Dowel nail plastic. Varieties of dowels for thermal insulation of surfaces with mineral wool and expanded polystyrene

Installation of insulation

The choice of reliable mounts for the installation of the insulation is a strategically important task. These tiny parts are capable of either forever eliminate the problem of cold in the house, ensuring reliable adjacent to the insulation to the surface of the facade, or lead to very sad consequences. After all, the inappropriate fastener does not securely fix the material, and then the winter will not only be outside the window - it will settle in your home. We will tell you about what you need to know about the dowels for fastening the insulation.

Dowels: Mushrooms and Plates

For fastening solid and soft insulation, so-called mushrooms dowels for thermal insulation, or, speaking otherwise, plate mushrooms. They are able to keep even a loose and fragile insulation. With the help of a mushroom dowel, you can mount the material for almost all types of flat surfaces made of concrete, brick, foam concrete and aerated concrete, as well as building stone.

Tarbed dowels methies It was widely widespread due to the unique design of the outer hat - it is wide enough in size and has tapered holes that allow you to reliably fix the mineral insulation. Good carrier load indicators provides a long zone of crushing. The disk of such a dowel has a rough surface and special technological holes. They provide reliable pressed material to the base. In addition to this fixing, the insulation contributes to the spacer area (60 mm), consisting of three sections, which completely completely eliminates the pullout of a dowel from the hole.

The main component in the manufacture of a dowel is low pressure polyethylene (PND), and the spacer nail is usually made of galvanized steel or glass-filled polyamide. Hardware not only contribute to the preservation of heat, but also differ in magnificent anti-corrosion properties. A plate dowel is tightly fixed in a prescribed place by retrace with a nail, screw or screw. Moreover, it is drunk in two or three directions, which makes it possible to perform effective fixation of all known types of insulation materials, as well as increase the strength of the fastening and carrying ability Dowel himself. In addition, the plastic material of the product allows to avoid the occurrence of cold bridges and is characterized by resistance to aging, which together with others quality characteristics Guarantees high fastener reliability for many years.

A plate dowel, in particular his hat, has high flexibility, due to which compensation occurs during thermal expansion and deformation of the material. This, in turn, reduces to zero damage to the insulating layer itself

Variety of shapes of dowels for insulation

A plate of a dowel consists of a core and a wide hat, which allows you to reliably fix any heat insulating material on the facade of the building using galvanized metal nails. Made from polyethylene, a plate dowel is resistant to corrosion and, unlike outdated wooden plugs, it does not destroy, does not rot, reliably and firmly fixes thermal insulation on the facade.

Appeared also dowel-nails with thread, at the expense of which they can be simply driven into the surface. They are made of glass-filled polyamide or galvanized metal. As a rule, the most common materials for the manufacture of mushroom dowels are metal and plastic.

Metal dowel for insulation it is more expensive, but at the same time withstands much large loads Compared to Plastics. Metal fungi is used for fastening to hollow and thin-walled structures. Thanks to the zinc coating, this fastener is not corrosion, which improves the durability and reliability of the entire thermal insulation system at home.

Plastic dowels Two types are on sale: nylon and polypropylene. Nylon dowels are designed for mounting to full-fledged, hollow materials and wood, that is, in fact to any reasons. They are supplied complete with a metal screw (diameter - from 2 to 16 mm), the dowels withstand the maximum load of 225 - 450 kg along concrete and 160 - 380 kg on brick. As for the polypropylene dowel, it is capable of accepting a load of 20 to 750 kg.

Installation of insulation

The principle of the attachment of the dowels for insulation

Despite the fact that there are different technological processes And the materials, physical law, are constantly being improved, thanks to which the dowel is fixing thermal insulation, it remains unchanged - this is the retention force of friction. In this process, it is so large that the fastener can only be used once - when removing from the hole, it simply collapses. You can spoil the fastening by another way - pull it out under the pressure of the insulation. Such trouble can be avoided if you carefully prepare the seat.

The hole for the installation of a plate dowel must match the desired diameter and depth of fasteners. Inside it is unacceptable, the presence of cracks, chips, sand residues or dust. Due to its forms and the presence of various spacer zones, fasteners for thermal insulation are reliably fixed almost on all types of surfaces. At the same time, external factors practically do not affect the strength of such an attachment upon subsequent operation of thermal insulation systems.

Dowels for monolithic bases have the right attachment principle, and for void anchor

Traditionally, the calculation of the required length of the dowel for the insulation is made according to the following formula: L \u003d H + K + I + W, where:

- L is the necessary length of the dowel;

- H is the thickness of the insulation layer, obtained on the basis of the heat engineering calculation;

- K is the thickness of the adhesive composition for the glue of the insulation;

- I is the length of the spacer part of the dowel (it must be at least 45 mm);

- W is the sum of the actual definite deviations of the base of the building from the vertical and the deviation of the facade plane in the places of installation of the dowels for thermal insulation (a peculiar margin of safety along the fastener length).

Mounting the heat insulating layer consisting of materials with high deformability (semi-rigid mineral wool plates), it is best to choose a dowel with an expansion washer with a diameter of 100 mm

The process of fastening the insulation dowel

Directly installing the solar dowels is simple and consists of just a few operations.

- Marking of the location of the intended installation.

- Drilling holes for fasteners through a layer of heat insulation.

- Installation of a dowel: it is pressed into the hole to a dense pressed cap to the insulating material.

- Installing a nail to retire and clog it to final fixation.

- Fastening the protective cover of a nail hat.

When fastening the insulation, be sure to remove the old plaster (if it is) or increase the depth of drilling. The attachment of the dowels implies the entry of the anchor element to the bearing layer of the wall exactly for the entire length. Reduced the length of the spacer item on its own (which happens quite often), it is necessary to sharpen the cropped end. To install a dowel, a hole with a diameter of 10 mm (± 0.3 - 5 mm) is performed. Its depth in the bearing wall should be 55 - 60 mm - for an anchor element of 50 mm in size, 105-110 mm - for an anchor element of 100 mm.

After that, a dowel is put in the hole, and the plate and the anchor elements are pre-put on the fiberglass rod. With the help of a hammer, the protruding part of the rod is clogged to the flange level. At the same time, the anchor element creates a tension, which ensures the reliability of the clutch in the "wall - anchor element - rod" system. For standard attachment, five to six dowels are used for 1Q. m wall. The exact amount of the required fastener is determined by calculation on the basis of the area of \u200b\u200bthe insulated surface.

Dowel for fastening insulation

Currently, the market shows a huge range of different types. dowels for insulationintended for various thermal insulation materials Taking into account their thickness, weight and other characteristics. Major producers of such hardware - Russia, Germany, China and Poland. Range of prices ranges from 3 - 30 rubles. Puzzle (the cost depends on the materials from which the dowel is made, as well as from the manufacturer's brand).

For the sake of justice it is worth saying that the fungi for fastening the insulation is not the only way of installation. But, most of them are used in most constructions. Even in those situations where, for example, foam plastic sits on a glue-foam, with a "wet facade" additionally use fungus for insulation. Let's gradually figure out in the principles of the work of this "miracle", choose the desired fastening type and calculate the cost.

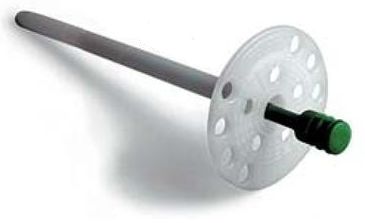

Dowel for thermal insulation are fasteners consisting of several parts. Namely:

- The hat is its task to distribute the load on the surface of the fixed material;

- Pouring element - He carries the load and creates the power of friction, ensuring the holding of the insulation on the wall;

- Nail - clogged into the spacer element for dense fixation;

- Some types of insulation fungi have an anchor sleeve for additional attachment.

- Also, exist expansion washers - Their task increase the area of \u200b\u200bcontact with thermal insulation and distribute the load on the surface. In practice, such washers are used for soft materials in order to avoid their deformation.

So, a plate dowel for fastening is a mechanical element with which the insulation is carried out to the wall.

Requirements for fasteners

The dowel for fastening the thermal insulation is exposed to high load, perform functions in an alkaline medium and placed in the conditions of extreme temperatures. So, they must correspond to several criteria.

We set the basic hardware requirements for insulation, now it is important to see how modern market satisfies these requirements.

Views

If you simply say, there are two main types of umbrellas.

From galvanized steel

The nail of such umbrellas in most cases is made of galvanized steel (sometimes polyamide). And although this material is more than other metallic resistive corrosion, nevertheless it is not protected from it. There is a second drawback. Metal works well, and therefore, in the place of attachment can form the bridges of cold and the condensate can accumulate. Over time, cracks can go in places of attachment. This type of fasteners has a higher cost.

The nail of such umbrellas in most cases is made of galvanized steel (sometimes polyamide). And although this material is more than other metallic resistive corrosion, nevertheless it is not protected from it. There is a second drawback. Metal works well, and therefore, in the place of attachment can form the bridges of cold and the condensate can accumulate. Over time, cracks can go in places of attachment. This type of fasteners has a higher cost.

Main characteristics:

- Dowel material: shockproof polypropylene.

- Anchor material: low carbon, galvanized steel;

- Temperature mode: -55 - +60 degrees;

- Load: up to 750 kg on square meter.

As a conclusion: such fungi is used in the case of fixing heavy insulation, when the use of plastic is impossible.

From plastic

Dowel for thermal insulation with plastic nail. It is used more often than metal, but have less cost and less strength. Although even their indicators are very impressive. The temperature regime is from -40 to + 80 degrees. Such umbrellas are also able to withstand the load from 20 to 380 kg per square meter. Plastic is also attributed nylon nails.

With thermal head

Dowel for thermal head thermal insulation is umbrellas with metal nails. The head of the polymer is put on the end of the anchor. This approach is used for different types walls, but especially necessary for wooden. The appointment of the head is a decrease in thermal conductivity. Such elements have a higher cost (the highest among dowels), but also the most low indicators thermal conductivity and strength.

The chrome of this fungi is distinguished by length. This is an important indicator to calculate correctly. The diameter of the rod under the anchor is distinguished. Most often used rods with a diameter of 8-10 mm.

If the fastener is chosen incorrectly, it will not keep thermal insulation. And it will have to tear it together with attached sheets. How not to make a mistake and calculate the desired length right away?

The task of the dowel. That is needed and getting. On the way to the solid surface lie:

- Insulation itself;

- The thickness of the adhesive composition (if any).

In addition, it is worth considering that the dowel must enter the wall to a depth of 50 mm.

Thus, we calculate the desired lengths by the formula:

L \u003d H + I + K + W.

L - the required total length of the dowel;

H is the thickness of the heat-insulating layer;

K - the thickness of the old plaster or adhesive composition, on which the insulation is attached;

I - a dowel fastening in a concrete / brick / wooden base of the wall (at least) 50 mm.

W - stock on the curvature of the wall.

For example, if you use a foam of 50 mm thick and use a thin layer of glue - 5-10 mm, you have enough dowel with a length of 110 mm. If the wall is smooth. But if the wall skew reaches 50 mm, it is worth adding this indicator and then you will need a dowel of 160 mm or more. If we increase the thermal insulation layer to 100 mm, in the last case we will need 210 mm of the length of the rod.

In the choice of fasteners: not always longer means better. If insulation occurs, for example, in the apartment, the thickness of the walls can be especially small and need to be correctly calculated.

Mounting schemes

In the first approach, 1 square of the material (as a rule, it is approximately 1 square meter) it is necessary to 5-6 dowels. 4 Fasten in the corners (5-10 cm from the edge) 1-2 in the center.

According to the second diagram, the dowel is rushed at the junction of two plates. Thus, one hat holds three plates at the junction. With this approach, one dowel must be scored in the center.

The folk craftsmen for the sake of the notorious economy manage to do and one dowel on the slab in the center.

Determining the number of fasteners, it is also necessary to take into account the floors of the building and the place of insulation fastening. At the corners recommend a greater number of fixtures. On buildings above 8 meters of 7 fasteners per square. On buildings above 20 meters from 9. This is due to the increased wind load and the load on the lower rows of thermal insulation from the upper.

Installation

The use of a dowel for fastening the insulation occurs in 3 stages: n

- A hole is drilled by the rod diameter and exceeding it with a length of 10 mm;

- Manually inserted a dowel (its hat should be in a heap with insulation);

- The locking anchor is embroidered and clogged.

If you use the expansion cuff you need to wear before inserting the fungus!

In the presence, cover with a cap with a cover.

Polypropylene, polyamide, or nylon can be used for the manufacture of plastic dowels. The main advantage of polymer dowels is a low price, however, the strength characteristics of such products leave much to be desired.

Plastic dowels can be mounted heat insulation to strong surfaces from concrete, or bricks, but they do not go to fix heavy insulation on hollow walls or surfaces from foamed concrete.

The average cost of one dowel for thermal insulation on with a polymer nail is about two rubles per 1 piece.

1.2 with a metal nail

Metal dowels are an order of magnitude stronger than polymer counterparts, but their use is limited to a high thermal conductivity of a metal that impairs the overall effectiveness of insulation.

Metallic dowels form the bridges of cold - elements, the thermal conductivity of which is different from the thermal conductivity of the entire structure.

Also, a dowel with a metal nail is prone to corrosion, during operation they can form yellow rust spots on the plastered facade.

The average cost of a dowel with a metal nail is 3.5-4 rubles.

1.3 with thermal head

Dowel with a thermal head - a widespread alternative to metallic dowels. They are based on all the same steel nail, but its hat is covered with a low thermal conductivity material.

As a rule, a shockproof polyamide is used as a coating, which has a thermal conductivity of 0.027 W / MK, which is comparable to a similar characteristic of most popular insulation.

The metal nail is completely recessed into the polymer case, as a result of which such a dowel is not afraid of moisture, and is not subject to corrosion.

The cost of products with the thermal head on varies from 4 to 6 rubles per 1 piece, depending on the manufacturer.

1.4 Features of the calculation of the number

To ensure reliable fixing of the insulation, it is necessary to use high-quality dowel mushrooms, while it is required to correctly calculate the required dowels. This can be done according to the following formula:

D \u003d t + k + i + z, in which

- T - the thickness of the insulation used;

- K is the thickness of the adhesive composition used to fix the panels of thermal insulation;

- I - the length on which the fungus should go into the wall (no less than 4.5 centimeters);

- Z is an optional value that is used in the event of a variation of the wall from the vertical, is used as needed.

As a rule, to mount the polyplex panels, or foam plastic, a thickness of 5 centimeters, a dowel mushroom is used at 10.5 centimeters.

The length of the anchor of the dowels, with the help of which the insulation is attached to the walls of the brick, or concrete brands M100, M200 and M300, should be 50 mm. In case the fixing of the insulation is performed to the walls of hollow bricks, or foam concrete (gas blocks, foam blocks, slag blocks), it is necessary to use fasteners with anchors of 100 mm.

When choosing a dowel mushroom for fastening thermal insulation, take into account the advantages and disadvantages of the material from which it is made.

Installation of dowels like "Mushroom

"Dowel mushroom with polyamide nail:

- Pros: Does not form cold bridges, as it has a low thermal conductivity; moisture and corrosion;

- Cons: possesses low strength that does not allow the use of such dowels to fix thermal insulation on the facades of multi-storey buildings. The same minuses have.

In general, a dowel with a nail of polyamide is well suited for fastening the heaters of slab insulation with a low density to the walls of bricks or concrete.

Metal nail products:

- Pros: High Strength;

- Cons: Afraid corrosion, worsens heat insulating properties Heatel, as it forms the bridges of the cold.

Dowels with a metal nail can be attached to the insulation of any density - minvatu, polystyrene foam, foam, both to normal and the hollow walls of the brick, or concrete.

Dowel Mushroom with polypropylene nail:

- Pros: low cost, low thermal conductivity, which eliminates the formation of cold bridges; not subject to corrosion;

- Cons: Strength.

The scope of operation of this dowel is similar to fungi with a nail of polyamide.

Products with thermal head:

- Pluses: High strength, not afraid of corrosion, does not forms the cold bridges;

- Cons: price as on

Dowel with a metal nail, the head of which is covered with heat-insulating polypropylene are a universal option, with which you can fix any insulation to any surfaces.

2 Features of the installation of thermal insulation

Mounting technology of any slab insulation - polystyrene foam, foam, or inferno, dowels like fungus is identical. All work on insulation, in fact, are reduced to the next algorithm:

- Preparation of a warmed surface;

- Installation of panel heat insulation on the adhesive solution;

- Fixation of panels dowels;

- Processing of insulation joints;

- Installation of insulating film;

- Testing heat insulation decorative materialor shocking.

Before installing the insulation, it is necessary to prepare the surface - remove the plaster, close cracks and irregularities, degrease.

Further, the panels of polystyrene foam, foam, or fasteners are planting on a special glue compositionwhich does not contain organic solvents - toluene and acetone. When installing adhesive mix It is necessary to evenly distribute over the entire back surface of the insulation.

In order to avoid heat-insulation shifts under its own weight, a metal profile is installed under the first row of plates, which assumes the function of the support.

After the day, mushrooms are used for additional fixation of thermal insulation, fungi is used to further fix thermal insulation.

For drilling holes, drills are used, the diameter of which is equal to the diameter of the leg, while the hole length should be more than the length of the dowel, so that reliable fixation does not interfere with the dust in the hole.

Construction standards and rules define the following standards by the number of dowels used:

- For fastening thermal insulation on interior Wallsor on the facades of single-storey buildings for each square meter of the insulation, five pieces are needed - 4 in the corners, and one in the center of the panel;

- For fastening at the corners of buildings - 6 pieces (fungi are installed in parallel to each other);

- For fastenings on buildings facades, height from 8 to 20 m, 7 pieces are necessary for 1 m² of insulation (parallel + 1 in the center);

- For fastening on the facades of multi-storey buildings at a height of more than 20 meters - 9 pieces per square meter of thermal insulation.

The fungi is best placed on the joints of the polyplate panels, or the foaming, since such a method does not lead to a significant increase in holes in thermal insulation, which negatively affect its efficiency.

In case the mushroom dowel must be installed in metal coating Of the professional flooring, the dowel is attached to the feet of a dowel, after which it is asleep insulation so that the screws reach the insulated surface.

After that, with the help of a screwdriver, a dowel with a tip of self-train screwed into the metal. The depth of the hole for self-press should be at least 10-15 millimeters.

Upon completion of the fastening of thermal insulation, the joints between the polyfoam panels, or the fleet, is sampled by aluminum reinforcing tape. The joints between the floor, or the ceiling, and the panels adjacent to them are closed with mounting foam.

2.1 Installation technology (video)

Dowel with plastic nail for an insulation mounting is used for fastening insulation and thermal insulation materials. The most simple and cheap version of the insulation fastening of different types on buildings facades. The dowel with a plastic nail for the insulation fastening consists of a dowel itself, an overhead with a large round perforated cap, which presses the insulation to the wall. In this dowel is inserted by a spacer nail, also from plastic, providing reliable fastening of the entire structure.

Characteristics

Wide demand plastic dowel With plastic nail is suitable for operation in conditions of any climate. The main characteristic is the principled inability of corrosion and the appearance of rust spots on the facade. Varieties are produced in length, calculated on different thicknesses of the insulation.

Installation

Mounting a dowel with a plastic nail also need to be installed in the insulation. A hole is drilled through it, a dowel is inserted into the hole, the round hat of which presses the insulation without unnecessary effort. In the hole of the dowel is clogged plastic nailwhich cuts the fastener and ensures the holding of a dowel in the wall.