Analysis of the structure of the range of ceramic tiles implemented in the market of Biysk. Specifications and properties of glazed ceramic tiles.

Ceramic cladding It has long been a reputation as a universal and practical type of finishing of premises. The modern industry produces a huge range of products for it, differing in its technical and aesthetic qualities due to differences in manufacturing technology. The glazed ceramic tiles and without coating, due to its properties, are used to finish the premises of different functional purpose and different architectural elements of buildings.

On the other hand, without glazed tiles can be subject to special procedures that change the appearance, we can find polished tiles, half-plated tiles and lined tiles. The support can be porous or compact, it is impossible to check the naked eye, but it is important to know that the compact stand will be more waterproof. Depending on the raw materials used in the test, support can take a variety of colors: a red paste, a white paste, painted.

Tile technique - Tile classification

- Select tiles.

- The manometer shows the actual tile label with millimeter accuracy.

- Tile tile indicates a homogeneous production part of color.

- Water absorption.

Products are characterized by surface coating, shape, water absorption, frost resistance, resistance to wear and influence of chemicals, surface hardness, leakage resistance, bending resistance, strength limit - All these characteristics adjusts GOST tiles.

Glazed tile - practicality and attractiveness

Such products are covered with a layer of glaze, giving them aesthetic attractiveness, waterproof and hardness. Purchase ceramic tiles glazed, characterized by a shiny surface, can be a wide variety of shades and textures, monophonic or decorated with ornaments and other images.

Remember: water absorption classifies tiles, so it does not give judgments about good or poor quality tile, but is a useful indicator to determine the most suitable destination destination. Removal and consumption of the surface of the tile, changing the aesthetic properties, with a change in color and loss of shine. For particularly intensive use, it is recommended to use porcelain tiles, unaled.

Sliding resistance. . No generally accepted classification, but rather standard. Just because of the costs and long terms required for laying, grinding and painting, which make you wait for forty days before using the floor, this type of parquet gradually lost the market share in favor of the pre-treated parquet. The pre-treated multilayer layer consists of several layers, even from different wood rocks, where the surface layer of precious wood should have a thickness of at least 2, 5 mm and disappear and varnished during production. The layers can be two if, in addition to the essence, there is only a less valuable wooden stand, which combines the rod fixation system, or three, if there is a counterweight, the purpose of which is to ensure greater stability, avoiding deformations due to time. Compounds are calibrated to ensure compatibility between different floorboards with engravings that provide ideal support for laying. Numerous advantages that determined the success of this type of parquet or were previously processed and painted at the production stage, do not require further work By laying, can be quickly put into operation and can be trampled within 24 hours after laying. You should not lose sight of the absence of odors, vapors and powders arising from grinding and painting during operation. Thanks to the industrial coating, it is possible to apply up to 6-7 layers of paint, which provides greater strength and durability compared with the traditional parquet coating. The existence of three layers of wood glued to the fibers in different directions causes natural tensions between the tree: this allows producing large 20 cm wide and 2 m long or more tiles without any in the problems of bending or swelling, which may occur when using the traditional parquet of that same size. It makes it easy and quickly stacked even during overlapping and, therefore, is also an ideal solution for repair, the cost of laying is significantly lower than that of the traditional parquet. The bottom must be absolutely dry and should not contain traces of moisture that may damage parquet. In this case, with a triangular dentifer, the glue spreads, trying to accurately adjust the amount, so excess glue does not create flaws. Parquet floors isolated from a screed or floor below foil from foamed polyethylene foam. This insulating layer helps limit the increase in humidity, weakens the tread noise and minimizes errors when laying. The advantages of this frame include: the ability to extract wooden planks for the future floor in another room; Speed \u200b\u200bof laying and use; Build economy. Floating styling is usually possible only for a pre-treated parquet. In this case, the wooden floor is glued to the concrete base with suitable adhesives. . In the parquet cover, what is lost over time is the top layer of paint.

The glaze is a glassy coating that is applied to ceramics before the firing in order to increase its technical and aesthetic properties that vary depending on the type of enamel. It can have different transparency, be painted or not. The glaze is low-melting silicate compounds that, when heated, gradually go into a liquid state and cooled as well - without sharp jumps. In the process of firing, the glaze melt and the components of the ceramic mass mutually penetrate each other.

Usually in the zones of intensive wear, paint tends to damage after 6-8 years. In this case, the parquet interferes, removing the woven layer and closing the floor again. If there is more damage, the layer is removed even more. After these operations, parquet is returned as new. The advantage of the wooden flooring is that with proper handling and periodic maintenance, they are practically defiable. Single cracks and cracks that can be obtained by cementing.

Laminated outdoor design

In the case of small scratches, however, pitting is enough. Some considerations that should be considered may be as follows. In winter, when the heaters are included, there may be disadvantages that can be avoided by maintaining the temperature as permanent as possible and without any heat change. Large wear resistance; Improved durability; Lack of color variation in extreme exposure to sunlight. Laminate thickness; Estimated use and, therefore, the type of wear to which the floor is exposed. Floating laying for laminate laying Laying the laminate lining is performed by the so-called floating machinery, that is, by connecting individual strips together with a combination between men and women: this type of laying allows you to fix the laminate even on the existing floor, without the first dismantling of the old jacket.

As a result, the product acquire the following properties that distinguish them from the unlawed:

- Higher durability;

- Spectacular and decorative appearance;

- Decreases water absorption;

- Increases gas-tightness;

- Hygienic qualities increase.

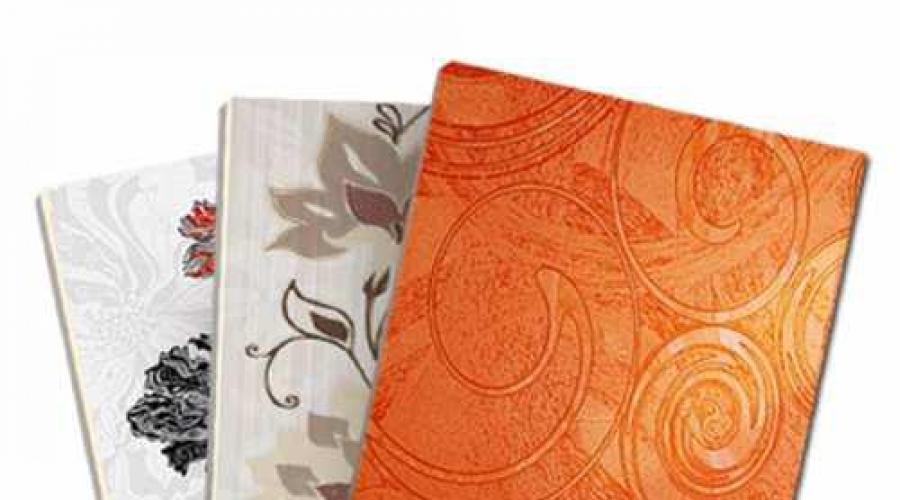

In addition to the wide range of color gamut, the ceramic tile glazed has a large range of surface types: glossy, matte and abrasive. Sometimes products are also produced with decorative inserts inside a glassy coating, which increases their aesthetic value. Photo of a variety of collections with the theme of various orientation make the problem of choice really difficult for a person without special knowledge in the field of design.

Before laying a laminate on the floor, an insulating layer is superimposed, as a rule, a polyethylene mat or other similar material is superimposed to prove the floor and soften any irregularities of the original base. During the stacking, do not forget to leave between the laminated floor and the wall of the game about one centimeter, since the laminate is dilated in the event of a change in temperature and humidity. Then this space will be hidden by putting the plinth. Laminate is usually compatible with outdoor heating. If the element of the sleeve is damaged, it can be easily replaced.

Maintenance and cleaning of laminate after laying laminate remains unchanged for many years, since the surface protection layer facilitates maintenance. This coating can be easily cleaned by a conventional vacuum cleaner, and for simple spots, quite well broken wet fabric. More complex stains require more intensive work with specific products.

Making tiles on monocotture technology

This method of processing products consists in their single firing and is considered more modern than bicotura. Mostly it is white or light tiles. During production, the compressed mixture is initially glazed, and then burned once, which provides high-quality clutch of the layers. For products, a non-slip matte surface is characteristic.

Avoid ammonia-based products that tend to extinguish the surface; Do not overload the surface: excess fluid may cause penetration and damage to the product. After reading these instructions, you can choose products that are yours, and properly perform most of the protective measures necessary for any type of floor or lining.

The steps in which the floor processing unit is divided. At the end of your marriage, the raw substances remain on the surface of the floor with conventional detergents, such as cement residues, glue and soil dirt: these substances are fixed on Earth, changing not only the color, but also the technical characteristics of the laid material, proper cleaning after laying provides.

Another modern monocotture technology suggests a joint pressing of the mixture and a layer of glaze. Such products have a reduced porosity and due to the considerable thickness of the glazed layer of suitability for the device. outdoor coatings In places of intensive movement.

Reconstructed stone protection. Depending on whether it is used for internal or external coatings, the restored stone is susceptible to wear, pollution, MSh and mold aggression. Its composition allows you to prevent the formation of moss and mold and protect the surface from the action of the degradation of atmospheric agents.

If the surface has lost its original beauty due to improper maintenance.

- If the treatment is very old, damaged or inefficient.

- In the case of stains that ordinary supporters cannot delete.

Manufacture of tiles using bicotura technology

This is the most old way to manufacture glazed products, a disadvantage of which compared to the method of monocottia is quite a high cost of production. The technology consists in a primary firing of the compressed mixture, after which it is covered with icing and is subjected to re-burning. The advantage of the technology is the possibility of making shiny surfaces without the occurrence of small defects as a result of penetration into gas-fried gas from the mixture during the firing process, as is the use of monocoturation.

But with the addition of a bit warm water It is unsurpassed: when you dilute detergents, in fact, effectiveness increases. Keep this in mind, and the result will be wonderful. If the processing of your sex is very old, damaged or ineffective, or if the surface has lost its original beauty due to improper maintenance, you must remove old or old layers of wax, and then restore them.

Ceramic tile, besides the fact that it is practical and durable, today is increasingly appreciated on the finish and has nothing that could envy the beauty and elegance of the parquet. From the collections of floral and geometric collections, ceramics has become elements of furniture of large aesthetic value. Do not lose sight of undisputed technical properties.

The tiles made by this method of bicoture have high porosity and low strength, due to which they are used primarily for wall cladding. You can buy such products with matte, and with glossy icing.

Pros and disadvantages of glazed tiles

The facing of various surfaces in the interiors of the premises of different functional purposes since ancient times is popular.

In addition, adhesives for laying produced by large Italian companies do not contain solvents, almost odorless and non-flammable. The product with natural raw materials can be recycled with re-use after use in the production process. Many of the new tiles have a percentage of recycled content from other products.

- The life cycle of tiles is estimated at about 50 years.

- Universality: This is a product intended for a wide range of applications.

- Ability to reuse: before and after.

This is due to the number of advantages with which the ceramic tile has glazed:

- Durability of operation;

- High aesthetic qualities;

- It is not a conductor of electricity, which allows to safely arrange warm floors with tiled coating;

- Fire resistance;

- High strength;

- Moisture resistance;

- Low susceptibility to temperature drops;

- Resistance to chemicals, with the exception of very aggressive media;

- Environmental friendliness and harmless to human health;

- Hygiene - on the ceramic glazed surface of the medium is completely unfavorable for the development of pathogenic microorganisms;

- Easy care - with regular cleaning it is enough to wipe it with a damp cloth;

- Resistance to ultravioleti;

- Universality - it can be used, both in bathrooms and in kitchens and in the living rooms.

The disadvantages of the material include:

The term "common" ceramics means a product obtained from a mixture of raw materials, such as clay, sand and natural landsSubsequently processed and baked in the furnace. Various typologies, with their quality and resistance characteristics, depend on the type of test, processing and time of preparation of the material. The range of products from which you can choose a ceramic slab, both for floor coatings and for floors, very wide.

Single firing: tiles made with modern ceramic and enamel support, guaranteeing a very thin product that reduces production and transportation costs. They can be red or white paste. They have excellent resistance to wear and abrasion and low porosity, which makes them particularly suitable for outdoor flooring. Monocoves are easy to clean. For careful cleaning of the bath or cooking panels, you can use specially designed detergents for ceramics.

- Fragility during transportation and laying;

- Exposure to mechanical damage, which is often used exclusively as wall;

- The ability to slip on the wet surface;

- Low thermal insulation;

- No possibility to encourage products.

Disgraced ceramic tile

Insoluated tiles are homogeneous in its structure and thickness, which do not have any differences between their base and coating. Such products are used to finish interior premises and cladding surfaces outdoors. Photo of country plots, where such cladding is applied, can immerse in the aristocratic, Mediterranean or medieval atmosphere.

Important! Facing products without glazed coating, as a rule, do not make design ornaments and patterns. But modern technologies for hardware and polishing have allowed to be applied to them. decorative elements, For example, in the form of multi-colored glazed patterns.

Advantages of unlawed tiles:

- High strength of clay raw materials compensates for the absence of a protective-decorative layer;

- Natural chemical resistance;

- Environmental friendliness;

- Resistance to atmospheric influences;

- Practically imperceptibility of wear due to the lack of distinction on the layers;

- Low moisture absorption and heat resistance, which makes it possible to use it on open spaces;

- Less slope of scratches on the surface than the glazed products.

Cons of unlawed products:

- Active accumulation of foreign substances, which does not allow it to be used for designing surfaces in rooms with a high possibility of pollution;

- The need to use for cleaning only special detergents that protect the surface from the appearance of spots on it;

- The boundedness of the color range from beige and yellowish shades to the brown tone.

Scope of application of glazed and unlawed products

Various operating and technical specifications of coated tiles and without glazes cause the specifics of their use. When choosing a type of product, it is required to consider the features of their place laying and operating conditions.

Application of glazed tiles

Such products have quite susceptible to mechanical effects by the upper layer, so they are used for walls and other vertical structures.

For the floor, most glazed coated models can be used in rooms with low motion intensity, for example, in bathrooms, bathrooms, in kitchens. Where there is a chance to slip, indispensable tile embossed. The rationality of this choice contributes to their ease of care, for which a sufficiently simple wiping by its wet cloth or the use of non-aggressive detergents. Low moisture absorption and gas permeability of ceramic tiles glazed makes it an optimal option for cladding kitchens and wet rooms.

Important! Products manufactured according to the modern technology of monocotture with glazing under pressure can be used for floors in the intensive movement places, and frost-resistant models are even for facades.

The variety of design solutions of the glazed products makes them particularly popular in the design of the interiors to which elevated aesthetic requirements are presented. The spectacular species is characteristic of tiles with small inserts in the form of plates. At the moment, designers are often proposed ceramic tile glazed with photo images or whole panels from it, which adds the originality of the interior. From the complexity of the design of products and the technologies used in their manufacture, their price is fluent.

Areas of using unlawned products

Specific scope of application of such tiles - facade finish houses, arbors, steps, passes, tracks and sites on the adjacent area. The use of this material is distributed in public and commercial buildings with intensive movement of visitors, in industrial premises, where there is a dynamic load on the floor. In the interiors, the tight tile is used primarily as the floor in the hallway, as well as for the embodiment of certain design ideas.

conclusions

Involved products inherent high wear resistance, and glazed - Effects external view and low moisture absorption. These and other properties that the manufacturer of the tile indicates in the marking on the packaging of products, must be determining when choosing. It is necessary to be guided, first of all, the conditions of cladding and the visual effect that is required to achieve.

Glazed ceramic tile is finishing materialfor which the multilayer coating is characterized. To create a monochrome product or with an image, a drawing is applied to the tile with special compositions, and then goes the layer liquid glass. The finished composition is sent to the baking furnace. Apply the glazed tile when finishing walls in the kitchen and bathroom.

The material under consideration has a number of advantages to which abrasion resistance and durability can be attributed. This effect is achieved at the expense of the glass layer, which creates reliable tile protection from scratches and scratches.

The finishing material does not absorb moisture and smells, which is important when finishing walls in the kitchen and bathroom. The glazed tile is unpretentious in terms of care, it is simple and easy to wash. Even if at times on the surface, soot is formed, then it is easy to get rid of it using ordinary detergents.

On the photo-ceramic glazed tile for the inner lining of the walls

On the photo-ceramic glazed tile for the inner lining of the walls But it is not devoid of glazed tile minuses. Its surface is quite slippery, which can be a real problem in the bathroom. And although the icing prevents scratches from occurring if the blow will be durable, then there is a risk of a defect. In addition, scratches are very well visible on the glazed tile, which cannot be said about ordinary tile.

Specifications

According to GOST 6141-91, the glazed tile can be produced in two types - a rectangle and square. The first option has the parties 75x150, 75x100, 100x150, 100x200 and 150x200 mm, and the square tile is 100, 150 and 200 mm. The surface of the facing material may be smooth or embossed, but is decorated with one or numerous shades.

According to GOST 6141091, the glazed tile must be resistant to chemical influences. Thus, its color and gloss should not be lost, and the drawing remain clear even when using chemicals.

On the video ceramic glazed tile for the inner lining of the walls:

Dimensions

Ceramics is durable material, and very hard. This manages to create like small and large facing materials. Today, the glazed tile can be produced by the following types:

Types of manufacturing method

Ceramics is a material that has a color and characteristics are determined by the method of obtaining it. It is inherent in the same personality as a stone and a tree, so the shade and the pattern depends on the distribution of coloring substances, temperature drops during firing, grade of raw materials and even its prey.

Equal firing product

Ceramic tile for decoration inland walls Thus are obtained: a layer of raw glaze is applied to a dry blank and send it to the firing furnace. There is a sintering of enamel with the surface, as a result of which they form a single whole.

On the photo-ceramic glazed single firing

On the photo-ceramic glazed single firing The resulting material is characterized by high hardness, as a powerful press is used for production. In addition, the tile of single annealing is resistant to frost and moisture. During the roasting, it is possible to get a bright or red product.

Double firing product

This group includes such types of tiles: Majolika, Fayans, Kottofort, Terrala. An additional billet burn occurs, after which enamel is applied to the semi-finished product and repeated firing.

On the photo- ceramic glazed double firing

On the photo- ceramic glazed double firing After that, it is possible to get a highly pitted bleach material, which is perfect for wall decoration.

What to use and how to choose them will help you understand the information from the article.

But how much will dry the tie of the floor under the tile and what the quality of the screed is affected, it will help to understand this

Classification by type

Since the surface finish is not amenable to mechanical influence, the following types of glazed ceramic tiles can be applied to clamp the wall:

But what is the price of cork tile for the floor and by what criteria is the choice, you can understand if you go

What and where you can use such construction materialcan be understood from this article.

But in which room it is best to use it. Tells here in the article.

Manufacturers and prices

You can buy the glazed tile today in any construction store.

To be confident in her quality, you need to pay attention to the following manufacturers:

The glazed tile is an excellent value for money. The tile will become a beautiful decoration of the bathroom or kitchen, because it is presented in a wide range. The choice of products is so large that you can create a real masterpiece. The glazed tile is very practical, as it is easy to care for it, thanks to which your room will always be beautiful and clean.