, should be most tightly pressed to each other, they must also be tightly pressed to the surface of the concrete wall. At the same time, it should be borne in mind that the joints should not be sized between sheets, they can then be filled with sealant.

Assembly adhesives

Designed for large smooth surfaces. These adhesives have several longer gluing and gluing times than those that are used on small surfaces. Allows you to bind the surface of irregular, porous materials - such as concrete, wood, brick or building stones. Such adhesives fill the gaps between the glued surfaces.

Gluing polystyolster with liquid nails

Some glue can be used in a rather wide range, we call it "universal". Others are provided for specific types of materials and for very specific applications. In any case, follow the manufacturer's recommendations. Neoprene adhesives are products labeled as harmful, sensitive and flammable substances and drugs.

It is not necessary to use the "moment" glue, which not only does not stick to the polystyrene foam, but also can spoil it. In order to glue such a material to the concrete surface, it is necessary to apply 5 portions of glue in different places on it (the most common option is in every corner for serving and one in the middle). If you need to increase the service life, you can still stick with dowels with umbrellas. But in this case, you need to wait as much time as it is necessary in order for the composition to reduce.

Two-component epoxy adhesives

There are many adhesives for specialized use. They have similar characteristics with general-purpose adhesives, but additionally, due to their composition, they are specially adapted to the conditions in which the surfaces and types of materials are located.

These weights are used to connect materials, especially porous surfaces and incorrect form. The principle of work is similar to the principle of operation of glue, the composition of the masses corresponds to the composition of adhesives, so we have neoprene, polymer, polyurethane mass. They are used to fill the cavities, when they are used, they expand or expand their volume by drying.

After the polystyrene foam will be passed onto the concrete, it is very important not to touch the sheets, otherwise it is possible to move individual elements even before everything finally dries.

Any house or other room where people will be, needing insulation. One of the easiest installation and affordable materials for thermal insulation is a foam.

They are used for sealing, but they also possess adhesive properties. Surfaces, such as glass with plastic or concrete, can be glued with silicone, polystyrene ceramics. In construction, it is used to fix all types of cans. In places where the exposed construction elements are exposed to atmospheric factors, such as wall crowns, eaves, plinths, window sills and external facades.

All information is based on many years of experience. This is a prerequisite for the successful use of technology, as well as for thorough and professional implementation of the recommended work. The warranty applies only to product quality.

It has excellent heat insulating properties And therefore is widely used for the insulation of residential and utility rooms. But many may have a question, and what to glue foam to concrete?

To begin with, we clarify that the polyster is attached directly to the wall, no crates and meshes are not pre-installed. Based on this, it is necessary to correctly pick up the adhesive mixture.

Selection of adhesive substances

The manufacturer cannot be responsible for the correctness of the work performed, as they do not enter into its competence. Any losses resulting from incorrect workare excluded from the warranty. The strength of the welded seam did not change after 30 years, as evidenced by the adhesion test in construction institutions. Tile or striped sheet Material Can be used to cover large surfaces of roofs or plywood veneer. Their glue allows you to mask inequalities. It can be successfully used to glue the cornice and coating the top of the walls.

There are many adhesive mixes For fastening the insulation, but not all of them are suitable for mounting foam plates. Different adhesive compositions They can act differently on the material itself, it can be deformed or completely denominates corrosion. It is still necessary to take into account that the foam of the foam is very bad adhesion, in other words the glue is very bad for him.

This allows you to suppress the impact of the drum drum sounds and prevent insect habitats under the surface of the sheets. Complete surface seal also protects the lower surfaces of corrugated metal plates from corrosion. The condition is that the adhesive seam is properly manufactured. In addition, glue is resistant to industrial exhaust gases, algae, sea water and rainwater. Ideal substrates are: concrete, brick, natural and artificial stone, plywood, fibrous fibrous construction Materials, such as cement-fibrous plates, slate, plywood with laminated veneer, etc. It is important that the basis is stable, durable, dry and clean. and evenly.

As mentioned earlier, in the building materials market, a huge set of different adhesives of dry mixtures and other chemistry, which will allow the modern consumer to choose the optimal option for fastening and gluing a variety of materials. So let's answer the question how to glue foam to concrete?

To glue foam plastic to concrete, it is necessary to use one and the moving methods below:

Clean, smooth and without dust bases do not require primer. It is necessary to repair the rolled plaster or solution. Remove loose and rushing surfaces, and then align the surface. Other coatings need to be checked for suitability. Inequalities will tighten adhesion wear.

Waiting time cannot exceed 60 minutes. Connecting pressure for immediate, good gluing on glued surfaces. Create uniform pressure is small enough to press up with your hand, you need to press a big one, for example, a thin trick.

- Fastening with the help of "liquid nails".

- Fastening using foam glue.

- Of course, with the help of a dry beehive mixture of foam.

Now let's briefly consider each of these methods separately and more.

Gluing polystyolster with liquid nails

To fulfill the work we will need:

Gluing horizontal surfaces to cover the crown of walls, attic, eaves, exterior window sills, etc. Using more than one sheet metal, it is necessary to lay and glue the width of the plates with a width of at least 10 cm and the same profile as the top sheet. These sheets are designed to seal the seams and compensate for changes in the length of the surface sheets depending on the temperature. The distance between the upper plates depends on temperature ambient and the expansion coefficient of the sheet used.

Inclined and vertical surfaces When using vertical or inclined surfaces, it is necessary to use the point-to-point mechanical fastening elements to secure freshly breeded sheets before slipping. As the protection of titanium-zinc plates, you can use hidden embroidery, stripes, stamps, etc. The number of fastening points depends on the type of fastening. In case of inclined surfaces, the role of compensators may be, for example, sheet leaf material. Soldane compounds require great caution.

- foam plates;

- liquid Nails;

- protective gloves.

Before starting work, learning instructions for their use, and make sure that they are designed to work with concrete. Before starting work, the surface to which gluits will be made, it is necessary to clean and brew it.

Liquid nails should not be applied to the entire surface of the plate, but only make several points on it and a solid line around the perimeter. The composition of liquid nails includes toxic substances, here for this and we will need protective gloves. After applying the mixture on the slab it must be pressed to the insulated surface.

This method of fastening is the most durable, compared to the rest.

Fastening using foam glue

We need:

- styrofoam;

- mounting foam;

- mounting gun for foam;

- cleaner for mounting foam.

Before starting the installation, it is necessary to prepare the surface and clean it carefully. It is not necessary to grind the wall, it is enough to clean it well, and the plates themselves are to pre-splash the cleaner.

Glue foam on the stove, we apply along its perimeter and give another strip in the middle of the slab. After applying foam we are waiting for a couple of minutes and after which we press it well to the wall. There is about 5 minutes to align the insulation, after which the foam hardens. After that, the same foam we can close the seams between the plates.

The quality of such a clutch is very high.

Dry mixture

Materials and tools:

- styrofoam;

- primer;

- dry glue mix;

- drill or mixer;

- spatula with teeth.

First of all, you need to do everything preparatory work. We clean the wall from dust dust, different spots, from everything that lowers adhesion of glue. Sharpen all deep irregularities in advance. The entire surface to handle the primer.

The adhesive mixture must be prepared strictly according to the recipe specified on the bag. It is necessary to stir in carefully so that there are no lumps, and the mixture was homogeneous.

The method of applying glue dependence on the curvature of the wall. If the walls are smooth, then the glue is applied on the stove with a spatula with teeth, it is also called a comb. If the wall has irregularities and depressions, the glue is applied to the slab "lepts".